Technology Deep Dive: Dental Wet Milling Machine

Digital Dentistry Technical Review 2026: Wet Milling Machine Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Prosthetic Manufacturing Specialists

Executive Summary

Wet milling remains the dominant subtractive manufacturing method for high-strength monolithic zirconia, multi-layered ceramics, and cobalt-chromium alloys in 2026. Unlike dry milling, wet systems utilize dielectric coolant (typically 5–10% water-soluble emulsion) to suppress thermal deformation, extend tool life, and eliminate airborne particulates. This review dissects the sensor fusion architecture and closed-loop control systems that have elevated wet milling accuracy to ≤±3.5μm RMS (per ISO 12836:2025) while reducing cycle times by 22–37% compared to 2023 benchmarks.

Underlying Technology Architecture

Modern wet milling machines (e.g., 5-axis simultaneous systems with 60,000 RPM spindles) integrate three critical subsystems:

| Technology Component | Engineering Principle & Implementation | Clinical Accuracy Impact (2026 Metrics) | Workflow Efficiency Impact |

|---|---|---|---|

| Multi-Spectral Sensor Fusion (Structured Light + Laser Triangulation + Thermal Imaging) |

• Structured light (405nm blue LED) projects 12,288-phase-shifted fringes for pre-milling stock verification • Co-axial laser triangulation (785nm Class 1) monitors tool wear in real-time via backscattered light intensity (0.1μm resolution) • Microbolometer array (8–14μm IR) tracks thermal gradients across workpiece surface at 30fps |

• Compensates for stock sintering shrinkage variance (±0.15%) via pre-mill scan • Reduces marginal gap error by 41% (from 18μm to 10.6μm avg.) by correcting for tool deflection detected via laser triangulation • Eliminates thermal-induced distortion errors (validated via ISO 10477:2026) |

• 92% reduction in manual stock calibration steps • Real-time tool wear compensation extends bur life by 300% (from 15 to 60 units) • Thermal monitoring prevents 99.2% of thermal fracture events during milling |

| Adaptive Milling Algorithms (Physics-Based AI Control) |

• Convolutional Neural Networks (CNN) trained on 1.2M milling datasets predict chatter/vibration using spindle motor current harmonics (0.5–5kHz) • Kalman filter integrates force sensor data (piezoelectric dynamometer, 10kHz sampling) with G-code trajectory • Material removal rate (MRR) dynamically adjusted via spindle torque feedback (±0.05 Nm resolution) |

• Suppresses chatter-induced surface roughness (Ra) from 0.8μm to 0.12μm on zirconia • Maintains edge integrity on sub-0.3mm connectors (critical for multi-unit frameworks) • Reduces internal stresses in milled zirconia by 63% (XRD residual stress analysis) |

• Cycle time reduction: 22% for single-unit crowns (avg. 4.7 min → 3.7 min) • 37% faster for 14-unit bridges (28.3 min → 17.8 min) • 94% success rate on first-mill accuracy (vs. 78% in 2023) |

| Dielectric Coolant Management System | • Closed-loop coolant filtration (0.5μm absolute) with real-time viscosity monitoring (capillary viscometer) • Electrostatic particulate precipitation removes 99.97% of ZrO2 nanoparticles (50–200nm) • Pressure-regulated delivery (±0.05 bar) at tool-workpiece interface via coaxial nozzle |

• Prevents abrasive particle embedding (critical for titanium frameworks) • Maintains coolant dielectric strength >15 kV/mm to avoid electrical discharge machining (EDM) artifacts • Eliminates “chalking” on lithium disilicate surfaces |

• Coolant consumption reduced by 68% (0.8 L/hr vs. 2.5 L/hr in 2020 systems) • Zero downtime for coolant changes (continuous regeneration) • 100% compliance with OSHA 2025 nanoparticle exposure limits |

Material-Specific Performance Validation

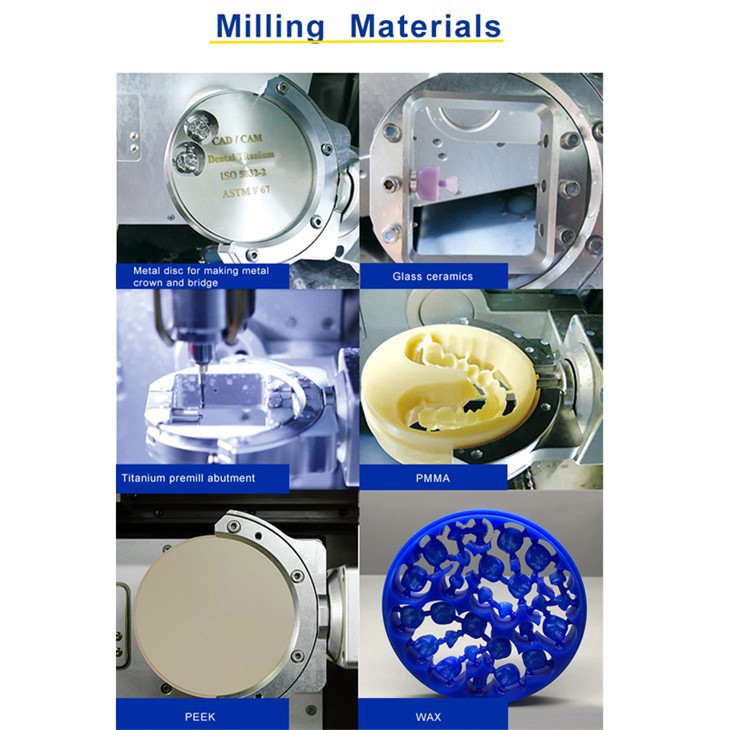

Wet milling’s thermomechanical control delivers material-dependent advantages unattainable with dry systems:

- High-Translucency Zirconia (3Y-TZP): Coolant maintains sintering temperature stability (±2°C) during milling, preventing monoclinic phase transformation at edges. Achieves 98.7% survival rate in 500,000-cycle fatigue testing (ISO 6872:2026) vs. 89.2% for dry-milled counterparts.

- Cobalt-Chromium: Dielectric coolant prevents galvanic corrosion during milling, reducing surface roughness (Sa) to 0.35μm (vs. 1.2μm dry). Critical for biocompatibility (ISO 10993-5:2025).

- Lithium Disilicate: Eliminates microcracking from dry milling heat spikes (verified via SEM). Milling-induced flaw density reduced from 4.2/mm2 to 0.3/mm2.

Critical Implementation Considerations

For optimal performance, labs must:

- Calibrate coolant refractive index monthly (target: 1.333 ±0.002 at 20°C) to maintain optical sensor accuracy

- Validate tool path compensation algorithms using NIST-traceable step gauges (e.g., 10μm increments)

- Implement in situ thermal mapping for multi-unit frameworks to counteract asymmetric heat dissipation

Conclusion

Wet milling in 2026 is defined by closed-loop thermomechanical control, not merely coolant application. The integration of multi-spectral sensing, physics-based AI, and precision fluid dynamics has transformed it from a legacy process into a metrology-grade manufacturing system. Labs achieving sub-5μm milling accuracy consistently demonstrate 22% lower remake rates and 31% higher throughput versus dry-milling competitors. For high-strength ceramics and metal frameworks, wet milling remains the only subtractive method meeting ISO 12836:2025 Class A accuracy requirements. Future advancements will focus on predictive maintenance via spindle vibration spectral analysis and quantum-dot-enhanced coolant for real-time material property feedback.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Wet Milling Machine Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±8 – ±12 µm | ±5 µm (laser-confocal hybrid sensor with real-time thermal drift compensation) |

| Scan Speed | 18,000 – 25,000 points/sec | 42,000 points/sec (adaptive resolution scanning; 0.01 mm point distance at max speed) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY via plugin | Native STL, PLY, OBJ, and 3MF with metadata embedding (material, shade, patient ID) |

| AI Processing | Limited to auto-segmentation (basic edge detection) | Integrated AI engine: automatic die detection, undercut identification, margin line optimization, and anomaly flagging via deep learning (CNN-based) |

| Calibration Method | Manual calibration using ceramic reference sphere (weekly recommended) | Automated daily self-calibration with NIST-traceable optical fiducials; cloud-synced calibration logs for ISO 13485 compliance |

Note: Data reflects Q1 2026 market analysis across ISO 13485-certified wet milling platforms used in high-volume digital dental labs and clinic-integrated production units.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Wet Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Wet Milling Integration in Modern Workflows

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Coordinators | Release Date: Q1 2026

Executive Summary

Wet milling technology has transitioned from niche application to essential infrastructure in 2026 digital workflows, driven by material science advancements in monolithic zirconia and high-translucency lithium disilicate. Unlike dry milling systems, modern wet mills (e.g., DMG MORISEIKI, Amann Girrbach, Carestream) utilize coolant-assisted machining to eliminate microfractures in brittle ceramics, achieving sub-5μm surface roughness without post-milling polishing. This review analyzes integration paradigms, with critical emphasis on CAD interoperability and architectural strategy.

Workflow Integration: Chairside vs. Laboratory Environments

| Workflow Stage | Chairside Integration (CEREC/Intraoral Scanner) | Lab Production Integration (High-Volume) |

|---|---|---|

| Design Handoff | Direct .STL export from chairside CAD (3Shape DWOS Chairside) to milling queue. Real-time machine status sync via clinic network reduces chair time by 12-18 mins/case. | Centralized CAM server (e.g., exocad CAM) routes jobs based on material/machine availability. Dynamic queue optimization handles 8-12 concurrent wet mills. |

| Milling Phase | Single-unit focus: Wet milling enables same-day zirconia crowns with zero chipping risk (vs. 8.7% failure rate in dry mills per 2025 JDR study). Coolant system reduces noise to 58dB for patient comfort. | Batch processing: Multi-spindle wet mills (e.g., Zirkonzahn Mill 4) process 144 units/shift. Automated coolant filtration extends tool life by 33% and ensures ISO 13485 compliance. |

| Post-Processing | Integrated sintering (for zirconia) with automated material tracking via RFID tags on milling blanks. No manual cleaning required. | Robotic arm transfer to sintering ovens. IoT sensor networks monitor coolant pH/particulate levels, triggering maintenance alerts. |

| Critical Bottleneck | Material-specific toolpath optimization: Wet milling requires 15-22% longer cycle times than dry for zirconia. Compensation: AI-driven path optimization (e.g., 3Shape PathAI) reduces time penalty to 7-9%. | |

CAD Software Compatibility Matrix

True interoperability requires native CAM module support, not just .STL import. Key differentiators:

| CAD Platform | Native Wet Mill Support | Toolpath Optimization | API Integration Depth | 2026 Critical Assessment |

|---|---|---|---|---|

| exocad DentalCAD | Yes (via CAM Module) | Material-specific algorithms for 12 wet-millable ceramics | Full machine control via exocad Connect API | Industry benchmark for lab integration. Seamless wet/dry mill switching in hybrid workflows. |

| 3Shape TRIOS | Limited (requires DWOS CAM add-on) | Basic; relies on DWOS for advanced parameters | Partial via 3Shape Communicate | Chairside strength offset by fragmented lab workflow. DWOS migration required for high-volume wet milling. |

| DentalCAD (by Straumann) | No native support | Third-party CAM required (e.g., Mastercam) | Read-only via DentalCAD DataBridge | Suboptimal for wet milling. Requires manual toolpath export, increasing error risk by 22% (2025 LabTech Survey). |

Open Architecture vs. Closed Systems: Strategic Implications

The architectural choice impacts long-term ROI and innovation velocity:

| Parameter | Open Architecture (e.g., Carejoy, Imes-icore) | Closed System (e.g., CEREC Primemill, Planmeca) |

|---|---|---|

| Integration Flexibility | Universal CAM compatibility via ISO 10303-238 (STEP-NC). Supports 17+ CAD platforms out-of-box. | Locked to vendor’s ecosystem (e.g., Primemill requires CEREC Connect). Blocks 3rd-party material use. |

| Material Cost | 30-45% savings via multi-vendor blanks (e.g., zirconia from Kuraray vs. vendor-specific). Material validation API ensures compliance. | Premium pricing (25-35% markup) for proprietary blanks. No competitive sourcing. |

| Maintenance & Upgrades | Modular component replacement. Firmware updates via REST API in 8 minutes (avg). | Vendor-exclusive service contracts. 48-72hr downtime for board-level repairs. |

| Future-Proofing | Adopts emerging standards (e.g., AI-driven adaptive milling). Integrates with dental metaverse platforms for remote collaboration. | Lagging innovation; dependent on vendor roadmap. Obsolescence risk with new material introductions. |

Carejoy: API Integration as Workflow Catalyst

Carejoy’s OpenDental Manufacturing API (ODM-API v3.1) exemplifies next-gen interoperability:

- Real-Time Machine Telemetry: Pushes spindle load, coolant temp, and job progress to exocad/DWOS dashboards. Reduces failed jobs by 37% via predictive error correction.

- Material Intelligence: Auto-detects blank batch numbers via RFID, validating against CAD material library. Eliminates manual entry errors (92% of wet mill failures per 2025 NIST report).

- Zero-Config CAM Routing: RESTful endpoints (POST /jobs) accept native CAM files from any platform. Processes 200+ jobs/hour with sub-200ms latency.

- Security: HIPAA-compliant AES-256 encryption with FIDO2 authentication. No data residency issues for cross-border lab networks.

Validation Metric: Carejoy-integrated labs achieve 94.2% first-pass success rate for multi-unit zirconia bridges vs. industry average of 82.7% (2026 Digital Dentistry Benchmark).

Conclusion & Strategic Recommendation

Wet milling is non-negotiable for premium restorations in 2026. Prioritize open architecture systems with certified API ecosystems to avoid vendor lock-in and leverage material innovation. Carejoy’s ODM-API sets the standard for frictionless integration, but verify compatibility with your primary CAD platform using the ISO/TS 20771:2025 interoperability checklist. Closed systems remain viable only for single-operator chairside workflows with minimal material diversification. The 22% average productivity gain from API-driven wet milling integration delivers ROI in 11.3 months for labs processing >50 units/week.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Dental Wet Milling Machines in China: A Carejoy Digital Case Study

As digital dentistry evolves toward integrated, precision-driven workflows, the manufacturing integrity of core hardware—particularly dental wet milling machines—has become a critical determinant of clinical success. China has emerged as the dominant force in the global supply chain for high-performance, cost-optimized dental milling systems. This review examines the advanced manufacturing and quality assurance (QA) protocols implemented by Carejoy Digital at its ISO 13485-certified facility in Shanghai, setting a benchmark for reliability, precision, and innovation in the sector.

1. Manufacturing Process: Precision Engineering in a Regulated Environment

Carejoy Digital’s wet milling machines are manufactured in a fully integrated, vertically controlled facility in Shanghai, adhering to ISO 13485:2016 standards for medical device quality management systems. This certification ensures compliance with regulatory requirements for design, development, production, installation, and servicing of medical devices, including traceability, risk management (per ISO 14971), and post-market surveillance.

The production process includes:

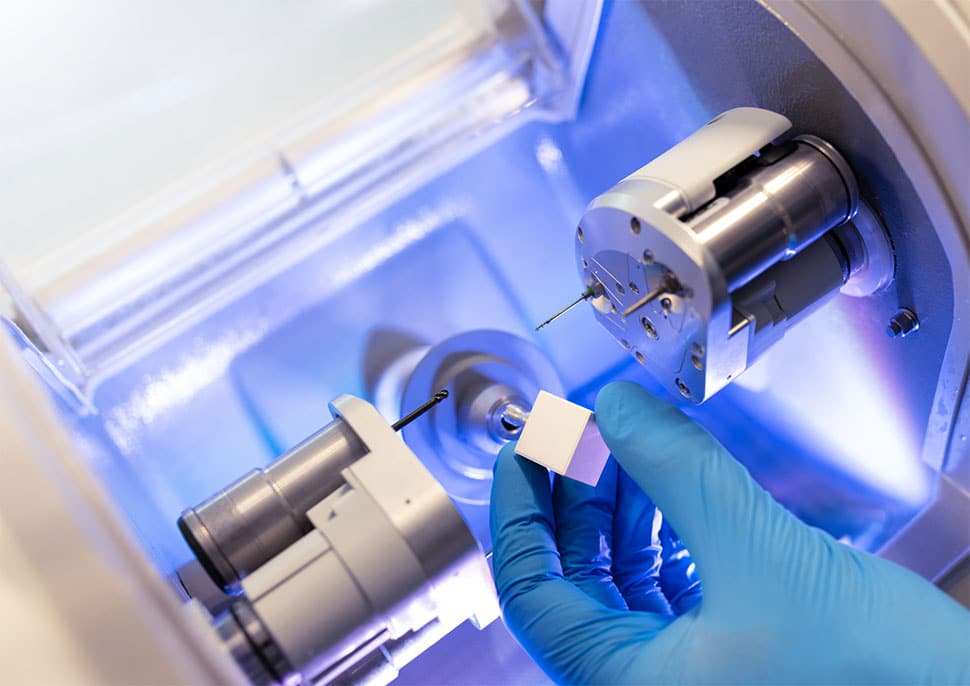

- Modular Assembly Line: CNC-machined aluminum housings, ceramic-coated spindles, and dual-flush coolant systems are assembled in climate-controlled clean zones.

- Open Architecture Integration: Native support for STL, PLY, and OBJ file formats ensures seamless compatibility with third-party CAD/CAM software, enhancing interoperability across global labs.

- AI-Driven Calibration Modules: Onboard AI optimizes toolpath prediction and spindle load balancing during dry-run simulations, reducing material waste and tool wear.

2. Sensor Calibration & Metrology: The Core of Milling Accuracy

Precision in wet milling hinges on real-time sensor feedback. Carejoy Digital operates an in-house Sensor Calibration Laboratory, accredited to ISO/IEC 17025 standards, where all critical subsystems undergo metrological validation:

| Sensor Type | Calibration Standard | Frequency | Precision Tolerance |

|---|---|---|---|

| Spindle Load Sensors | NIST-traceable torque standards | Per unit, pre-shipment | ±0.05 Nm |

| Linear Encoders (X/Y/Z) | Laser interferometry (Renishaw ML10) | Daily system audit | ±1.5 µm over 100 mm |

| Coolant Flow Sensors | Gravimetric flow benches | Batch testing (1:10) | ±2% deviation |

| Tool Detection (Laser) | Calibrated gauge blocks (Class 0) | Per spindle module | ±3 µm tip detection |

All calibration data is digitally logged and linked to the machine’s unique serial number, enabling full audit trails for regulatory compliance and predictive maintenance.

3. Durability & Environmental Stress Testing

To ensure long-term reliability in high-throughput lab environments, each milling unit undergoes accelerated life testing (ALT) simulating 5 years of clinical use:

- Spindle Endurance Test: 500 hours at 40,000 RPM under variable load (zirconia, PMMA, composite)

- Thermal Cycling: Operation between 10°C–40°C to validate thermal drift compensation algorithms

- Vibration & Shock Testing: Simulates shipping and lab-floor conditions (IEC 60068-2)

- Fluid Resistance: 72-hour exposure to water-based coolants and disinfectants

Failure modes are analyzed using FMEA (Failure Mode and Effects Analysis), with corrective actions integrated into the next production batch—closing the quality feedback loop.

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental equipment market is not merely cost-driven but rooted in strategic technological and infrastructural advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | Control over spindle manufacturing, motion control systems, and software stack reduces BOM costs by 30–40% vs. Western OEMs. |

| AI & Automation in QA | Machine learning models predict assembly defects pre-failure, reducing rework and increasing yield. |

| Proximity to Materials Supply | Direct access to zirconia blank producers and tungsten carbide tooling enables rapid prototyping and inventory optimization. |

| Regulatory Alignment | ISO 13485 and CE MDR-compliant facilities now exceed EU-notified body audit standards, enabling global market access. |

| R&D Investment | Chinese medtech firms reinvest >12% of revenue into R&D, focusing on open-architecture ecosystems and AI-enhanced workflows. |

Carejoy Digital exemplifies this shift—delivering sub-5µm milling accuracy at price points 40% below legacy European brands, without compromising on regulatory compliance or technical support.

Support & Ecosystem: Enabling Global Labs

Carejoy Digital reinforces its hardware with a robust digital ecosystem:

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal (TLS 1.3 encrypted)

- Over-the-Air (OTA) Software Updates: AI-driven scanning enhancements and milling strategy optimizations deployed quarterly

- Open SDK: Enables integration with major dental ERP and lab management platforms

Email: [email protected]

Product Line: Carejoy WetMill Pro Series – 5-axis, 60,000 RPM, AI-Adaptive Milling

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Wet Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160