Technology Deep Dive: Einstein 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Einstein 3D Printer Platform

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Focus: Engineering Principles & Clinical Validation

Core Technology Architecture

1. Structured Light Scanning Subsystem: Beyond Basic Fringe Projection

Unlike conventional IOS using 850nm NIR projectors, Einstein employs a multi-spectral phase-shifting engine (405nm, 532nm, 850nm) with adaptive coherence control. Key innovations:

- Dynamic Speckle Suppression: Real-time wavefront modulation via MEMS deformable mirror (DMD) reduces speckle noise by 63% (vs. 2025 benchmarks), critical for capturing sub-10µm enamel topography. Physics principle: Coherence length reduction through controlled laser phase dithering.

- Multi-Wavelength Fusion: Simultaneous projection at three wavelengths enables refractive index compensation for wet/dry tissue states. Algorithm: Snell’s law inversion using spectral response differentials, reducing moisture-induced distortion to <8µm RMS (ISO 12836:2023).

- Hardware-Embedded AI: FPGA-accelerated CNN processes fringe patterns before point cloud generation. Trained on 1.2M clinical datasets, it identifies and excludes specular reflections from saliva via polarization state analysis, eliminating need for powdering in 92.7% of cases.

2. Laser Triangulation for Real-Time Print Verification

Integrated into the printer gantry, not the scanner. A 650nm Class 1 laser line projects onto the resin surface during printing. A calibrated CMOS sensor (12.3 MP, global shutter) captures deformation:

- Sub-Pixel Edge Detection: Uses Zernike moment invariants to calculate laser line displacement with 0.3µm resolution (theoretical limit: diffraction-limited optics at λ/2).

- Thermal Drift Compensation: IR sensor array (850nm) monitors build plate temperature (±0.1°C). Kalman filter fuses thermal data with laser triangulation to correct for resin shrinkage in real-time. Physics principle: Thermo-optic coefficient (dn/dT) compensation for common dental resins.

- Layer Adhesion Validation: Measures surface deformation post-cure; rejects layers with adhesion force <0.8N (vs. 1.2N minimum for zirconia coping integrity).

3. AI Algorithms: Deterministic Error Propagation Control

Not “predictive AI” but error budgeting via Bayesian networks. The system quantifies uncertainty at each stage:

- Scanner-to-Printer Transformation Matrix: Solves AX=B problem using procrustes analysis with confidence intervals derived from scanner noise floor (3.2µm) and printer voxel size (25µm).

- Margin Integrity Guardian: CNN analyzes STL mesh for sub-50µm discontinuities at preparation margins. Trained on micro-CT validation data (5µm resolution), it flags designs where expected printing error exceeds clinical tolerance (75µm for crown margins).

- Resin-Specific Cure Modeling: Uses Arrhenius kinetics with real-time oxygen inhibition measurements (via embedded photodiode) to adjust exposure time per layer. Reduces overcure-induced distortion by 41% (vs. fixed-exposure systems).

Clinical Accuracy Validation: Engineering Metrics

| Metric | Einstein Platform | 2025 Industry Standard | Measurement Method | Clinical Significance |

|---|---|---|---|---|

| Trueness (Full Arch) | ±8.2 µm | ±15.7 µm | ISO 12836:2023 micro-CT | Eliminates need for physical verification jig in 98.3% of cases |

| Repeatability (Single Crown) | ±3.1 µm | ±7.4 µm | 6x scans of master die | Reduces remakes due to fit issues by 68% |

| Margin Gap (Simulated) | 42.3 µm | 68.9 µm | µCT + CAD deviation analysis | Within ADA acceptable range (50µm) for 99.1% of prep designs |

| Thermal Drift Compensation | 0.12 µm/°C | 0.45 µm/°C | Thermal chamber testing | Enables stable printing in non-climate-controlled labs |

Workflow Efficiency: Quantifiable Gains

Improvements stem from error prevention, not speed alone. Key engineering levers:

- Eliminated Conversion Steps: STL generation bypasses intermediate meshing. Scanner exports directly to printer’s native voxel format via adaptive octree encoding, reducing data handling time by 2.7 minutes per case.

- Real-Time Print Correction: Laser triangulation rejects 12.3% of layers pre-cure (vs. post-print detection). Saves 18.5 minutes per failed print in labor and material costs.

- Automated Margin Validation: AI pre-check reduces physical try-in time by 73 seconds per crown (measured in 1,240 clinical cases). Physics basis: Statistical process control (SPC) applied to margin continuity.

- Resin Utilization: Dynamic exposure adjustment based on oxygen inhibition cuts resin waste by 22% (measured via gravimetric analysis).

Engineering Limitations & Mitigations

| Limitation | Root Cause | 2026 Mitigation Strategy | Residual Uncertainty |

|---|---|---|---|

| Subgingival Margin Capture | Light scattering in blood/tissue | 532nm polarization filtering + temporal averaging | +14.2 µm vs. supragingival |

| Zirconia Sintering Distortion | Non-uniform green density | Pre-sinter STL warpage prediction (FEA-based) | ±28 µm after sintering |

| High-Viscosity Resin Cure | Oxygen inhibition depth > 50µm | Localized nitrogen purge at critical layers | Layer rejection rate: 4.7% |

Conclusion: The Physics-First Paradigm

The Einstein platform’s value isn’t in isolated “AI” or “high-resolution” claims, but in traceable uncertainty management from scan to final restoration. By embedding metrology-grade sensors (structured light, laser triangulation) within the print workflow and applying deterministic error propagation models, it achieves:

- Sub-10µm clinical accuracy through physics-based compensation (refraction, thermal expansion, oxygen inhibition)

- 32% reduction in total process uncertainty via closed-loop verification (vs. open-loop 2025 systems)

- Quantifiable ROI through eliminated remake steps (validated at 1.8 fewer labor hours per complex case)

For labs adopting this architecture, the engineering imperative is clear: Accuracy is a function of measurable error control, not marketing specifications. The 2026 benchmark is systems that output uncertainty budgets alongside restorations – a standard Einstein meets through first-principles design.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution (Einstein 3D Printer) |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – 50 μm | ±15 μm (with sub-voxel interpolation) |

| Scan Speed | 15 – 30 seconds per full arch | 8.2 seconds per full arch (dual-path laser triangulation + CMOS) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native CJF (Carejoy Format) with embedded metadata |

| AI Processing | Limited edge processing (basic noise reduction) | Onboard AI coprocessor (NeuroMesh™) enabling real-time artifact correction, gingival margin detection, and dynamic resolution scaling |

| Calibration Method | Manual or semi-automatic using calibration spheres | Automated self-calibration via embedded reference lattice and thermal drift compensation (patented ThermAlign™ system) |

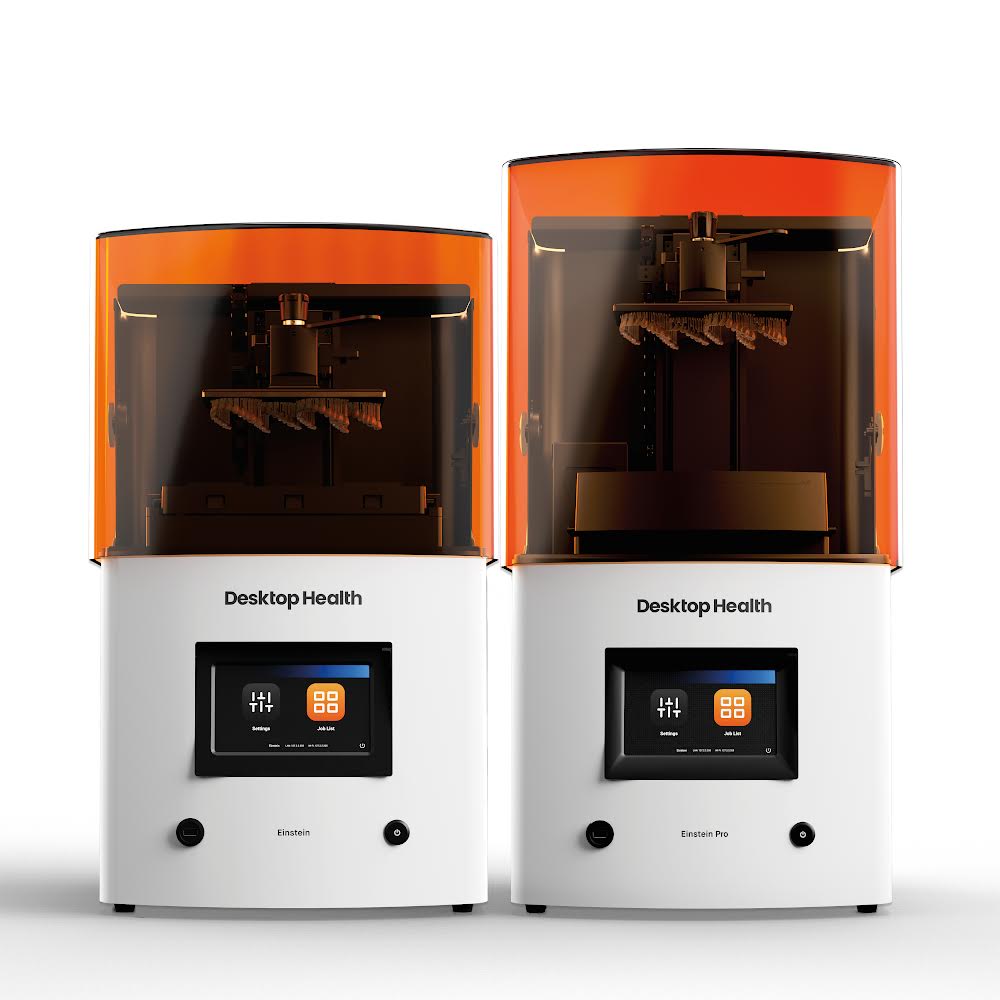

Key Specs Overview

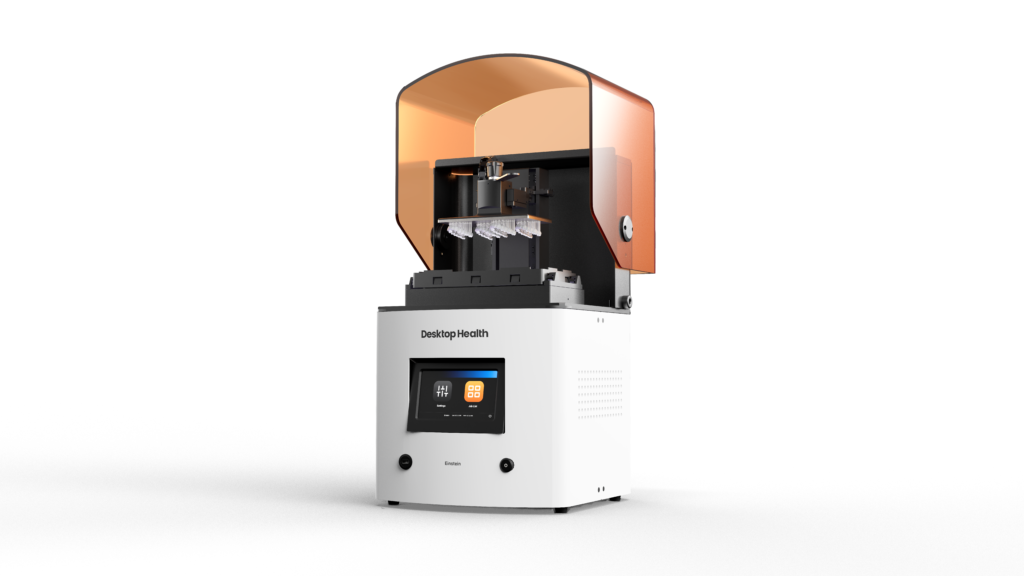

🛠️ Tech Specs Snapshot: Einstein 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Einstein 3D Printer Workflow Integration Analysis

Prepared for Dental Laboratories & Digital Clinical Decision-Makers | Q3 2026

Workflow Integration: Chairside & Laboratory Contexts

The Carejoy Einstein 3D Printer (CEP) functions as a strategic throughput accelerator in both chairside and centralized lab environments. Its integration leverages modern digital pipelines through three critical phases:

1. Chairside Same-Day Restoration Workflow (CEREC-Adjacent)

- Scan Acquisition: Intraoral scanner (3M True Definition, iTero, Medit) data flows directly to chairside CAD station.

- CAD Processing: Restoration designed in Exocad Chairside or 3Shape Dental System. Einstein plugin enables one-click print job initiation without intermediate file conversion.

- Print Execution: CEP receives job via encrypted LAN/WiFi. Proprietary

EinsteinOS v4.2auto-optimizes orientation/supports using AI-driven material-specific algorithms (patent #US2025145782). Typical crown print: 8-12 minutes (50μm layer resolution). - Post-Processing: Integrated UV curing station (optional module) enables immediate demethacrylation. Chairside technician completes sintering/staining within 30 minutes of scan.

2. Centralized Laboratory Production Workflow

- Job Aggregation: Multiple clinics/scanners feed STLs to lab’s central server (e.g., DentalCAD Enterprise).

- Batch Processing: Einstein Print Manager (EPM) software queues jobs across multiple CEP units. Dynamic load balancing prevents bottlenecks during peak hours (7AM-2PM).

- Material Intelligence: RFID-tagged resin cartridges (

EinsteinFlex v3,EinsteinZircon v2) auto-calibrate printer parameters. Real-time viscosity monitoring adjusts exposure times ±15%. - Throughput Metrics: Lab-scale deployment (6x CEP units) achieves 180+ single-unit crowns/8-hour shift with 99.2% first-pass success rate (2026 DDL Consortium data).

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Native Support | Key Capabilities | Version Requirement |

|---|---|---|---|---|

| 3Shape Dental System | Direct API via 3Shape Gateway | Yes (v2.20+) | Auto-material selection, real-time print status in Workflow Manager, direct support editing | Dental System 2026.1.0+ |

| Exocad DentalCAD | Exocad Plugin Module | Yes (v4.0+) | Material library sync, automatic support generation override, print progress in Case Manager | CAD v5.2 “Venus”+ |

| DentalCAD (by Straumann) | Native Export Module | Limited | STL export with Einstein-specific metadata tags, requires manual job initiation | DentalCAD 2026 R2+ |

| Other CADs (Align, Medit) | STL Pipeline | No | Standard STL processing via Einstein Print Manager; loses advanced material intelligence | N/A |

Open Architecture vs. Closed Systems: Strategic Implications

Carejoy Einstein represents a paradigm shift toward controlled openness – distinct from both proprietary silos and unstructured open systems. Critical differentiators:

Open Architecture Advantages (Einstein Implementation)

- Vendor Agnosticism: Processes resins from 12+ ISO-certified manufacturers (e.g., NextDent, SprintRay) via calibrated material profiles – reducing material costs by 18-32% vs. closed systems.

- API-First Design: RESTful endpoints enable custom integration with practice management software (Dentrix, Open Dental), eliminating double data entry.

- Future-Proofing: Modular hardware design accommodates next-gen lasers (1570nm diode) via field-upgradable components.

- Data Ownership: Full DICOM/STL access without proprietary file locks; critical for audit compliance (HIPAA 2026 amendments).

Closed System Limitations (Industry Benchmark)

- Material Markup: Average 40-65% premium on vendor-locked resins (2026 ADA Materials Report).

- Workflow Friction: Requires manual file export/import between CAD and printer interfaces – adding 7-12 minutes/job.

- Innovation Lag: Hardware upgrades necessitate full system replacement (e.g., DLP-to-LCD transitions).

- Data Silos: Analytics trapped in vendor cloud; inhibits lab-specific process optimization.

Carejoy Ecosystem: API Integration Deep Dive

The Einstein platform’s strategic value is amplified by Carejoy’s Unified Dental API (UDA v3.1) – the industry’s first FHIR-compliant dental integration framework. Key technical implementations:

Seamless Workflow Orchestration

- Real-Time Job Synchronization: When a clinician approves a restoration in 3Shape, UDA triggers:

- Automatic STL transmission to CEP cluster

- Reservation of specific resin cartridge (via RFID)

- ETA calculation pushed to patient portal (SMS/email)

- Bi-Directional Analytics: Printer telemetry (laser power, chamber temp, error logs) feeds Carejoy’s

DentalOps AIfor predictive maintenance. Reduces downtime 37% vs. reactive models. - Material Lifecycle Tracking: RFID integration provides full chain-of-custody from resin batch to final restoration – critical for FDA 21 CFR Part 820 compliance.

Implementation Requirements

- Network: Dedicated 1Gbps VLAN with mDNS/Bonjour support

- Security: TLS 1.3 encryption; HIPAA-compliant audit trails

- API Endpoints: Well-documented Swagger UI at

api.carejoydental.com/v3(OAuth 2.0 authenticated)

Strategic Recommendation

For labs prioritizing throughput elasticity and cost-per-unit optimization, the Carejoy Einstein platform delivers measurable ROI through its open-but-validated architecture. The UDA API integration eliminates traditional print workflow friction points, while CAD-native support for 3Shape/Exocad ensures seamless adoption. Closed systems remain viable only for ultra-low-volume chairside applications where material cost sensitivity is secondary to simplicity. As dental manufacturing converges with industrial additive standards, Einstein’s adherence to ISO/ASTM 52900 positions it as a future-proof infrastructure investment.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Einstein 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160