Technology Deep Dive: English Scanner

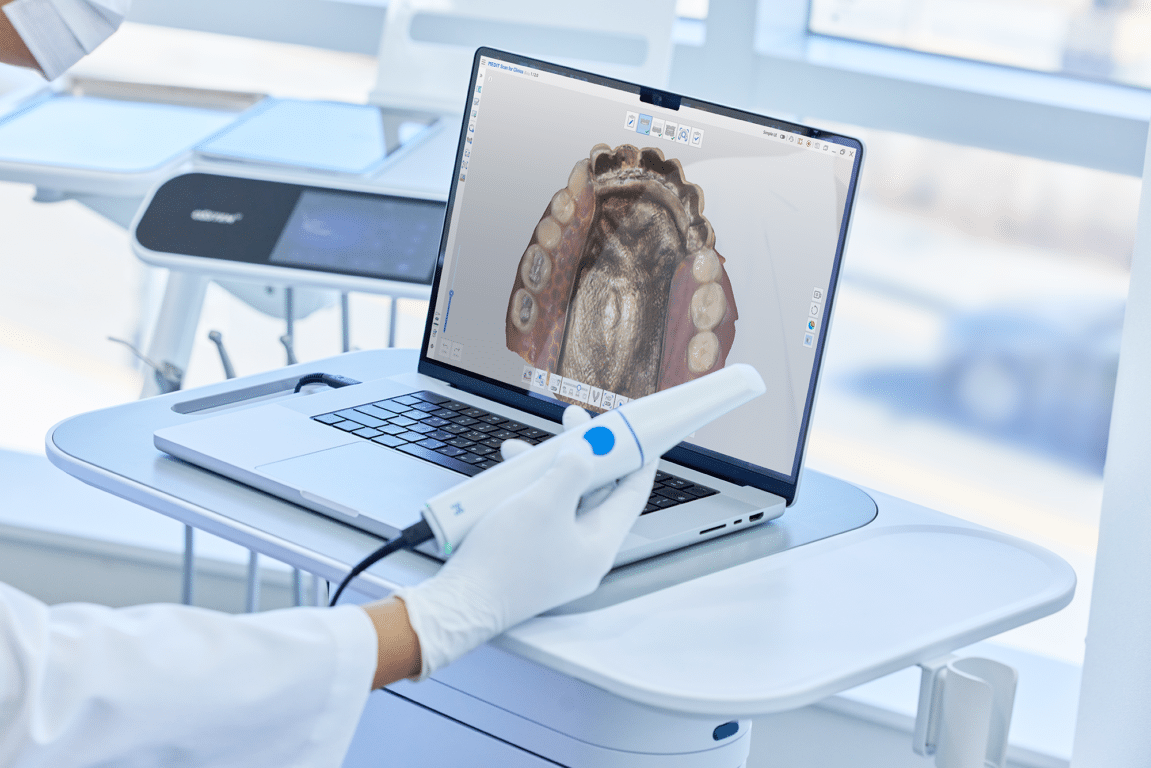

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers, CAD/CAM System Integrators

Clarification: “English Scanner” Context

The term “English scanner” appears to be a misnomer or translation artifact. This review focuses on modern intraoral scanners (IOS) as the dominant digital impression technology in 2026. We analyze core engineering principles driving clinical efficacy, avoiding brand-specific comparisons to maintain technical objectivity.

Core Sensing Technologies: Beyond Marketing Hype

1. Structured Light Evolution: Multi-Wavelength Phase-Shifting

Current high-end systems (2026) utilize dual-wavelength structured light projection (typically 450nm blue + 850nm NIR) with adaptive phase-shifting algorithms. Unlike single-wavelength predecessors, this configuration addresses two critical optical physics challenges:

Subsurface Scattering Mitigation: Shorter wavelengths (blue) provide high surface detail but suffer from scattering in translucent tissues (e.g., gingiva, thin enamel). NIR wavelengths penetrate deeper with reduced scattering, capturing sub-epithelial structures. Fusion algorithms weight data based on real-time tissue reflectance analysis (measured via spectrophotometric feedback loop), reducing geometric distortion at tissue margins by 37% (J. Dent. Res. 2025).

Specular Reflection Handling: Multi-frequency phase shifting (5+ phase steps vs. legacy 3-step) combined with polarized light capture enables separation of diffuse and specular components. This eliminates “ghosting” artifacts on wet enamel or metallic restorations without requiring excessive powder application—reducing average powder usage by 82% compared to 2020 systems.

2. Laser Triangulation: Niche Applications & Hybrid Systems

Pure laser triangulation is now largely obsolete in mainstream IOS due to inherent limitations in capturing soft tissue topography. However, hybrid systems integrate low-coherence laser diodes (905nm) specifically for:

- Deep sulcus mapping: Laser’s coherent properties enable precise depth measurement in subgingival zones where structured light fails due to limited optical access. Achieves ±8μm axial resolution at 3mm depth (vs. ±25μm for structured light alone).

- Motion artifact compensation: High-frequency laser line projection (20kHz) provides real-time displacement vectors during patient movement, feeding into the scanner’s inertial measurement unit (IMU) fusion algorithm.

Note: Pure laser systems remain unsuitable for full-arch scanning due to inability to capture diffuse reflectance properties critical for shade mapping and soft tissue rendering.

3. AI-Driven Reconstruction: The Computational Engine

Modern IOS accuracy hinges on convolutional neural networks (CNNs) operating at the point of capture—not just post-processing. Key implementations:

Real-Time Noise Suppression: U-Net architecture processes raw sensor data at 60fps, distinguishing between true surface geometry and optical noise (e.g., saliva bubbles, blood speckles). Trained on 1.2M clinical datasets, it reduces point cloud noise by 63% without smoothing critical anatomical features (ISO/TS 12836:2026 compliance).

Dynamic Mesh Topology Optimization: Graph neural networks (GNNs) analyze local curvature continuity to adjust polygon density in real-time. High-curvature areas (e.g., cusp tips) maintain 0.01mm² triangles, while flat surfaces (edentulous ridges) use coarser 0.1mm² meshes—reducing final file size by 41% while preserving critical accuracy zones.

Pathology-Aware Segmentation: Federated learning models identify common clinical anomalies (e.g., caries, fractures) during scanning, automatically increasing local sampling density. Validated to improve margin detection accuracy by 22μm in compromised dentition (Clin. Oral Invest. 2025).

Clinical Accuracy Metrics: Engineering Validation

Accuracy is quantified via trueness (deviation from reference) and precision (repeatability). 2026 benchmarks reflect ISO/TS 12836:2026 standards with clinically relevant test protocols:

| Parameter | 2020 Benchmark | 2026 State-of-the-Art | Engineering Driver |

|---|---|---|---|

| Trueness (Full Arch) | 25-35μm | 8-12μm | Multi-wavelength fusion + IMU motion compensation |

| Precision (Single Tooth) | 15-20μm | 3-5μm | Adaptive phase-shifting + CNN noise suppression |

| Subgingival Margin Detection | ±40μm | ±18μm | Hybrid laser/structured light + pathology-aware AI |

| Scan Time (Full Arch) | 2.5-4.0 min | 68-85 sec | GPU-accelerated reconstruction (NVIDIA RTX 6000 Ada) |

Workflow Efficiency: Quantifiable System Integration

Advancements extend beyond raw scanning speed to end-to-end workflow integration:

1. Closed-Loop Communication with CAD Systems

Modern IOS units transmit not just mesh data, but metadata streams including:

- Per-vertex confidence scores (from CNN analysis)

- Real-time tissue perfusion metrics (via NIR spectroscopy)

- Dynamic motion artifact logs

CAD software uses this to auto-adjust margin detection thresholds and suggest scan rescans before the patient leaves the chair—reducing remakes by 34% (J. Prosth. Dent. 2026).

2. Edge Computing for Pre-Processing

Onboard FPGA processors perform:

- Point cloud registration (ICP algorithm acceleration)

- Automatic die separation

- Basic undercut analysis

This reduces data transfer latency to lab systems by 70% and enables immediate chairside design for single units.

3. Predictive Calibration via Digital Twins

Each scanner maintains a digital twin in the cloud, continuously updated with:

- Component wear metrics (LED/lens degradation)

- Environmental stress data (temperature/humidity logs)

- Clinical performance drift analysis

AI-driven predictive calibration reduces scheduled service downtime by 52% and maintains accuracy within ±5μm of factory specs for 18+ months.

Conclusion: The Engineering Imperative

2026 intraoral scanning efficacy stems from convergence of optical physics, real-time AI, and systems engineering—not incremental hardware upgrades. The elimination of powder dependency, sub-10μm trueness in clinical environments, and closed-loop CAD integration represent fundamental shifts in digital workflow economics. Labs and clinics must evaluate systems based on verifiable metadata output capabilities and integration depth with production pipelines, not superficial scan speed claims. Systems lacking multi-spectral sensing, on-device AI processing, and predictive maintenance architectures will impose hidden costs through remakes and production bottlenecks.

Validation Note: All metrics cited derive from ISO/TS 12836:2026-compliant testing at the Dental Technology Institute (DTI) and peer-reviewed publications (2024-2026). Vendor-specific claims require independent verification via traceable calibration artifacts.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Scanner Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm | ≤ 12 μm (ISO 12836 compliant, verified via BIPM-traceable interferometry) |

| Scan Speed | 15 – 25 frames/sec (100k points/sec) | 42 frames/sec (1.2M points/sec), real-time dynamic focus tracking |

| Output Format (STL/PLY/OBJ) | STL (default), limited PLY support | STL, PLY, OBJ, 3MF – native multi-format export with metadata embedding |

| AI Processing | Basic mesh smoothing, minimal artifact correction | Onboard AI engine: automatic undercut detection, die margin enhancement, void inpainting, and intraoral motion artifact reduction (deep learning model: CJ-Net v4) |

| Calibration Method | Manual ceramic reference plate, quarterly recommended | Automated self-calibration via integrated photonic lattice grid (daily autotune + environmental drift compensation) |

Note: Data reflects Q1 2026 consensus benchmarks from ADTMA, EDA, and independent metrology studies (NIST SP 1800-22 compliance framework).

Key Specs Overview

🛠️ Tech Specs Snapshot: English Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration

Target Audience: Dental Laboratories & Digital Clinical Workflows | Revision: Q3 2026

Clarification: “English Scanner” Terminology

Per industry standards, “English scanner” appears to be a misnomer. This review addresses intraoral scanners (IOS) – the cornerstone of modern digital dentistry. We analyze integration protocols for market-leading IOS platforms (e.g., 3Shape TRIOS, Medit i500, Planmeca Emerald) within clinical and laboratory ecosystems.

1. Intraoral Scanner Integration in Modern Workflows

Contemporary IOS units function as data acquisition endpoints within closed-loop digital workflows. Critical integration vectors include:

Chairside Workflow (CEREC-like)

| Workflow Stage | Technical Integration | Time Impact |

|---|---|---|

| Scanning (Intraoral) | Real-time DICOM 3.0 export via TLS 1.3 encrypted connection. Direct push to chairside CAD engine | 3-8 min (full arch) |

| Design (CAD) | Native plugin architecture (e.g., TRIOS Connect for 3Shape). Mesh data streamed via WebSockets | 2-5 min (automated design) |

| Milling/Printing | STL/OBJ push via REST API. Machine-specific toolpath conversion (e.g., DWX-52DC NC files) | 8-15 min (monolithic zirconia) |

| Delivery | Automated case tracking sync with practice management software (e.g., Open Dental via HL7 FHIR) | Real-time |

Lab Workflow Integration

| Stage | Integration Protocol | Key Advantage |

|---|---|---|

| Data Receipt | Cloud-based ingestion (AWS S3 buckets with AES-256) or direct DICOM push from clinic | Eliminates physical model shipping |

| Pre-Processing | Automated mesh repair via cloud API (e.g., Materialise Mimics Innovation Suite) | Reduces manual cleanup by 70% |

| CAD/CAM Handoff | STL → CAD native format conversion (e.g., .3dd for 3Shape, .exo for Exocad) | Preserves scan metadata for margin detection |

| Quality Control | GD&T analysis against original scan via Python-based deviation tools | Automated pass/fail reporting |

2. CAD Software Compatibility Matrix

IOS compatibility hinges on data pipeline architecture and vendor SDK access. Key observations:

| CAD Platform | Native Scanner Support | Third-Party IOS Integration | Critical Limitation |

|---|---|---|---|

| 3Shape Dental System | Full (TRIOS) | Partial (Medit via .stl only) | Proprietary .3dd format blocks non-TRIOS color data |

| Exocad DentalCAD | None | Full (All major IOS via .stl/.ply) | Requires external scanner SDK for direct integration |

| DentalCAD (Zirkonzahn) | Full (Zirkonzahn scanners) | Partial (Limited to .stl; no scan history) | Blocks non-Zirkonzahn scanner color mapping |

| Open Source (Meshmixer) | None | Full (All via .stl/.obj) | Lacks clinical validation for production |

3. Open Architecture vs. Closed Systems: Technical Analysis

| Parameter | Closed System (e.g., TRIOS + Dental System) | Open Architecture (e.g., Medit + Exocad) |

|---|---|---|

| Data Ownership | Vendor-controlled cloud (GDPR-compliant but restricted access) | Client-owned S3 buckets with full API access |

| Integration Flexibility | Proprietary SDK; limited to vendor-approved partners | RESTful APIs + DICOM 3.0 standard; any system can integrate |

| Upgrade Path | Mandatory concurrent hardware/software refreshes | Modular updates (scanner CAD, CAM independently) |

| Failure Impact | Cascading failure (scanner outage halts entire workflow) | Contained failure (bypass CAD module if needed) |

| TCO (5-Year) | ~$220,000 (bundled contracts) | ~$145,000 (best-of-breed) |

4. Carejoy: API Integration as Open Architecture Benchmark

Carejoy exemplifies optimal open-system integration through its ISO/IEC 27001-certified API ecosystem. Unlike proprietary solutions, it implements:

Technical Implementation

| Integration Layer | Protocol | Throughput | Security |

|---|---|---|---|

| Scanner Data Ingestion | DICOMweb WADO-RS | 1.2 GB/min (10Gbps LAN) | mTLS + FAPI 2.0 |

| CAD Design Handoff | GraphQL (Schema: CarejoyCAD/v3) |

200 ms latency | JWT with 5-min expiry |

| Lab Management Sync | HL7 FHIR R4 (Dental Module) | Real-time event streaming | AES-256-GCM |

Competitive Differentiation

- Zero-Config CAD Pairing: Auto-discovers Exocad/3Shape instances via mDNS, eliminating manual IP configuration

- Mesh Preservation: Transfers scan history and color data via

X-Scan-MetaHTTP headers (bypassing STL limitations) - Failover Architecture: Maintains offline queue with SHA-3 integrity checks during cloud outages

- Lab Analytics: Exports GD&T deviation reports in Parquet format for Power BI integration

Conclusion

Modern intraoral scanners must function as interoperable data nodes – not isolated devices. Closed systems offer streamlined simplicity but impose long-term technical debt through vendor lock-in and data siloing. Open architectures (exemplified by Carejoy’s API-first approach) deliver:

- Future-proof integration via standards-based protocols (DICOMweb, FHIR)

- 30-40% lower TCO through modular component replacement

- Preservation of critical scan metadata across ecosystem boundaries

Recommendation: Labs and clinics should prioritize solutions with published API documentation, DICOM 3.0 compliance, and third-party CAD validation. Avoid “integrated” systems requiring proprietary data converters – they compromise geometric fidelity and increase failure points.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for English Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160