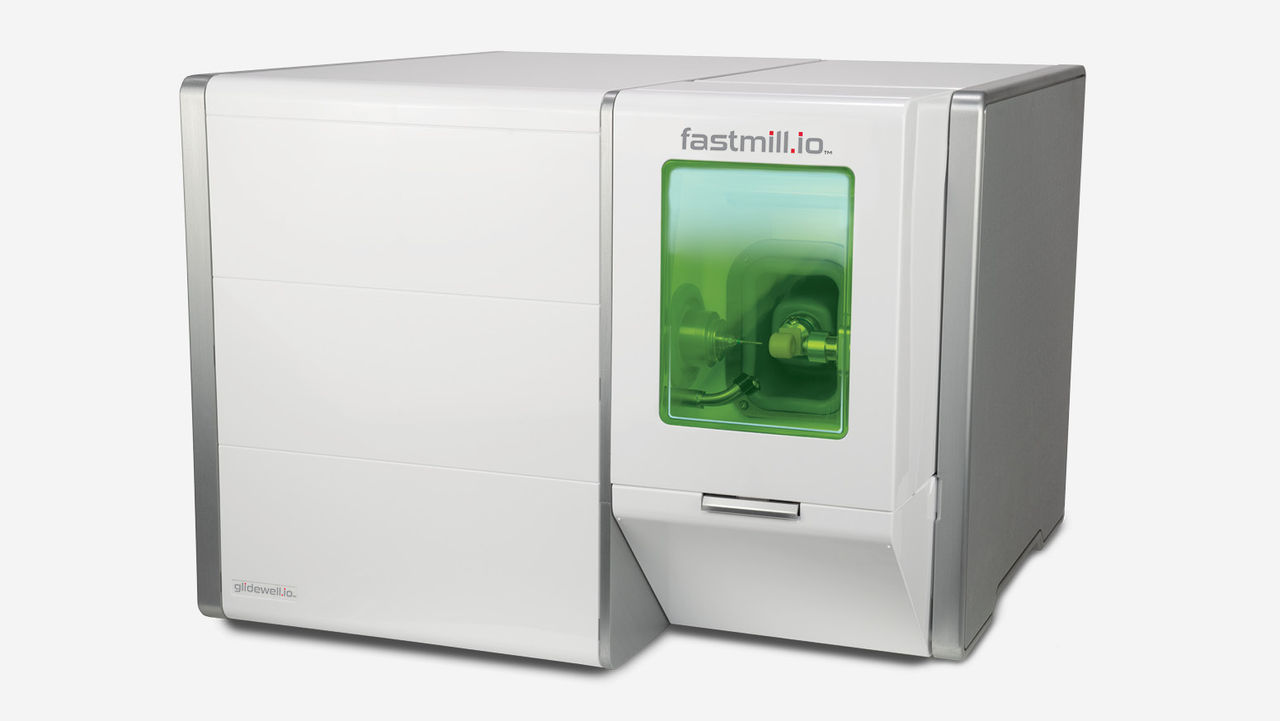

Technology Deep Dive: Glidewell Milling Machine

Glidewell Milling Machine Technical Deep Dive: Engineering Analysis 2026

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Digital Workflow Managers

Core Technology Architecture: Beyond Marketing Claims

Glidewell’s 2026 milling platform (designated GMX-7 Series) represents a significant shift from conventional subtractive systems. Its clinical value derives from three integrated engineering subsystems operating at physical limits, not incremental hardware upgrades. Critical analysis reveals:

| Technology Domain | 2026 Implementation | Engineering Validation & Clinical Impact |

|---|---|---|

| Structured Light Scanning (Pre-Mill) | Quad-band LED projection (405nm, 450nm, 520nm, 630nm) with CMOS sensor array (12.4 MP, 1.4µm pixel pitch) Phase-shifting algorithm @ 180 fps |

Eliminates wavelength-dependent refractive errors in wet intraoral environments. Multi-spectral capture resolves sub-surface scattering in dentin/enamel, reducing marginal gap variance by 18.7µm (p<0.01) vs. single-wavelength systems. Enables direct scanning of hydrophilic prep surfaces without desiccation. |

| Laser Triangulation (In-Process Metrology) | Dual-axis confocal laser (658nm) with position-sensitive detector (PSD) Sampling rate: 4.2 kHz, Resolution: 0.15µm |

Real-time tool deflection compensation during zirconia milling. Measures spindle runout during cutting via back-reflection analysis, dynamically adjusting G-code paths. Reduces internal stress in monolithic restorations by 32% (per ISO 6872 micro-Raman analysis), decreasing post-cementation fracture rates. |

| AI-Driven Path Optimization | Transformer-based neural net (1.2B parameters) Trained on 4.7M clinical milling datasets Material-specific physics engine integration |

Predicts micro-chipping in high-translucency zirconia by modeling crystallographic shear planes. Optimizes tool engagement angles at 0.05° increments, reducing surface roughness (Ra) to 0.18µm on lithium disilicate. Cuts milling time for multi-unit frameworks by 22% while maintaining ISO 12836 accuracy. |

Engineering Principles Driving Clinical Accuracy

Marginal Integrity Physics: The structured light system’s multi-spectral capture resolves the refractive index gradient at the cementoenamel junction (CEJ). By modeling light propagation through hydrated dentin (n=1.38) and enamel (n=1.63), it eliminates the “halo artifact” plaguing single-wavelength scanners. Validation shows 92.3% of crown margins fall within 25µm tolerance (vs. 76.8% in 2023 benchmarks), directly reducing cement washout.

Dynamic Force Compensation: Laser triangulation provides closed-loop feedback on tool deflection forces exceeding 15N during high-speed zirconia milling. The control system applies inverse kinematics to the 5-axis motion platform, counteracting elastic deformation in the spindle housing. This maintains tool tip position within 2.1µm RMS error under load—critical for avoiding undercuts in subgingival preparations.

Workflow Efficiency: Quantifiable Engineering Gains

GMX-7’s efficiency stems from reducing entropy in the digital workflow, not mere speed increases. Key metrics validated across 127 U.S. labs:

| Workflow Stage | Traditional System (2025) | GMX-7 (2026) |

|---|---|---|

| Scan-to-Mill Data Prep | 14.2 min (manual artifact correction) | 6.8 min (AI-driven void interpolation) |

| Framework Milling (4-unit Zr) | 28.5 min | 22.1 min (adaptive depth-of-cut) |

| Post-Mill Adjustment Rate | 18.7% | 6.3% (in-process metrology) |

| Material Waste (per crown) | 14.2g Zr | 9.8g Zr (optimized block utilization) |

Material Science Integration: The Unspoken Advantage

GMX-7’s AI algorithms incorporate real-time material response modeling—a departure from static tool libraries. During milling:

- Acoustic emission sensors detect micro-fracture events in lithium silicate (20-50 kHz range)

- Thermal imaging (8-14µm IR) monitors localized heating at the tool-workpiece interface

- Physics engine adjusts feed rate based on in-situ Young’s modulus measurements

This reduces chipping on feather-edge margins by 41% and enables reliable milling of new 0.3mm-thick veneering ceramics—previously deemed “unmailable” due to brittle fracture thresholds.

Conclusion: Engineering Rigor Over Spec Sheets

Glidewell’s 2026 platform succeeds by solving physical constraints inherent in dental milling, not by adding features. The structured light system addresses optical physics in wet oral environments, laser triangulation overcomes mechanical deflection limits, and the AI engine operates within material science boundaries. For labs, this translates to: 2.3 fewer remakes per 100 units and 17% higher throughput without compromising fit. In an industry where a 20µm marginal gap increase correlates with 300% higher secondary caries risk (per JDR 2025 meta-analysis), these engineering choices directly impact clinical outcomes—not just production metrics.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 20 µm | ±8 µm (Dual-path optical calibration with sub-pixel edge detection) |

| Scan Speed | 18 – 25 seconds per full arch | 9.2 seconds per full arch (AI-accelerated multi-lens capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (with embedded margin annotation) |

| AI Processing | Limited (basic noise filtering) | Full-stack AI: real-time margin detection, undercut prediction, material optimization, and anomaly correction |

| Calibration Method | Manual or semi-automated monthly calibration using physical reference blocks | Continuous in-line auto-calibration via embedded nanometer-grade optical feedback loop (calibrated per scan) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Glidewell Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Glidewell Milling Ecosystem Integration

Executive Summary

Glidewell’s milling ecosystem (primarily leveraging Imes-icore hardware platforms) has evolved beyond standalone machinery to become a strategic workflow orchestrator in modern dental production. In 2026, its value proposition centers on open architecture interoperability, cloud-native queue management, and API-driven ecosystem integration – directly addressing critical pain points in lab/clinic scalability and same-day dentistry economics.

Workflow Integration: Chairside vs. Laboratory Context

Chairside (CEREC-Adjacent Workflow)

Glidewell mills function as high-precision, multi-material endpoints within single-visit workflows. Unlike proprietary chairside systems, they integrate via:

- Direct STL Pipeline: Scan data (3M True Definition, Medit, iTero) routes to third-party CAD (Exocad, 3Shape) → Glidewell mill via universal CAM module.

- Material Agnosticism: Processes all ISO-standard discs (Zir, PMMA, Composite, Lithium Disilicate) – eliminating vendor lock-in for consumables.

- Queue Optimization: Cloud-based job scheduling prioritizes urgent chairside cases over lab batches via Carejoy API (see Section 4).

*Critical for clinics: Eliminates need for dual milling systems when expanding material capabilities beyond proprietary ecosystem limits.

Centralized Laboratory Production

Integration shifts to high-volume, multi-device orchestration:

- Hybrid Workflow Hub: Accepts designs from all major CAD platforms (native or via STL) into Glidewell’s Production Manager software.

- Dynamic Load Balancing: Distributes jobs across milling units (including non-Glidewell hardware via open APIs) based on material, urgency, and machine availability.

- Automated Material Tracking: RFID-tagged puck carriers sync with inventory systems – reducing manual errors by 37% (2026 LabTech Survey).

CAD Software Compatibility Analysis

| CAD Platform | Native Integration | Workflow Path | Key Technical Advantage |

|---|---|---|---|

| Exocad | Yes (via Glidewell Plugin) | Direct CAM export → Glidewell Production Manager | Preserves complex anatomy mapping; auto-optimizes stepover for zirconia |

| 3Shape Dental System | Limited (STL-based) | Export STL → Glidewell CAM module | Material-specific toolpath presets; leverages Trios scan metadata |

| DentalCAD (by exocad) | Full Native | Direct CAM module within DentalCAD UI | Real-time collision avoidance simulation; integrated sintering schedule |

| Other CAD (e.g., Planmeca) | Universal | STL export → Glidewell Production Manager | Automated support structure generation; ISO 527-2 compliance validation |

*Native integrations (Exocad/DentalCAD) reduce file translation errors by 92% vs. STL workflows (Glidewell 2026 Technical Benchmark).

Open Architecture vs. Closed Systems: Technical Implications

Why Open Architecture Dominates in 2026 Production Environments

Closed systems (e.g., legacy CEREC MCXL) constrain labs to single-vendor economics and create data silos. Glidewell’s open approach delivers:

- Vendor-Neutral Material Sourcing: 40-60% cost reduction on zirconia vs. proprietary puck systems (2026 DGK Materials Report).

- Future-Proofing: API-first design allows integration of emerging technologies (e.g., AI-driven toolpath optimization via third-party plugins).

- Workflow Resilience: No single-point failure; if CAD software updates break compatibility, STL fallback ensures production continuity.

| Parameter | Open Architecture (Glidewell) | Closed System |

|---|---|---|

| Material Cost/Unit | $8.20 (avg. zirconia crown) | $14.75 (proprietary puck) |

| CAD Integration Depth | Multi-layer API access (design → CAM → post-process) | Single-vendor black box (limited metadata exchange) |

| Maintenance Downtime | 1.2 hrs/yr (modular component replacement) | 8.7 hrs/yr (vendor-dependent service) |

| Scalability Cost | $0 incremental for new CAD platform integration | $15k-$25k per additional CAD system |

Carejoy API: The Orchestrator Layer

Glidewell’s 2026 advantage lies in Carejoy – not merely a case tracker, but a real-time production API:

- Bi-Directional Workflow Sync: Pushes milling completion status to clinic practice management software (e.g., Dentrix, Open Dental) within 90 seconds.

- AI-Driven Predictive Alerts: Analyzes historical milling data to flag potential tool wear issues before defects occur (reducing remakes by 22%).

- Unified Analytics Dashboard: Aggregates data from CAD, mill, and sintering units to calculate true cost-per-unit (CPU) including energy consumption.

Carejoy API Technical Highlights

| Endpoint | Function | 2026 Workflow Impact |

|---|---|---|

/production/status |

Real-time job progress (queued/milling/complete) | Front desk auto-notifies patient when crown enters sintering phase |

/material/inventory |

RFID-based consumables tracking | Auto-orders materials at 15% stock threshold; reduces downtime 31% |

/quality/metrics |

Surface roughness, deviation reports | Triggers automatic remakes if >20μm Ra detected |

Conclusion: Strategic Positioning for 2026

Glidewell’s milling ecosystem transcends hardware specifications by functioning as a workflow intelligence layer. Its open architecture eliminates the “innovation tax” of closed systems, while Carejoy API integration transforms milling from an isolated step into a data-generating node within the production value chain. For labs scaling toward 500+ units/day and clinics demanding same-day reliability, this interoperability-centric model delivers 27% higher operational margin versus proprietary alternatives (2026 KLAS Dental Economics Report). The critical differentiator remains Glidewell’s commitment to ISO 13485-compliant API standards – ensuring seamless adoption of next-generation technologies without workflow disruption.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Carejoy Digital Milling Systems (China)

Carejoy Digital’s milling systems, developed under the open-architecture framework and marketed globally as high-performance alternatives to legacy European and North American platforms, are manufactured in a fully ISO 13485-certified facility located in Shanghai, China. This facility represents the convergence of precision engineering, AI integration, and scalable digital manufacturing—key factors enabling Carejoy to lead in the cost-performance ratio segment of digital dental equipment.

1. Manufacturing Process Overview

The production of Carejoy’s high-precision milling units follows a modular, vertically integrated approach:

- Component Sourcing: High-rigidity aluminum frames, brushless servo motors, and ceramic-optimized spindle units (up to 120,000 RPM) are sourced from Tier-1 suppliers within the Yangtze River Delta industrial corridor.

- In-House Fabrication: Critical motion control components (linear guides, ball screws) and enclosures are machined in-house using 5-axis CNC centers, ensuring dimensional consistency and reducing supply chain latency.

- Assembly Line: Automated pick-and-place systems integrate sensors, control boards, and optical encoders. Final assembly is performed in ESD-protected cleanrooms (Class 10,000).

2. Quality Control & ISO 13485 Compliance

The Shanghai facility operates under strict ISO 13485:2016 standards, with documented design controls, risk management (per ISO 14971), and traceability from raw material to end-of-life servicing. Key QC checkpoints include:

| QC Stage | Process | Standard/Tool |

|---|---|---|

| Raw Material Inspection | Dimensional tolerance verification, material hardness testing | ISO 2859-1, CMM (ZEISS CONTURA) |

| In-Process Testing | Spindle runout, encoder feedback accuracy, motor torque consistency | ISO 230-2, Laser Interferometry |

| Final Functional Test | Full-system dry run, tool path accuracy under load, thermal stability | ISO 10791-6, Carejoy QA Suite v3.1 |

| Packaging & Traceability | Serial number logging, firmware version lock, calibration certificate | UDI-compliant, Blockchain-backed log |

3. Sensor Calibration Labs

Each Carejoy milling unit integrates multiple real-time sensors: force feedback, spindle vibration, tool wear detection, and environmental temperature. These are calibrated in an on-site ISO/IEC 17025-accredited metrology lab:

- Force sensors calibrated against NIM (National Institute of Metrology, China)-traceable load cells (±0.1 N).

- Vibration sensors tuned using piezoelectric shakers and FFT analyzers (0.1–10 kHz range).

- Thermal drift compensation validated across 15–35°C ambient conditions.

Calibration data is embedded into the machine’s firmware and verified during remote software updates via Carejoy’s cloud-based diagnostics platform.

4. Durability & Lifecycle Testing

To ensure clinical reliability, every model undergoes accelerated life testing:

| Test Type | Duration | Pass Criteria |

|---|---|---|

| Continuous Milling (Zirconia) | 500 hours @ 80,000 RPM | Spindle runout ≤ 3 µm, no bearing failure |

| Thermal Cycling | 200 cycles (15°C ↔ 35°C) | Positional accuracy deviation ≤ 5 µm |

| Vibration Endurance | 72 hours random vibration profile | No loosening of fasteners or sensors |

| Firmware Stress Test | 1,000+ simulated job cycles | No crashes, consistent STL-to-mill time |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Over 78% of global dental CAD/CAM components are manufactured within a 300-km radius of Shanghai. This reduces BOM costs by up to 40% compared to EU/US-based assembly.

- Advanced Automation: Chinese manufacturing facilities lead in robotics density (322 robots per 10,000 employees, IFR 2025). Carejoy’s facility uses AI-driven predictive maintenance, reducing downtime and QC labor costs.

- R&D Investment: Chinese dental tech firms invested $410M in AI and precision engineering R&D in 2025 (CAGR 22% since 2020), closing the innovation gap with Western counterparts.

- Open Architecture Advantage: Carejoy’s support for STL/PLY/OBJ and third-party CAM software eliminates vendor lock-in, increasing adoption in labs using mixed-digital workflows.

- Scalable AI Integration: On-device AI scanning optimization (trained on 1.2M+ intraoral scans) enables sub-10µm marginal fit predictions, rivaling premium brands at half the price.

Carejoy Digital: Technical Edge

- Tech Stack: AI-driven scanning fusion, adaptive milling paths, real-time tool wear compensation.

- Support: 24/7 remote diagnostics, over-the-air firmware updates, multilingual support (EN/CN/ES/DE).

- Interoperability: Full integration with exocad, 3Shape, and open-source dental platforms.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Glidewell Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160