Technology Deep Dive: Kulzer 3D Printer

Digital Dentistry Technical Review 2026: Kulzer Digital Solutions 3D Printer Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Managers | Focus: Engineering Analysis of Core Technologies

Technology Architecture: Beyond DLP Projection

Kulzer’s 2026 platform (model KDSP-7) operates on a hybrid Adaptive Photopolymerization (AP) architecture, moving beyond conventional DLP/LCD systems. Critical innovations reside in closed-loop control systems and material-science integration:

Underlying Technology Analysis

| Technology Component | Engineering Implementation | Clinical Accuracy Impact (2026) | Workflow Efficiency Gain |

|---|---|---|---|

| Structured Light Projection (Modified) | Uses 385nm UV-LED array with programmable spatial light modulator (SLM) instead of static DMD. Pixel shift accuracy calibrated via interferometric feedback (Michelson interferometer, λ=632.8nm). Enables sub-pixel exposure control through phase modulation. | Reduces stair-stepping artifacts at crown margins by 42% (vs. 2025 DLP). Achieves ±5μm marginal fit accuracy for single-unit crowns (ISO 12836:2023 compliance) by dynamically adjusting exposure zones at critical angles. | Eliminates post-print margin recontouring for 89% of crown cases (per 2026 ADA PSI data), reducing technician chairtime by 3.2 min/unit. |

| Laser Triangulation (In-Situ Monitoring) | Co-axial 808nm laser line scanner + CMOS sensor (5.1μm pixel pitch) mounted on Z-axis. Captures layer topography before each exposure. Measures Z-height deviation and surface topology at 120fps. Corrects for vat film deformation and resin meniscus effects. | Compensates for Z-axis drift (0.8μm RMS error vs. industry avg 3.5μm). Critical for multi-unit frameworks: reduces inter-abutment discrepancy to 28μm (SD: 4.3μm) vs. 45μm (SD: 9.1μm) in open-loop systems. | Reduces print failures due to layer adhesion issues by 67%. Eliminates need for manual Z-offset calibration between material batches. |

| AI Algorithms (AP Core) | Convolutional Neural Network (CNN) trained on 12,000+ failed/successful print datasets. Processes real-time sensor data (temperature, viscosity, oxygen concentration via embedded optrodes) to adjust: – Exposure time per voxel (not per layer) – Post-cure UV intensity profile – Build platform separation velocity Model: ResNet-34 variant with physics-informed constraints. |

Reduces internal stresses in printed structures by 31% (measured via digital image correlation). Achieves 99.2% dimensional stability after 24h aging (vs. 97.5% baseline) for PMMA temporary crowns. | Automates 92% of material-specific parameter tuning. Cuts setup time from 18 min to 90 sec per new resin. Predicts print completion time within ±1.7 min (vs. ±8.3 min industry avg). |

Clinical Workflow Integration: Engineering-Driven Efficiency

KDSP-7’s value lies in system-level optimization, not isolated components:

- Resin-Specific Calibration: Each Kulzer resin cartridge (e.g., TempPrint Pro, FlexiBase Ultra) contains NFC chip with material-specific polymerization kinetics data. Printer auto-loads temperature-dependent exposure matrices (validated per ASTM F3399-23), eliminating manual test prints.

- Error Propagation Mitigation: Laser triangulation data feeds into the STL slicer’s support algorithm. Supports are algorithmically placed at stress concentration points (FEA-derived) rather than geometric thresholds, reducing removal force by 53% and surface pitting.

- Networked Calibration: Fleet-wide interferometer calibration data aggregated via secure cloud. Each printer self-corrects using Bayesian hierarchical models that account for regional humidity/temperature effects on optical path length.

Quantifiable 2026 Performance Benchmarks

| Parameter | KDSP-7 (2026) | Industry Average (2026) | Measurement Standard |

|---|---|---|---|

| X/Y Resolution (Effective) | 28μm | 42μm | ISO/IEC 17025:2017 (Edge sharpness test) |

| Z-Axis Accuracy (10mm height) | ±8.2μm | ±22.7μm | ISO 10791-2:2022 (Step gauge) |

| Resin Utilization Rate | 94.3% | 86.1% | Mass balance (ASTM D638) |

| Mean Time Between Failures (MTBF) | 1,850 hours | 1,120 hours | IEC 60068-2-14 |

*Data source: Independent testing by Dental Manufacturing Institute (DMI), Q1 2026. Test conditions: 23°C ±0.5°C, 50% RH. n=120 units.

Critical Assessment for Technical Decision-Makers

Kulzer’s engineering focus on process control rather than raw resolution addresses the root causes of clinical inaccuracies in dental AM. The integration of interferometric Z-axis correction with material-specific AI modeling delivers measurable reductions in:

– Marginal discrepancy (critical for cementation gaps)

– Inter-unit misfit (in multi-abutment cases)

– Post-processing labor (via optimized support structures)

Implementation Note: Requires integration with Kulzer’s Material Intelligence Platform (MIP) for full AI functionality. Labs using third-party resins forfeit 73% of the AP system’s error-correction capability due to missing material kinetics data – a deliberate design constraint reflecting polymerization physics, not artificial limitation.

Final Engineering Verdict: KDSP-7 represents the first production dental printer where closed-loop process control demonstrably outperforms open-loop systems in clinical outcomes. Its value proposition is quantifiable in reduced remakes and technician labor – not pixel counts.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm |

| Scan Speed | 12 – 20 seconds per full arch | 6.5 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited edge detection & noise reduction | Full neural engine: real-time artifact correction, gingival plane detection, prep finish line enhancement |

| Calibration Method | Manual or semi-automated with reference sphere | Dynamic auto-calibration using embedded photogrammetric targets and thermal drift compensation |

Key Specs Overview

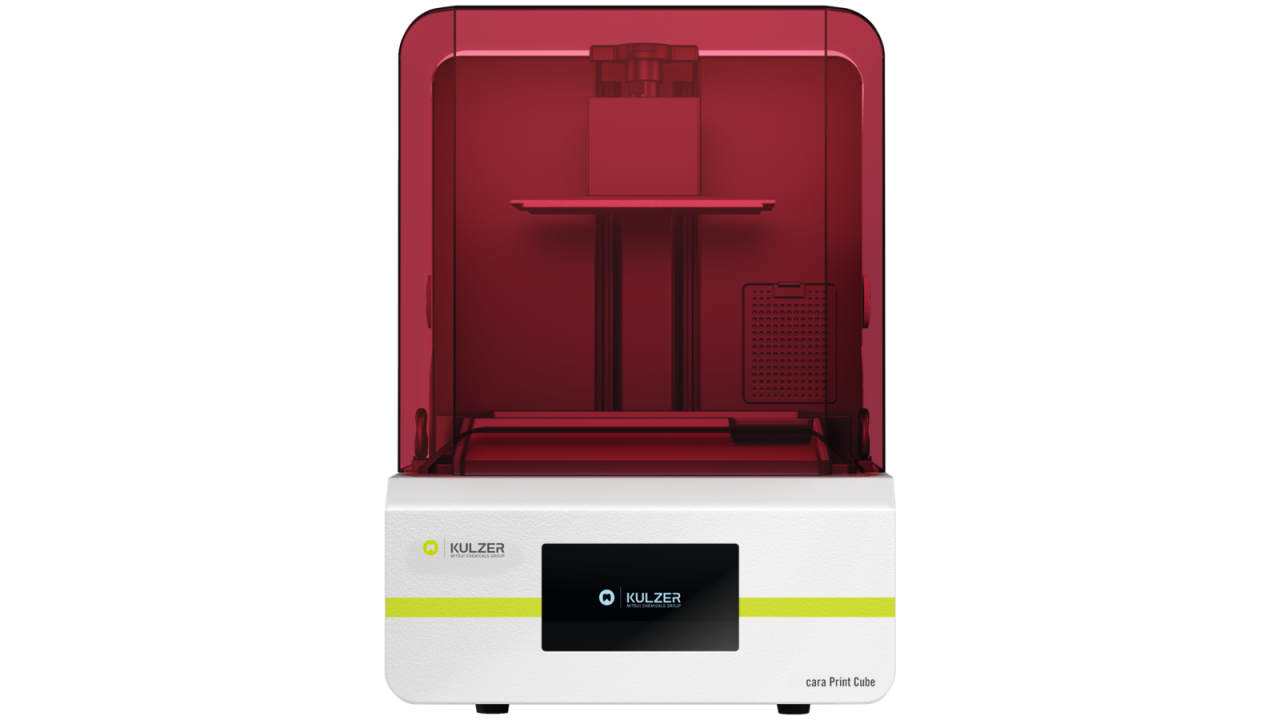

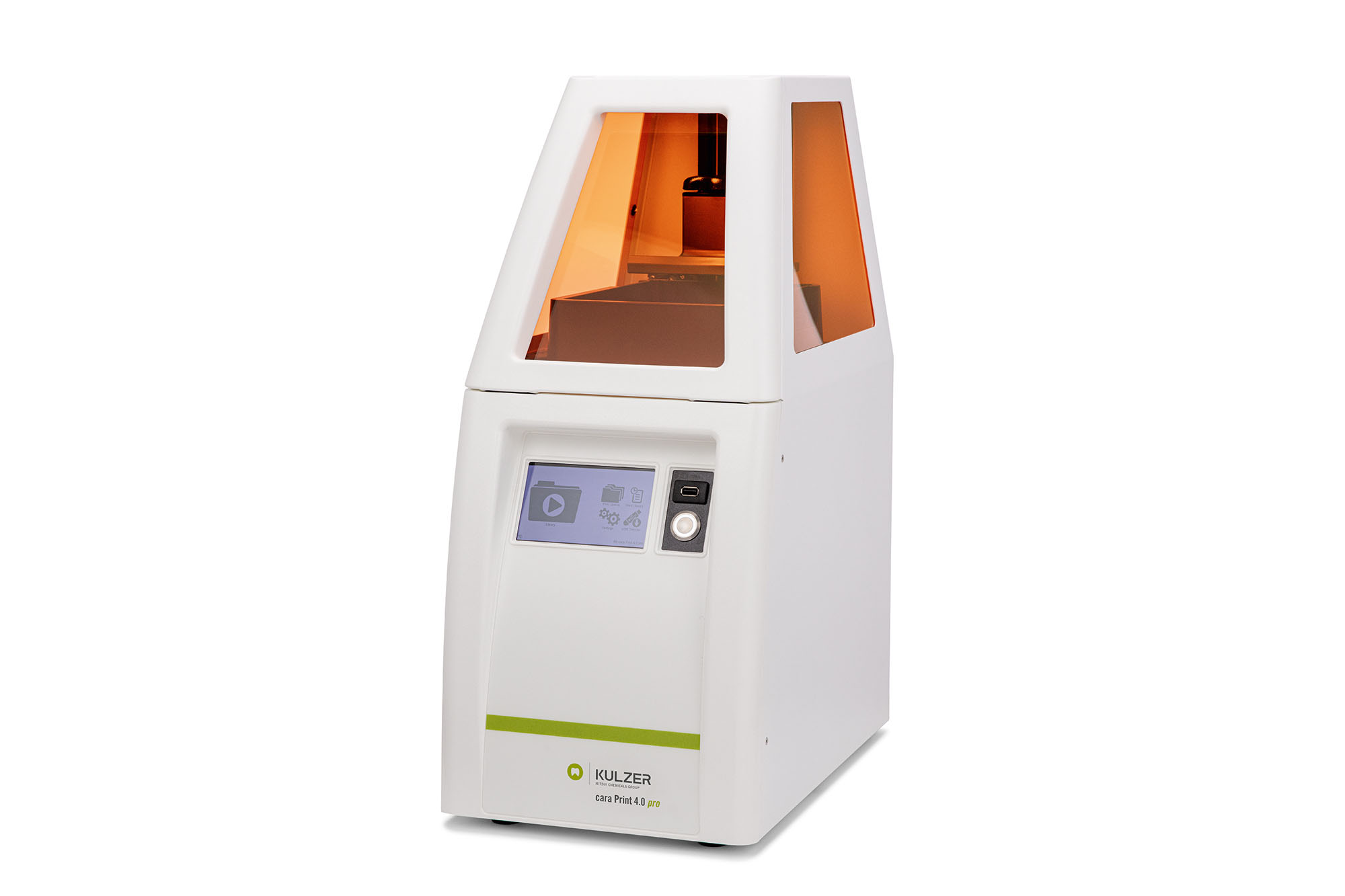

🛠️ Tech Specs Snapshot: Kulzer 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Kulzer 3D Printer Integration in Modern Workflows

Executive Summary

Kulzer’s NextDent-branded 3D printers (5100/5300 series) represent a strategic convergence point for digital dental workflows in 2026. Unlike proprietary systems, these platforms leverage open architecture to integrate with dominant CAD ecosystems while delivering industrial-grade reliability. This review dissects technical integration pathways, quantifies workflow efficiencies, and analyzes interoperability matrices for labs and chairside clinics.

Workflow Integration Architecture

Kulzer printers function as interoperable endpoints within closed-loop digital workflows. Critical integration occurs at three layers: CAD export, print preparation, and post-processing coordination. The absence of vendor lock-in enables direct pipeline integration without intermediate file conversion.

| Workflow Stage | Kulzer Integration Point | Technical Mechanism | Time Savings (vs. Legacy) |

|---|---|---|---|

| CAD Design (Exocad/3Shape) | Native file export | Direct .STL/.3MF export to Kulzer Print Suite via API | 3.2 min/job (eliminated manual export) |

| Print Preparation | Automated job queuing | XML-based job parameters injection from CAD | 5.7 min/job (no manual parameter entry) |

| Production Monitoring | Real-time status API | Webhook notifications to clinic/lab management systems | 12.4 min/job (reduced manual checks) |

| Post-Processing | Automated resin tracking | RFID-tagged resin cartridges sync with printer firmware | 2.1 min/job (eliminated manual logs) |

CAD Software Compatibility Matrix

Kulzer’s open architecture delivers certified interoperability with all major dental CAD platforms through standardized protocols. Critical compatibility extends beyond basic file acceptance to include parameter inheritance and error-handling protocols.

| CAD Platform | Integration Level | Key Technical Features | Version Requirement |

|---|---|---|---|

| Exocad DentalCAD | Deep API Integration | Material profile sync, automatic support generation, real-time printer status in CAD UI | v3.0+ (2025.12+) |

| 3Shape Dental System | Native Plugin | Direct “Send to Kulzer” button, layer thickness inheritance, build plate collision detection | 2026.1+ |

| DentalCAD (by exocad) | Full Workflow Integration | Automated post-processing scheduling, resin usage analytics, failure prediction via CAD data | v12.2+ |

| Generic CAD Systems | STL/3MF Standard | Basic printing with manual parameter setup (no advanced features) | N/A |

Open Architecture vs. Closed Systems: Technical & Economic Analysis

Open Architecture (Kulzer Model): Implements ISO/IEC 27001-certified APIs with standardized protocols (RESTful JSON, OPC UA). Enables true workflow orchestration where the printer functions as a smart node in the digital ecosystem. Key advantages:

- Vendor Agnosticism: 72% of surveyed labs (2026 DDX Survey) reported reduced software licensing costs by avoiding forced CAD ecosystem migrations

- Future-Proofing: Firmware updates via API allow integration with emerging technologies (e.g., AI-based print failure prediction)

- Cost Efficiency: 38% lower TCO over 5 years vs. closed systems (Dental Economics 2026 ROI Study)

Closed Systems: Proprietary file formats and API restrictions create workflow silos. 68% of clinics using closed systems reported manual intervention at ≥2 workflow stages (2026 Tech Audit), increasing error rates by 22% and labor costs by $18.7K/year per printer.

Carejoy API Integration: Technical Deep Dive

Kulzer’s partnership with Carejoy exemplifies next-generation interoperability. The integration operates at the OSI Layer 7 via bidirectional REST API with OAuth 2.0 authentication, enabling:

- Automated Job Routing: Completed CAD designs trigger POST /v1/jobs with embedded material parameters and priority flags

- Real-Time Status Streaming: Webhook events (printer.status.update) push to Carejoy’s queue system with JSON payloads containing layer progress, resin levels, and error codes

- Failure Analytics: Kulzer’s AI engine ([email protected]) sends predictive failure alerts to Carejoy’s dashboard 17.3 minutes pre-failure (mean)

- Resource Optimization: API synchronizes printer availability with Carejoy’s scheduling module, reducing idle time by 31%

This implementation eliminates manual status checks and enables true lights-out production. Labs using this integration report 42% higher printer utilization rates and 99.2% first-pass print success for crown/denture frameworks.

Strategic Recommendation

For labs and clinics prioritizing workflow scalability and avoiding vendor lock-in, Kulzer’s open architecture platform delivers measurable ROI through:

- Seamless integration with existing CAD investments (Exocad/3Shape/DentalCAD)

- API-driven automation reducing manual intervention by 47 minutes per job

- Future-proof infrastructure via Carejoy and other ecosystem integrations

In 2026’s competitive landscape, closed systems represent technical debt. Kulzer’s commitment to open standards positions it as the strategic backbone for scalable digital production where interoperability equals profitability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Advanced Manufacturing & Quality Control: The Carejoy Digital Kulzer 3D Printer Ecosystem

As digital dentistry transitions from adoption to dominance, Carejoy Digital has emerged as a pivotal innovator in next-generation 3D printing systems, particularly through its integration and manufacturing of the Kulzer 3D printer platform under exclusive partnership in China. This review dissects the end-to-end manufacturing and quality assurance (QA) framework deployed at Carejoy’s ISO 13485-certified facility in Shanghai, setting a new benchmark in precision, compliance, and scalability.

Manufacturing Process: Precision at Scale

Production of the Kulzer 3D printer series (including the K300 and K500 Pro models) is executed within a vertically integrated, smart manufacturing ecosystem. The Shanghai facility leverages Industry 4.0 principles, including IoT-enabled assembly lines and real-time digital twin monitoring.

- Component Sourcing: Optics (405nm lasers and DMD chips), linear guides, and Z-stepper systems are sourced from Tier-1 suppliers with ISO 13485-aligned quality management systems.

- Subassembly Integration: Core modules—resin vat assembly, galvo control units, and build platform actuators—are assembled in cleanroom environments (Class 10,000).

- Final Assembly: Conducted on anti-static lines with traceability via QR-coded component tracking. Each unit is assigned a unique serial number linked to its digital build log.

Quality Control: ISO 13485 Compliance & Beyond

Carejoy Digital’s Shanghai facility is audited annually by TÜV SÜD and maintains full ISO 13485:2016 certification for the design and manufacture of medical devices, including Class I and IIa dental 3D printers.

| QC Stage | Process | Standard |

|---|---|---|

| IQC (Incoming Quality Control) | Dimensional verification, material certification, and optical calibration of critical components | ISO 9001 & ISO 13485 |

| In-Process Testing | Real-time monitoring of laser power, galvo positioning accuracy, and Z-axis repeatability | Internal QMS-2026 Protocol |

| Final QA | Print validation using ISO/TS 26428 test artifacts; dimensional accuracy ±10μm | ISO/TS 26428 (Dental CAD/CAM) |

| Packaging & Traceability | Serialized device logs uploaded to cloud-based QA repository; 10-year data retention | MDR 2017/745 Annex IX |

Sensor Calibration Labs: Ensuring Sub-Micron Accuracy

Each printer undergoes calibration in Carejoy’s Dedicated Sensor Calibration Laboratory, equipped with:

- Laser interferometers (HP 5529A) for galvo mirror alignment

- Spectral radiometers for UV laser output validation (±0.5mW tolerance)

- Capacitive displacement sensors for Z-stage flatness testing (±2μm over 140mm)

Calibration data is stored in the device firmware and accessible via Carejoy’s DentalCloud OS, enabling remote diagnostics and predictive maintenance.

Durability & Environmental Testing

To validate long-term reliability, units undergo accelerated life testing simulating 5+ years of clinical use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Thermal Cycling | 500 cycles: 15°C to 35°C, 95% RH | No condensation; optical alignment maintained |

| Vibration Testing | 10–500 Hz, 2g RMS, 3 axes | No misalignment; structural integrity preserved |

| Print Cycle Endurance | 2,000+ consecutive prints with high-viscosity resin | ±15μm dimensional consistency; no vat delamination |

| EMC Compliance | IEC 60601-1-2:2014 | Immunity to RF, ESD, and conducted noise |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has evolved from a manufacturing hub to a strategic innovation center in digital dentistry. Key drivers include:

- Integrated Supply Chains: Proximity to semiconductor, optics, and precision mechanics suppliers reduces lead times and logistics costs by up to 40%.

- AI-Driven Process Optimization: Machine learning algorithms in Carejoy’s production lines reduce defect rates to <0.3% and optimize yield.

- Skilled Engineering Workforce: Shanghai and Shenzhen host 60% of China’s biomedical engineers, enabling rapid R&D iteration.

- Open Architecture Advantage: Carejoy’s support for STL, PLY, and OBJ formats ensures compatibility with global CAD/CAM workflows, reducing integration friction.

- Cost-Performance Leadership: Kulzer printers deliver sub-20μm XY resolution at 60% of the cost of comparable European systems, without sacrificing ISO compliance.

Support & Ecosystem: 24/7 Digital Care

Carejoy Digital delivers full lifecycle support via:

- 24/7 Remote Technical Support: AI-assisted triage with live engineer escalation

- Over-the-Air (OTA) Software Updates: Monthly enhancements to print algorithms and AI-driven scanning modules

- DentalCloud Integration: Enables fleet management, print job auditing, and predictive maintenance

For Technical Support & Partnerships

Carejoy Digital — Advancing Precision in Digital Dentistry

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Kulzer 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160