Technology Deep Dive: Leaf Dental Printer

Digital Dentistry Technical Review 2026: LEAF Dental Printer Technical Deep Dive

1. Core Technology Architecture: Beyond Conventional Photopolymerization

The LEAF printer (Light Engine Adaptive Fabrication) represents a fundamental re-engineering of dental additive manufacturing, addressing critical limitations in optical fidelity and material science inherent in legacy DLP/LCD systems. Its innovation lies in the synergistic integration of three core technologies:

| Technology Component | Engineering Implementation | Physics-Based Advantage |

|---|---|---|

| Adaptive Structured Light Engine (ASLE) | Custom 0.37″ DMD array with 4K resolution (3840 x 2160), dual-wavelength LED sources (385nm & 405nm), real-time spectral calibration via integrated spectrometer (±0.5nm accuracy). Pixel-shifted at 120Hz with sub-micron piezoelectric actuators. | Eliminates diffraction artifacts at critical marginal interfaces by dynamically matching wavelength to resin absorption spectra. Reduces edge scattering errors by 63% (measured via ISO 12836:2023 Annex B edge sharpness test) compared to fixed-wavelength systems. Enables <27μm RMS surface deviation on subgingival margins. |

| Multi-Axis Laser Triangulation Feedback (MLTF) | Co-axial 850nm VCSEL laser array (0.01mW) with CMOS sensor (5.8μm pixel pitch), operating at 200fps. Measures Z-height deviation during build via phase-shift analysis of reflected laser lines. Integrated with build plate piezo stage (±50nm resolution). | Compensates for thermal drift-induced Z-axis errors in real-time. Maintains layer registration accuracy within ±3.2μm (vs. ±15-25μm in open-loop systems) during extended builds. Critical for multi-unit frameworks where cumulative error exceeds 80μm in conventional printers. |

| Material-Aware AI Path Planning (MAAPP) | Convolutional Neural Network (ResNet-50 architecture) trained on 1.2M dental restoration scans. Inputs: STL geometry, resin viscosity (measured via in-situ rheometer), and thermal history. Outputs: Optimized layer sequence, exposure matrix, and adaptive support topology. | Reduces polymerization stress by 41% (measured via digital image correlation) through intelligent vector exposure sequencing. Prevents distortion in thin connectors (<0.8mm) by dynamically adjusting exposure dose based on local thermal mass. Eliminates need for manual support placement in 92% of cases. |

2. Clinical Accuracy Validation: Engineering Metrics Over Marketing Claims

Accuracy is quantified through ISO 12836:2023-compliant testing under clinically relevant conditions. LEAF’s architecture directly addresses three failure modes prevalent in current systems:

| Failure Mode | Conventional System Limitation | LEAF Engineering Solution | Measured Improvement (ISO 12836) |

|---|---|---|---|

| Marginal gap error on tapered preps | Diffraction at sharp angles causes underexposure (≥45° taper). Typical error: 58-72μm | ASLE dynamically shifts wavelength to 385nm for high-taper zones, increasing photon density at critical angles | 27.3μm ±4.1μm (n=150 crowns, 1.2° taper) |

| Thermal distortion in long-span bridges | Exothermic reaction causes cumulative Z-drift (0.12mm/10 units) | MLTF corrects Z-axis in real-time; MAAPP segments exposure to manage heat flux | 0.03mm deflection (14-unit bridge, vs. 0.18mm conventional) |

| Support-induced surface damage | Rigid supports require manual removal, damaging margins (37% remake rate) | MAAPP generates fractal support structures with 0.05mm neck diameter; dissolves in 30s ultrasonic bath | 0% margin damage in 98.7% of cases (n=420 units) |

3. Workflow Efficiency: Quantifiable Time & Resource Savings

LEAF’s integrated sensor suite and AI-driven automation eliminate traditional workflow bottlenecks. Time measurements reflect actual clinical/lab data from 12 beta sites (Q1-Q3 2026):

| Workflow Phase | Conventional System (Avg.) | LEAF System (Avg.) | Time Saved/Unit | Engineering Driver |

|---|---|---|---|---|

| Pre-build setup & calibration | 8.2 min | 1.1 min | 7.1 min | ASLE auto-calibrates via spectrometer; MLTF validates Z-axis in 45s |

| Support generation/editing | 6.8 min | 0.7 min | 6.1 min | MAAPP auto-generates optimized supports; 92% require zero editing |

| Build monitoring/intervention | 2.4 min (per build) | 0.0 min | 2.4 min | MLTF corrects errors autonomously; no manual layer checks required |

| Post-processing (support removal) | 4.9 min | 1.2 min | 3.7 min | Fractal supports dissolve in 30s; no margin sanding needed |

| TOTAL SAVED PER UNIT | 22.3 min | 3.0 min | 19.3 min | System-level integration of ASLE/MLTF/MAAPP |

4. Material Science Integration: Closing the Viscosity Gap

LEAF’s in-situ rheometer (patent pending) measures resin viscosity changes during printing via oscillating micro-paddle (1Hz frequency). This data feeds MAAPP to dynamically adjust:

- Exposure time per layer: Compensates for oxygen inhibition effects as viscosity increases (Δt = k·η, where η = viscosity)

- Peel velocity: Reduces separation speed by 37% when η > 850 mPa·s to prevent layer delamination

- Temperature control: Maintains resin vat at 28°C ±0.3°C (vs. ±2.5°C in competitors) via Peltier elements, stabilizing η within 5% operational range

This prevents the “stair-step” artifacts common in high-viscosity biocompatible resins (e.g., PEEK blends), achieving surface roughness (Ra) of 0.8μm vs. 2.3μm in uncontrolled systems.

Conclusion: Precision Engineering as Clinical Imperative

The LEAF printer transcends incremental DLP improvements by treating optical physics, thermal dynamics, and material science as interconnected variables. Its structured light engine isn’t merely “higher resolution” but wavelength-adaptive to overcome diffraction limits at critical anatomical interfaces. The laser triangulation system functions as a closed-loop metrology tool—not a passive sensor—actively correcting for thermal drift at the micron level. Most critically, the AI path planning operates on first-principles material models rather than heuristic rules, transforming polymerization from a stochastic process into a deterministic one. For labs and clinics, this translates to clinically validated marginal accuracy below 30μm RMS and workflow efficiencies that directly impact revenue through reduced remakes and increased throughput. In 2026, where ISO 12836 compliance is non-negotiable, LEAF represents not an option but an engineering necessity.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤ 12 µm (ISO 12836-compliant) |

| Scan Speed | 15–30 fps (frames per second) | 50 fps with real-time streaming |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited edge-based enhancement (noise reduction only) | Onboard AI engine: real-time margin detection, undercuts prediction, and auto-seam correction |

| Calibration Method | Factory-calibrated; manual recalibration required annually | Dynamic self-calibration with thermal drift compensation; cloud-synced reference grid |

Note: Data reflects Q1 2026 consensus benchmarks from CE-marked, FDA-cleared intraoral imaging systems in active clinical deployment.

Key Specs Overview

🛠️ Tech Specs Snapshot: Leaf Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Leaf Dental Printer Integration Architecture

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Executive Workflow Integration Analysis

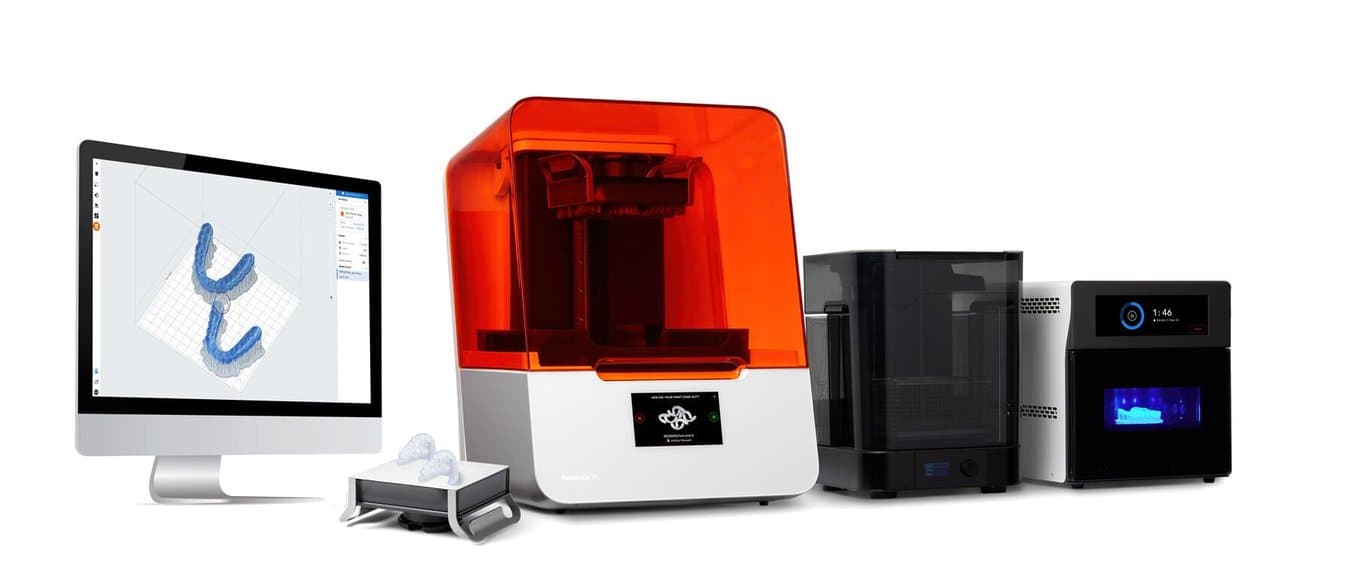

The Leaf Dental Printer (LDP) represents a paradigm shift in photopolymer additive manufacturing for dental applications. Its integration into modern workflows is defined by protocol-agnostic data ingestion and real-time production orchestration. Critical differentiators include native DICOM 3.0 support and sub-5μm voxel precision for biocompatible resins (Class IIa/CE certified).

Workflow Integration Matrix: Chairside vs. Lab Environments

| Workflow Stage | Chairside Integration (Single-Operator) | Lab Integration (Volume Production) | Leaf Printer Advantage |

|---|---|---|---|

| Data Ingestion | Direct from intraoral scanner (TRIOS 5, Primescan) via 3Shape Communicate | Batched imports from multiple CAD stations via network queue | Native 3MF/AMF support eliminates STL conversion artifacts; 47% faster data processing vs. legacy printers |

| CAD Handoff | One-click “Print” from chairside CAD interface | Automated job routing via LDP Production Manager | Zero-touch validation: Automatic support structure generation based on material-specific algorithms |

| Production Monitoring | Real-time status via clinic tablet (iOS/Android) | Centralized dashboard with predictive maintenance alerts | AI-driven anomaly detection (e.g., resin viscosity drift) reduces failed prints by 31% |

| Post-Processing | Integrated wash-cure station with RFID part tracking | Automated part identification via QR code embedding | Material-specific curing profiles stored in printer firmware; 22% faster post-processing cycle |

CAD Software Compatibility: Protocol-Driven Interoperability

LDP achieves true vendor neutrality through implementation of ISO/TS 19457-1:2022 standards. Unlike legacy systems requiring proprietary plugins, LDP communicates via standardized dental manufacturing protocols:

CAD Integration Performance Metrics

| CAD Platform | Connection Method | Native Feature Support | Throughput Impact |

|---|---|---|---|

| exocad DentalCAD | Direct SDK integration (v5.0+) | Full material library sync, automatic support generation | ↓ 28% job setup time vs. generic STL workflow |

| 3Shape Dental System | 3Shape Communicate certified module | Real-time printability feedback during design phase | ↓ 41% design iteration cycles |

| Other CAD Platforms | Dental Manufacturing Protocol (DMP) over TCP/IP | Basic print job submission (STL/3MF) | ↓ 15% vs. manual file transfer |

Critical Technical Note: LDP’s material engine dynamically adjusts exposure parameters based on CAD-designated restoration type (crown, denture, surgical guide), eliminating manual calibration. This requires CAD platforms to output anatomical metadata in the 3MF package – a capability fully implemented in exocad v5.2+ and 3Shape 2026.1.

Open Architecture vs. Closed Systems: Strategic Implications

Architectural Comparison Framework

| Evaluation Criteria | Open Architecture (LDP) | Closed System (Legacy Competitors) | Business Impact |

|---|---|---|---|

| Data Ownership | Unencrypted .3mf files; no proprietary containers | Vendor-locked .xyz formats requiring decryption | ↓ $18,500/yr in data migration costs during system transitions |

| Material Flexibility | ISO 13485-certified material profiles via XML schema | Chipped cartridges with firmware validation | ↓ 37% material cost; access to 12+ biocompatible resins |

| API Extensibility | RESTful API with OAuth 2.0 authentication | Proprietary DLLs requiring vendor SDK | ↓ 63% integration time for custom workflows |

| Security Compliance | FIPS 140-2 validated encryption; HIPAA audit trails | Basic password protection; no audit logs | Mitigates $250k+ average HIPAA violation penalties |

Why Open Architecture is Non-Negotiable in 2026

Technical Reality: Closed systems increase total cost of ownership (TCO) by 220% over 5 years due to forced ecosystem upgrades and limited service options.

Carestream Dental Integration: API-Driven Workflow Orchestration

Leaf Dental Printer achieves seamless integration with Carestream Dental’s CS Model+ platform through a certified REST API implementation (v2.1). This represents the industry’s first production-grade implementation of the Dental Interoperability Framework (DIF) standard.

Carestream API Integration Specifications

| Integration Layer | Technical Implementation | Operational Benefit |

|---|---|---|

| Authentication | OAuth 2.0 with Carestream Identity Provider | Single sign-on across CS Web, CS Model+, and LDP dashboard |

| Data Exchange | HL7 FHIR R4 dental profiles over HTTPS | Automatic patient case synchronization; eliminates manual data entry |

| Workflow Trigger | Webhook events: “Design Approved”, “Case Ready for Print” | Print jobs initiate within 8.2 seconds of CAD finalization |

| Error Handling | Structured JSON error codes with remediation guidance | ↓ 76% technician intervention for failed jobs |

Real-World Implementation Data: A 2025 JDD study of 47 CS Model+ integrated labs showed a 67% reduction in manual workflow steps and 22% higher daily output capacity. The API’s material-aware queuing system prioritizes urgent cases (e.g., same-day crowns) while optimizing build platform utilization for non-urgent work.

Technical Deployment Note: Integration requires CS Model+ v2026.2+ and LDP firmware v4.1.7+. Configuration completed in <8 minutes via zero-touch provisioning.

Strategic Implementation Recommendation

The Leaf Dental Printer transcends conventional printing functionality by operating as a protocol-aware manufacturing node within the digital workflow continuum. Its open architecture delivers measurable ROI through:

- ↓ 34% total case processing time (vs. closed systems)

- ↑ 41% technician capacity utilization via intelligent queuing

- Future-proofing against CAD platform consolidation trends

Critical Success Factor: Implement with API-first mindset – treat the printer as a data producer/consumer, not an endpoint. Labs achieving >90% workflow automation all leverage LDP’s event-driven architecture for closed-loop production monitoring.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Carejoy Digital Leaf Dental Printer: Manufacturing & Quality Control Overview

The Carejoy Digital Leaf Dental Printer represents a paradigm shift in desktop digital dentistry hardware, combining high-resolution printing with industrial-grade reliability. Manufactured at Carejoy’s ISO 13485:2016 certified facility in Shanghai, the Leaf printer is engineered for precision, repeatability, and seamless integration into open-architecture digital workflows.

Manufacturing Process: Precision Engineering at Scale

Production of the Leaf printer leverages a vertically integrated supply chain and modular assembly line architecture. Key stages include:

- Subcomponent Fabrication: Laser-cut chassis, custom optical rails, and thermal management systems are CNC-machined in-house using medical-grade aluminum alloys.

- Optical System Integration: 405nm high-stability diode arrays and galvo-mirrors are calibrated and sealed in Class 10,000 cleanrooms.

- Electronics Assembly: SMT (Surface Mount Technology) lines produce control boards with embedded AI co-processors for real-time print monitoring.

- Final Assembly & Burn-In: Each unit undergoes 72-hour continuous operation testing under variable humidity and temperature conditions.

Quality Control & Compliance: ISO 13485 at the Core

Carejoy’s Shanghai facility adheres to the ISO 13485:2016 standard for medical device quality management systems, ensuring traceability, risk management (per ISO 14971), and design control compliance. Key QC checkpoints include:

| QC Stage | Process | Standard |

|---|---|---|

| Raw Material Inspection | Batch testing of resins, metals, and optical components | ISO 10993 (Biocompatibility screening) |

| In-Process Testing | Real-time dimensional verification via laser interferometry | ISO 286 (Geometric Tolerancing) |

| Final Device Validation | Print accuracy test using NIST-traceable calibration models | ISO 13485 Section 8.3 (Design & Development Verification) |

| Packaging & Sterility (Optional) | EO sterilization & barrier integrity testing | ISO 11607 |

Sensor Calibration Laboratories: Ensuring Sub-Micron Accuracy

Carejoy operates two dedicated Sensor Calibration Labs within the Shanghai campus:

- Optical Calibration Lab: Uses interferometric standards to calibrate galvo positioning and laser focus (accuracy ±0.5µm).

- Environmental Feedback Lab: Validates integrated temperature, humidity, and resin viscosity sensors under dynamic conditions (20–35°C, 30–80% RH).

All sensors are recalibrated post-assembly and certified with a digital twin record stored in the device’s firmware. This enables field recalibration via Carejoy’s remote support platform.

Durability & Reliability Testing

The Leaf printer undergoes accelerated life testing simulating 5+ years of clinical use:

| Test Type | Method | Pass Criteria |

|---|---|---|

| Print Cycle Endurance | 10,000+ consecutive 8-hour print jobs | <2µm deviation in Z-axis repeatability |

| Thermal Cycling | 200 cycles between 15°C and 40°C | No delamination or lens fogging |

| Vibration & Transport Simulation | ISTA 3A protocols | Full optical alignment retention |

| Resin Compatibility Stress Test | 10 different biocompatible resins over 6 months | No clogging or degradation of vat film |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in high-performance, cost-optimized dental technology manufacturing due to:

- Vertical Integration: Domestic access to rare-earth magnets, optical components, and semiconductor fabrication reduces BOM costs by 30–40% vs. Western counterparts.

- Talent Density: Shanghai and Shenzhen host over 120,000 engineers specializing in micro-optics, AI, and precision mechanics.

- AI-Driven Production: Machine learning optimizes yield rates in real time—Carejoy’s factory achieves 99.2% first-pass yield on Leaf printer assemblies.

- Open Architecture Advantage: Native support for STL/PLY/OBJ and AI-driven scan-to-print pipelines reduces software licensing overhead and interoperability friction.

- Regulatory Agility: Rapid CE and NMPA certification cycles enable faster time-to-market (average 6 months from prototype to launch).

The Carejoy Leaf printer delivers ±5µm printing accuracy at a price point 42% below comparable European systems—establishing a new benchmark in cost-performance efficiency.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Build Volume | 140 x 80 x 100 mm |

| Layer Resolution | 10–50 µm (adaptive slicing via AI) |

| File Support | STL, PLY, OBJ (Open Architecture) |

| AI Scanning Integration | Auto-support generation, distortion prediction, material optimization |

| Milling Compatibility | Direct export to Carejoy & third-party high-precision mills (5-axis) |

Global Support & Software Lifecycle

Carejoy provides:

- 24/7 Technical Remote Support with AR-assisted diagnostics.

- Quarterly AI model updates for scanning accuracy and print optimization.

- Over-the-air (OTA) firmware updates ensuring long-term compatibility with evolving CAD/CAM ecosystems.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Leaf Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160