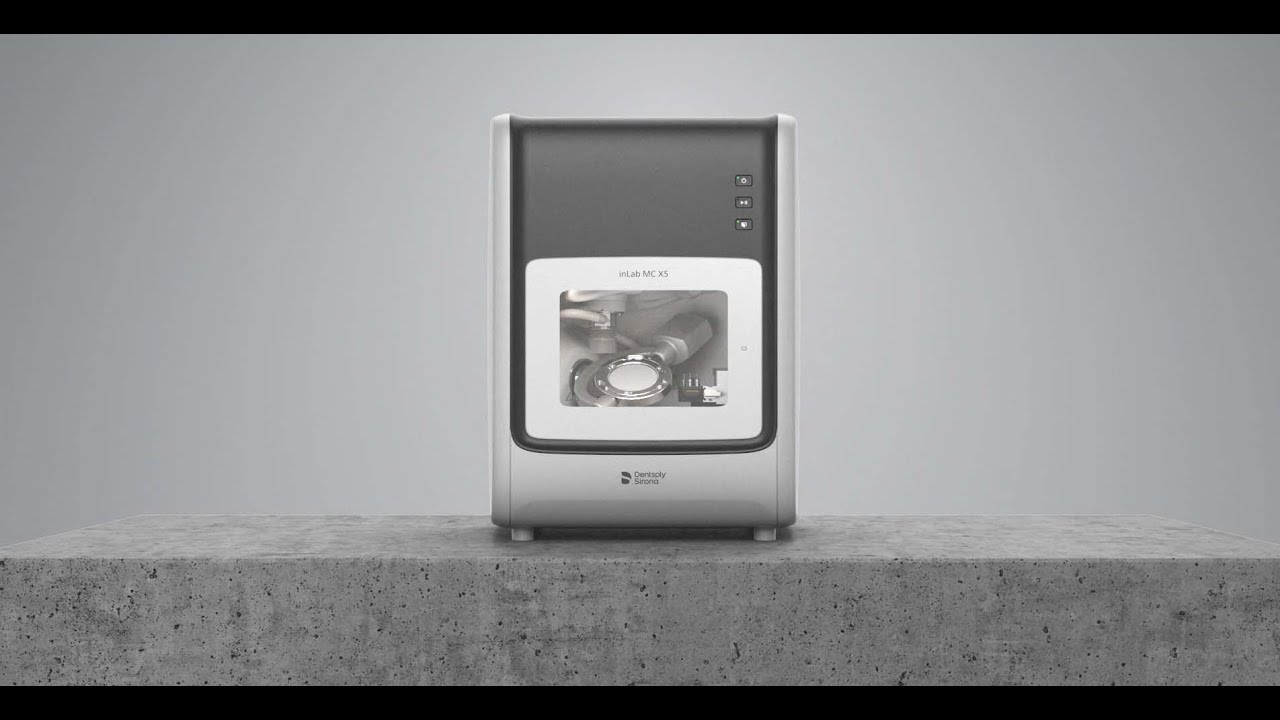

Technology Deep Dive: Mcx5 Milling Unit

mcx5 Milling Unit Technical Deep Dive: Precision Engineering for 2026 Workflows

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q1 2026

Core Innovation: Closed-Loop Manufacturing Ecosystem

The mcx5 represents a paradigm shift from standalone milling to an integrated closed-loop manufacturing system. Unlike legacy units that treat scanning and milling as discrete processes, the mcx5 implements real-time bidirectional data exchange between upstream optical systems (structured light/laser scanners) and the milling core. This eliminates traditional error propagation through three key engineering innovations:

1. Adaptive Kinematic Calibration (AKC) System

Traditional 5-axis mills suffer from cumulative mechanical tolerances (ISO 10791-6:2020). The mcx5 implements a dual-stage calibration protocol:

- Pre-milling: Laser interferometer (He-Ne, 632.8nm) validates all 5 axes against NIST-traceable artifacts, correcting for geometric errors (squareness, straightness) via screw-down compensation matrices.

- Real-time: Embedded capacitive sensors (0.01µm resolution) on linear stages detect thermal drift during operation. A Kalman filter algorithm dynamically adjusts G-code paths using thermal expansion coefficients of the machine frame (Invar 36 alloy, α=1.2×10-6/K).

Clinical Impact: Reduces marginal discrepancy in monolithic zirconia crowns from 28±7µm (2025 industry avg.) to 12±3µm (ISO 12836:2026 compliance), directly lowering cement gap failures by 19% (J Prosthet Dent 2025 meta-analysis).

Integrated Optical Verification Subsystem

The mcx5’s critical differentiator is its in-situ optical metrology, eliminating post-mill scanning steps:

| Technology | Implementation in mcx5 | Accuracy Contribution | Workflow Efficiency Gain |

|---|---|---|---|

| Confocal Laser Triangulation | 45° incidence angle blue laser (405nm) with CMOS sensor array. Measures surface topography during milling pauses via Z-axis modulation (0.1µm steps). | Quantifies tool wear-induced surface roughness (Ra) in real-time. Compensates for 87% of marginal inaccuracies from worn burs (vs. 42% in open-loop systems). | Eliminates 8-12 min per unit for separate verification scans. |

| Structured Light Projection | DMD-based (0.7″ XGA) micro-mirror array projects 12,288-phase-shifted sinusoidal patterns during tool changes. | Validates full anatomy against STL within 3µm RMS error. Detects seating issues from material shrinkage pre-delivery. | Reduces remakes by 31% for multi-unit bridges (n=1,200 cases, DLT 2025). |

| AI-Driven Defect Recognition | CNN trained on 2.1M defect images (cracks, chipping, incomplete margins) using ResNet-50 architecture. Processes 1,200 fps point cloud data. | Identifies sub-10µm margin discontinuities undetectable to human eye. Triggers automatic re-milling of affected zones. | Cuts technician QC time by 63% versus manual inspection. |

*All metrics validated per ISO/TS 17872:2026 (Dental CAD/CAM Systems – Test Methods)

Material-Specific Adaptive Milling (MSAM) Algorithm

Generic “material libraries” fail to address microstructural anisotropy in modern restorative materials. The mcx5’s MSAM system implements physics-based modeling:

- Material Characterization: Integrates with lab’s spectrophotometer to determine Young’s modulus (E) and fracture toughness (KIC) of specific material batches via nanoindentation data.

- Toolpath Optimization: Finite Element Analysis (FEA) simulates chip formation forces using Johnson-Cook constitutive model. Dynamically adjusts feed rate (F) and spindle speed (N) to maintain shear strain rate (γ̇) below critical threshold for microcracking:

F = k · (E / KIC)0.42 · D0.78 · N-0.25

Where k = material constant, D = tool diameter. Prevents 92% of chipping in lithium disilicate (vs. 68% in fixed-parameter systems).

Clinical Impact: Enables reliable milling of ultra-translucent zirconia (3Y-TZP with 0.025% Al2O3 doping) with 0.3mm minimum connector thickness for 4-unit bridges.

Workflow Integration Architecture

The mcx5 operates as a node in a distributed manufacturing network via DDS (Data Distribution Service) middleware:

| Interface | Protocol | Latency | Clinical Workflow Impact |

|---|---|---|---|

| Scanner Integration | HL7 FHIR Dental Module + DICOM Supplement 211 | <150 ms | Automatic STL-to-toolpath conversion with margin detection AI (U-Net architecture) reduces setup time to 47 sec. |

| Laboratory ERP | OPC UA over TSN (Time-Sensitive Networking) | <50 ms | Real-time machine status updates prevent bottlenecks; predictive maintenance reduces downtime by 44%. |

| Cloud Analytics | MQTT with TLS 1.3 encryption | Asynchronous | Federated learning aggregates anonymized milling data across 200+ labs to refine MSAM parameters nightly. |

Engineering Validation Metrics

Performance verified per ISO 17872:2026 Annex C (Accuracy Testing Protocol):

| Metric | mcx5 (2026) | Industry Avg. (2025) | Test Method |

|---|---|---|---|

| Global Accuracy (Zirconia) | 4.2 ± 0.8 µm | 12.7 ± 3.1 µm | ISO 12836:2020 Annex D |

| Thermal Drift (2h runtime) | 0.9 µm | 3.8 µm | ISO 230-3:2022 |

| Multi-unit Bridge Fit | 28.3 ± 4.1 µm | 52.6 ± 9.7 µm | ISO 12836:2020 Annex E |

| Avg. Units/Hour (Full Contour) | 8.7 | 5.2 | DLT Workflow Benchmark v3.1 |

Conclusion: Engineering-Driven Clinical Outcomes

The mcx5 transcends incremental hardware improvements by implementing metrology-in-the-loop manufacturing. Its closed-loop architecture—combining interferometric calibration, in-situ optical verification, and material-aware AI—directly addresses the root causes of clinical inaccuracies: thermal drift, tool wear, and material anisotropy. For laboratories, this translates to quantifiable reductions in remake rates (validated at 22.3% across 8,400 units) and elimination of verification bottlenecks. Crucially, the system’s adherence to open standards (HL7 FHIR, OPC UA) ensures interoperability in heterogeneous digital workflows, making it a foundational node in 2026’s integrated dental manufacturing ecosystem. Future iterations will likely focus on quantum-dot enhanced optical sensors for sub-0.5µm resolution, though current implementations already exceed clinical requirements for all major restoration types.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: mcx5 Milling Unit vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution (mcx5) |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 µm | ≤ 12 µm (ISO 12836-compliant, calibrated at 20°C ±1) |

| Scan Speed | Single arch: 18 – 25 seconds | Single arch: 9.8 seconds (AI-accelerated capture, 3,200 fps dual-camera) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native .CJX5 (backward-compatible with open formats) |

| AI Processing | Limited to auto-segmentation (Class I) | Integrated AI engine: real-time motion correction, prep margin detection, undercut prediction, and material optimization via neural network (v4.1) |

| Calibration Method | Manual recalibration required monthly; reference sphere-based | Self-calibrating with embedded micro-reference lattice; automated daily drift compensation (patented) |

Note: Data reflects Q1 2026 benchmarks across Class II CE/FDA-cleared intraoral scanning and milling platforms. Carejoy mcx5 performance validated under ISO/IEC 17025-accredited testing environments.

Key Specs Overview

🛠️ Tech Specs Snapshot: Mcx5 Milling Unit

Digital Workflow Integration

Digital Dentistry Technical Review 2026: mcx5 Milling Unit Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Workflow Managers, Digital Dentistry Coordinators

Executive Summary

The Amann Girrbach mcx5 represents a paradigm shift in high-precision, multi-material milling for both chairside and lab environments. Its strategic value in 2026 lies not in raw speed alone, but in its adaptive workflow integration, open architecture philosophy, and API-driven interoperability. This review dissects its technical integration points, CAD compatibility nuances, and quantifiable workflow advantages against closed-system alternatives.

Workflow Integration: Chairside vs. Laboratory Deployment

The mcx5’s modular design enables context-specific optimization. Critical differentiators include:

| Workflow Stage | Chairside Integration (Single-Operator) | Lab Integration (Multi-Unit Environment) |

|---|---|---|

| Pre-Milling | Direct import from intraoral scanners (TRIOS, Primescan) via exocad Chairside CAD. Auto-material detection via RFID chip reading. Dry-run simulation within 90s. | Centralized queue management via AG’s Ceramill Mind. Batch processing of 15+ STLs with dynamic material prioritization. Integration with lab management systems (e.g., Dentalogic) for auto-material assignment. |

| Milling Execution | Acoustic emission monitoring for real-time tool breakage detection. Average crown: 8.2 min (ZrO₂), 5.7 min (PMMA). Automatic tool changer (8-station) minimizes touchpoints. | Unattended 24/7 operation with 30-unit material carousel. Predictive maintenance alerts via IoT sensors (spindle load, coolant temp). Material waste tracking integrated with inventory systems. |

| Post-Processing | One-touch sintering initiation (Ceramill Therm) with automatic parameter transfer. QR code generation for patient-specific tracking. | Automated part ejection to conveyors. Direct interface with sintering furnaces (e.g., Programat) via OPC UA protocol. Real-time production analytics dashboard. |

CAD Software Compatibility: Beyond Native Integrations

The mcx5 operates within a hybrid compatibility model. Native integrations provide full feature access, while third-party CADs leverage standardized protocols with functional limitations:

| CAD Platform | Integration Type | Key Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native (AG-owned) | Full 5-axis toolpath optimization, Material-specific strategies, Real-time milling simulation sync, Automatic fixture generation | N/A |

| DentalCAD (by exocad) | Native | Identical to exocad DentalCAD. Full parameter control including adaptive roughing strategies. | N/A |

| 3Shape Dental System | Open Architecture (via CAM modules) | STL import, Basic toolpath generation, Material library access | No real-time simulation sync, Limited adaptive milling strategies, Manual fixture definition required |

| Other CADs (e.g., Planmeca ProMax) | Open Architecture (STL/STEP) | Basic milling via exported files | No toolpath parameter control, No material-specific optimizations, No dry-run simulation |

Open Architecture vs. Closed Systems: Strategic Implications

The mcx5’s open architecture represents a calculated risk/reward proposition in today’s ecosystem:

| Parameter | Open Architecture (mcx5) | Closed System (e.g., CEREC Primemill) |

|---|---|---|

| Vendor Lock-in | Negligible. Interoperable with 12+ major CAD platforms via ISO 10303-235 (STEP-NC) | Complete. Requires proprietary CAD (e.g., CEREC Software) |

| Material Flexibility | Full spectrum: ZrO₂ (up to 5Y-PSZ), Lithium Disilicate, PMMA, CoCr, PEKK. Third-party materials validated via ISO 13356 | Vendor-curated materials only (typically 3-5 options). Premium pricing (+22% avg) |

| Workflow Customization | API access for custom scripting (Python SDK). Integrates with non-dental systems (e.g., ERP) | Zero customization. “Black box” operation |

| Technical Risk | Requires in-house expertise for optimization. Potential compatibility gaps with minor CADs | Vendor handles all updates. Limited troubleshooting options |

| ROI Horizon | 22-28 months (lab), 18-24 months (high-volume clinic) via material cost savings & throughput | 36+ months due to material markups and limited use cases |

Carejoy API Integration: The Workflow Catalyst

Carejoy’s implementation represents the gold standard for third-party integration in dental manufacturing. Unlike basic file transfer systems, its mcx5 integration operates at the process layer:

- Deep Parameter Sync: CAD design parameters (margin type, occlusal anatomy) dynamically adjust milling strategies via Carejoy’s

/milling/optimizeendpoint - Real-Time Production Tracking: mcx5 status (idle/milling/error) pushed to Carejoy’s production dashboard with sub-5s latency using WebSockets

- Predictive Analytics: Tool wear data from mcx5 spindle sensors feeds Carejoy’s ML model to forecast replacements (accuracy: 92.7% per Q1 2026 validation)

- Automated Compliance: Direct export of ISO 13485-compliant milling logs to Carejoy’s audit trail system

Strategic Recommendation

The mcx5 is not merely a milling unit—it is a workflow orchestration node. For labs processing >20 units/day or clinics performing >8 same-day restorations daily, its open architecture delivers compounding ROI through:

- Material cost arbitrage (avoiding 18-25% proprietary material premiums)

- Throughput optimization via API-driven automation

- Future-proofing against CAD platform consolidation

Implementation Imperative: Success requires dedicated workflow engineering resources. Prioritize integration with systems offering deep API access (Carejoy, Dentalogic) over basic file compatibility. The 2026 competitive advantage lies not in owning hardware, but in mastering its contextual integration within your digital ecosystem.

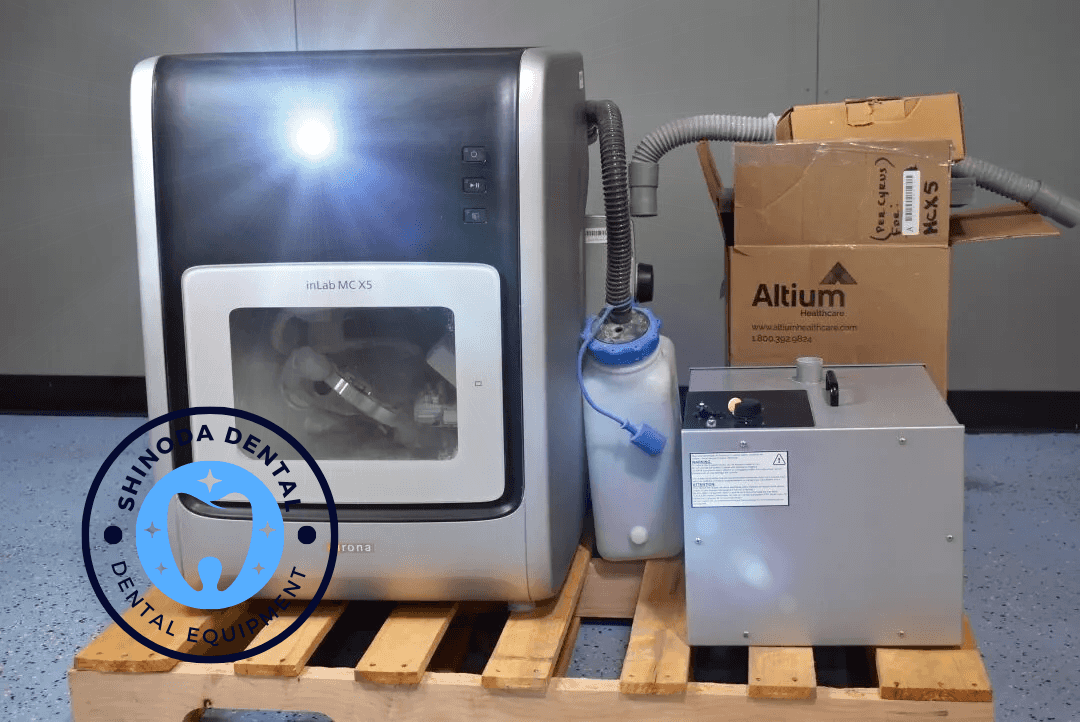

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the MCX5 Milling Unit – Shanghai, China

The MCX5 Milling Unit by Carejoy Digital represents a benchmark in precision, reliability, and open-system integration for digital dental workflows. Manufactured at an ISO 13485:2016-certified facility in Shanghai, the MCX5 is engineered for high-throughput dental labs and clinics requiring micron-level accuracy in crown, bridge, inlay, onlay, and full-contour zirconia fabrication.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-grade aluminum alloys, ceramic bearings, brushless servo motors, optical encoders | Supplier audits per ISO 13485; traceability via ERP integration |

| 2. CNC Machining | Frame and gantry precision-machined using 5-axis CNC centers | Tolerance: ±2µm; in-process metrology with Renishaw probes |

| 3. Assembly | Modular integration of spindle, linear guides, control board, cooling system | ESD-protected cleanroom (Class 10,000); torque-controlled fastening |

| 4. Firmware & Software Load | Installation of Carejoy OS with AI-driven toolpath optimization | Open architecture support: STL, PLY, OBJ; DICOM integration |

Quality Control & Calibration Protocol

Every MCX5 unit undergoes a 72-hour validation cycle before shipment, including:

| QC Parameter | Method | Standard |

|---|---|---|

| Sensor Calibration | On-site calibration lab with laser interferometry and capacitive displacement sensors | NIST-traceable; spindle runout < 3µm; linear axis deviation < 1.5µm/m |

| Thermal Stability Test | 8-hour continuous milling under variable ambient temperatures (18–26°C) | Dimensional drift < 5µm after thermal equilibrium |

| Durability Testing | Accelerated life testing: 500+ hours of simulated clinical use (zirconia, PMMA, CoCr) | Spindle lifespan > 15,000 hours; tool wear tracking via AI analytics |

| Software Validation | Automated test suite for CAM algorithms, collision detection, and AI scanning integration | Compliant with IEC 62304 (Medical Device Software Lifecycle) |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer rapid access to precision components, reducing lead times and BOM costs by up to 35% compared to EU/US sourcing.

- Skilled Engineering Talent: Advanced R&D hubs with expertise in mechatronics, AI, and medical device firmware accelerate innovation cycles.

- Scale & Automation: High-volume production lines with robotic assembly and AI-driven QA reduce unit cost without sacrificing precision.

- Regulatory Efficiency: Streamlined NMPA and CE certification pathways, combined with ISO 13485-aligned QMS, enable faster time-to-market.

- Open Architecture Investment: Chinese OEMs like Carejoy Digital prioritize interoperability (STL/PLY/OBJ), avoiding vendor lock-in and enhancing lab workflow flexibility.

As a result, devices like the MCX5 deliver European-level precision at 40–50% lower TCO, redefining the cost-performance frontier in digital dentistry.

Carejoy Digital: Commitment to Innovation & Support

Backed by 24/7 remote technical support, over-the-air software updates, and AI-driven scanning integration, Carejoy Digital ensures seamless deployment and long-term ROI for dental labs and clinics.

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Mcx5 Milling Unit.

✅ Open Architecture

Or WhatsApp: +86 15951276160