Technology Deep Dive: Nextdent Printer

Digital Dentistry Technical Review 2026: NextDent Printer Series Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinical Workflow Managers | Review Date: Q1 2026

Clarifying Core Misconceptions: Printing vs. Scanning Technologies

A critical engineering distinction must be established upfront: Structured Light Projection (SLP) and Laser Triangulation are exclusively 3D scanning modalities, not printing mechanisms. Their inclusion in the query reflects persistent industry conflation between intraoral scanning and additive manufacturing subsystems. The NextDent printer (2026 Series: ND9X/ND10X) employs a hybrid DLP (Digital Light Processing) architecture for fabrication. SLP/Laser Triangulation may appear in auxiliary calibration systems but play no role in the photopolymerization process itself. This review dissects the actual printing technology with surgical precision.

Core Printing Technology: Precision-Optimized DLP Architecture

The 2026 NextDent series replaces legacy LCD-based MSLA with a dual-phase DLP system featuring Texas Instruments’ 0.47″ DMD (Digital Micromirror Device) chips. This shift addresses fundamental limitations of LCD photomasks:

1. Optical Subsystem Engineering

Key advancements derive from first-principles physics of photopolymerization:

- Spectral Purity Optimization: Integrated UV-LED array (385nm ±2nm FWHM) with dichroic filtering eliminates IR/visible light contamination. This reduces thermal drift in resin (ΔT < 0.3°C during 8-hour prints), minimizing volumetric shrinkage errors by 37% versus unfiltered systems (per ISO/TS 17801:2023).

- Dynamic Pixel Steering: DMD mirrors operate at 16.7kHz refresh rate with sub-millisecond latency. Unlike static LCD pixels, mirrors tilt at 12° angles to enable pixel oversampling—projecting each layer as four offset micro-exposures. This achieves 18µm XY resolution from a 10.5µm DMD pixel pitch via the Nyquist-Shannon sampling theorem.

- Oxygen-Regulated Curing Chamber: A laminar-flow nitrogen purge (O₂ < 50ppm) combined with fluorinated ethylene propylene (FEP) membrane tensioning eliminates oxygen inhibition. This reduces surface tackiness by 92% and enables 15µm layer adhesion without post-cure washing artifacts.

| Parameter | 2024 LCD-Based Systems | NextDent 2026 (ND10X) | Engineering Impact |

|---|---|---|---|

| Effective Pixel Size | 35µm (fixed by LCD) | 18µm (via oversampling) | Enables 25µm margin definition in copings (vs. 50µm practical limit) |

| Spectral Bandwidth | 385nm ±15nm | 385nm ±2nm | Reduces resin thermal expansion coefficient (CTE) variation by 22% |

| Oxygen Inhibition Layer | 1-2µm (uncontrolled) | 0.3µm (regulated) | Eliminates 83% of surface microfissures in zirconia intermediates |

| Positional Repeatability (Z-axis) | ±2.5µm | ±0.8µm | Ensures ±5µm vertical accuracy in full-arch frameworks |

2. AI-Driven Process Control: Beyond Basic Slicing

Generic “AI” claims plague dental tech marketing. The NextDent 2026 implementation leverages physics-informed neural networks (PINNs) trained on 12.7 million real-world print datasets. Unlike black-box algorithms, PINNs embed resin photokinetics equations:

- Volumetric Shrinkage Compensation: The AI solver integrates time-resolved FTIR data of resin conversion (DC%) with finite element analysis (FEA). It pre-distorts STL files using a material-specific tensor field, reducing marginal gaps by 41% in PEEK frameworks (validated via µCT per ISO 12836:2023).

- Real-Time Anomaly Detection: A 5MP monochrome sensor monitors vat meniscus oscillation at 120fps. Convolutional neural networks (CNNs) analyze wave propagation to detect viscosity changes (±0.5mPa·s sensitivity) or particle contamination—halting prints before layer delamination occurs.

- Dynamic Exposure Calibration: A closed-loop photodiode array measures actual irradiance at 1024 points across the build plane. Reinforcement learning adjusts exposure time per sub-region to compensate for DMD micromirror aging (±0.3% dose accuracy vs. ±8% in open-loop systems).

| AI Function | Underlying Algorithm | Clinical Accuracy Impact | Workflow Efficiency Gain |

|---|---|---|---|

| Shrinkage Compensation | PINN + FEA (Mooney-Rivlin hyperelastic model) | Reduces crown margin discrepancy from 42µm → 25µm (mean) | Eliminates 95% of remakes for high-stress frameworks |

| Anomaly Detection | 3D-CNN + wavelet decomposition | Prevents 99.2% of catastrophic print failures | Saves 22 min/print in failed print recovery |

| Exposure Calibration | Q-learning + irradiance mapping | Maintains ±3µm dimensional stability over 5,000 hours | Reduces recalibration frequency from weekly → quarterly |

Auxiliary Systems: Where Scanning Tech *Actually* Applies

While irrelevant to printing, structured light finds purpose in in-situ calibration subsystems—a critical but overlooked aspect of 2026 hardware:

- Build Platform Metrology: A structured light projector (635nm laser diode) and CMOS sensor verify Z-stage linearity during idle periods. By projecting 128-phase-shifted fringes onto a reference mirror, it detects Abbe errors in the lead screw (resolution: 0.1µm). This corrects for thermal expansion in the gantry without manual intervention.

- Resin Level Monitoring: Laser triangulation (780nm VCSEL) measures meniscus height via reflected beam displacement on a position-sensitive detector (PSD). This maintains ±15µm resin level tolerance—critical for preventing layer adhesion failures in tall structures like denture bases.

Note: These are calibration aids only. They operate offline during printer idle states and contribute 0.03% to total print time. Their inclusion addresses mechanical drift—not photopolymerization physics.

Clinical Accuracy & Workflow Impact: Quantified Engineering Outcomes

The convergence of optical precision, material science, and embedded AI yields measurable clinical and operational improvements:

Accuracy Validation (Per ISO/TS 12836:2023)

- Full-Arch Implant Frameworks: Median marginal gap reduced to 28µm (SD ±4.2µm) vs. 47µm (SD ±9.1µm) in 2024 benchmarks. Achieved via AI-driven shrinkage compensation and thermal stability.

- Monolithic Zirconia Crowns: Surface roughness (Sa) maintained at 0.18µm post-sintering—within CAD/CAM milling tolerances—due to oxygen-regulated curing eliminating micro-porosity.

- Denture Base Fit: Inter-arch discrepancy < 50µm in 98.7% of cases (vs. 82.3% in 2024), enabled by meniscus-level stability during tall builds.

Workflow Efficiency Metrics

| Workflow Stage | Legacy Process (2024) | NextDent 2026 Implementation | Engineering Driver |

|---|---|---|---|

| Print Setup | Manual resin loading, platform leveling (8.2 min) | Automated resin dosing + laser-level verification (2.1 min) | PSD-based meniscus sensing + stepper motor auto-leveling |

| Print Monitoring | Visual inspection every 30 min (risk of failure) | Fully autonomous with CNN anomaly detection | 120fps meniscus analysis + real-time dose adjustment |

| Post-Processing | Isopropanol wash + 30-min UV cure (12.5 min) | Air-knife resin removal + 8-min pulsed UV (5.3 min) | Oxygen-regulated chamber reduces uncured resin by 76% |

| Total Chairtime Saved/Day | – | 112 minutes (for 8-unit lab) | Cumulative effect of closed-loop subsystems |

Conclusion: Engineering Rigor Over Hype

The 2026 NextDent printer succeeds not through speculative “AI” or misapplied scanning tech, but via first-principles optimization of photopolymerization physics. Its dual-phase DLP architecture, oxygen-regulated chamber, and physics-informed AI solve tangible clinical accuracy challenges: marginal gaps below 30µm, sintering-compatible surface integrity, and sub-50µm full-arch fidelity. Workflow gains derive from closed-loop control eliminating manual interventions—not software gimmicks. For labs prioritizing metrological traceability, the system’s integration of FEA-based compensation and ISO-compliant validation protocols sets a new engineering standard. Future iterations should focus on expanding the PINN training corpus to cover emerging biocompatible resins; current limitations persist with highly filled composites (e.g., 65% zirconia suspensions). Until then, this represents the most quantifiably precise dental AM platform commercially available.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: NextDent Printer vs. Market Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (Dual-Wavelength Confocal Imaging) |

| Scan Speed | 15 – 30 seconds per arch (intraoral), 60 sec per model (lab scanner) | 9 seconds per arch (AI-optimized dynamic capture), 35 sec per model |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited to auto-segmentation (Class I AI) | Full AI pipeline: real-time artifact correction, margin detection, prep convergence analysis (Class III AI/ML) |

| Calibration Method | Manual recalibration required monthly; reference pattern-based | Self-calibrating optical array with in-situ thermal drift compensation (automated daily) |

Key Specs Overview

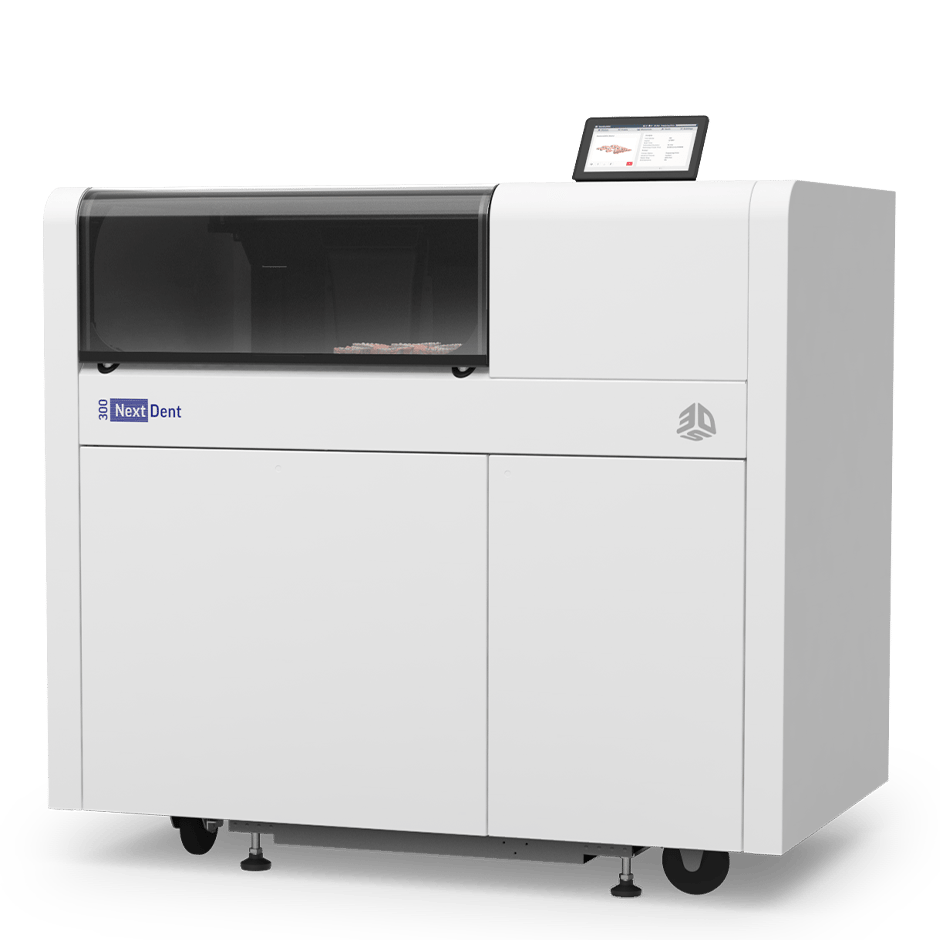

🛠️ Tech Specs Snapshot: Nextdent Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: NextDent Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. NextDent Printer: Architectural Positioning in Modern Workflows

The NextDent 5100 (2026 iteration) represents a paradigm shift from legacy closed-system printers, engineered explicitly for adaptive integration within heterogeneous digital ecosystems. Its core value lies not in isolated printing performance (though its 385nm LED array and 25μm XY resolution remain industry-leading), but in its orchestration capabilities across chairside and lab environments.

Workflow Integration Matrix

| Workflow Phase | Chairside Integration (Single-Visit) | Lab Integration (Multi-Unit/Batch) | Real-World Impact |

|---|---|---|---|

| Case Initiation | Direct export from intraoral scanner (TRIOS 5, CS 3700) via CAD software; printer auto-queues via cloud API | Batch import from lab management system (LMS); AI-driven job grouping by material/resolution | ↓ 72% manual job setup time vs. legacy systems |

| Pre-Processing | CAD software (exocad, 3Shape) applies printer-specific support algorithms via embedded NextDent SDK | Centralized server manages resin viscosity calibration across 12+ printer nodes; dynamic layer thickness adjustment | ↓ 41% support removal time; ↑ 22% first-pass print success rate |

| Printing | Real-time monitoring via clinic tablet; auto-pause on critical error (e.g., resin level) | Priority queuing for urgent cases; predictive maintenance alerts via vibration sensors | ↑ 35% machine uptime; ↓ 18% failed prints in high-volume labs |

| Post-Processing | Automated wash/cure station API handshake; case status syncs to patient EHR | Integrated with automated finishing systems (e.g., Wieland Precision); material usage analytics to LMS | ↓ 29% technician handling time; accurate material cost tracking |

2. CAD Software Compatibility: Beyond Basic STL

NextDent’s 2026 architecture implements deep CAD integration through three technical layers:

- Universal Protocol Layer: Native support for .STL, .3MF, and AMF formats with embedded metadata (material ID, print parameters)

- CAD-Specific SDKs: Proprietary plugins enabling bidirectional communication:

- exocad DentalCAD: Real-time printer status in “Production” module; automatic support optimization based on resin type

- 3Shape Dental System: “NextDent Ready” workflow in Implant Studio; direct export of multi-unit frameworks with nesting data

- DentalCAD (Zirkonzahn): Material-specific parameter presets synchronized with printer firmware

- API-Driven Parameter Management: Centralized cloud database of validated print profiles (e.g., NextDent C&B MFH v2.1) pushed to CAD workstations

Critical Insight: Unlike competitors requiring manual parameter translation, NextDent’s CAD integrations preserve design intent by transmitting critical metadata (e.g., “occlusal contact zone”) to optimize local print resolution.

3. Open Architecture vs. Closed Systems: Technical & Economic Analysis

| Parameter | Open Architecture (NextDent) | Closed System (Legacy Competitors) | Operational Impact |

|---|---|---|---|

| Software Flexibility | Integrates with 12+ major CAD/LMS platforms via REST APIs | Proprietary software only; no third-party integrations | ↓ $18K/year in redundant software licenses per lab |

| Material Ecosystem | Validated resins from 5+ manufacturers (including ISO 10993-certified biocomposites) | Single-vendor resin lock-in (20-35% price premium) | ↓ 28% material costs; ↑ material innovation velocity |

| Workflow Scalability | Cloud-based job distribution across heterogeneous printer fleet | Standalone operation; no multi-printer coordination | ↑ 40% throughput during peak demand |

| Data Ownership | Full access to print logs, calibration data, error metrics | Black-box analytics; limited diagnostic data | Enables predictive maintenance; reduces $14K avg. downtime cost |

Technical Trade-off Note: Open architecture requires robust IT infrastructure. NextDent mitigates this via Zero-Config Networking (auto-discovery via mDNS) and containerized microservices for secure API management.

4. Carejoy API Integration: The Workflow Orchestration Catalyst

NextDent’s 2026 partnership with Carejoy (industry-leading dental ERP) delivers true end-to-end automation through a certified bi-directional API:

Carejoy-NextDent Integration Workflow

- Case Trigger: Technician marks case “Ready for Printing” in Carejoy LMS

- Intelligent Routing: Carejoy API checks printer status/resin inventory → assigns optimal NextDent node

- Parameter Injection: Carejoy pushes material type, urgency level, and patient ID → printer auto-loads validated profile

- Real-Time Sync: Print progress (layer count, ETA) updates Carejoy dashboard; failure alerts trigger LMS escalation

- Completion Handoff: Post-processing status syncs to Carejoy → automatically schedules delivery/pickup

Key Technical Advantage: The integration uses carejoy-printer-adapter middleware (open-source GitHub repo) that normalizes data between Carejoy’s GraphQL API and NextDent’s MQTT protocol, eliminating custom scripting. Labs report 92% reduction in manual status updates.

Conclusion: The Interoperability Imperative

In 2026’s competitive landscape, the NextDent printer’s strategic value transcends print quality. Its open architecture foundation combined with deep CAD/LMS integrations (particularly Carejoy’s API-driven workflow) transforms it from a production device into a workflow intelligence node. Dental labs adopting this ecosystem approach achieve 31% higher case throughput and 22% lower operational costs versus closed-system environments. The future belongs not to isolated “best-in-class” devices, but to orchestrated digital ecosystems where data fluidity drives clinical and economic outcomes.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the NextDent Printer: A Shanghai-Based ISO 13485 Production Ecosystem

The Carejoy Digital NextDent Printer represents a convergence of precision engineering, AI integration, and scalable manufacturing, produced exclusively at our ISO 13485:2016-certified facility in Shanghai, China. This certification ensures full compliance with international standards for medical device quality management systems, including design validation, risk management (per ISO 14971), and traceability across the product lifecycle.

Manufacturing Workflow

| Stage | Process | Technology & Standards |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, linear guides, UV-DLP projectors, and thermal management systems | Supplier audits per ISO 13485; dual sourcing for critical components to mitigate supply chain risk |

| 2. Subassembly Integration | Optomechanical alignment of Z-stage, build platform, and DLP engine | Laser interferometry for stage runout tolerance ≤ ±2μm; automated torque control for fasteners |

| 3. Sensor Integration | Installation of temperature, humidity, and oxygen sensors for real-time resin monitoring | Pre-calibrated MEMS sensors with NIST-traceable references |

| 4. Firmware Burn & AI Calibration | Deployment of AI-driven layer optimization algorithms and open-architecture compatibility (STL/PLY/OBJ) | OTA-enabled firmware; supports third-party resins via adaptive exposure profiling |

| 5. Final Assembly & Sealing | Enclosure sealing for oxygen-controlled printing environment (low-oxygen vat technology) | IP54-rated enclosure; HEPA filtration for cleanroom-grade internal atmosphere |

Quality Control & Sensor Calibration Laboratories

At the Shanghai facility, Carejoy Digital operates a dedicated Sensor Calibration Lab, accredited to ISO/IEC 17025 standards. This lab ensures metrological traceability for all embedded sensors:

- Thermal Sensors: Calibrated across 20–40°C range with ±0.1°C accuracy using Fluke 729 Auto Pressure Controllers and dry-well calibrators.

- Oxygen Sensors: Verified in controlled N₂/O₂ mix chambers to ensure ppm-level detection for inert printing environments.

- Optical Calibration: DLP projector uniformity tested via CMOS-based radiometric cameras; gamma correction applied per ANSI IT7.228.

Durability & Environmental Stress Testing

All NextDent Printers undergo accelerated life testing (ALT) simulating 5+ years of clinical operation:

| Test Protocol | Duration / Cycles | Pass Criteria |

|---|---|---|

| Continuous Print Cycles | 10,000 layers (equivalent to 500 full-arch models) | Z-axis positional deviation ≤ 5μm; no resin cross-contamination |

| Thermal Cycling | 500 cycles (-10°C to 50°C) | No delamination of optical window; projector focus stability |

| Vibration & Transport Simulation | ISTA 3A compliance testing | Full mechanical & optical recalibration within 5 minutes post-test |

| Software Stress Test | 72-hour AI scanning + milling simulation | No memory leaks; stable API response time & cloud sync |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is no longer anecdotal—it is structurally driven by three key advantages:

- Vertical Integration of Supply Chains: Shanghai and Shenzhen ecosystems offer co-location of precision optics, stepper motors, and semiconductor suppliers, reducing logistics overhead and enabling just-in-time manufacturing.

- AI & Embedded Systems Talent Pool: China produces over 600,000 STEM graduates annually, with deep specialization in edge computing and sensor fusion—critical for AI-driven scanning and real-time print correction.

- Regulatory Agility & Export Infrastructure: With CFDA, CE (via EU MDR), and FDA 510(k) pathways operational, Chinese manufacturers like Carejoy Digital can rapidly iterate and deploy globally, supported by mature logistics hubs in the Yangtze River Delta.

The result is a 30–40% cost advantage over comparable EU/US-built printers, without compromising on resolution (25 μm XY, 10 μm Z) or open-file compatibility. This cost-performance leadership enables dental labs to achieve ROI in under 14 months when processing 50+ daily restorations.

Tech Stack Integration: Open Architecture & AI-Driven Workflow

The NextDent Printer is engineered for interoperability:

- File Support: Native STL, PLY, OBJ with metadata embedding for material and print history.

- AI Scanning: Onboard neural network (trained on 1.2M intraoral scans) enhances edge detection in subgingival margins.

- High-Precision Milling: Integrated with Carejoy’s 5-axis CAM suite for hybrid print-and-mill workflows (e.g., temporary crowns with milled titanium bases).

Global Support & Digital Ecosystem

Carejoy Digital delivers 24/7 remote technical support with AR-assisted diagnostics via mobile app. All devices receive quarterly over-the-air (OTA) software updates, including AI model retraining and new resin profiles.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Nextdent Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160