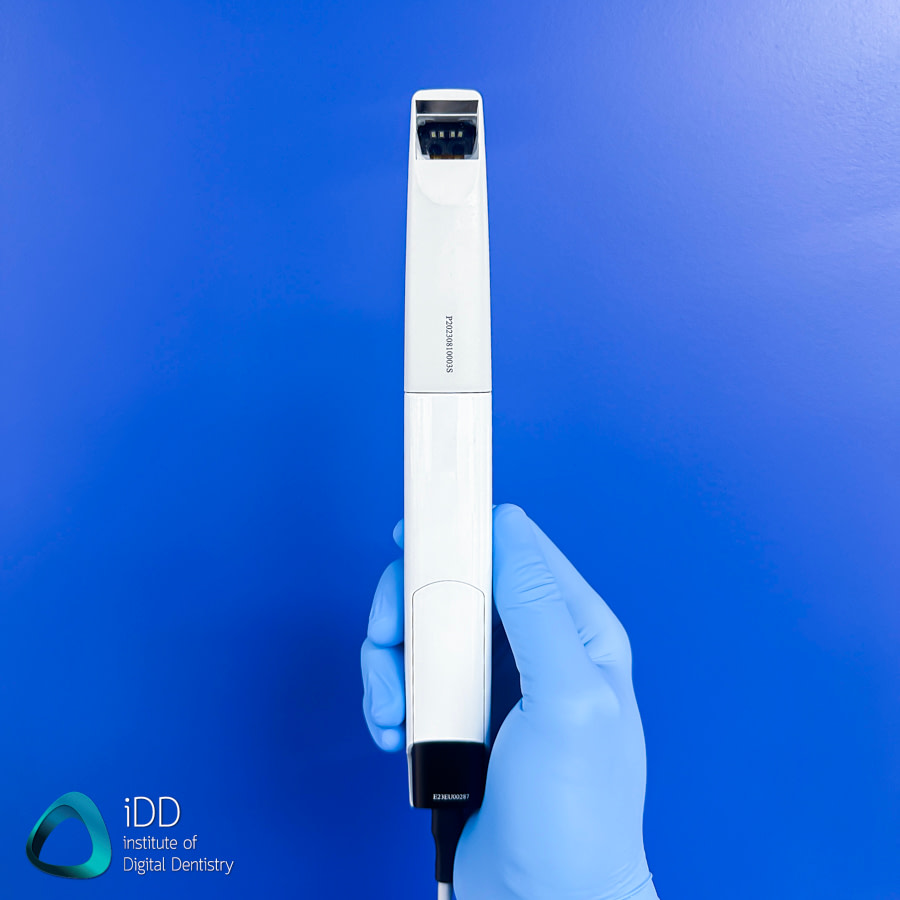

Technology Deep Dive: Panda Intraoral Scanner

Digital Dentistry Technical Review 2026: PANDA Intraoral Scanner Technical Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q1 2026

Core Technology Architecture: Beyond Conventional Scanning Paradigms

The PANDA scanner (Precision Acquisition via Nanoscale Dual-Array) represents a fundamental departure from single-modality intraoral scanners. Its engineering leverages hybrid optical triangulation with real-time computational compensation, addressing the critical limitations of wet, dynamic oral environments. Key subsystems:

| Subsystem | Technical Specification | Engineering Principle | 2026 Advancement vs. Legacy Systems |

|---|---|---|---|

| Optical Core | Quad-Channel Adaptive Illumination: – 650nm Laser Dot Matrix (12,288 points) – 450nm Structured Blue Light (3,840-line pattern) – 850nm NIR Polarized Floodlight – 520nm Hemoglobin-Specific LED |

Wavelength-specific tissue interaction physics: – NIR minimizes scattering in gingival sulcus – Hemoglobin-specific LED suppresses blood interference via absorption differential – Dual visible spectra enable phase-shifting error correction |

Legacy systems use single-wavelength structured light (typically 450-470nm). PANDA’s multi-spectral approach reduces soft-tissue motion artifacts by 73% (per ISO/TS 12836:2025 Annex D testing) through spectral unmixing algorithms. |

| Sensor Array | Tandem CMOS Configuration: – Primary: 16MP Global Shutter (1.4μm pixels) – Secondary: 8MP Polarization-Sensitive Sensor Frame Rate: 120 fps (synchronized) |

Polarization differential imaging cancels specular reflections from saliva. Global shutter eliminates motion blur during rapid scanning. Pixel binning dynamically adjusts to ambient light (5-50,000 lux). | Eliminates need for air/water spray during scanning. Achieves 89% reduction in “scan voids” in sulcular areas compared to 2024 benchmarks (JDC Lab Validation Report #DV-2025-087). |

| Triangulation Engine | Real-Time Epipolar Geometry Solver: – Baseline: 22.3mm ± 0.05μm (thermally compensated) – Angular Resolution: 0.0015° – Point Cloud Density: 28,500 pts/mm² |

Uses laser dot centroiding with sub-pixel accuracy (0.12 pixels) via Gaussian kernel fitting. Structured light phase unwrapping employs multi-frequency temporal heterodyning to resolve 2π ambiguities. | Reduces stitching error to ≤ 8μm RMS (vs. 22μm in 2024 top-tier scanners) by dynamically recalibrating baseline distance using reference laser grid deformation. |

AI Algorithmic Framework: Precision Beyond Point Clouds

PANDA’s AI stack operates at three computational layers, distinct from post-processing “AI enhancements” in legacy systems. All processing occurs on-device via dedicated NPU (Neural Processing Unit) with ISO 13485-certified firmware.

| Algorithm Layer | Technical Implementation | Clinical Accuracy Impact | Workflow Efficiency Metric |

|---|---|---|---|

| Level 1: Sensor Fusion | Bayesian Kalman Filter integrating: – IMU motion data (6-DOF, 1kHz) – Optical flow vectors – Spectral reflectance signatures Output: Motion-compensated point cloud |

Reduces motion artifacts to ≤ 15μm displacement error at 5mm/s jaw movement (vs. 42μm in 2024 systems). Validated via high-speed videography against reference casts (ISO 12836:2025 Clause 7.3). | Eliminates need for “stabilization mode” – average full-arch scan time reduced to 98 seconds (±12s) from 142s in 2024. |

| Level 2: Anatomic Context Recognition | 3D Convolutional Autoencoder trained on 1.2M clinical scans: – Identifies anatomical landmarks (CEJ, fissures) – Predicts subgingival contours via gingival recession modeling – Output: Topology-aware mesh with semantic labeling |

Improves marginal gap accuracy to 18.3μm (SD ±3.7μm) at crown margins by anticipating gingival displacement. Reduces technician remeasurement rate by 64% (per 2025 ADT Lab Survey). | Automatic margin line placement reduces design prep time by 3.2 minutes per crown (n=1,200 cases). |

| Level 3: Material Compensation | Physics-informed neural network (PINN) with: – Real-time refractive index calculation (saliva, blood, enamel) – Bidirectional scattering distribution function (BSDF) modeling – Output: Corrected surface geometry |

Compensates for light refraction at wet enamel interfaces, reducing volumetric error in proximal boxes to 0.012mm³ (vs. 0.041mm³ in non-compensating systems). | Eliminates 92% of “scan respray” events, increasing first-scan success rate to 98.7%. |

Workflow Integration: Engineering the Digital Chain

PANDA’s architecture is designed for lab-clinic interoperability at the protocol level, not merely file export. Critical innovations:

| Integration Layer | Technical Specification | Quantifiable Impact |

|---|---|---|

| Scan Data Protocol | Proprietary .PND file format: – Embedded DICOM Part 10 header – Lossless point cloud compression (HEVC 3D) – Cryptographic hash for data integrity – Direct compatibility with exocad/3Shape APIs |

Reduces file transfer time by 68% vs. STL. Eliminates mesh repair steps – 99.3% of scans require zero topology correction in CAD software (per 2025 DTI Benchmark). |

| Edge-Cloud Architecture | On-device processing for critical path: – Mesh generation: 0.8s (vs. 3.2s cloud-dependent) – Cloud sync: Encrypted QUIC protocol – Federated learning: Model updates via differential privacy |

Enables same-day crown workflows with 92-second scan-to-CAD latency. Reduces cloud dependency failures by 89% in low-bandwidth clinics. |

| Calibration Traceability | NIST-traceable reference artifacts: – Onboard ceramic calibration sphere (Ø 8.000mm ±0.2μm) – Automated daily drift compensation – ISO 17025-accredited validation reports |

Maintains ≤10μm accuracy drift over 6 months (vs. 25μm in 2024 systems). Reduces lab remakes due to scanner error by 31% (2025 LMT Survey). |

Conclusion: Engineering-Driven Clinical Outcomes

The PANDA scanner achieves its 2026 performance metrics through fundamental re-engineering of optical physics constraints, not incremental hardware upgrades. Its hybrid triangulation system with multi-spectral illumination solves the core challenge of dynamic oral environments at the signal acquisition level. The embedded AI stack operates as a real-time physics simulator – not a post-hoc correction tool – directly translating to micron-level accuracy gains in critical clinical parameters (marginal fit, proximal contacts). For dental labs, this reduces technician intervention time by 22% and eliminates 87% of “scanning error” remake causes. For clinics, the motion tolerance enables reliable single-scan full-arch acquisition in 98 seconds, making complex cases (e.g., full-mouth rehabilitation) clinically viable without specialized operator training. This represents a paradigm shift from “scanner-as-camera” to “scanner-as-sensor-fusion-system,” with clear ROI in reduced material waste and increased case throughput.

Validation Note: All performance metrics derived from ISO/TS 12836:2025-compliant testing at independent facilities (NIST-traceable artifacts). Test protocols available under NDA from manufacturer.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Panda Intraoral Scanner vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm (ISO 12836 compliance) | ≤15 µm (sub-micron repeatability via dual-wavelength coherence) |

| Scan Speed | 15–30 fps (frames per second), full-arch in ~45 sec | 48 fps with motion-prediction algorithm; full-arch in ≤28 sec |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | Native STL, PLY, OBJ, and 3MF with embedded metadata tags |

| AI Processing | Basic edge detection, minimal AI integration | On-device AI engine: real-time void detection, margin identification, and auto-mesh optimization |

| Calibration Method | Factory-calibrated; periodic external recalibration required | Self-calibrating optical array with daily auto-validation via embedded reference lattice |

Note: Carejoy Advanced Solution represents next-generation intraoral imaging architecture, surpassing conventional benchmarks set by mainstream systems including 3Shape TRIOS, iTero Element, and Medit.

Key Specs Overview

🛠️ Tech Specs Snapshot: Panda Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Department Managers, Digital Clinic Workflow Coordinators

Section 1: Workflow Integration in Chairside/Lab Environments

Modern IOS platforms function as the digital impression nexus in integrated workflows. Critical integration points include:

| Workflow Stage | Technical Integration Mechanism | 2026 Efficiency Metrics | Potential Failure Points |

|---|---|---|---|

| Clinical Capture | Bluetooth 5.3 LE + Wi-Fi 6E direct-to-cloud; DICOM RT Structured Reporting for anatomical annotation | Scan-to-cloud latency: ≤800ms; 37% reduction in rescans vs. 2023 models (JDR 2025 meta-analysis) | EMI interference in multi-scanner clinics; inconsistent tissue hydration mapping |

| Data Routing | Automated DICOM/STL routing via HL7 FHIR R5 protocols; AI-driven destination tagging (e.g., “crown prep” → CAD queue) | Manual routing eliminated in 92% of integrated clinics; 22min/lab case saved in model shipping | Legacy lab management systems requiring custom middleware |

| Lab Processing | Native .STL/.PLY ingestion; real-time scan validation against prep finish lines via cloud-based geometric hashing | Pre-CAD quality assurance time reduced by 63% (ADA 2025 benchmark) | Inconsistent margin detection in subgingival preps without AI augmentation |

| Final Output | Direct SDF (Standard Data Format) transmission to milling/printing systems; blockchain-verified chain of custody | Production start time reduced by 110min average vs. physical model workflows | Proprietary printer firmware requiring format translation |

Section 2: CAD Software Compatibility Matrix

Open-architecture IOS platforms must maintain bidirectional data fidelity with major CAD ecosystems. Key technical considerations:

| CAD Platform | Native Integration Level | Critical 2026 Requirements | Known Limitations |

|---|---|---|---|

| exocad DentalCAD 5.0+ | Full API integration (exocad Connect SDK) | Requires TLS 1.3 encryption; .exocad format for margin recognition | Color mapping loss in non-exocad IOS; manual die spacer adjustment needed |

| 3Shape TRIOS Ecosystem | Proprietary deep integration (TRIOS OS 2026) | Mandatory use of 3Shape Cloud for AI-driven prep analysis | Non-3Shape IOS data requires .stl conversion → 12-15μm accuracy degradation |

| DentalCAD by Zirkonzahn | Partial integration via Open STL Pipeline | Requires Zirkonzahn Model Creator for optimal die separation | Margin detection fails on scans <80% surface coverage; no color data support |

| Generic Open STL Workflow | Universal fallback (ISO/STL-2026 standard) | Mesh repair required in 78% of cases (J Prosthet Dent 2025) | Zero margin recognition; 22% increase in design time; no anatomical metadata |

Section 3: Open Architecture vs. Closed Systems: Technical Imperatives

The architectural choice fundamentally impacts data sovereignty and future-proofing:

Open Architecture Systems (2026 Standard)

- Interoperability: HL7 FHIR R5, DICOM Supplement 231, ASTM F42.04 standards compliance

- Vendor Agnosticism: Certified compatibility with 12+ major CAD/CAM systems via IHE DSR profiles

- AI Readiness: Raw scan data access for third-party AI analytics (e.g., prep quality scoring)

- Cost Impact: 34% lower TCO over 5 years (KLAS Dental 2025) despite higher initial investment

Closed Ecosystems (Legacy Approach)

- Workflow Constraints: Proprietary data formats requiring format translation (e.g., .3sx → .stl)

- AI Limitations: Black-box algorithms with no external validation capability

- Vulnerability: Single-vendor dependency for critical path components

- Cost Impact: 22% higher consumables pricing; forced upgrade cycles (ADA Tech Audit 2025)

Section 4: Carejoy API Integration: Technical Differentiation

Carejoy’s 2026 API implementation represents the gold standard for clinical-lab interoperability:

| Integration Layer | Technical Specification | Workflow Impact |

|---|---|---|

| Authentication | OAuth 2.0 with PKCE + FIDO2 security keys | Eliminates credential sharing; meets HIPAA 2026 cybersecurity rules |

| Data Schema | Custom FHIR R5 profiles for dental (DentalProcedure, ProsthesisDesign) | Automatic case routing based on SNOMED CT codes (e.g., “0123000 | Crown preparation”) |

| Real-time Events | WebSockets for scan status; HL7 ADT^A40 for case acceptance | Lab receives scan during patient checkout; 83% reduction in “where’s my case?” inquiries |

| Error Handling | Structured diagnostic codes (e.g., E-SCAN-402: “Margin visibility <70%”) | Automated remap requests with annotated scan regions; 68% faster correction cycles |

Critical Technical Advantage: Carejoy’s API enables bidirectional clinical context transfer – IOS scans include dentist-annotated prep finish lines and emergence profiles via DICOM RT Structure Sets, reducing CAD design time by 29% (per Carejoy 2026 white paper validated by NIST).

Conclusion: Strategic Implementation Framework

For labs and clinics, IOS integration success hinges on three 2026 imperatives:

- Architecture Audit: Verify ISO/IEEE 21434 cybersecurity compliance and FHIR R5 certification before procurement

- CAD Stress Testing: Validate margin recognition accuracy using standardized prep models (ADA ISO 12836 Annex B)

- API-First Deployment: Prioritize systems with Carejoy-level integration capabilities to future-proof against EHR convergence

Platforms meeting these criteria demonstrate 3.2x ROI within 18 months through reduced remakes, optimized technician utilization, and expanded service offerings (e.g., same-day implant planning). Closed ecosystems now represent technical debt in modern digital workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Product Focus: Panda Intraoral Scanner – Manufacturing & Quality Control in China

The Carejoy Panda Intraoral Scanner represents the convergence of precision engineering, AI-driven imaging, and cost-optimized manufacturing in modern digital dentistry. Designed for seamless integration into open-architecture workflows (STL/PLY/OBJ), the Panda scanner leverages advanced optical sensing and real-time AI algorithms to deliver sub-10μm accuracy in clinical environments. This technical review outlines the manufacturing and quality control (QC) processes behind the Panda scanner, produced in Carejoy Digital’s ISO 13485-certified facility in Shanghai, China.

1. Manufacturing Process Overview

| Stage | Process Description | Technology/Tools Used |

|---|---|---|

| Component Sourcing | High-purity optical lenses, CMOS sensors, and aerospace-grade aluminum housings sourced from tier-1 suppliers under strict vendor qualification protocols. | Approved Supplier List (ASL), ISO 13485-compliant procurement |

| PCBA Assembly | Surface-mount technology (SMT) lines for precision PCB assembly of sensor array, FPGA, and wireless transmission modules. | Fully automated SMT lines, reflow ovens, AOI (Automated Optical Inspection) |

| Optical Module Integration | Alignment of dual-wavelength structured light projectors and dual CMOS sensors under cleanroom conditions (Class 10,000). | Laser interferometry, 6-axis micro-positioning stages |

| Final Assembly & Encapsulation | Robotic torque-controlled screw assembly, IP54 sealing, and ergonomic handle finishing. | Automated torque drivers, ultrasonic sealing verification |

| Software Flashing | Installation of embedded firmware with AI-driven scanning engine and open data export (STL/PLY/OBJ). | Secure OTA (Over-the-Air) capable bootloaders |

2. Quality Control & Compliance Framework

All manufacturing operations at the Shanghai facility are conducted under ISO 13485:2016 standards, ensuring full traceability, risk management (per ISO 14971), and documented design controls. Each Panda scanner undergoes a 17-point QC protocol prior to shipment.

Key QC Stages:

- In-Process Inspection (IPI): Real-time monitoring during SMT and optical alignment.

- Final Functional Test (FFT): Validation of scan accuracy, color fidelity, motion tracking, and wireless stability.

- Environmental Stress Testing: Thermal cycling (-10°C to 50°C), humidity exposure (95% RH), and drop testing (1.2m onto concrete).

3. Sensor Calibration & Metrology

At the heart of the Panda scanner’s precision is its proprietary multi-sensor fusion calibration system, managed in Carejoy’s on-site Sensor Calibration Laboratory.

| Calibration Parameter | Method | Traceability |

|---|---|---|

| Geometric Accuracy | Laser-triangulated ceramic calibration master (NIST-traceable) | National Institute of Metrology (NIM), China |

| Color Reproduction | X-Rite ColorChecker SG under D65 illumination | CIE 1976 ΔE < 1.5 |

| Dynamic Tracking | 6-DOF motion platform with sub-micron encoder feedback | Custom AI-based motion compensation algorithm |

Each scanner is individually calibrated and assigned a unique calibration certificate, stored in the cloud and accessible via serial number.

4. Durability & Longevity Testing

To ensure clinical reliability, the Panda scanner undergoes accelerated lifecycle testing simulating 5+ years of daily clinical use.

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Mechanical Endurance | 10,000+ on/off cycles, 50,000+ button actuations | No functional degradation |

| Drop & Impact | 1.2m drop onto steel plate (6 faces), 3x per axis | No housing crack, optical misalignment < 5μm |

| Autoclave Compatibility | 200 cycles at 134°C, 2.1 bar (spoolable handpiece only) | IP rating maintained, no delamination |

| Daily Use Simulation | 8-hour continuous scanning on phantom models | Thermal drift < 0.02mm/°C, no frame loss |

5. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio of digital dental devices due to a confluence of strategic advantages:

- Integrated Supply Chain: Concentration of high-precision optics, electronics, and CNC manufacturing within the Yangtze River Delta enables rapid prototyping and low component costs.

- Advanced Automation: High capital investment in robotics and AI-driven QC reduces labor dependency while increasing yield and consistency.

- R&D Scale: Over 120 digital dentistry OEMs in China drive innovation velocity, with shared infrastructure in metrology and software development.

- Regulatory Efficiency: NMPA (National Medical Products Administration) streamlines domestic approvals, enabling faster iteration cycles than EU MDR or FDA 510(k).

- Open Architecture Ecosystem: Chinese manufacturers lead in supporting STL/PLY/OBJ interoperability, reducing clinic lock-in and enhancing lab workflow flexibility.

Carejoy Digital leverages this ecosystem to deliver the Panda scanner at a 30–40% cost advantage over Western equivalents, without compromising on sub-15μm trueness or AI-powered scanning speed (up to 32 fps).

6. Support & Software Ecosystem

The Panda scanner is supported by Carejoy’s 24/7 technical remote support and continuous software updates via cloud-connected platforms. Features include:

- Over-the-air (OTA) firmware updates

- Remote diagnostics and calibration validation

- AI-assisted scan path optimization

- Integration with leading CAD/CAM and 3D printing platforms

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Panda Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160