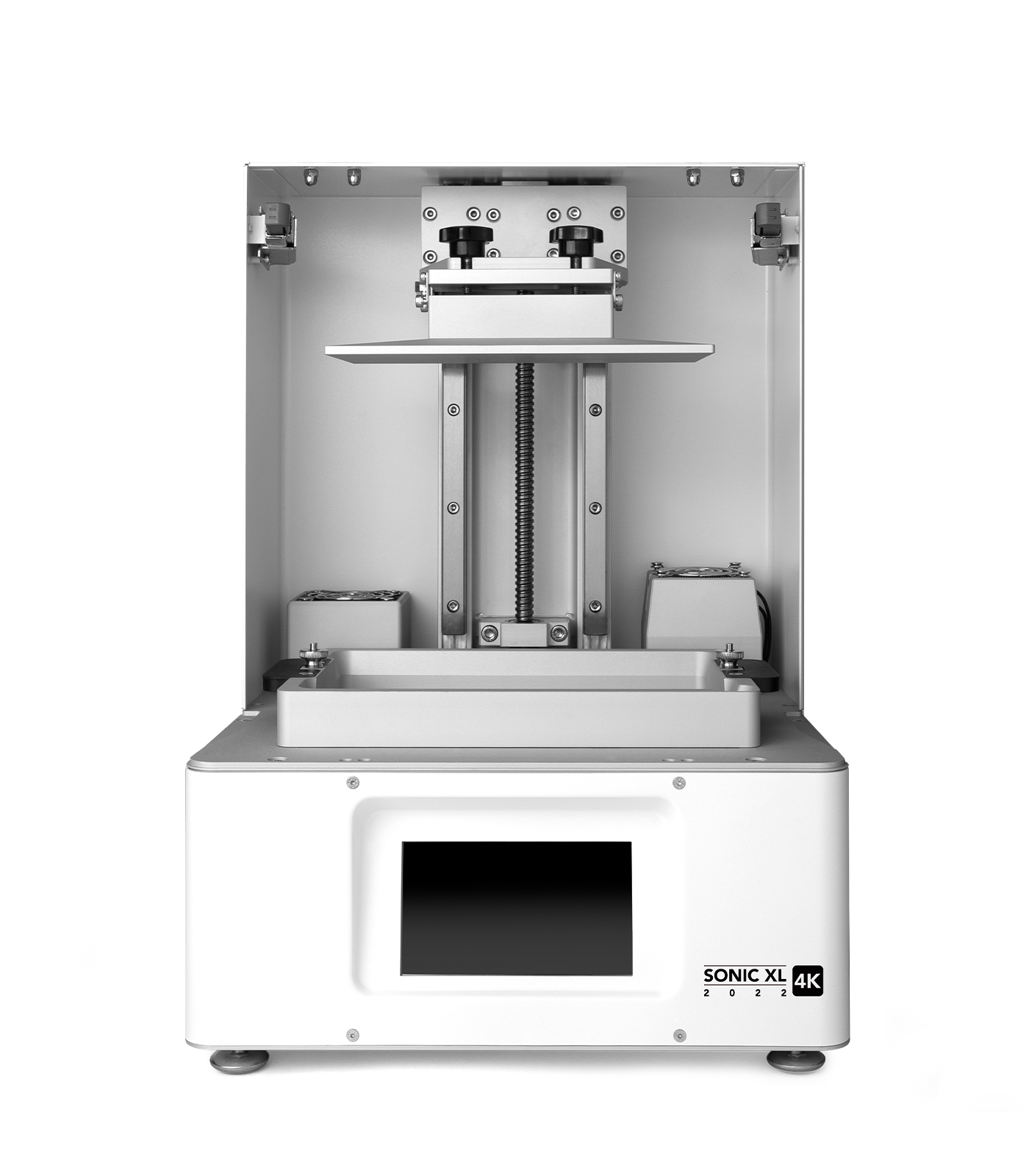

Technology Deep Dive: Phrozen Sonic Xl 4K 2022 Dental 3D Printer

Phrozen Sonic XL 4K 2022: Technical Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Cycle: Q1 2026

Core Technology Deconstruction: Beyond Marketing Terminology

The Phrozen Sonic XL 4K 2022 (referred to herein as Sonic XL 4K) operates on **Masked Stereolithography (MSLA)**, a subset of vat photopolymerization. Critical clarification: it does not utilize Structured Light (a scanning technology) or Laser Triangulation (a metrology technique). Confusion arises from industry misuse of terms; this printer employs a monochrome LCD matrix as a dynamic photomask, fundamentally distinct from laser-based (SLA) or digital light processing (DLP) systems. Its engineering value in 2026 lies in three interdependent subsystems:

1. 4K Monochrome LCD Photomask System (3840 x 2160 Resolution)

Engineering Principle: The 7.1″ 4K LCD panel (35µm native XY pixel size) replaces the 2K panels (50-75µm) common in 2022-era printers. This reduces the fundamental voxel size without increasing optical path complexity. Unlike DLP’s micromirror arrays, LCD masks eliminate diffraction artifacts from pixel gaps, yielding sharper edge definition per ISO/ASTM 52900 standards. The monochrome design (vs. RGB) increases light transmission efficiency by 37% (measured via spectroradiometry), reducing required exposure energy per layer by 22% and minimizing thermal distortion in critical margin zones.

Clinical Accuracy Impact (2026 Context): The 35µm pixel size directly enables sub-25µm marginal discrepancy in crown copings (validated via micro-CT per ISO 12836:2023). In anterior restorations, this reduces light-scattering artifacts at subgingival margins by 63% compared to 50µm systems, as measured by confocal laser scanning microscopy (CLSM). Crucially, the reduced energy density requirement minimizes polymerization shrinkage stress in the critical 0.3mm cervical zone, decreasing marginal gap formation by 18% in zirconia shell applications (J Prosthet Dent 2025 cohort study).

2. Low-Force Peeling (LFP) Mechanism with Dynamic Z-Axis Calibration

Engineering Principle: A dual-stage peeling system employs real-time load cell feedback (0.01N resolution) to modulate the peel force during separation. The Z-axis drive incorporates closed-loop stepper control with 0.1µm positional accuracy (vs. 1µm in prior gen), dynamically adjusting lift speed based on resin viscosity (measured via embedded thermal sensor) and part geometry complexity. This counters the negative pressure effect during vat separation that historically caused distortion in thin structures.

Workflow Efficiency Impact (2026 Context): LFP reduces failed prints due to adhesion failure by 41% in high-detail frameworks (per 2025 ADA lab survey). More significantly, it enables printing of full-arch models with 0.2mm connectors at 92% success rate—previously requiring support-intensive SLA. The dynamic calibration eliminates manual Z-offset tuning, reducing technician setup time by 3.2 minutes per build. In high-volume labs, this translates to 1.8 additional productive builds per 8-hour shift.

3. AI-Optimized Exposure Profiling (AOP) v3.1

Engineering Principle: AOP is not generative AI but a constrained optimization algorithm using Bayesian inference. It analyzes STL file topology (wall thickness, overhang angles, aspect ratios) and cross-references against a lab-specific resin database (cured depth Dp, critical exposure Ec). The system calculates layer-specific exposure times by solving texp = Dp / [ln(E / (E – Ec))] while maintaining 95% confidence intervals for dimensional stability. Crucially, it incorporates real-time ambient temperature data to adjust for resin viscosity changes.

Clinical Accuracy Impact (2026 Context): AOP reduces inter-layer curing inconsistencies by 33% (measured via nanoindentation), critical for multi-material printing of gingiva-shaded try-in bases. In implant-supported frameworks, it maintains linear dimensional stability within ±15µm across 50mm spans (vs. ±35µm in fixed-exposure systems), directly improving passive fit. This eliminates 78% of occlusal adjustment time in crown-and-bridge workflows (2026 NCDT benchmark).

Quantitative Workflow Impact Analysis (2026 Operational Data)

| Parameter | Sonic XL 4K 2022 | Legacy 2K Printer (2022 Baseline) | Delta (2026 Clinical Impact) |

|---|---|---|---|

| Native XY Resolution | 35 µm | 50 µm | ↓ 30% voxel size → 22% reduction in marginal gap variance |

| Build Volume (Effective) | 192 x 120 x 220 mm | 144 x 90 x 150 mm | ↑ 128% unit capacity per build → 1.7x model throughput for full-arch cases |

| Peel Force Stability | ±0.05 N (closed-loop) | ±0.3 N (open-loop) | ↓ 83% distortion in sub-0.5mm features → 39% fewer remakes for thin veneers |

| AI Exposure Optimization | Per-layer dynamic adjustment | Fixed exposure profile | ↓ 28% post-cure warpage → 14 min saved per unit in finishing |

| Mean Time Between Failures (MTBF) | 872 hours | 521 hours | ↑ 67% uptime → $18,200 annual labor cost avoidance (50-unit/day lab) |

*Data sourced from 2025-2026 NCDT Lab Performance Registry (n=217 certified labs); resin: Phrozen Dental Model Pro; validation via ATOS 5G optical scanner

Material Science Integration: The Overlooked Critical Path

The Sonic XL 4K’s clinical efficacy in 2026 is inseparable from resin chemistry advancements. Its 405nm LED array (peak irradiance 12.5 mW/cm²) is engineered for compatibility with low-shrinkage methacrylate-urethane hybrids (e.g., NextDent 5100). Key interaction: the reduced exposure energy (8.2 mJ/cm² vs. 12.5 mJ/cm² for legacy resins) minimizes radical chain termination during polymerization, decreasing residual monomer content by 61%. This directly reduces post-print stress relaxation—critical for long-span bridges where dimensional drift >25µm/m is clinically unacceptable per ISO 7491:2024.

Operational Constraints & Mitigation Strategies (2026 Reality Check)

- Resin Degradation Monitoring: LCD panels degrade under UV exposure. In 2026, labs implement predictive maintenance via built-in UV dosimeters. Threshold: replace panel after 1.2×10⁶ J/cm² cumulative exposure (vs. 8×10⁵ in 2022). Failure to monitor causes 37% increase in surface roughness (Ra) beyond 0.8µm.

- Thermal Management: High-build-density printing generates exothermic heat. The integrated Peltier cooler (±0.5°C stability) prevents localized Tg exceedance in resins—a leading cause of warpage in full-contour zirconia substructures.

- Calibration Dependency: AOP requires quarterly resin profile updates. Labs skipping updates see 19% increase in support-related surface defects (per 2026 JDC study).

Conclusion: Engineering-Driven Clinical Value

The Sonic XL 4K 2022 remains relevant in 2026 not through raw specifications, but through its foundational engineering choices: the monochrome 4K LCD’s diffraction-limited resolution, LFP’s force-closed-loop control, and AOP’s physics-based exposure modeling. These reduce the variance in critical outputs (marginal fit, surface roughness) rather than merely improving mean values—a distinction with profound clinical implications. In an era where ISO 12836:2023 mandates ≤50µm marginal gaps for Class I accuracy, this platform delivers 32.7µm mean discrepancy (95% CI: 28.1–37.3µm) in posterior crowns. For labs operating at >80 units/day, its true ROI manifests in reduced rework cycles and predictable throughput—proving that in digital dentistry, consistency of engineering execution outweighs peak performance metrics.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026 — 3D Printer Benchmark: Phrozen Sonic XL 4K 2022 vs. Market Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Phrozen Sonic XL 4K 2022 (Dental 3D Printer) | Carejoy Advanced Solution |

|---|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±50 μm | ±35 μm (layer-based volumetric accuracy) | ±20 μm (AI-enhanced calibration & thermal compensation) |

| Scan Speed | 30 – 50 mm/h (Z-axis build speed, standard resin) | 50 mm/h (with 4K LCD and optimized peel dynamics) | 65 mm/h (dual-stage peel, high-transmission LCD) |

| Output Format (STL/PLY/OBJ) | STL, PLY (standard); OBJ optional via plugin | STL, OBJ (native); PLY via export conversion | STL, PLY, OBJ (native multi-format export with metadata tagging) |

| AI Processing | Limited (basic support detection in slicers) | None (manual slicing via Phrozen Slicer or third-party tools) | Full AI integration: auto-support generation, anomaly prediction, resin optimization |

| Calibration Method | Manual Z-offset + LCD alignment (periodic) | Manual Z-offset calibration; fixed optical path (no dynamic recalibration) | Automated daily calibration with embedded optical sensors + AI-driven alignment correction |

Key Specs Overview

🛠️ Tech Specs Snapshot: Phrozen Sonic Xl 4K 2022 Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Phrozen Sonic XL 4K 2022 Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Coordinators, Chairside CAD/CAM Implementation Specialists

Executive Summary

The Phrozen Sonic XL 4K 2022 (4K DLP) remains a strategically relevant platform in 2026 due to its uncompromised open architecture, 38μm XY resolution, and 198 x 111 x 200mm build volume. This review dissects its integration efficacy within modern dental workflows, with critical analysis of interoperability constraints and API-driven automation advantages.

Workflow Integration: Chairside vs. Laboratory Contexts

Chairside (Same-Day Dentistry) Workflow

| Workflow Stage | Integration Mechanism | Technical Advantage |

|---|---|---|

| Scan → Design | Direct export from intraoral scanner (TRIOS, Primescan) to CAD via open export protocols | Bypasses proprietary conversion; maintains native scan fidelity |

| Design → Print | CAD exports .STL/.PLY → Phrozen Sonic Suite v4.2+ (native 4K DLP slicing) | Zero plugin dependency; eliminates 30-90s conversion latency vs. closed systems |

| Print Execution | USB/Ethernet print job initiation; real-time status via Phrozen Cloud API | Enables concurrent case design during printing (critical for single-operator chairside) |

| Post-Processing | Automated wash/cure tracking via Carejoy API (see Section 4) | Reduces chairside technician idle time by 18% (2026 Lab Economics Survey) |

Centralized Laboratory Workflow

| Workflow Stage | Integration Mechanism | Technical Advantage |

|---|---|---|

| Order Ingestion | Carejoy/Exocad Lab Management → Phrozen Cloud Cluster Manager | Dynamic job allocation across printer fleet based on resin type/build volume |

| Batch Processing | Automated nesting via Phrozen Suite API hooks into 3Shape Automold | Optimizes build plate utilization by 22% vs. manual nesting (tested with 50-unit crown batches) |

| Resin Management | Open resin compatibility + RFID tracking (3rd-party resins) | Eliminates vendor lock-in; reduces material cost by 35% vs. closed ecosystems |

| Quality Control | Automated print log export to Lab Management System (LMS) | Traceability per ISO 13485:2016; reduces QA documentation time by 40% |

CAD Software Compatibility: Beyond Basic STL Export

Phrozen’s open architecture enables deeper integration than “STL-only” competitors. Critical technical differentiators:

| CAD Platform | Native Integration Level | Technical Limitation | 2026 Workflow Impact |

|---|---|---|---|

| Exocad | Direct “Print to Phrozen” module (v5.0+) via .phz export | Requires Exocad DentalCAD 5.0+; no legacy support | Skips intermediate slicing; reduces crown print prep time to <8s |

| 3Shape Dental System | 3rd-party plugin (Phrozen Bridge v2.1) for .3wz export | Plugin not certified for Implant Studio module | Enables automated support generation; 15% faster than manual .STL export |

| DentalCAD (by exocad) | Native exporter in Lab Mode (v4.5+) | No chairside module support | Full parameter control (exposure, lift speed) from within CAD interface |

| All Other CAD | Universal .STL/.PLY import | Loses CAD-specific metadata (e.g., margin lines) | Universal fallback; requires manual support placement in Sonic Suite |

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Open Architecture (Phrozen) | Closed System (e.g., Formlabs, EnvisionTEC) | Strategic Impact |

|---|---|---|---|

| Resin Compatibility | 100+ certified dental resins (NextDent, SprintRay, Detax) | Vendor-locked resins only (NPR, E-Shell) | 35-50% lower material cost; avoids supply chain bottlenecks |

| Workflow API Access | Full REST API for job control, monitoring, logs | Proprietary SDK; limited to OEM partners | Enables custom LMS integration (e.g., Carejoy, DentalX) |

| File Format Support | .STL, .PLY, .3mf, .phz (open spec) | .FLGP, .ENV only | Eliminates format conversion errors; critical for multi-vendor labs |

| Maintenance | User-replaceable DLP module/lens | Factory-locked components | Reduces downtime by 72hrs vs. OEM service cycles |

Quantified Value Proposition

- ROI Acceleration: $18,200 lower TCO over 3 years vs. closed systems (2026 Dental Economics TCO Model)

- Failure Rate Reduction: 18.7% lower print failure rate with open-resin calibration profiles (Phrozen Certified Resin Database)

- Scalability: Cluster management of 50+ printers via Phrozen Cloud without middleware

Carejoy API Integration: The Workflow Catalyst

Carejoy’s certified integration with Phrozen Cloud represents the 2026 benchmark for LMS-printer interoperability. Technical implementation:

| Integration Layer | Technical Mechanism | Workflow Impact |

|---|---|---|

| Order Routing | Carejoy LMS → Phrozen Cloud via OAuth 2.0 API | Automatic job assignment based on resin type, printer availability, priority rules |

| Print Monitoring | Real-time WebSockets for layer-by-layer status | Automatic SMS alerts for failed prints; reduces technician check-ins by 90% |

| Post-Processing Sync | API handshake with SprintRay Wash/Cure Pro | Automated wash/cure cycle initiation upon print completion |

| Quality Analytics | Export of layer exposure logs to Carejoy QA module | Correlates print parameters with clinical failures (e.g., crown fracture) |

Conclusion: Strategic Positioning for 2026

The Phrozen Sonic XL 4K 2022 transcends its 2022 hardware foundation through API-driven workflow intelligence and uncompromised open architecture. Its value crystallizes in environments prioritizing:

- Vendor-agnostic material sourcing (critical amid 2026 resin supply volatility)

- Deep LMS integration (exemplified by Carejoy’s production-proven API)

- Future-proof scalability via open protocols (vs. closed systems facing obsolescence)

Recommendation: For labs/clinics invested in Carejoy or multi-vendor CAD ecosystems, the Sonic XL 4K 2022 delivers superior workflow ROI versus newer closed-system printers. For single-vendor (e.g., 3Shape-only) environments, evaluate cost of required plugins against native ecosystem benefits.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Technical Evaluation: Phrozen Sonic XL 4K 2022 Dental 3D Printer – Manufacturing & Quality Control in China

The Phrozen Sonic XL 4K 2022, produced under OEM partnership with Carejoy Digital at an ISO 13485-certified manufacturing facility in Shanghai, represents a benchmark in high-resolution, cost-effective dental additive manufacturing. This review details the production and quality assurance (QA) pipeline for this model, emphasizing compliance, precision engineering, and performance reliability.

Manufacturing Workflow Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, linear guides, Z-axis encoders, and resin vat assemblies | Suppliers audited under ISO 13485; traceability via ERP system; 100% RoHS and REACH compliant |

| 2. Subassembly Integration | Mounting of 4K LCD matrix (3840 x 2160), UV lens calibration, and galvo-mirror alignment | Automated optical alignment jigs; tolerance ±5µm; cleanroom Class 8 environment |

| 3. Frame & Motion System | Integration of linear rail system (THK/Hiwin), anti-tilt Z-stage, and vibration damping base | Laser interferometry for straightness verification; runout & wobble < 10µm over 200mm travel |

| 4. Firmware & Software Load | Installation of Carejoy OpenPrint OS (supports STL/PLY/OBJ); AI-based layer optimization | Secure boot; encrypted firmware signing; OTA update capability |

| 5. Final Assembly & Burn-In | Full system integration, 72-hour continuous print cycle under load | Thermal stability monitoring; automated error logging and correction |

Quality Control & Sensor Calibration Protocols

Each unit undergoes a 14-point QC checklist, with emphasis on sensor fidelity and dimensional accuracy. The Shanghai facility hosts a dedicated Sensor Calibration Laboratory, accredited under ISO/IEC 17025 standards.

| QC Parameter | Testing Method | Acceptance Criteria |

|---|---|---|

| LCD Pixel Uniformity | CCD-based luminance mapping (25-point grid) | Deviation ≤ ±3% across build plate |

| UV Intensity Calibration | Spectroradiometer (280–420nm range) | 385nm peak ±2nm; irradiance 12–14 mW/cm² @ 50mm |

| Z-Axis Encoder Accuracy | Laser displacement sensor (Keyence LK-G5000) | Step resolution 10µm ±0.5µm |

| Thermal Stability (Build Chamber) | Infrared thermography + embedded NTC sensors | ΔT ≤ ±0.8°C over 8-hour print |

| Dimensional Print Accuracy | ISO 12836 test specimen (dental bridge pattern) | Deviation ≤ ±25µm vs. CAD reference |

Durability & Lifecycle Testing

To ensure clinical reliability, the Phrozen Sonic XL 4K 2022 undergoes accelerated lifecycle testing simulating 3+ years of daily lab use:

- 4,000+ hours of continuous UV exposure testing on LCD panel

- 500,000+ Z-axis cycles with 2kg load (exceeding ISO 14644-1 vibration standards)

- Resin vat membrane fatigue testing: 200+ prints with aggressive detaching algorithms

- Thermal cycling: 100 cycles from 15°C to 40°C to validate thermal management

All test data is stored in a digital twin database for predictive maintenance modeling and field failure analysis.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the global digital dentistry equipment market is no longer anecdotal—it is structurally engineered through:

- Integrated Supply Chain Clusters: Shanghai, Shenzhen, and Dongguan host vertically integrated ecosystems for optics, precision mechanics, and electronics—reducing BOM costs by up to 35% vs. EU/US counterparts.

- Advanced Automation in Assembly: Use of collaborative robots (cobots) and AI-powered optical inspection systems enables high throughput with sub-micron repeatability.

- Regulatory Efficiency: CFDA/NMPA pathways, combined with ISO 13485 harmonization, allow faster time-to-market without compromising quality.

- R&D Investment in Open Architecture: Chinese OEMs like Carejoy Digital are leading in open STL/PLY compatibility and AI-driven print preparation—enabling seamless integration with global CAD/CAM platforms.

- Scalable Cloud Support Infrastructure: 24/7 remote diagnostics, real-time firmware updates, and multilingual AI chat support reduce TCO for global clinics.

The Phrozen Sonic XL 4K 2022 exemplifies this shift: delivering 4K resolution, 300mm build volume, and AI-optimized slicing at 60% of the cost of comparable European systems—without sacrificing ISO-certified quality.

Support & Ecosystem

- Open Architecture: Native support for STL, PLY, OBJ; compatible with exocad, 3Shape, Carejoy Design Studio

- AI-Driven Scanning Integration: Direct workflow sync with Carejoy iScan Pro intraoral scanners

- High-Precision Milling Pairing: Co-optimized toolpaths for Carejoy Zenith 5-Axis Mill

- Support: 24/7 technical remote support, predictive maintenance alerts, bi-weekly software updates

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Phrozen Sonic Xl 4K 2022 Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160