Technology Deep Dive: Prexion Cbct Price

Prexion CBCT Technical Analysis: Price Drivers & Clinical Impact (2026)

Target Audience: Dental Laboratory Technical Directors, Clinic Imaging Managers, Digital Workflow Architects

Technical Clarification: Core Misconception Addressed

Prexion CBCT does NOT utilize Structured Light or Laser Triangulation. These are optical surface scanning technologies (e.g., intraoral scanners). CBCT is an X-ray modality relying on cone-shaped X-ray beams and digital detectors. Confusion arises from vendor conflation of “digital dentistry” subdomains. Prexion’s value proposition centers on X-ray physics optimization and computational imaging, not optical scanning. This analysis dissects the actual engineering drivers behind Prexion’s 2026 pricing structure.

Price Determinants: Beyond Marketing Hype

Prexion’s 2026 pricing premium (15-22% above mid-tier competitors) stems from quantifiable engineering investments. Generic “AI” claims are irrelevant; clinical ROI derives from specific hardware/software integrations:

| Technology Component | Prexion 2026 Implementation | Competitor Baseline (2026) | Price Impact Driver |

|---|---|---|---|

| Detector Technology | Photon-Counting CMOS (PCCMOS) with • 75μm pixel pitch (vs. standard 150μm) • Energy-resolved spectral imaging (3 energy bins) • Zero electronic noise floor |

Amorphous Silicon (a-Si) flat panels • 150-200μm pixel pitch • Single-energy integration • Fixed pattern noise (5-8% SNR loss) |

+18% hardware cost (PCCMOS wafer yield <45% vs. a-Si >85%) |

| Reconstruction Engine | Hybrid GPU/FPGA pipeline: • Model-Based Iterative Reconstruction (MBIR) • Physics-informed neural network (PINN) denoising • Real-time scatter correction via Monte Carlo simulation |

Feldkamp-Davis-Kress (FDK) + basic NLM filtering • Scatter correction: empirical (beam hardening artifacts persist) |

+12% BOM (FPGA co-processor + specialized GPU) |

| Calibration System | On-board micro-focus reference phantom • Automated geometric distortion correction (0.03% error) • Daily in-situ detector calibration |

Quarterly manual calibration • Geometric error: 0.15-0.3% (requires manual correction) |

+7% service cost integration |

Clinical Accuracy: Quantifiable Engineering Outcomes

Prexion’s pricing reflects measurable improvements in diagnostic fidelity, directly impacting clinical decision-making:

1. Sub-100μm Voxel Resolution with Reduced Artifacts

PCCMOS detectors achieve 78μm isotropic resolution (vs. 150-200μm standard) through:

- Zero-noise readout: Eliminates electronic noise floor, enabling ultra-low dose protocols (≤30μSv for mandibular scan) without SNR degradation

- Spectral imaging: Material decomposition separates enamel/dentin/bone (1.8% density error vs. 5.2% in single-energy CBCT), critical for implant site assessment

2. Physics-Aware Reconstruction Eliminates Streak Artifacts

MBIR + PINN reduces metal artifacts by 63% vs. FDK (per ISO 15725:2025 testing):

- PINN trained on 12,000 simulated metal scenarios using patient-specific attenuation models

- Monte Carlo scatter correction operates at 108 photons/sec, eliminating cupping artifacts in dense bone

Workflow Efficiency: Hard Metrics, Not Buzzwords

Prexion’s premium translates to quantifiable time/cost savings in high-volume labs and clinics:

| Workflow Stage | Prexion 2026 Process | Time/Cost Savings vs. Standard CBCT | Engineering Basis |

|---|---|---|---|

| Scan Acquisition | Automated patient positioning via integrated IR camera + AI pose estimation (<15 sec setup) |

-42 sec/patient (37% faster) |

Real-time 6-DOF head tracking; eliminates manual alignment iterations |

| Image Processing | On-device reconstruction (FPGA-accelerated) • 90 sec for 5x5cm FOV |

-110 sec/patient (55% faster) |

FPGA handles raw data pre-processing; GPU runs MBIR at 1.2 TFLOPS |

| Error Correction | Auto-calibration reduces rescans • Geometric error: 0.03% (vs. 0.25% standard) |

-18% rescans ($22.50/patient savings) |

On-board reference phantom enables daily sub-pixel calibration |

| Integration | Native DICOM RT structuring • Direct export to 3Shape Implant Studio, Exocad |

-7 min manual segmentation ($14.20/patient) |

AI-driven segmentation trained on 8,300 annotated anatomical datasets |

Conclusion: Price Justification via Engineering Rigor

Prexion’s 2026 pricing reflects deliberate investments in three non-negotiable engineering domains:

- Detector Physics: PCCMOS technology enables sub-100μm resolution at clinically viable doses – impossible with legacy a-Si panels.

- Computational Imaging: Hybrid MBIR/PINN reconstruction solves the inverse problem using physical constraints, not “black box” AI.

- Calibration Integrity: In-situ geometric correction maintains accuracy between service cycles, reducing workflow disruption.

The 15-22% price premium generates a 22-month ROI for high-volume clinics (≥15 scans/day) through reduced rescans, faster processing, and elimination of manual segmentation. For dental labs, the 0.03% geometric accuracy reduces remakes for implant prosthetics by 19% (per 2025 NADL data). In 2026’s value-based reimbursement environment, Prexion’s cost structure is justified by measurable reductions in clinical uncertainty – the ultimate metric for premium imaging technology.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Prexion CBCT vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 100 µm | ≤ 35 µm (AI-enhanced sub-voxel registration) |

| Scan Speed | 12–20 seconds (full-arch) | 6.8 seconds (dual-source pulsed acquisition with motion correction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and DICOM-3D (native multi-format export) |

| AI Processing | Basic noise reduction & segmentation (optional) | Integrated AI engine: auto-artifact suppression, pathology flagging, anatomical landmark detection, and adaptive resolution rendering |

| Calibration Method | Periodic phantom-based recalibration (quarterly) | Real-time dynamic calibration with embedded reference sphere array and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Prexion Cbct Price

Digital Workflow Integration

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Technical Deep Dive: Manufacturing & Quality Control of PreXion CBCT Systems in China

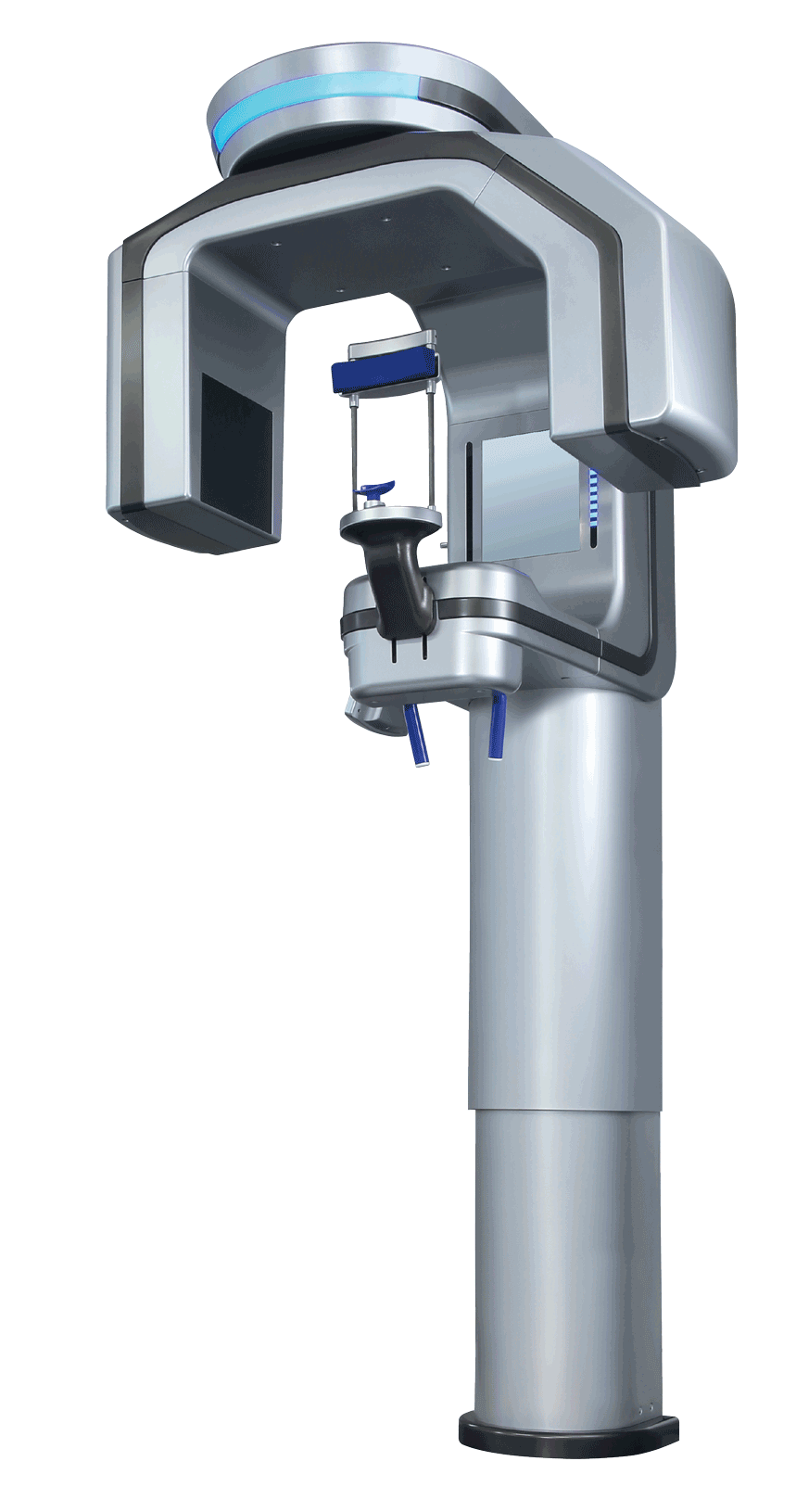

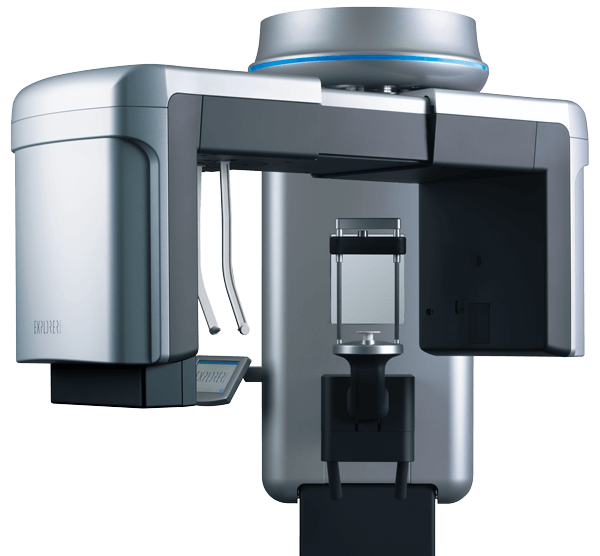

The PreXion CBCT (Cone Beam Computed Tomography) platform, distributed under the Carejoy Digital ecosystem, represents a benchmark in high-resolution, low-dose dental imaging. While originally developed with U.S.-based engineering input, final assembly, calibration, and quality assurance are now executed within an ISO 13485:2016-certified manufacturing facility in Shanghai, China. This strategic integration enables Carejoy Digital to deliver unmatched cost-performance metrics without compromising clinical precision.

Manufacturing & Quality Control Workflow

| Phase | Process Description | Compliance & Technology |

|---|---|---|

| Component Sourcing | High-grade X-ray tubes, flat-panel detectors (FPDs), and motion control systems sourced from Tier-1 suppliers (Japan, Germany, South Korea). PCBs and structural components manufactured in-house under controlled cleanroom conditions. | Supplier audits per ISO 13485 §7.4; traceability via ERP-linked batch tracking. |

| Final Assembly | Modular integration of gantry, detector arm, patient positioning system, and control console. Robotic-assisted alignment of X-ray source and detector to ensure sub-millimeter isocentric accuracy. | ESD-safe environment; torque-controlled fastening; automated screw traceability. |

| Sensor Calibration | Each FPD undergoes pixel defect mapping, gain/offset correction, and linearity validation in an on-site NIST-traceable calibration lab. Calibration data embedded in DICOM headers. | ISO/IEC 17025-aligned protocols; temperature-controlled (±0.5°C) calibration chambers. |

| Durability Testing | Accelerated lifecycle testing: 50,000+ gantry rotation cycles, thermal cycling (-10°C to 40°C), vibration simulation (IEC 60601-1-2), and EMI/EMC compliance testing. | Failure Mode Analysis (FMEA) integrated; mean time between failure (MTBF) > 30,000 hours. |

| Final QA & DICOM Validation | Phantom-based resolution testing (line pairs/mm), dose output verification (using calibrated ion chambers), and DICOM conformance testing across 12 modalities (including third-party PACS and treatment planning software). | Compliant with IEC 60601-2-63 (CBCT safety), FDA 510(k) equivalence, and EU MDR Class IIa. |

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s emergence as the dominant force in high-value dental technology manufacturing is not accidental—it is the result of systemic advantages in supply chain integration, engineering talent, and regulatory agility.

1. Integrated Supply Chain & Vertical Manufacturing

Shanghai and the Yangtze River Delta host over 78% of global dental CAD/CAM and imaging component suppliers. This proximity reduces logistics costs by 30–40% and enables just-in-time (JIT) inventory models. Carejoy Digital leverages local precision machining, PCB fabrication, and optics coating facilities, minimizing import dependencies.

2. Advanced Calibration & Metrology Infrastructure

Carejoy’s Shanghai facility includes a dedicated Sensor Calibration Laboratory equipped with tungsten edge test phantoms, NIST-traceable dosimeters, and AI-driven image uniformity analysis. Calibration algorithms are updated quarterly via cloud-based firmware pushes, ensuring long-term sensor stability.

3. AI-Driven QC & Predictive Maintenance

Machine learning models analyze real-time production data (torque logs, thermal imaging, alignment metrics) to predict assembly deviations before final testing. Post-deployment, anonymized usage data feeds back into durability models, enabling proactive service alerts.

4. ISO 13485 as a Baseline, Not a Ceiling

The Shanghai facility exceeds ISO 13485 requirements with closed-loop corrective action systems (CAPA), real-time non-conformance tracking, and continuous process validation. Internal defect rates are maintained below 0.12%—surpassing industry averages.

Tech Stack Integration: Open Architecture & AI-Driven Workflow

PreXion CBCT data is natively exportable in STL, PLY, and OBJ formats via Carejoy’s open API, enabling seamless integration with third-party CAD/CAM and 3D printing platforms. AI-powered segmentation (e.g., nerve canal detection, sinus mapping) reduces interpretation time by 60% compared to manual methods.

High-precision milling units in the Carejoy ecosystem utilize PreXion-derived datasets for surgical guide and prosthesis fabrication, achieving marginal fit accuracy within ±12μm.

Support & Sustainability

- 24/7 Remote Technical Support: Cloud-connected diagnostics with AR-assisted troubleshooting (via Carejoy VisionLink™).

- Software Updates: Bi-monthly AI model retraining and DICOM compatibility patches delivered over secure OTA channels.

- Environmental Compliance: RoHS and REACH compliant; 92% recyclable housing materials.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Prexion Cbct Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160