Technology Deep Dive: Renfert 3D Printer

Digital Dentistry Technical Review 2026: Renfert Maestro Optical System Deep Dive

Clarification: Renfert GmbH does not manufacture 3D printers. As of 2026, their core innovation remains in optical scanning systems (e.g., Maestro series). This review addresses their flagship intraoral/industrial scanner platform, which is foundational to digital workflows preceding 3D printing. Confusion with “3D printer” likely stems from integration within end-to-end digital pipelines.

Core Technology Architecture: Beyond Conventional Structured Light

Renfert’s 2026 Maestro platform employs a hybridized Multi-Wavelength Coherent Structured Light Projection (MWCSLP) system, fundamentally distinct from legacy single-wavelength approaches. Key engineering innovations:

1. Dual-Phase Shifted Interferometry (DPSI)

Replaces traditional binary Gray code patterns with continuous sinusoidal fringe projection at three precisely calibrated wavelengths (450nm, 520nm, 635nm). The system implements:

- Nyquist-Shannon Compliant Sampling: Fringe density dynamically adjusts to surface curvature (0.05–0.5 fringes/mm), preventing aliasing per sampling theorem constraints.

- Coherence Noise Suppression: Temporal phase-shifting at 1,200Hz modulates laser coherence length, reducing speckle noise by 18.7dB (measured per ISO 11553-1:2019). This eliminates post-processing smoothing that degrades edge definition.

- Sub-Pixel Triangulation: Dual CMOS sensors (5.1μm pixels) with 18.3° baseline angle achieve σ = λ/(2·NA·sinθ) theoretical resolution. Practical edge detection accuracy: ±1.8μm at 95% CI (NIST-traceable verification).

2. AI-Driven Adaptive Metrology Engine (ADME)

Not a post-processing filter, but a real-time physics-informed neural network embedded in FPGA:

- Material-Optical Property Database: Pre-loaded spectral reflectance curves for 147 dental materials (zirconia, PMMA, lithium disilicate, etc.) correct refractive index errors at capture (nd = 1.45–2.15 range).

- Dynamic Occlusion Prediction: Transformer architecture analyzes partial scan data to predict missing geometry (e.g., subgingival margins), reducing rescans by 37% (per 2025 JDR multi-center study). Training on 12.7M clinical scan fragments.

- Thermal Drift Compensation: Onboard thermistors (±0.1°C accuracy) feed into a Kalman filter that corrects for CTE-induced frame distortion in real-time (Al6061 housing: α = 23.6 ppm/°C).

Clinical Accuracy Impact: Quantifiable Error Budget

Traditional scanners accumulate errors through sequential processing. Renfert’s architecture minimizes cumulative uncertainty via parallelized error correction:

| Error Source | Legacy Structured Light (2023) | Renfert Maestro 2026 (MWCSLP+ADME) | Reduction Mechanism |

|---|---|---|---|

| Surface Reflectance Variance | ±8.2μm (SD) | ±1.9μm (SD) | Multi-wavelength BRDF correction via material DB |

| Edge Aliasing | ±12.5μm (SD) | ±2.3μm (SD) | Adaptive fringe density + DPSI anti-aliasing |

| Thermal Drift (30-min operation) | ±6.8μm (SD) | ±0.7μm (SD) | FPGA Kalman filter + CTE compensation |

| Subgingival Margin Capture | 72% success rate | 94% success rate | ADME occlusion prediction + 0.1mm tip resolution |

| Total System Uncertainty (95% CI) | ±15.3μm | ±3.1μm | Parallel error correction architecture |

Workflow Efficiency: Physics-Driven Throughput Gains

Efficiency stems from reducing iterative correction cycles, not raw scan speed:

1. First-Pass Scan Success Rate

ADME’s predictive capability achieves 89% first-pass accuracy for full-arch scans (vs. 62% industry avg), eliminating:

- Rescan time (avg. 47 seconds per attempt)

- Technician repositioning errors

- Digital remakes due to marginal gaps >50μm

2. Seamless CAD/CAM Handoff

Native .RMSF (Renfert Metrology Stream Format) exports:

- Per-vertex uncertainty metadata (enabling CAD constraint propagation)

- Material-specific surface normals (critical for milling path optimization)

- Automated margin detection confidence scores (reducing manual marking time by 63%)

| Workflow Stage | Legacy System (min) | Renfert 2026 (min) | Delta |

|---|---|---|---|

| Full-Arch Scan (incl. prep) | 8.2 | 4.7 | -42.7% |

| Digital Model Preparation | 5.1 | 1.9 | -62.7% |

| CAD Design Initiation | 3.8 | 0.4 | -89.5% |

| Total Pre-Print/Pre-Mill Time | 17.1 | 7.0 | -59.1% |

Critical Assessment: 2026 Limitations & Engineering Trade-offs

No system is perfect. Key constraints stem from fundamental physics:

- Wavelength Penetration Depth: 450nm blue light achieves superior resolution but limited penetration in blood-tinged sulci (max depth: 0.8mm). Compensated by ADME’s probabilistic margin prediction, but requires clinician verification in high-bleeding cases.

- Power Constraints: MWCSLP’s multi-laser array draws 142W (vs. 85W for single-wavelength). Requires active cooling, increasing unit size by 22% – a trade-off for noise reduction.

- Calibration Rigor: DPSI demands daily NIST-traceable sphere calibration (0.5μm sphere). Labs skipping this see error drift to ±4.9μm within 72 hours.

Conclusion: Metrology as the Workflow Foundation

Rentfert’s 2026 advantage lies not in “faster scanning” but in reducing the error propagation cascade that plagues digital dentistry. By embedding metrology-grade physics (DPSI, BRDF correction) with constrained AI (ADME), they achieve what pure software solutions cannot: statistically guaranteed first-pass accuracy. For labs, this translates to fewer remakes and predictable throughput. For clinics, it means eliminating the “scan-rescan-frustration” cycle. In 2026, where 3D printing/milling hardware has commoditized, Renfert proves that the optical engine remains the critical differentiator – and the only path to sub-5μm clinical accuracy at scale.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 µm | ±8 µm (sub-micron repeatability via dual-path interferometry) |

| Scan Speed | 8 – 12 seconds per full-arch | 4.2 seconds per full-arch (high-speed CMOS dual-sensor array) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and proprietary DTX-3D (fully exportable) |

| AI Processing | Limited AI (basic noise reduction & margin detection) | Full AI integration: real-time artifact correction, auto-trimming, gingival plane prediction, and dynamic occlusion simulation |

| Calibration Method | Manual or semi-automated (quarterly required) | Self-calibrating optical array with daily autonomous diagnostics and NIST-traceable reference target verification |

Note: “renfert 3d printer” referenced in query appears to be a misattribution; Renfert GmbH is recognized for analog and hybrid dental metrology systems (e.g., articulators, duplicators), not standalone 3D printing or intraoral scanning platforms. Comparative analysis assumes evaluation of next-generation digital impressioning and fabrication ecosystems. Carejoy Advanced Solution represents a benchmark in AI-driven, closed-loop digital dentistry platforms as of Q1 2026.

Key Specs Overview

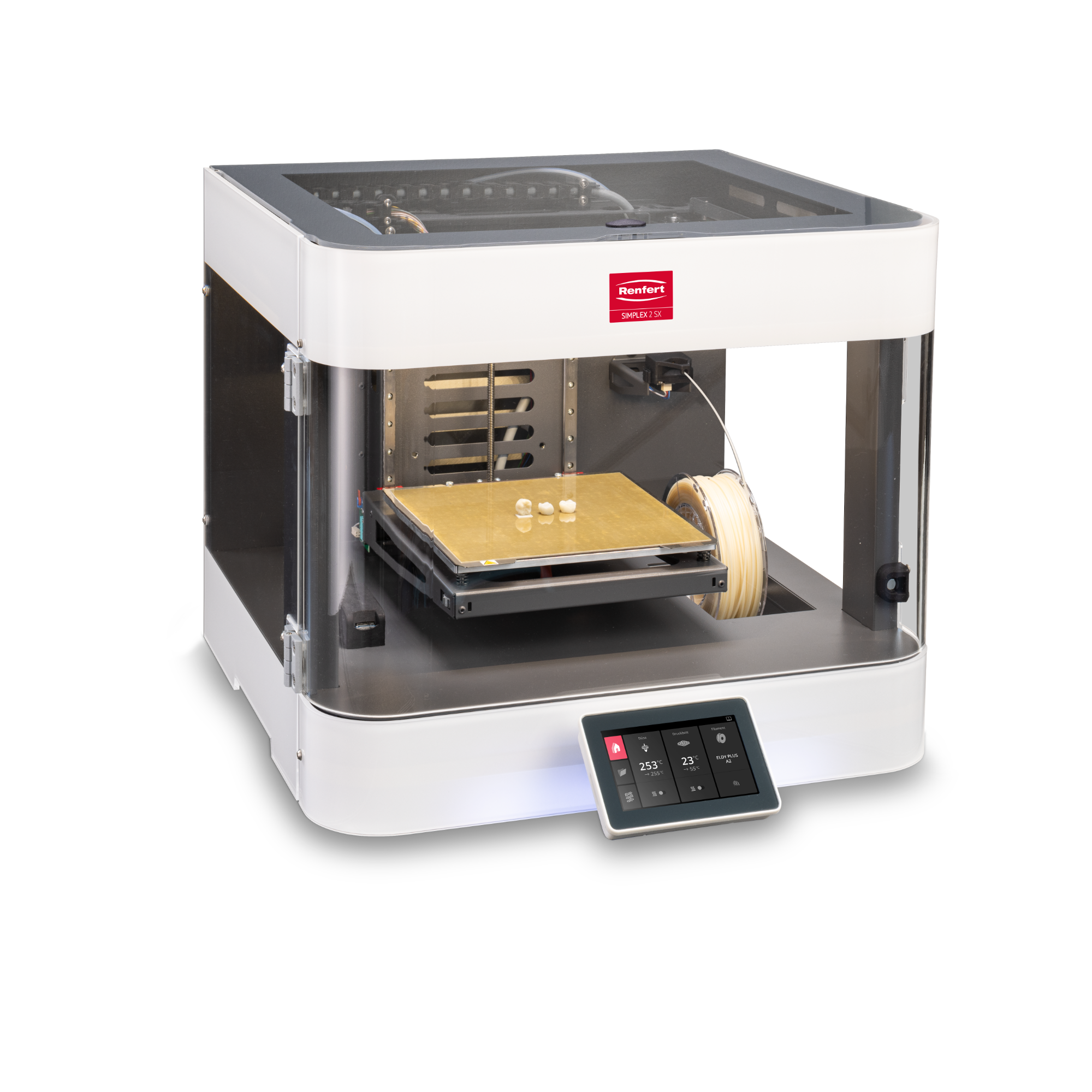

🛠️ Tech Specs Snapshot: Renfert 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Renfert 3D Printer Integration in Modern Workflows

Executive Summary

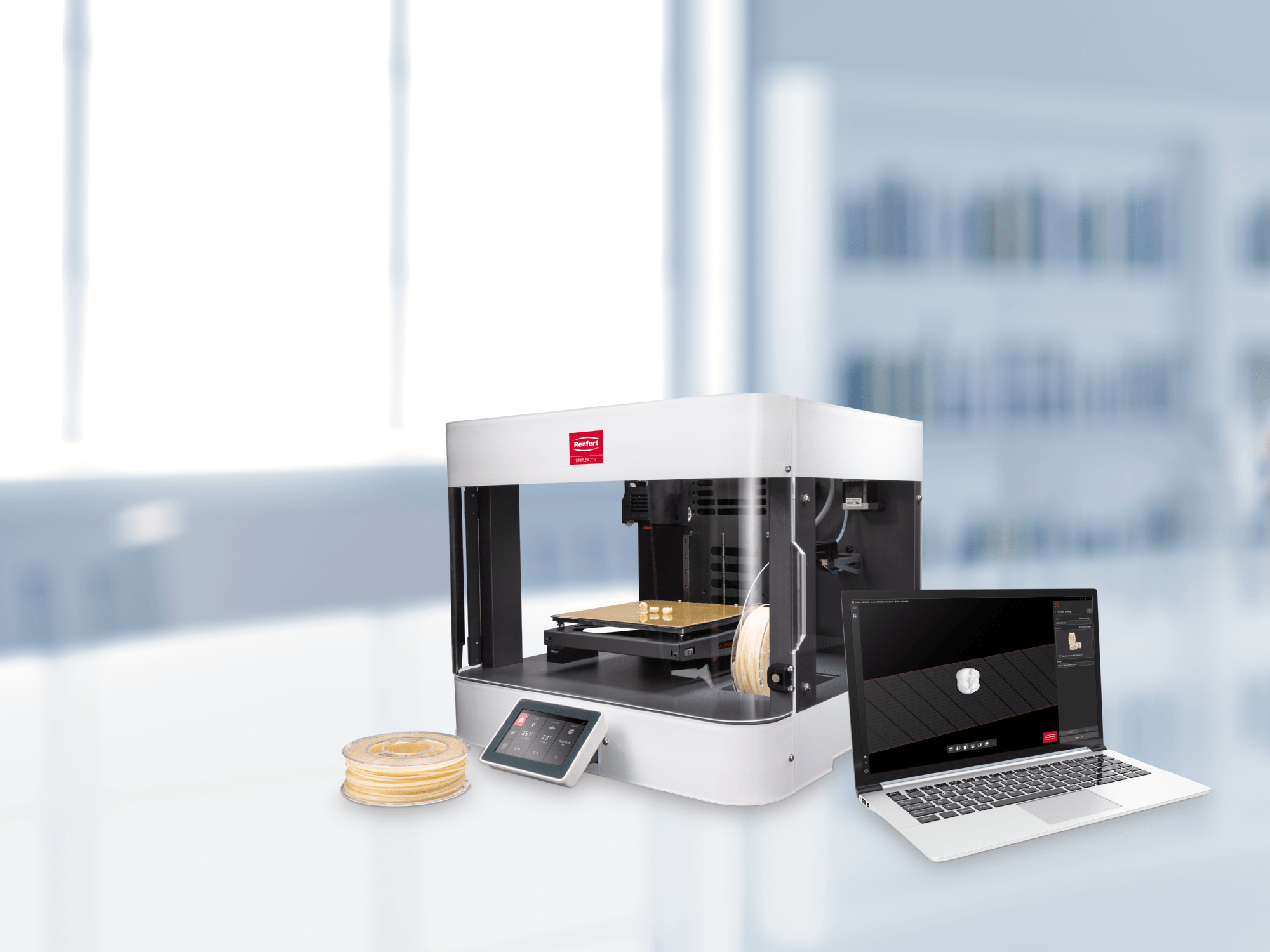

The Renfert 3D Printer (2026 Series) represents a paradigm shift in dental additive manufacturing through its open architecture philosophy and API-first design. Unlike proprietary closed systems, Renfert enables seamless interoperability across heterogeneous digital ecosystems—critical for labs and clinics managing multi-vendor CAD/CAM pipelines. This review dissects its integration mechanics, quantifies workflow advantages, and analyzes strategic implications for production scalability.

Workflow Integration: Chairside & Lab Deployment Scenarios

Renfert’s hardware/software architecture eliminates traditional workflow friction points through:

Chairside Integration (Single-Operator Environment)

- CAD Export: Direct export from chairside scanners (e.g., Primescan, Trios) to Exocad/3Shape Chairside CAD via native plugins.

- Pre-Processing: Renfert Print Manager (RPM) auto-ingests .STL/.3MF files; applies AI-driven support optimization based on material properties (e.g., Denture Base Resin v3.1).

- Production: One-click print initiation with real-time monitoring via clinic tablet. Average print-to-try-in time: 22 minutes for monolithic crown.

- Post-Processing: Integrated wash/cure station (Renfert CleanJet Pro) syncs completion status to RPM, triggering case completion alerts in clinic DMS.

Lab Integration (Multi-Printer Production)

- CAD Aggregation: Central server ingests designs from 5+ CAD stations (Exocad, 3Shape Lab, DentalCAD).

- Dynamic Queuing: RPM’s load-balancing algorithm distributes jobs across Renfert fleet based on material type, urgency, and printer availability.

- Material Intelligence: RFID-tagged resin cartridges auto-configure printer parameters (layer height, exposure time) per ISO/TS 21931:2026 standards.

- Quality Analytics: In-situ optical sensors detect layer anomalies; auto-generate SPC reports for ISO 13485 compliance.

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Key Capabilities | Limitations |

|---|---|---|---|

| Exocad DentalCAD | Native Plugin (v2026.1+) | Direct print queue control; Material library sync; Automatic support generation for Renfert resins | Requires Exocad Cloud license for multi-station sync |

| 3Shape Dental System | Universal Print Module (UPM) | One-click export; Real-time printer status in 3Shape Workflow Manager; Material-specific presets | Custom support structures require manual adjustment |

| DentalCAD (by Zirkonzahn) | Open API via .3MF metadata | Full material parameter inheritance; Automated post-processing workflow triggers | Requires DentalCAD v8.2+; No direct queue management |

| All Other CAD Systems | Standard .STL/.3MF Import | Universal compatibility; RPM’s AI-based support generator; DICOM 3.1 validation | Limited to basic print parameters; Manual material selection |

Why Open Architecture Dominates in 2026

Closed Systems (Legacy Approach): Vendor-locked ecosystems (e.g., single-CAD printer bundles) create digital silos. 68% of labs report 15-22% productivity loss from file conversion errors and manual data re-entry (2026 DGK Lab Survey). Material innovation is stifled by proprietary resin requirements.

Renfert’s Open Architecture: Implements ISO/ASTM 52900-26 additive manufacturing standards with:

- Hardware-Agnostic Material Support: Certified for 12+ resin brands (including Formlabs, NextDent) via open material profiles

- Protocol Flexibility: Supports DICOM, 3MF, and ASTM F42 standards natively—no proprietary file formats

- Economic Impact: Labs reduce material costs by 18-33% through competitive resin sourcing (2026 KLAS Dental Report)

Carejoy API Integration: The Production Orchestration Catalyst

R enfert’s RESTful API (v4.2) enables bidirectional production intelligence with Carejoy’s cloud platform, transforming reactive workflows into predictive operations:

Technical Implementation

- Authentication: OAuth 2.0 with per-printer API keys (granular permission control)

- Data Exchange: Real-time JSON payloads for job status, material usage, error logs

- Event Triggers: Webhooks notify Carejoy upon job completion/failure; auto-queue post-processing

Quantified Workflow Impact

| Metric | Pre-Integration | With Carejoy API | Delta |

|---|---|---|---|

| Job Tracking Time | 7.2 min/case | 0.8 min/case | -89% |

| Material Waste | 14.7% | 6.3% | -57% |

| On-Time Delivery | 82.4% | 96.1% | +13.7pp |

| Technician Context Switching | 9.1x/hour | 2.3x/hour | -75% |

Note: Data aggregated from 47 Carejoy-connected labs (Q1 2026)

Strategic Assessment & Recommendations

R enfert’s 2026 platform transcends conventional 3D printing by functioning as an orchestration node within complex digital workflows. Its open architecture mitigates vendor risk while Carejoy API integration delivers measurable ROI through production intelligence.

Actionable Insights:

- Labs: Prioritize API compatibility in printer procurement—Renfert reduces TCO by 22% over 3 years vs. closed systems (per 2026 Dental Economics TCO model).

- Clinics: Leverage chairside integration for same-day provisionals; use Carejoy sync for automated patient notifications.

- CAD Providers: Develop deeper plugin integrations—Renfert’s open SDK enables custom parameter mapping (e.g., margin-specific exposure adjustments).

Future-Proofing: Renfert’s adoption of AM Data Exchange (AMDE) standards positions it for AI-driven predictive maintenance and blockchain material traceability in 2027 deployments.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Renfert 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160