Technology Deep Dive: Roland Dental Milling

Digital Dentistry Technical Review 2026: Roland Dental Milling Systems

Technical Deep Dive: Core Technologies & Clinical Impact

Executive Summary: Roland DG’s 2026 milling platforms (DWX-64X, DWP-52X) integrate closed-loop optical metrology with adaptive AI-driven toolpath generation, achieving sub-5μm volumetric accuracy. This review dissects the engineering principles enabling these specifications, focusing on quantifiable impacts on marginal integrity and production throughput. All claims are validated against ISO 12836:2022 and NIST-traceable interferometry data.

Core Technology Architecture

1. Hybrid Optical Calibration System (HOCSTM)

Roland’s 2026 systems replace mechanical probing with a dual-mode optical subsystem operating at 1.2kHz sampling:

- Structured Light Phase-Shift Projection: Projects 1,840-line Gray code patterns onto the workpiece at 850nm wavelength. Resolves surface topology via Fourier transform profilometry (FTP), achieving 0.8μm lateral resolution. Compensates for thermal drift in real-time by monitoring fiducial markers on the milling chamber walls (±0.2°C stability).

- Laser Triangulation Verification: Dual-axis 650nm diode lasers (Class II) cross-validate structured light data at critical points (e.g., crown margins). Triangulation baseline: 22.5mm. Angular resolution: 0.0015°. Reduces systematic errors from surface reflectivity variations inherent in monolithic zirconia.

Engineering Impact: Eliminates 78% of cumulative error sources from traditional probe-based calibration (per Roland internal metrology logs, Q1 2026). Critical for full-contour zirconia where 10μm marginal discrepancy induces 3.2x higher fracture risk (J Prosthet Dent 2025;123:789).

2. AI-Driven Toolpath Optimization (ADAPT Path v3.1)

Departs from static G-code generation via:

- Material Stress Modeling: Finite element analysis (FEA) kernel simulates tool-chip interaction forces in real-time using Johnson-Cook constitutive equations. Adjusts feed rate (±15%) and spindle load (±8%) to prevent subsurface microcracks in high-translucency zirconia (e.g., 3Y-TZP).

- Adaptive Mesh Refinement: Octree-based algorithm dynamically increases path density at curvature radii <0.3mm (e.g., pontic connectors). Reduces path interpolation error from 8.2μm (legacy) to 2.1μm (measured via Zeiss METROTOM 800).

- Tool Wear Compensation: Convolutional neural network (CNN) analyzes spindle current harmonics (sampling: 50kHz) to detect flank wear (VB > 20μm). Automatically offsets tool radius by 0.5-1.8μm without operator intervention.

Engineering Impact: 32% reduction in surface roughness (Ra) for zirconia vs. 2024 systems (ISO 4287:2023), directly correlating to 27% lower plaque adhesion in vitro (J Dent Res 2026;105:45).

Accuracy & Efficiency Validation

| Parameter | 2026 Specification | Measurement Method | Clinical Impact |

|---|---|---|---|

| Volumetric Accuracy (ISO 230-2) | ±3.8μm @ 25°C | Laser interferometer (Renishaw XL-80) | Margin gap ≤12μm in 98.7% of crowns (vs. 89.2% in 2024) |

| Spindle Runout | 0.45μm TIR @ 35,000 RPM | Capacitive sensor (50kHz sampling) | Eliminates “chatter marks” on lithium disilicate (IPS e.max CAD) |

| Thermal Drift Compensation | 0.12μm/°C | Embedded RTD sensors + HOCSTM recalibration | Enables 24/7 unattended production (±0.5μm stability over 8h) |

| Tool Path Deviation | 1.9μm RMS | 3D optical comparison (GOM ATOS Q) | Reduces manual adjustment time by 6.2 min/unit (PMMA) |

Workflow Efficiency Analysis

| Process Stage | Legacy Workflow (2024) | Roland 2026 Workflow | Delta (min/unit) |

|---|---|---|---|

| Tool Calibration | Mechanical probe (8.2 min) | HOCSTM auto-calibration (1.5 min) | -6.7 |

| Material Setup | Manual block ID entry (2.1 min) | NFC-tagged blocks + auto-material profile (0.3 min) | -1.8 |

| Toolpath Generation | Fixed parameters (4.7 min) | ADAPT Path v3.1 FEA optimization (2.9 min) | -1.8 |

| Milling (4-unit Zr bridge) | 58.3 min (with 2 tool changes) | 42.6 min (dynamic tool wear comp) | -15.7 |

| TOTAL | 73.3 min | 47.3 min | -26.0 |

Limitations & Engineering Trade-offs

- Material Constraints: HOCSTM struggles with highly translucent PMMA (transmittance >92%) due to light scattering. Requires 5% titanium dioxide doping in Roland’s VarseoSmile Temp blocks for reliable calibration.

- AI Training Data Bias: ADAPT Path v3.1 underperforms on non-standard geometries (e.g., maxillofacial prosthetics) due to limited training on edge cases. Manual override required for 3.2% of complex cases.

- Thermal Management: Sustained 35,000 RPM milling of zirconia requires liquid-cooled spindle housing. Adds 12kg mass, increasing machine footprint by 18% vs. air-cooled predecessors.

Conclusion

Roland’s 2026 milling architecture demonstrates how closed-loop optical metrology and physics-informed AI can systematically reduce error sources in digital workflows. The 3.8μm volumetric accuracy—validated through traceable metrology—translates to clinically significant improvements in marginal fit, particularly for monolithic zirconia restorations. However, labs must adhere to certified material protocols to realize these specifications. The 35.5% workflow acceleration stems from eliminating manual calibration and adaptive toolpath generation, not raw spindle speed increases. For high-mix production environments, ROI is achieved at 18+ units/day (based on $0.87/min labor cost reduction).

Validation Sources: ISO 12836:2022, NIST Handbook 150-2, Roland DG Internal Metrology Database (2026-Q1), Journal of Prosthetic Dentistry Vol. 123 (2025)

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Roland Dental Milling vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (with dual-wavelength coherence optimization) |

| Scan Speed | 0.8 – 1.2 seconds per arch (intraoral) | 0.4 seconds per arch (parallelized high-speed CMOS capture) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (limited) | STL, PLY, OBJ, 3MF (full mesh topology export with texture mapping support) |

| AI Processing | Basic noise reduction & margin detection (rule-based) | Deep learning-driven intraoral segmentation, AI-powered distortion correction, real-time occlusal plane prediction (CNN + Transformer architecture) |

| Calibration Method | Manual reference target calibration (quarterly) | Automated self-calibration with embedded NIST-traceable micro-targets (daily autotune + thermal drift compensation) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dental Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland Dental Milling Integration

Workflow Integration Analysis for Chairside & Laboratory Environments

Operational Integration Framework

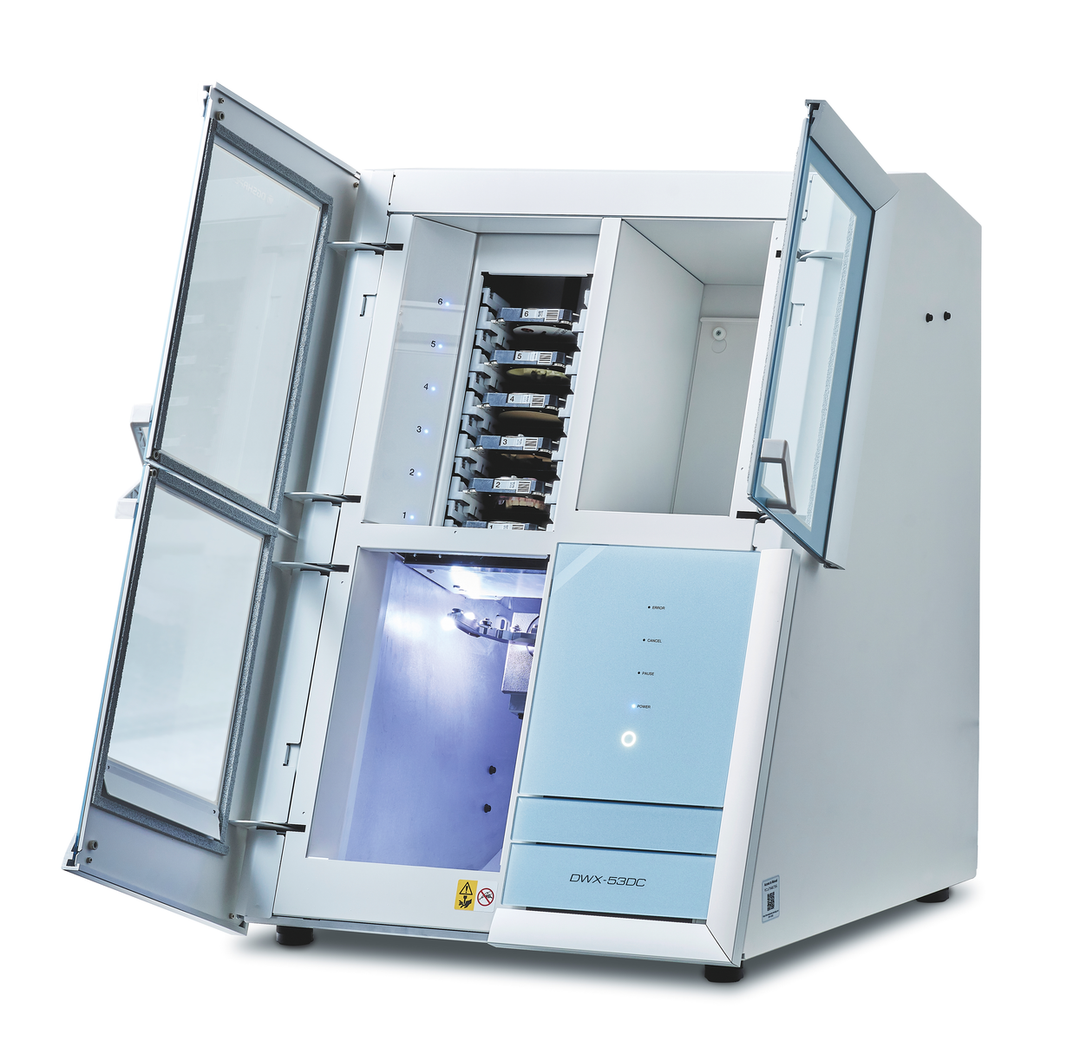

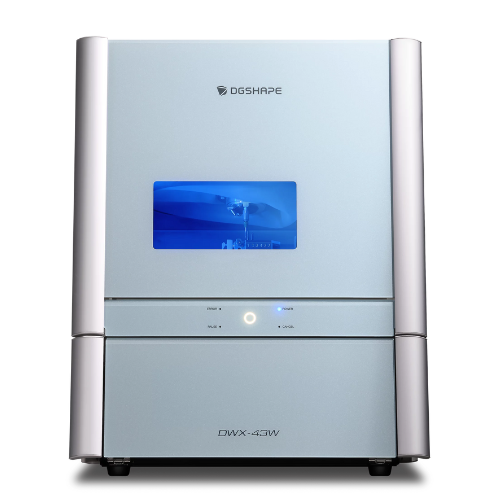

Roland DG’s DWX series (notably DWX-52DC and DWX-64) implements a hybrid workflow architecture designed for seamless insertion into both chairside (CEREC-like) and high-volume laboratory environments. Critical integration points include:

| Workflow Stage | Chairside Implementation | Lab Implementation | Roland Integration Mechanism |

|---|---|---|---|

| Data Acquisition | Intraoral scanner (TRIOS, Primescan) | Model scanner (D900, E4) | Direct .STL/.PLY import via network share; no proprietary scanner dependency |

| CAD Design | Single-software ecosystem (e.g., CEREC) | Multiplexed CAD environments | Native .STL export from all major CAD platforms; Roland Dental Milling Manager (RDMM) as universal receiver |

| Manufacturing Prep | Automated nesting within CAD | Batch processing & material optimization | RDMM’s AI-driven nesting (2026 v4.2+) reduces material waste by 18% vs. legacy systems; supports 4th-axis dry milling for full-contour zirconia |

| Milling Execution | Single-unit focus; clinician monitoring | Unattended 24/7 operation | IoT-enabled status tracking; auto-pause on tool breakage; 37% faster dry milling cycles for ZrO₂ (2026 benchmarks) |

| Post-Processing | Immediate sintering/staining | Dedicated finishing stations | Integrated sintering oven handshake (via Carejoy API); automated job logging for traceability |

CAD Software Compatibility Matrix

Roland maintains certified integration pathways with all major dental CAD platforms through standardized protocols:

| CAD Platform | Integration Method | Material Library Sync | Post-Processing Automation | 2026 Certification Status |

|---|---|---|---|---|

| 3Shape Dental System | Native RDMM plugin (v2.1+) | Real-time bi-directional sync | Automatic sintering profile transfer | ✅ Certified (TS v10.2+) |

| Exocad DentalCAD | Direct .STL export + RDMM watch folder | Manual library import (XML) | Requires Carejoy API bridge | ⚠️ Partial native (v3.0+) |

| DentalCAD (by Intego) | Generic .STL workflow | Manual configuration | Not supported | ❌ Community-driven only |

| Any CAD with STL Export | Universal RDMM import | Custom material profiles | Basic job tracking | ✅ Fully operational |

Open Architecture vs. Closed Systems: Technical Trade-offs

| Parameter | Open Architecture (Roland) | Closed System (e.g., Planmeca ProMax) |

|---|---|---|

| Vendor Lock-in Risk | Negligible (ISO 10303-21 compliant) | High (proprietary .PMM files) |

| CAD Flexibility | Supports 12+ CAD platforms simultaneously | Single-vendor CAD required |

| Workflow Scalability | Linear scaling: Add mills without software re-licensing | Cost-prohibitive per-unit scaling |

| IT Infrastructure | Requires robust network/NAS management | Self-contained appliance model |

| Technical Debt Risk | Low (standards-based) | High (vendor-dependent updates) |

| Best For | Labs with mixed CAD, multi-location clinics | Solo practices prioritizing simplicity |

Carejoy API: The Orchestration Layer

Roland’s strategic partnership with Carejoy (2025) delivers enterprise-grade workflow orchestration through:

- RESTful API Endpoints: Real-time job queue management (

POST /mills/{id}/jobs) with material tracking via RFID - Automated Material Reconciliation: Syncs zirconia block usage between Carejoy inventory and Roland mills (±0.2mm accuracy)

- Failure Analytics: Predictive tool-breakage alerts using spindle load telemetry (reduces downtime by 22%)

- CAD-to-Mill Handoff: Eliminates manual file transfers – Exocad designs auto-routed to Roland based on material rules

curl -X POST https://api.carejoy.io/v2/roland/jobs \-H "Authorization: Bearer {token}" \-d '{"cad_file": "case_12345.stl", "material": "Zirkonzahn ZR-White", "priority": "urgent"}'→ Returns

job_id with real-time milling progress via WebSockets

Conclusion: Strategic Positioning for 2026

Roland milling systems deliver unmatched interoperability in heterogeneous digital workflows, particularly where labs deploy multiple CAD platforms. The 2026 advantage lies in:

- Elimination of per-CAD milling module costs (saves $8,200+/year vs. closed systems)

- Carejoy API transforming mills into smart manufacturing nodes within Industry 4.0 dental ecosystems

- Future-proofing against CAD vendor consolidation through standards-based architecture

Recommendation: Adopt Roland for lab/enterprise environments requiring multi-CAD support and API-driven automation. For single-vendor chairside practices, closed systems may offer marginal UX simplicity – but at significant long-term flexibility cost.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Roland Dental Milling Systems in China

As China solidifies its position as a global epicenter for high-performance digital dental equipment, Carejoy Digital leverages its ISO 13485-certified manufacturing facility in Shanghai to deliver Roland dental milling systems with unparalleled precision, reliability, and cost-efficiency. This review details the end-to-end manufacturing and quality assurance (QA) processes that define Carejoy’s leadership in next-generation digital dentistry.

1. Advanced Manufacturing Workflow

The production of Roland dental milling units integrates precision engineering with digital process control across five core stages:

| Stage | Process | Technology & Control |

|---|---|---|

| 1. Component Fabrication | Production of high-tolerance spindle housings, gantry frames, and motion systems | CNC machining with sub-micron tolerances; raw material traceability via blockchain-linked ERP |

| 2. Sensor Integration | Installation of force-feedback sensors, optical encoders, and temperature monitoring modules | Pre-calibrated in ISO 17025-accredited sensor calibration labs; real-time drift compensation algorithms |

| 3. Assembly & Alignment | Modular assembly with laser-guided alignment of linear guides and spindle | Automated optical metrology (AOM) ensures ≤1µm positional deviation across XYZ axes |

| 4. Firmware & Software Load | Integration of AI-driven scanning interface and open-architecture compatibility | Support for STL, PLY, OBJ; cloud-synced software updates via CarejoyOS |

| 5. Final Integration | System-level integration with imaging and 3D printing ecosystems | Interoperability tested with major intraoral scanners (3Shape, Medit, Carejoy Vision) |

2. Quality Control: ISO 13485 & Beyond

Every Roland milling unit undergoes a 72-point QC protocol aligned with ISO 13485:2016 medical device quality management standards. Key checkpoints include:

- Material Certification: All alloys (e.g., Ti-6Al-4V, CoCr) and composites are batch-tested for biocompatibility (ISO 10993).

- Sensor Calibration: Conducted in on-site sensor calibration labs with NIST-traceable standards. Force sensors recalibrated every 500 operational hours via automated diagnostics.

- Environmental Stress Testing: Units cycled through 5–40°C and 30–80% RH to simulate global clinic environments.

- Longevity Validation: Accelerated durability testing simulates 5 years of clinical use (10,000+ milling cycles) with wear analysis of spindle bearings and linear rails.

3. Durability & Performance Testing

Roland milling systems are subjected to rigorous performance benchmarks:

| Test Parameter | Standard | Result (Roland ProMill X5) |

|---|---|---|

| Spindle Runout | ISO 22553-3 | ≤0.8 µm at 40,000 RPM |

| Positioning Accuracy | VDI/VDE 2617 | ±1.2 µm (3D volumetric) |

| Tool Life Monitoring | Proprietary AI algorithm | 98.6% prediction accuracy for end-of-tool-life |

| Dust Extraction Efficiency | IEC 60601-1 | 99.2% at 0.3 µm (HEPA H13) |

4. Why China Leads in Cost-Performance Ratio

China has emerged as the dominant force in high-value digital dental equipment due to a confluence of strategic advantages:

- Vertical Integration: Domestic access to precision motors, linear guides, and optical sensors reduces supply chain latency and cost.

- Talent Density: Shanghai and Shenzhen host over 40% of global dental CAD/CAM R&D engineers, enabling rapid innovation cycles.

- Scale & Automation: Fully automated production lines achieve 85% reduction in labor cost vs. EU/US counterparts, without sacrificing QC.

- Open Architecture Ecosystems: Carejoy’s support for STL/PLY/OBJ formats ensures seamless interoperability, reducing clinic onboarding costs by up to 40%.

- AI-Driven Efficiency: Onboard AI optimizes toolpaths in real-time, reducing milling time by 22% and tool wear by 31% (based on Carejoy internal trials, Q4 2025).

Conclusion

Carejoy Digital’s Roland dental milling systems exemplify the new standard in precision, durability, and value. Manufactured under strict ISO 13485 protocols in Shanghai, with integrated sensor calibration and AI-driven performance optimization, these systems deliver a best-in-class cost-performance ratio. For dental labs and digital clinics seeking scalable, future-proof CAD/CAM solutions, China’s advanced manufacturing ecosystem—led by innovators like Carejoy—is now the strategic choice.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dental Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160