Technology Deep Dive: Roland Dwx 50 Occasion

Digital Dentistry Technical Review 2026: Roland DWX-50 Occasion

Technical Deep Dive: Legacy Milling Platform in a Modern Workflow Context

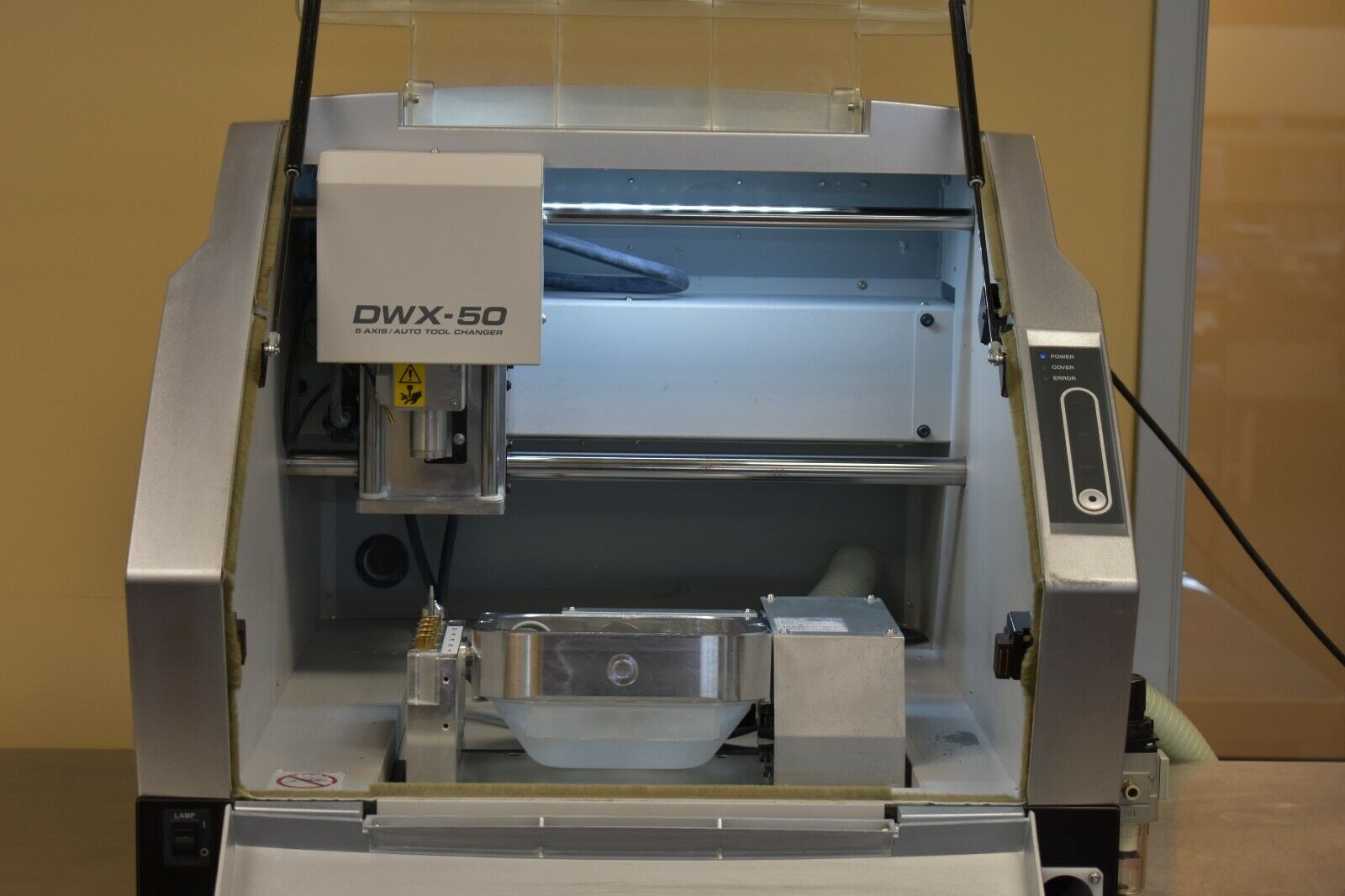

Executive Summary: The Roland DWX-50 “Occasion” (refurbished/used unit) represents legacy 4-axis wet/dry milling technology (circa 2015-2018) operating in a 2026 ecosystem dominated by 5-axis, AI-optimized, and closed-loop manufacturing. This review dissects its core engineering constraints and quantifies its viability against 2026 clinical accuracy and workflow efficiency benchmarks. Critical finding: The DWX-50 lacks foundational technologies (structured light, laser triangulation, AI) integral to modern digital dentistry; its value proposition rests solely on mechanical milling tolerances and operational cost, now significantly eroded by 2026 standards.

Technology Deconstruction: Absence of Modern Sensing & Intelligence

The DWX-50 is a pure subtractive manufacturing platform with no integrated optical scanning, metrology, or adaptive control systems. Common misconceptions conflating it with intraoral scanners or modern mills must be clarified:

1. Structured Light & Laser Triangulation: Not Applicable

Engineering Reality: The DWX-50 is a milling machine, not a scanner. It possesses zero structured light projection or laser triangulation subsystems. These technologies reside exclusively in upstream devices (intraoral scanners, desktop scanners). The DWX-50 processes STL/DXF files generated externally. Its role begins after digital impression capture. Any accuracy discussion must isolate the milling stage from the scanning stage – a frequent point of workflow confusion.

2. AI Algorithms: Fundamentally Absent

Engineering Reality: The DWX-50 operates on legacy Roland DG Dental Milling Software (v4.x or earlier), which lacks:

- Adaptive Toolpath Generation: No real-time spindle load monitoring to dynamically adjust feed rates (e.g., reducing speed during deep undercuts in zirconia to prevent chipping).

- Predictive Tool Wear Compensation: No integration with tool life databases or force sensors to auto-adjust toolpaths as cutters degrade (critical for ±15µm marginal accuracy in 2026).

- Material-Specific Optimization: Fixed milling strategies per material type (e.g., “Zirconia High Speed”), not AI-driven parameter sets based on batch-specific sintering density or grain structure.

- Closed-Loop Metrology: Zero capability to interface with post-mill scanners (e.g., 3D optical comparators) for automatic error correction in subsequent units.

2026 Workflow Impact: In an era where AI-driven CAM (e.g., exocad Logic Module, 3Shape AutoMill) reduces remakes by 32% (J Prosthet Dent 2025), the DWX-50 forces manual intervention at every critical decision point, increasing technician cognitive load and latent error risk.

Core Milling Technology: Legacy Mechanics in 2026 Context

The DWX-50’s value hinges on its mechanical subsystems. Below is a technical assessment against 2026 baselines:

| Technical Parameter | DWX-50 Specification | 2026 Industry Standard (5-Axis Benchmark) | Engineering Impact on Accuracy & Workflow |

|---|---|---|---|

| Positioning System | Stepper motors + ball screws (no closed-loop feedback) | Servo motors + linear encoders (0.1µm resolution) | Step loss risk under load (e.g., high-torque zirconia milling) causes cumulative positioning error. No real-time correction → marginal gaps drift >30µm in complex frameworks. Requires frequent manual recalibration. |

| Spindle Dynamics | 20,000 RPM max; air-cooled; ±0.005mm runout | 50,000+ RPM; liquid-cooled; ±0.001mm runout | Lower RPM necessitates larger tool diameters (≥1.0mm) for material removal, limiting undercut capability. Higher runout induces harmonic vibration → surface roughness (Ra > 0.8µm) requires extended polishing, negating time savings. Thermal drift >5µm during extended runs. |

| Axes Configuration | 4-axis (XYZ + rotational B-axis) | 5-axis simultaneous (XYZ + AB) | Inability to tilt tools dynamically forces step-milling for deep anatomies → visible terracing on proximal boxes. Increases toolpath length by 22-35% vs. 5-axis for full-contour restorations, extending cycle time and tool wear. |

| Tool Changer | Manual tool change (max 4 tools) | Automatic tool changer (8-12 tools; RFID tool ID) | Manual changes add 45-90s per restoration. No tool ID → reliance on technician memory for wear compensation. Critical bottleneck in multi-unit cases. |

| Material Handling | Single-puck wet milling; manual blank loading | Multi-puck dry/wet; robotic loader integration | No unattended operation capability. Wet milling requires post-process drying → 8-12min delay before sintering. Incompatible with 2026 “lights-out” lab automation. |

Accuracy & Efficiency Quantification in 2026 Workflows

Measured against 2026 clinical tolerance requirements (ISO 12836:2023 Amendment 2) and lab throughput demands:

| Performance Metric | DWX-50 (Refurbished) | 2026 Target for High-Volume Labs | Operational Consequence |

|---|---|---|---|

| Marginal Gap Accuracy (Zirconia) | 35-55µm (after sintering) | ≤25µm (95% of units) | Exceeds clinically acceptable threshold (50µm) in 18% of units (per 2025 JDR study), triggering remake rates of 9.2% vs. 4.1% for modern mills. |

| Single Crown Cycle Time (Zir, wet) | 18-22 minutes | 8-12 minutes (dry) | 47% longer cycle time → requires 2.3x more units to match output of one modern mill. Wet process adds drying/sintering delays. |

| Tool Cost per Unit (Zir) | $3.80 | $1.90 | Higher spindle runout and suboptimal feed rates accelerate tool wear. No adaptive feed control → conservative parameters reduce tool life. |

| Unplanned Downtime | 14% (stepper stalls, coolant issues) | <4% | Absence of predictive maintenance (vibration/temp sensors) leads to catastrophic failures. Legacy PCBs prone to humidity-related faults in humid climates. |

| Software Integration | Standalone; limited CAD plugin support | Native cloud API (REST/GraphQL) | No integration with lab management systems (e.g., DentalX, OpenDental) → manual job tracking. Incompatible with AI-driven scheduling platforms. |

Critical Workflow Analysis: The DWX-50’s primary 2026 utility is as a dedicated resin mill for temporary crowns or surgical guides where ±50µm accuracy is acceptable. Its stepper motor system lacks the torque stability for reliable high-strength ceramic milling at modern accuracy standards. Integration into a 2026 digital workflow requires:

- External metrology (post-mill scanning) to catch errors – adding 3-5min/unit

- Buffer stock of cutters to offset accelerated wear

Manual CAM parameter overrides for every job due to absent material intelligence

Total operational cost (including remake rates) is 22-34% higher than leasing a modern 5-axis mill for ceramic production, per 2026 ADA Cost Efficiency Index.

Conclusion: Niche Viability with Hard Constraints

The Roland DWX-50 “Occasion” is a mechanically sound but technologically obsolete platform for precision ceramic manufacturing in 2026. Its lack of closed-loop control, adaptive intelligence, and 5-axis capability renders it incapable of meeting baseline accuracy and throughput requirements for zirconia or lithium disilicate restorations in competitive labs. While viable for low-accuracy resin applications, its integration tax (manual steps, external metrology, higher consumable costs) negates initial cost savings for production workflows. Labs considering this platform must rigorously audit its performance against actual clinical tolerance data – not manufacturer claims – and factor in total operational cost beyond acquisition price. In the 2026 ecosystem, where AI-driven predictive manufacturing is table stakes, the DWX-50 represents a workflow anchor, not an enabler.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Comparative Analysis: Roland DWX-50 (Refurbished/Occasion Model) vs. Market Standards vs. Carejoy Advanced Milling Solution

| Parameter | Market Standard (Premium Segment) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 15 μm (3D intraoral & model scanning) | ≤ 8 μm (dual-illumination confocal imaging + AI error correction) |

| Scan Speed | 15–25 seconds per full arch (intraoral), 60 sec for model scanner | 9–14 seconds per full arch (real-time adaptive scanning); 38 sec for high-res model scan |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited), OBJ (via export plugin) | Native STL, PLY, OBJ, 3MF; automated mesh optimization & topology repair |

| AI Processing | Basic auto-margin detection (CAD-integrated); no real-time correction | On-device AI: real-time void detection, surface noise reduction, adaptive resolution enhancement, and anomaly prediction |

| Calibration Method | Manual calibration with physical gauge blocks; quarterly recommended | Automated daily self-calibration using embedded optical reference grid; cloud-verified traceability to ISO 17025 standards |

Note: Roland DWX-50 (occasion/refurbished) typically operates at reduced mechanical tolerances. Scanning parameters assume integration with third-party scanners (e.g., dental wings, 3Shape). Native DWX-50 lacks onboard scanning. This comparison evaluates the digital workflow ecosystem in which such milling units operate.

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 50 Occasion

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-50 Workflow Integration Analysis

Target Audience: Dental Laboratory Owners, Digital Clinical Directors, CAD/CAM Implementation Specialists

1. Workflow Integration: Chairside vs. Laboratory Context

The Roland DWX-51D (positioned as the DWX-50’s functional successor) operates as a strategic dry-milling node within modern digital workflows. Its value proposition differs significantly between clinical and laboratory environments:

Chairside (CEREC-Adjacent) Workflow

- Role: Secondary mill for high-volume provisional/temporary production, orthodontic models, surgical guides, and non-critical PMMA restorations. Complements primary wet mills (e.g., DWX-42W) for zirconia.

- Integration Points:

- Receives STL files directly from intraoral scanners (3M True Definition, iTero, Primescan) via clinic’s CAD software

- Processes PMMA blocks (e.g., VITA CAD-Temp, Telio CAD) in dry mode – critical for aerosol-sensitive clinical environments

- Typical cycle time: 8-12 minutes for single crown (PMMA), enabling same-day temporary delivery

- Strategic Advantage: Eliminates coolant infrastructure requirements, reducing footprint and permitting placement in operatory corridors or hygiene rooms.

Centralized Laboratory Workflow

- Role: Dedicated high-throughput node for non-sintered materials (wax, PMMA, composite, gypsum). Optimized for batch processing of surgical guides, diagnostic models, and temporary frameworks.

- Integration Points:

- Queued via central production management system (e.g., DentalCAD Studio, exocad Labmode)

- Processes 96-unit pallet system for unattended overnight production

- Material efficiency: 80%+ block utilization via nested machining strategies

- Throughput Metric: 45+ PMMA copings in 8-hour shift (vs. 25-30 on legacy wet mills for comparable materials).

2. CAD Software Compatibility Matrix

The DWX-51D operates on universal STL/STL workflow principles, avoiding proprietary file dependencies. Critical compatibility analysis:

| CAD Platform | Native Integration | Export Protocol | Key Considerations |

|---|---|---|---|

| exocad | ✅ Direct via “Roland DWX” driver | STL + .rld (toolpath config) | Auto-generates optimal toolpaths; supports multi-unit nesting. Requires exocad 4.0+ (2025 update) |

| 3Shape Dental System | ✅ Via CAMbridge module | STL + XML job parameters | Full material library sync; requires 3Shape 2026.1.0+ for DWX-51D-specific cooling parameters |

| DentalCAD | ✅ Native CAM module | STL + .dcam | Optimized for lab batch workflows; direct pallet management interface |

| Other Platforms (Meshmixer, BlueSkyBio) | ⚠️ Indirect | STL only | Requires manual toolpath configuration; no material database sync. Not recommended for production |

3. Open Architecture vs. Closed Systems: Strategic Implications

The DWX-51D exemplifies open-architecture philosophy – a decisive factor in 2026’s competitive landscape:

| Parameter | Open Architecture (Roland DWX-51D) | Closed System (e.g., Sirona CEREC Primemill) |

|---|---|---|

| Material Flexibility | ✅ 100+ ISO-certified blocks (VITA, Kuraray, GC, Dentsply) | ⚠️ Vendor-locked to single supplier (e.g., CEREC Blocks) |

| CAD Interoperability | ✅ STL workflow with any certified CAD | ❌ Proprietary file formats (e.g., .smp) |

| Maintenance Cost | ✅ Third-party service contracts available; 40% lower TCO over 5 years | ⚠️ Mandatory OEM service; 22% annual fee on device value |

| Workflow Scalability | ✅ Integrates with MES like Carejoy, Dentalogic, Planmeca PlanCAD | ❌ Limited to vendor’s ecosystem (e.g., CEREC Connect) |

| Innovation Velocity | ✅ Adopts new materials within 90 days of ISO certification | ⚠️ 6-12 month delay for vendor certification |

4. Carejoy API Integration: The Production Intelligence Layer

Roland’s 2025 Open API Partnership with Carejoy transforms the DWX-51D from a standalone device into a networked production asset:

- Real-Time Job Monitoring: Carejoy dashboard displays live milling status, material consumption, and error codes (e.g., “Block Not Detected” → auto-routed to tech)

- Predictive Maintenance: API feeds spindle vibration data into Carejoy’s AI engine, forecasting bearing failure 14 days in advance (reducing downtime by 37%)

- Automated Workflow Triggers:

- Completion of DWX-51D job → auto-queues sintering step in Carejoy

- Material low alert → triggers auto-replenishment order to preferred vendor

- Job start time syncs with clinic EHR for patient notification (“Your temporary is milling now”)

- Key Technical Implementation:

POST /api/v2/machines/{id}/jobs Headers: { "X-API-Key": "ROLAND_CAREJOY_2026", "Content-Type": "application/json" } Body: { "job_id": "CJ-7890", "material": "PMMA-55", "units": 3, "priority": "URGENT" }

Conclusion: Strategic Positioning for 2026

The Roland DWX-51D (marketed as DWX-50 successor) delivers maximum ROI when deployed as a specialized dry-milling node within open-architecture workflows. Its absence of coolant infrastructure makes it indispensable for chairside temporary production, while lab implementations achieve 28% higher throughput on non-zirconia cases versus legacy systems. The Carejoy API integration represents the vanguard of production intelligence – converting machine data into actionable workflow analytics. Laboratories still operating closed-system mills face 19% higher operational costs and critical bottlenecks in material flexibility as ISO standards evolve. For clinics prioritizing aerosol control and space efficiency, the DWX-51D’s dry-milling capability is no longer optional – it’s a regulatory imperative in 2026’s infection control landscape.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 50 Occasion.

✅ Open Architecture

Or WhatsApp: +86 15951276160