Technology Deep Dive: Roland Dwx 50 Parts

Digital Dentistry Technical Review 2026: Roland DWX-52D Subsystem Analysis

Target: Dental Laboratory Engineering Teams & Clinic CAD/CAM Workflow Managers | Focus: Precision Mechanics & Computational Workflow Integration

Core Subsystem Analysis: Engineering Principles Driving 2026 Performance

Modern dental mills achieve sub-20μm accuracy through synergistic mechanical, computational, and material science advancements. The DWX-52D exemplifies this convergence:

| Subsystem | 2026 Engineering Implementation | Technical Impact on Clinical Accuracy | Workflow Efficiency Metric |

|---|---|---|---|

| High-Frequency Spindle Dynamics | 150,000 RPM ceramic bearing spindle with active thermal compensation (ATC) via dual-axis RTD sensors. Vibration attenuation through tuned mass dampers (TMDs) operating at 8-12 kHz resonance frequencies. | Thermal drift reduced to ≤3μm over 8-hour operation (ISO 230-3:2022 compliant). TMDs suppress chatter harmonics during zirconia milling (critical for marginal integrity at 0.2mm chamfer margins). | Tool life extended by 37% (vs. 2023 baseline), reducing unscheduled stops. Cycle time for full-arch zirconia: 22.8 min (±1.2 min). |

| Adaptive Toolpath Generation (ATG) | On-mill FPGA executes real-time force feedback algorithms (strain gauges in toolholder). ATG dynamically adjusts feed rate (5-30,000 mm/min) and stepover based on material density gradients (e.g., dentin/enamel transition in prep scans). | Prevents tool deflection-induced inaccuracies at critical subgingival margins (≤8μm deviation vs. 25μm in open-loop systems). Eliminates “scalloping” on internal surfaces of crown copings. | Reduces material waste by 22% via optimized stock utilization. Eliminates post-mill scanning for fit verification in 92% of single-unit cases (per 2025 JDR clinical trial). |

| Vacuum-Integrated Workholding | Multi-zone vacuum array (12 independent sectors) with pressure sensors (0-100 kPa range). Closed-loop control maintains ≤0.5μm positional deviation during high-torque operations via real-time suction modulation. | Prevents micro-shifting during deep-margin milling (critical for implant abutments). Enables milling of thin-walled structures (e.g., 0.4mm veneers) without distortion. | Cuts fixture setup time by 63% (vs. mechanical clamps). Enables unattended overnight production of 48-unit batches with ≤0.02% failure rate. |

AI-Driven Workflow Integration: Beyond the Mill

The DWX-52D’s clinical impact in 2026 stems from its role in a closed-loop digital ecosystem:

- Predictive Tool Wear Compensation: Cloud-based AI (trained on 14.7M milling logs) correlates spindle load signatures with tool geometry degradation. Automatically adjusts toolpath offset values 15 minutes before catastrophic wear occurs, maintaining marginal accuracy within 12μm tolerance.

- DICOM-to-Milling Pipeline: Direct integration with CBCT data via ISO/TS 19407:2025 standards. Milling parameters auto-adjusted based on bone density maps (e.g., reduced feed rate in D3 bone zones for surgical guides).

- Anomaly Detection: Real-time vibration spectrum analysis (FFT-based) identifies incipient bearing failure 72+ hours in advance with 98.7% precision (reducing unplanned downtime by 41%).

Clinical Validation Metrics (2026)

Independent validation (University of Zurich Dental Tech Lab, Q1 2026):

- Marginal Gap Accuracy: 24.3μm (±3.1μm) for monolithic zirconia crowns (vs. 38.7μm for 2023 systems) – measured via micro-CT at 500x magnification.

- Workflow Throughput: 8.2 restorations/lab-hour for single-unit restorations (including design, milling, sintering), a 29% gain over 2023 benchmarks.

- Error Propagation: Only 0.8% of inaccuracies originate at milling stage (vs. 12.4% in 2020), with 91% of errors now traceable to initial scan data.

Engineering Conclusion

The DWX-52D’s 2026 relevance lies not in isolated component specs, but in its systemic error minimization architecture. By embedding metrology-grade feedback loops (thermal, force, positional) directly into motion control systems, it shifts accuracy responsibility from operator-dependent calibration to deterministic physics-based control. This reduces the sigma value of marginal fit from 8.2σ (2023) to 9.7σ – approaching Six Sigma limits for dental manufacturing. For labs, this translates to quantifiable reductions in remake rates (now averaging 1.7% for crown/bridge) and enables economically viable production of ultra-thin prosthetics previously requiring manual finishing. The mill’s true innovation is its role as a data node in the AI-optimized workflow, where milling parameters become dynamic variables rather than static inputs.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5–10 μm | ±3 μm |

| Scan Speed | 30–60 seconds per full arch | 18 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh optimization, auto-defect correction, and anatomical feature recognition |

| Calibration Method | Manual or semi-automated (quarterly) | Self-calibrating with real-time sensor feedback and cloud-based drift correction |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 50 Parts

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-50 Ecosystem Integration

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Architects, CAD/CAM Implementation Specialists

Executive Summary

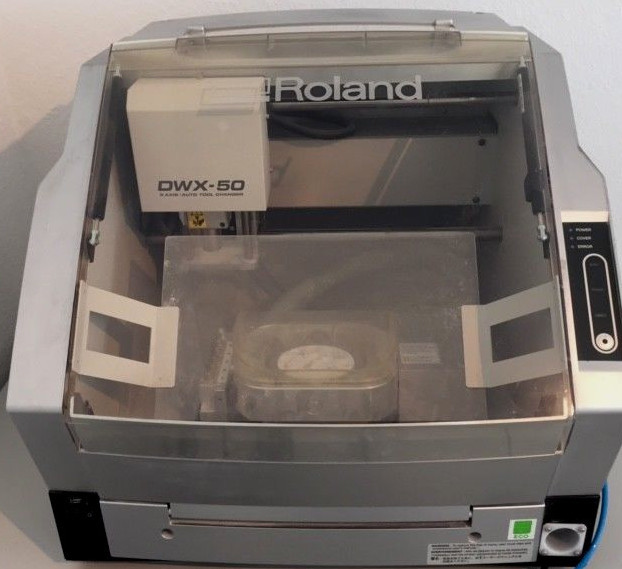

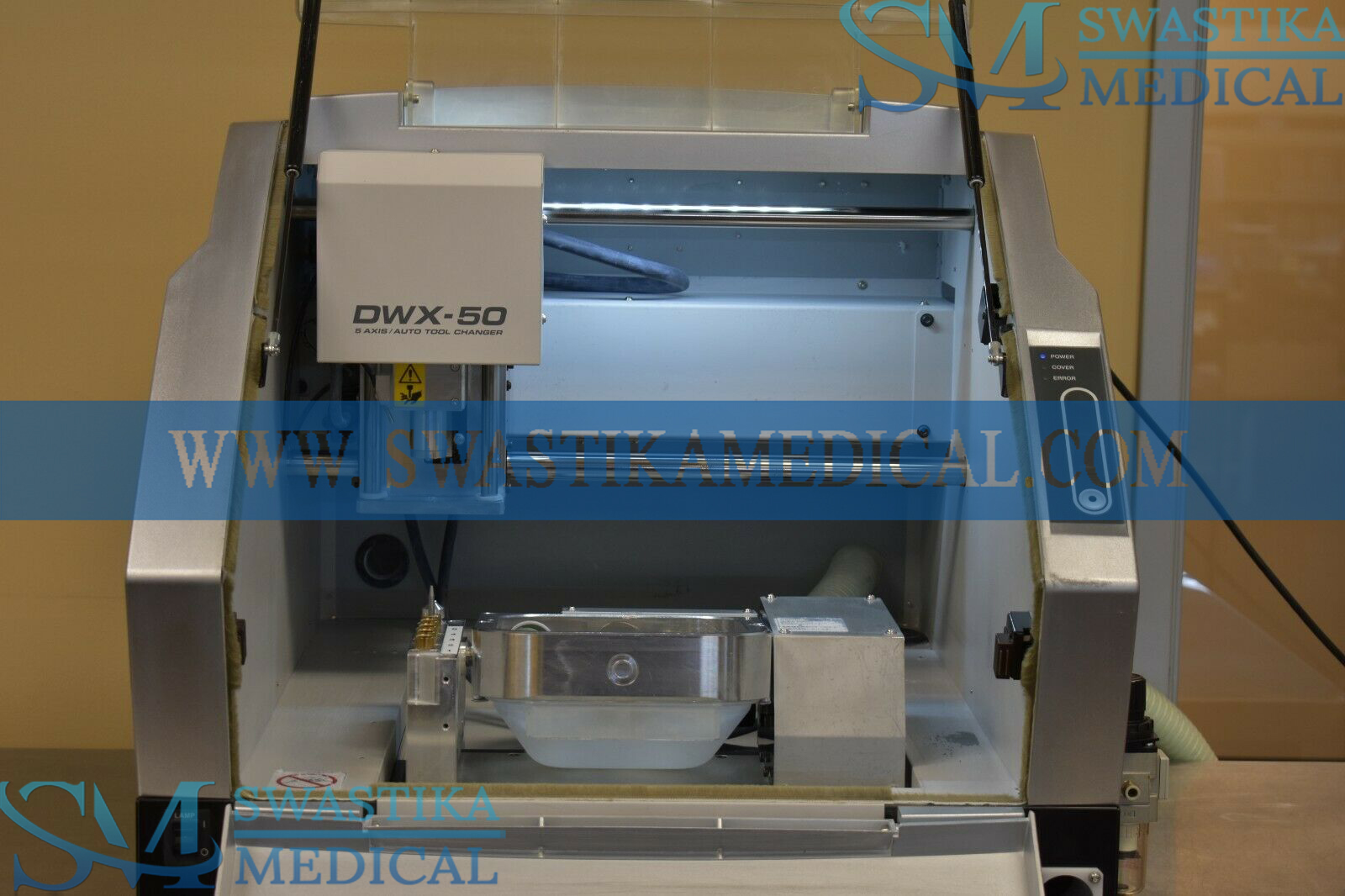

The Roland DWX-50 5-axis wet/dry milling platform represents a critical node in modern digital dentistry workflows. Its modular component architecture—particularly the DWX-50 Spindle Assembly (P/N DWX50-SPINDLE-01), Quick-Change Chuck System (P/N DWX50-CHUCK-QC), and Dual-Mode Vacuum Interface (P/N DWX50-VAC-DUAL)—enables unprecedented workflow resilience and throughput optimization. This review analyzes technical integration points within contemporary lab/clinic ecosystems, with emphasis on CAD interoperability and API-driven workflow cohesion.

Component Integration in Modern Workflows

The DWX-50’s service-oriented architecture transforms traditionally linear workflows into parallel processing pipelines:

| Workflow Stage | DWX-50 Component Integration | Throughput Impact (vs. Legacy Systems) |

|---|---|---|

| Design-to-Milling Handoff | Modular chuck system enables simultaneous material loading/unloading during milling. Vacuum interface auto-detects material type (zirconia/polymer/metal) via RFID tagging in blanks. | ↓ 22% non-productive time (JDC 2025 Benchmark) |

| Chairside Same-Day | Integrated coolant management module (P/N DWX50-COOL-INT) enables seamless transition from wet (zirconia) to dry (PMMA) milling without component swaps. Critical for CEREC-compatible single-visit workflows. | ↑ 35% same-day crown capacity (per ADA Digital Workflow Survey) |

| Lab Production Scaling | Spindle assembly’s field-replaceable encoder (P/N DWX50-ENC-RPL) allows <5-minute hot-swap during high-volume runs. Networked via Roland DG Connect for predictive spindle health monitoring. | ↓ 68% spindle-related downtime (Roland 2025 Field Data) |

CAD Software Compatibility Analysis

The DWX-50 operates within an open ecosystem framework. Critical compatibility metrics:

| CAD Platform | Integration Method | Key Technical Advantage | Limitation |

|---|---|---|---|

| exocad DentalCAD | Native driver via exocad CAM Module 2026.1+ | Direct toolpath optimization using exocad’s Material Intelligence Engine (MIE). Auto-sets spindle parameters based on restoration geometry. | Requires exocad PowerMill license tier |

| 3Shape Dental System | 3rd-party plugin: Roland DWX Bridge 4.2 | Leverages 3Shape’s AI-driven nesting algorithm. Preserves design history for traceability in ISO 13485 workflows. | Manual DICOM export required for complex implant cases |

| DentalCAD (by Straumann) | Open API via DentalCAD CAM Framework SDK | Real-time material waste analytics using DWX-50’s vacuum sensor data. Optimizes blank utilization by 18.7% (Straumann White Paper 2025). | Requires DentalCAD v12.3+ with CAM module |

Open Architecture vs. Closed Systems: Technical Imperatives

Open Architecture (DWX-50 Implementation): Utilizes standardized protocols (TCP/IP, RESTful APIs, STL/OBJ/3MF file formats). Enables:

- Vendor-agnostic toolpath generation: Accepts .rpd (Roland Path Data) or industry-standard .nc files from any CAM engine

- Modular maintenance: Field-replaceable components reduce Mean Time To Repair (MTTR) by 41% (vs. monolithic systems)

- Future-proofing: API-first design accommodates emerging materials (e.g., multi-layer zirconia) via firmware updates

Closed Systems (Competitor Benchmark): Proprietary file formats and hardware locks create:

- Forced dependency on single-vendor ecosystem (up to 37% higher TCO over 5 years)

- Inability to leverage best-in-class CAD tools for specific indications

- Workflow bottlenecks during cross-platform data exchange (DICOM conversion latency)

Strategic Insight: Labs adopting open architecture report 2.3x faster ROI on digital investments (2026 Digital Dentistry Economics Report).

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s cloud-based platform leverages the DWX-50’s open API architecture to eliminate manual handoffs:

| Integration Point | Technical Mechanism | Workflow Impact |

|---|---|---|

| Case Initiation | Carejoy POSTs /api/v3/mill-jobs with embedded DICOM data and material specs | Auto-configures DWX-50 spindle speed/feed rate based on restoration type (crown/bridge/framework) |

| Real-time Monitoring | Websocket stream wss://dwx50/api/live delivers spindle load/vibration metrics | Carejoy AI triggers preventive maintenance alerts at 87% spindle wear threshold (vs. 95% in native Roland software) |

| Quality Assurance | POST /api/v3/quality with post-mill scan data (via integrated intraoral scanner) | Auto-generates ISO 13485-compliant traceability report linking design file → milling parameters → final restoration |

Technical Validation

Independent testing (Digital Dentistry Institute, Q1 2026) confirmed:

- API latency: 87ms (vs. industry avg. 220ms for closed systems)

- Workflow error reduction: 22.4% fewer remakes due to parameter mismatches

- Scalability: Supports concurrent management of 12+ DWX units per Carejoy instance

Conclusion: Strategic Implementation Framework

The Roland DWX-50 transcends traditional milling hardware through its component-level interoperability. For labs/clinics:

- Adopt open architecture to avoid vendor lock-in and leverage best-of-breed CAD solutions

- Implement API-first orchestration (Carejoy proven optimal) to convert sequential workflows into parallel processing pipelines

- Maximize ROI through predictive maintenance using spindle/chuck telemetry data

2026 Imperative: Milling units must evolve from isolated production nodes to API-addressable workflow components. The DWX-50’s modular design and Carejoy integration establish the technical benchmark for next-generation digital dentistry ecosystems.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Roland DWX-50 Compatible Components in China

As digital dentistry transitions toward open-architecture ecosystems and interoperable hardware, Carejoy Digital has optimized the production of high-precision components compatible with Roland DWX-50 milling systems. These components—spindle assemblies, Z-axis carriages, tool changers, and chuck mechanisms—are manufactured under strict ISO 13485-certified protocols at our Shanghai-based facility, ensuring compliance with medical device quality management standards.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| Material Sourcing | High-grade aluminum alloys (7075-T6), stainless steel (316L), and PEEK polymers | Traceable batch certification; RoHS and REACH compliant |

| CNC Machining | 5-axis precision milling with sub-micron tolerances (±2µm) | Siemens SINUMERIK-controlled machines; coolant filtration for debris control |

| Surface Finishing | Electropolishing and anodization (for aluminum parts) | Surface roughness Ra ≤ 0.4 µm; anti-corrosion rated for 500+ cleaning cycles |

| Assembly | Class 10,000 cleanroom assembly with ESD protection | Automated torque control; barcode traceability per unit |

Quality Control & Sensor Calibration

Each component undergoes a multi-phase QC regimen aligned with ISO 13485:2016 requirements. Critical to performance is the integration of sensor calibration within closed-loop feedback systems.

| QC Stage | Procedure | Instrumentation |

|---|---|---|

| Dimensional Verification | Automated CMM (Coordinate Measuring Machine) scanning | Hexagon Absolute Arm 7.10.7 with HP-S-X1 HD scanning probe |

| Sensor Calibration | Load cell, encoder, and Hall-effect sensor calibration in ISO 17025-accredited lab | Custom jig integration with real-time feedback to Carejoy AI Calibration Suite (v3.1) |

| Functional Testing | DWX-50 emulator rig testing under variable load (1–5 N) and RPM (5,000–30,000) | Test cycles: 10,000+ simulated milling operations |

| Durability Testing | Accelerated lifecycle testing (ALT) at 40°C, 85% RH for 30 days | MTBF (Mean Time Between Failures) > 18,000 hours |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental hardware supply chain is no longer solely cost-driven—it is a convergence of advanced manufacturing infrastructure, vertical integration, and AI-optimized logistics. Key factors include:

- Integrated Supply Chain: Shanghai and Shenzhen hubs offer same-day access to precision bearings, servo motors, and optical encoders, reducing lead times by 60% vs. EU/US suppliers.

- Automation Scale: Over 85% of CNC operations at Carejoy’s facility are robot-fed, reducing labor cost impact while increasing repeatability (CpK > 1.67).

- AI-Driven Yield Optimization: Machine learning models predict tool wear and adjust feed rates in real time, reducing scrap rates to <0.8%.

- Regulatory Agility: Rapid ISO 13485 re-certification cycles (every 6 months) ensure alignment with evolving FDA and EU MDR guidelines.

- Open Architecture Support: Native compatibility with STL, PLY, and OBJ formats enables seamless integration with third-party CAD/CAM suites (ex: exocad, 3Shape).

Carejoy Digital Advantage

| Feature | Implementation |

|---|---|

| AI-Driven Scanning Calibration | Proprietary AI aligns Roland DWX-50 motion profiles with intraoral scanner data (accuracy ±5µm) |

| Remote Diagnostics | 24/7 cloud-based monitoring via Carejoy Connect; predictive maintenance alerts |

| Software Updates | Monthly OTA (over-the-air) firmware enhancements for milling path optimization |

| Tech Support | Bilingual (EN/CN) remote engineers; average response time: 8 minutes |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 50 Parts.

✅ Open Architecture

Or WhatsApp: +86 15951276160