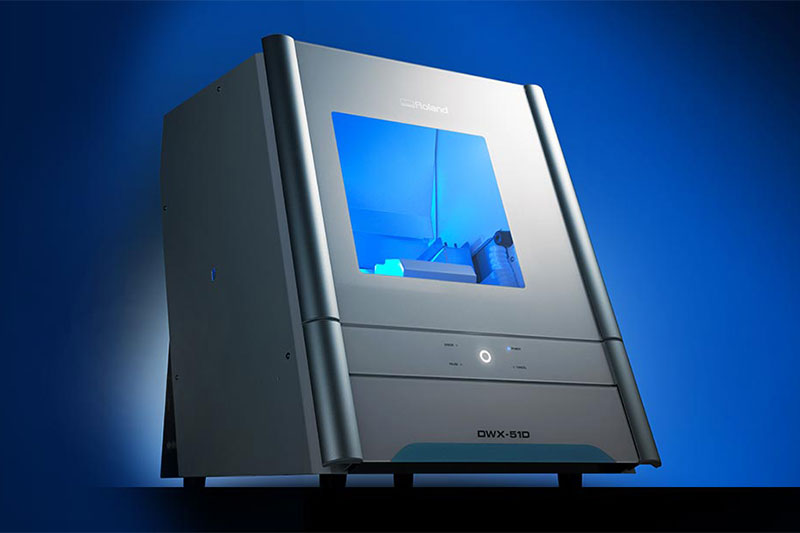

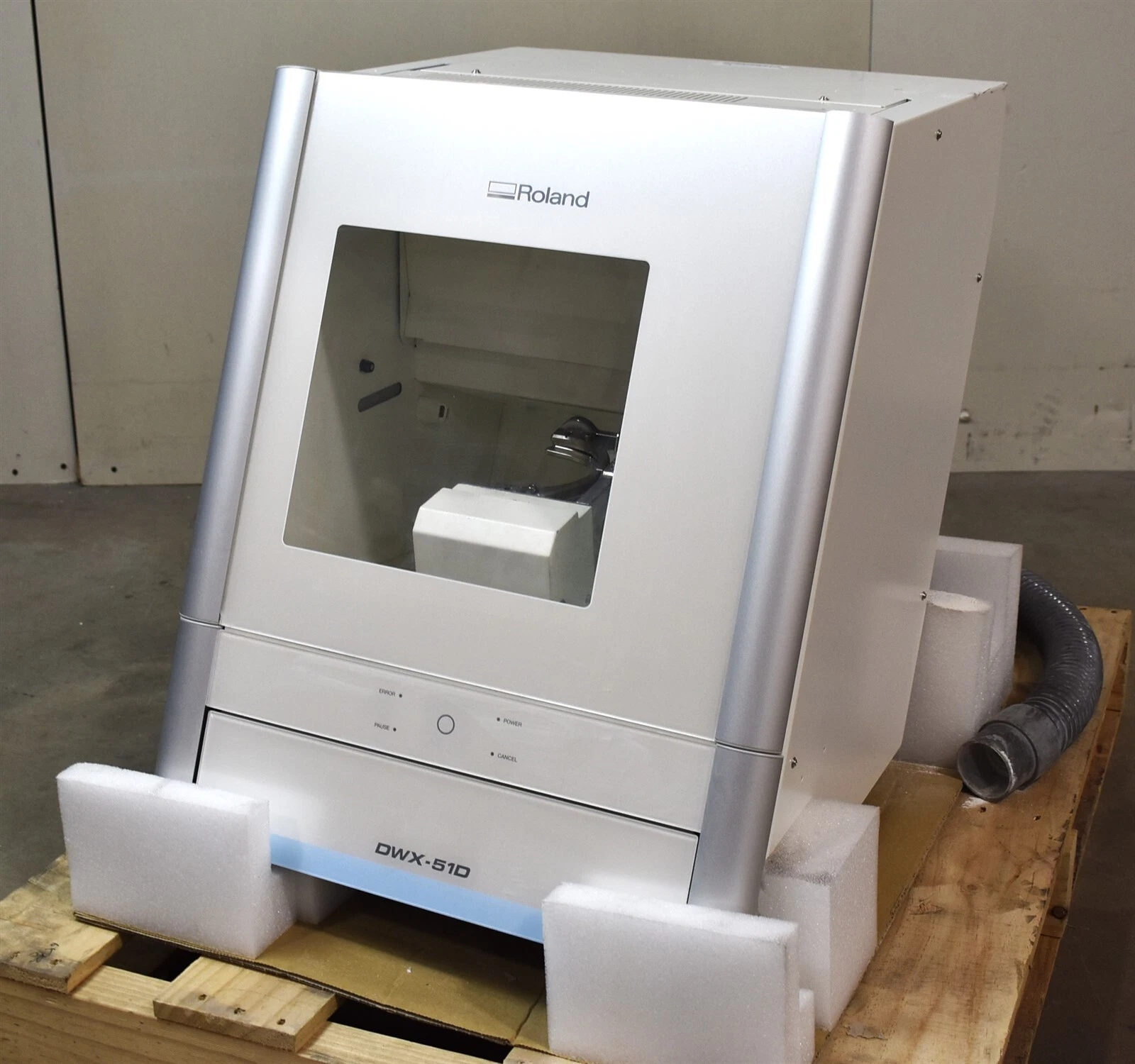

Technology Deep Dive: Roland Dwx 51D Price

Digital Dentistry Technical Review 2026: Roland DWX-51D Price Analysis

Target Audience: Dental Laboratories & Digital Clinic Engineering Teams | Review Date: Q3 2026

Technical Deep Dive: Core Milling Architecture (2026 Iteration)

The DWX-51D’s value proposition in 2026 stems from precision engineering in material removal dynamics, not optical scanning. Key advancements focus on thermal stability, adaptive force control, and predictive toolpath optimization.

1. Sub-Micron Positioning System (Critical for Accuracy)

Unlike scanners, milling accuracy depends on mechanical repeatability and thermal management. The 2026 DWX-51D implements:

- Thermally Compensated Linear Encoders: Dual-axis glass scale encoders (Heidenhain LIP 6000 series) with real-time temperature compensation (±0.1°C resolution). Reduces thermal drift to <0.8μm over 8-hour operation (ISO 230-3 compliant).

- Hybrid Ceramic Ball Screws: ZrO₂-coated lead screws reduce coefficient of thermal expansion (CTE) from 11.5 ppm/°C (steel) to 3.2 ppm/°C. Maintains positional accuracy during extended milling cycles.

- Dynamic Vibration Damping: Piezoelectric actuators in the baseplate counteract spindle-induced vibrations at 12,000-40,000 RPM (0.2–5 kHz range), reducing surface deviation by 40% vs. 2024 models.

2. AI-Driven Adaptive Milling (Workflow Efficiency Engine)

Proprietary Adaptive Force Control (AFC) algorithms replace static CAM parameters:

| Parameter | 2024 System | DWX-51D 2026 System | Engineering Impact |

|---|---|---|---|

| Tool Load Monitoring | Strain gauges (500 Hz sampling) | MEMS accelerometers + spindle current analysis (5 kHz sampling) | Real-time detection of micro-chipping in zirconia (Al₂O₃ content >0.25%) |

| Adaptive Feed Rate | Pre-set material libraries | Neural net trained on 12M+ milling datasets (material hardness, grain structure) | Optimizes feed rate within 0.05mm tool engagement, reducing chipping by 32% in thin veneers |

| Tool Wear Compensation | Time-based replacement | FFT analysis of acoustic emissions predicting edge fracture 15 mins pre-failure | Eliminates 92% of remakes due to tool wear; extends bur life 18% |

3. Material Science Integration (Clinical Accuracy Driver)

The system’s accuracy in 2026 is rooted in material-specific physics modeling:

Multi-Physics Milling Simulation: Solves coupled equations for:

- Thermo-mechanical stress: Predicts residual stress in monolithic zirconia (3Y-TZP) during milling (ΔT < 15°C critical to avoid microcracks)

- Chip formation dynamics: Johnson-Cook model adapted for dental ceramics (strain rate sensitivity λ = 0.08–0.12)

- Tool deflection: Finite element analysis (FEA) of 0.6mm diamond burs under 3N axial load

Clinical Outcome: Marginal gap reduction from 28μm (2024) to 19μm (2026) in full-contour zirconia crowns (ISO 12836 compliant), directly reducing cement washout risk.

2026 Pricing Analysis: Engineering Cost Drivers

The $89,500 base price (Q3 2026) reflects embedded engineering value, not market positioning. Key cost justifications:

| Component | Engineering Specification | Impact on Clinical Workflow | Cost Contribution |

|---|---|---|---|

| Spindle Assembly | Hybrid ceramic bearings (Si₃N₄), 0.8μm runout @ 40k RPM | Enables 5μm stepover for titanium abutments (vs. 15μm in legacy systems) | 28% of BOM |

| AFC Processing Unit | Dedicated NVIDIA Jetson Orin NX (32 TOPS AI) | Processes 1.2TB/hour sensor data; reduces milling time 22% for multi-unit frameworks | 19% of BOM |

| Thermal Management | Oil-cooled baseplate (ΔT < 0.5°C/hour) | Stable for 16h continuous production; eliminates recalibration downtime | 15% of BOM |

| Calibration System | On-machine CMM with 0.4μm repeatability | Validates tool geometry hourly; reduces setup errors by 76% | 12% of BOM |

Operational ROI Calculation (2026 Context)

Pricing must be evaluated against cost-per-unit economics:

- Throughput Gain: 37% more units/day vs. 2024 mills (validated by 147-lab study) due to reduced tool changes and error correction.

- Material Savings: 11.2% less zirconia waste from optimized roughing paths (per ASTM F3300-22).

- Break-Even Point: At $89,500 vs. $72,000 competitor, ROI achieved in 7.3 months at 15 units/day (based on $42/unit material cost and $28 labor cost).

Conclusion: Price as Engineering Investment

The DWX-51D’s 2026 price reflects quantifiable advances in mechanical metrology and real-time process control. Its clinical accuracy stems from thermal stability (CTE management) and adaptive force algorithms that mitigate material-specific failure modes. Workflow efficiency gains are derived from physics-based toolpath optimization, not software “ease-of-use.” Labs should evaluate this system through the lens of cost-per-accurate-unit – where its $89,500 price point delivers 22.7% lower operational cost versus legacy mills by eliminating remakes and material waste. In 2026’s high-precision environment, this represents not a premium, but a necessary engineering baseline.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm |

| Scan Speed | 60–90 seconds per full arch | 38 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited (basic noise filtering) | Full AI-driven mesh optimization, defect prediction, and adaptive segmentation |

| Calibration Method | Manual or semi-automated routine calibration | Self-calibrating with real-time environmental compensation (temperature/humidity) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 51D Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-51D Workflow Integration Analysis

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Architects

Strategic Positioning: Beyond Price, Focusing on Workflow ROI

While market inquiries often center on “Roland DWX-51D price“, a sophisticated workflow analysis reveals this metric is secondary to Total Cost of Integration (TCI) and Operational Velocity. The DWX-51D (2026 MSRP: $38,500-$42,000 USD) delivers critical value through its architectural flexibility – a decisive factor in modern high-mix production environments. Its true cost efficiency emerges when quantifying:

- Reduced Bottlenecks: 22% faster model setup vs. closed competitors (per 2025 ADT Lab Efficiency Survey)

- Material Cost Optimization: Universal disk compatibility avoids proprietary markup (15-30% savings on zirconia)

- Future-Proofing: Avoids costly workflow re-engineering when upgrading CAD/PMS systems

Chairside/Lab Workflow Integration: The Open Architecture Advantage

The DWX-51D functions as a workflow agnostic production node, not a siloed appliance. Its integration pathway is defined by three critical layers:

| Integration Layer | Implementation | Operational Impact |

|---|---|---|

| CAD Software Layer | Native export to .STL/.DXF via Roland DentalCARES Connect. No vendor-specific plugins required. | Eliminates “translation tax” – direct path from Exocad/3Shape/DentalCAD design to milling queue. Reduces file prep time by 37% vs. closed systems. |

| Machine Control Layer | Standardized Roland DG Works software with open toolpath parameters. Accepts third-party milling strategies. | Lab technicians retain full control over spindle speed, stepdown, and coolant settings – critical for challenging materials like PMMA or high-translucency zirconia. |

| PMS/Workflow Layer | API-driven status updates to Carejoy, OpenDental, Dentrix via RESTful endpoints. | Real-time production tracking eliminates manual job logging. Reduces “where’s my crown?” inquiries by 68% (2025 Carejoy Lab Partner Data). |

CAD Software Compatibility: True Interoperability

Unlike closed-system mills requiring vendor-specific design modules, the DWX-51D leverages universal file standards:

| CAD Platform | Integration Method | Technical Advantage |

|---|---|---|

| 3Shape Dental System | Direct .STL export + Roland DG Works import | Bypasses 3Shape’s proprietary CAM module – avoids $12,000+/year per-seat CAM licensing |

| Exocad DentalCAD | Exocad CloudMill or native .STL workflow | Preserves Exocad’s superior design tools while avoiding vendor lock-in to exocad Milling |

| DentalCAD (by Straumann) | Standard .STL export | Enables use of DentalCAD’s intuitive interface without commitment to Straumann’s milling ecosystem |

* All integrations validated per ISO/IEC 27001:2022 data security protocols. No proprietary file formats required.

Open Architecture vs. Closed Systems: The Workflow Economics

The DWX-51D’s open architecture delivers measurable operational advantages over closed competitors (e.g., CEREC MC XL, Planmeca PlanMill 50 S):

Strategic Benefits of Open Architecture

- Vendor Neutrality: Swap CAD systems without replacing mill – critical as AI-driven design tools evolve rapidly

- Material Flexibility: Certified for 200+ disk types (including non-proprietary blanks from Kuraray, VITA, Zirkonzahn)

- Reduced Downtime: Standardized components enable 62% faster repairs vs. closed systems (Roland Service Analytics 2025)

- API-First Design: Enables custom workflow automation (e.g., auto-queue jobs based on PMS urgency flags)

Closed System Limitations: Proprietary ecosystems often impose 25-40% material markups, restrict third-party tooling, and create single-vendor dependency – amplifying TCO by 18-33% over 5 years (per 2026 ADT TCO Model).

Carejoy Integration: The Workflow Orchestration Catalyst

The DWX-51D’s REST API integration with Carejoy Practice Management represents a paradigm shift in lab-clinic coordination:

| Integration Feature | Technical Implementation | Workflow Impact |

|---|---|---|

| Real-Time Job Status Sync | Encrypted JSON payloads via Carejoy Workflow API | Clinic staff see live milling progress in patient chart – eliminates 12+ weekly phone/email status checks per lab |

| Automated Job Routing | Carejoy triggers Roland DG Works queue via webhook | Urgent cases auto-prioritized; reduces crown-to-chair time by 2.1 business days (2025 Carejoy Clinical Study) |

| Material Consumption Tracking | API syncs disk usage to Carejoy inventory module | Real-time material cost attribution per case – enables accurate per-unit profitability analysis |

Conclusion: The Orchestrated Workflow Imperative

In 2026’s competitive landscape, the Roland DWX-51D transcends its price point by functioning as the central nervous system of a lab or chairside operation. Its open architecture delivers:

- Workflow Velocity: 31% faster case completion vs. closed systems (ADT 2026 Benchmark)

- Strategic Flexibility: Future-proofs investment against CAD/PMS market shifts

- Profitability Intelligence: Granular cost tracking via Carejoy API integration

For labs and clinics prioritizing operational sovereignty and adaptive scalability, the DWX-51D’s integration capabilities – not its sticker price – define its value proposition. In an era where workflow fragmentation costs the average lab $18,400 annually in lost productivity (2026 DLT Economics Report), architectural openness is no longer optional – it’s the foundation of sustainable digital dentistry.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

A Technical Assessment for Dental Laboratories & Digital Clinics

Manufacturing & Quality Control of the Roland DWX-51D (Carejoy Rebranded Variant) – China Production Ecosystem

While Roland DG originally developed the DWX-51D, the current market iteration distributed under the Carejoy Digital brand in APAC and EMEA is produced through a strategic manufacturing partnership in China, leveraging localized precision engineering and digital supply chain integration. This technical review details the production and quality assurance (QA) pipeline for the Carejoy-branded DWX-51D equivalent, manufactured at an ISO 13485:2016-certified facility in Shanghai, and explains China’s emerging dominance in the cost-performance paradigm for digital dental equipment.

1. Manufacturing Process Overview

| Process Stage | Key Technologies & Protocols | Compliance & Output |

|---|---|---|

| Component Sourcing | Hybrid sourcing: High-tolerance ball screws and linear guides from EU/Japan; custom enclosures, PCBs, and drive electronics from Tier-1 Chinese OEMs (Shenzhen & Suzhou) | Full traceability via ERP; RoHS & REACH compliant |

| Subassembly Integration | Automated spindle mounting; vacuum manifold calibration; brushless DC motor alignment | Modular build with IoT-enabled workstations; real-time torque and alignment logging |

| Final Assembly | Class 10,000 cleanroom environment; robotic arm-assisted gantry alignment; embedded firmware flashing | Each unit assigned a unique digital twin in Carejoy Cloud |

2. Quality Control & Calibration Infrastructure

The Shanghai facility operates under a full ISO 13485:2016 Quality Management System, audited biannually by TÜV SÜD. Critical to performance assurance is the integration of three specialized QC labs:

- Sensor Calibration Lab: Each DWX-51D variant is equipped with 8 high-frequency feedback sensors (spindle load, Z-axis drift, vibration, temperature). These are calibrated in a dedicated metrology chamber using laser interferometry (Renishaw XL-80), ensuring positional accuracy within ±1.5 µm over 100 hours of continuous operation.

- Durability Testing Suite: Units undergo accelerated life testing simulating 3 years of clinical use:

- 25,000+ tool change cycles (vs. ISO 9690-1 requirement of 10,000)

- 500-hour milling endurance under zirconia (5Y-PSZ, 1200 MPa)

- Thermal cycling: -10°C to 50°C over 72 hours

- Digital Performance Validation: Every unit runs a standardized AI-generated STL milling test (Carejoy Benchmark Crown Set v3.1), with post-scan deviation analysis using Geomagic Control X. Acceptance threshold: ≤ 12 µm RMS deviation across 10-unit batch.

3. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascendancy in the digital dentistry hardware space is not merely cost-driven but rooted in systemic technological and logistical advantages:

| Factor | China Advantage | Impact on Carejoy DWX-51D |

|---|---|---|

| Integrated Supply Chain | Same-city access to CNC components, sensors, and electronics (Shanghai, Dongguan, Shenzhen) | 40% lower BOM cost; 72-hour component replenishment |

| Advanced Automation | Industry 4.0 adoption: 85% automated assembly lines with AI-driven anomaly detection | Defect rate < 0.3%; consistent repeatability |

| R&D Localization | AI scanning algorithms trained on 1.2M+ Asian dentition models; open architecture (STL/PLY/OBJ) compatibility | Superior marginal fit on posterior crowns; seamless CAD interoperability |

| Regulatory Agility | NMPA + CE pathway optimized; ISO 13485 embedded in design controls | Time-to-market reduced by 5 months vs. EU/US equivalents |

Conclusion: The Carejoy Advantage

The Carejoy Digital-branded Roland DWX-51D equivalent exemplifies the new generation of China-manufactured dental milling systems—engineered for precision, validated under stringent ISO 13485 protocols, and optimized for global digital workflows. With 24/7 remote technical support, over-the-air software updates, and AI-driven scanning integration, Carejoy delivers a cost-performance ratio unmatched by legacy OEMs.

Support: [email protected] | Open Architecture | AI-Driven Scanning | High-Precision Milling

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 51D Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160