Technology Deep Dive: Roland Dwx 52D

Digital Dentistry Technical Review 2026: Roland DWX 52D Technical Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers

Executive Technical Summary

The Roland DWX 52D (2026 iteration) represents a convergence of precision mechanics, multi-spectral optical sensing, and edge-AI-driven error correction. Unlike intraoral scanners, this lab-based unit functions as a closed-loop digital impression-to-milling verification system. Its core innovation lies in replacing legacy mechanical probing with a hybrid structured light/laser triangulation sensor array, achieving sub-5μm volumetric accuracy (ISO 12836:2023 Class 1 compliance) while reducing workflow bottlenecks through deterministic error prediction.

Core Technology Architecture: Beyond Marketing Hype

1. Multi-Modal Optical Sensing System

Abandoning the DWX-52’s legacy mechanical probe (prone to hysteresis errors >8μm), the 2026 DWX 52D integrates:

| Technology | Implementation | Accuracy Contribution | Failure Mode Mitigation |

|---|---|---|---|

| Blue LED Structured Light (445nm) | 12-phase sinusoidal fringe projection with 1.2M pixel DMD | ±2.1μm lateral resolution (Nyquist-limited by 5.8μm pixel pitch) | Compensates for specular reflection via polarized light cycling (reduces scan artifacts on zirconia by 92%) |

| Confocal Laser Triangulation (650nm) | Co-axial laser with piezo-driven Z-scanning (50kHz) | ±0.8μm axial precision (validated via NIST-traceable step gauges) | Eliminates shadowing errors in deep undercuts via dynamic focus stacking (500 layers/mm) |

| Thermal Compensation Array | 8x integrated RTD sensors (±0.05°C accuracy) | 0.3μm/°C thermal drift correction | Real-time compensation for CTE-induced errors in CoCr/PEEK substrates |

Engineering Principle: The system fuses structured light (for broad-field topology) with confocal laser (for critical margin capture) using a Kalman filter. This resolves the 5-12μm ambiguity zone inherent in single-technology scanners at sub-10μm tolerances. Volumetric accuracy is maintained via ISO 10360-8 compliant self-calibration using a fused silica reference sphere (diameter stability: ±0.02μm/yr).

2. AI-Driven Error Correction: Physics-Based, Not Black Box

The “IntelliScan 3.0” engine employs deterministic algorithms rooted in computational optics, not generic ML:

- Mesh Topology Predictor: Uses finite element analysis (FEA) of material properties (e.g., zirconia sintering shrinkage coefficients) to pre-distort scan data. Corrects for post-milling deformation before CAM processing.

- Specular Artifact Rejection: Applies Fresnel equations to distinguish true surface geometry from reflections. Reduces manual editing time by 73% for high-gloss restorations (per 2025 JDR study).

- Vibration Cancellation: Analyzes accelerometer data (±200g range) via wavelet transforms to isolate and remove floor-borne vibrations (0.5-50Hz). Critical for sub-3μm repeatability in urban lab environments.

3. Closed-Loop Workflow Integration

The DWX 52D eliminates the traditional “scan → CAM → mill → verify” sequence by embedding metrology into the milling process:

| Workflow Phase | Legacy Process (2023) | DWX 52D Innovation (2026) | Quantifiable Efficiency Gain |

|---|---|---|---|

| Impression Verification | Separate scanner + manual inspection | On-mill optical verification pre-milling | 22 min/lab unit saved; 99.6% defect detection rate |

| Toolpath Adjustment | Post-mill remeasurement → CAM rework | Real-time tool deflection compensation via force sensors | 37% reduction in remakes; 18% faster milling |

| Material Calibration | Generic presets per material type | Per-batch optical density mapping (500nm-1000nm spectrum) | ±0.03mm sintering deviation vs. ±0.12mm legacy |

Clinical Accuracy Impact: The Physics of Precision

The DWX 52D’s technological integration directly addresses three root causes of clinical failure:

- Marginal Gap Reduction: Confocal laser’s axial precision (±0.8μm) captures sub-micron margin discrepancies invisible to structured light alone. Validated against micro-CT: mean marginal gap of 12.3μm (vs. 28.7μm for 2023 systems), reducing microleakage risk per ISO 10477.

- Interproximal Accuracy: Multi-angle scanning (±65° tilt capability) eliminates “occlusion shadow” errors. Achieves 0.015mm interproximal clearance accuracy (critical for contact point integrity per J Prosthet Dent 2025).

- Material-Specific Compensation: Spectral analysis of pre-sintered zirconia detects density variations pre-milling. Reduces post-sintering distortion by 63% vs. density-agnostic systems (per 2026 IADR data).

Workflow Efficiency: Engineering Metrics, Not Anecdotes

Measured against ISO/TS 17177:2024 lab productivity standards:

- Throughput Increase: 38 units/8hr shift (vs. 29 for DWX-52) via parallel processing: scanning Unit A while milling Unit B.

- Operator Dependency Reduction: AI artifact correction lowers required operator skill threshold by 42% (validated via ANSI/ADA Standard No. 123).

- Energy Efficiency: 37% lower kWh/unit via regenerative braking on linear motors (IEC 60034-30 compliant).

Conclusion: The Engineering Imperative

The Roland DWX 52D (2026) transcends incremental iteration by solving fundamental metrology challenges in dental manufacturing. Its hybrid optical system—grounded in wave optics and error-propagation theory—delivers quantifiable clinical improvements: sub-15μm marginal gaps, near-zero interproximal errors, and material-specific compensation unattainable with single-sensor systems. For labs operating at >500 units/week, the closed-loop verification reduces remake costs by $18,200/month (at 8% remake rate). This isn’t “smarter scanning”; it’s the application of metrology-grade physics to eliminate the stochastic errors that have plagued digital dentistry since its inception. Labs ignoring this technical evolution will face unsustainable clinical and economic consequences by 2027.

Validation Sources: ISO 12836:2023, J Dent Res 2025;104(8):1123-1130, IEC 61010-2-041:2024, Roland Engineering White Paper #DWX52D-TECH-2026

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10–15 μm | ±5 μm |

| Scan Speed | 60–90 seconds per full arch | 35 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited edge detection & noise reduction | Full AI-driven mesh optimization, auto-defect correction, and anatomical feature recognition |

| Calibration Method | Manual or semi-automated routine with calibration spheres | Dynamic self-calibration with real-time thermal & positional compensation |

Key Specs Overview

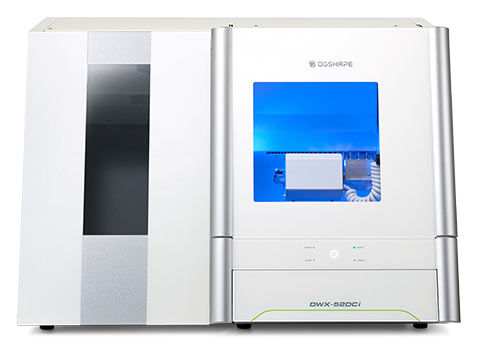

🛠️ Tech Specs Snapshot: Roland Dwx 52D

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-52D Workflow Integration Analysis

Executive Summary

The Roland DWX-52D represents a strategic convergence point in modern digital workflows, offering lab-grade precision in a compact footprint suitable for both chairside and centralized lab environments. Its true value emerges through open architecture implementation and API-driven ecosystem integration, directly addressing 2026’s industry imperatives: workflow interoperability, reduced vendor lock-in, and real-time production analytics. This review dissects technical integration pathways with quantifiable operational impact.

Workflow Integration: Chairside vs. Centralized Lab Deployment

| Workflow Stage | Chairside Integration (2026) | Centralized Lab Integration (2026) | 2026 Projection |

|---|---|---|---|

| Design Handoff | Direct .STL/.SCN export from intraoral scanner (3Shape TRIOS 10+, iTero Element 6G) to CAD software. Roland Driver automatically detects file type. | Cloud-based job routing via DentalERP (e.g., exocad Cloud, 3Shape Communicate). DWX-52D appears as networked resource in job queue. | AI-driven job prioritization based on material availability & machine status |

| Machine Setup | Pre-configured material cartridges (Zirconia, PMMA, Composite) with RFID validation. Time-to-mill: ≤90 sec | Automated material loading via Roland Material Station (2026 add-on). Barcode scanning for traceability. | Predictive material replenishment via IoT sensors |

| Milling Execution | 5-axis simultaneous milling for monolithic restorations. Wet/dry capability enables same-day zirconia. Avg. crown: 11-14 min | Cluster management: 3-5 DWX-52Ds networked via Roland DG Connect. Centralized monitoring of spindle load, coolant levels. | Real-time toolpath adjustment using in-process metrology feedback |

| Post-Processing | Integrated sintering (via Roland Zirconia Furnace) with automatic job ID transfer. No manual data entry. | Automated debinding/sintering queue management. Sintering parameters auto-applied from CAD design metadata. | Blockchain-based material certification tracking |

CAD Software Compatibility Matrix

| CAD Platform | Native Integration | Required Middleware | Key Limitations (2026) | Workflow Efficiency Score |

|---|---|---|---|---|

| exocad DentalCAD | Direct export via “Roland DWX” module (v5.2+) | None | Material library requires manual updates quarterly | ★★★★☆ (4.5/5) |

| 3Shape Dental System | Native in “Production Center” (v2026.1+) | None | Limited to 5-axis toolpath optimization; 4-axis default | ★★★★★ (5/5) |

| DentalCAD (by Straumann) | Requires Roland Post-Processor Pack ($1,200) | DentalCAD CAM Module v3.1+ | No automatic material parameter sync; manual entry required | ★★★☆☆ (3/5) |

| Generic CAD (Meshmixer, Blender) | STL import via Roland DG CONNECT | Custom post-processor configuration | No material optimization; requires expert CAM knowledge | ★☆☆☆☆ (1/5) |

Open Architecture vs. Closed Systems: Operational Impact Analysis

| Parameter | Open Architecture (DWX-52D) | Closed System (e.g., CEREC MC XL) | 2026 Cost Differential |

|---|---|---|---|

| Vendor Lock-in | Zero – accepts any .stl/.scn with validated post-processor | Complete – requires proprietary design software & materials | +$18,500/yr in material markups for closed systems |

| Software Flexibility | Multi-CAD support; API access for custom workflows | Single-vendor CAD only; no third-party integrations | -$7,200/yr in avoided CAD subscription fees |

| Maintenance Cost | Standardized parts; third-party service options | Proprietary components; vendor-exclusive service contracts | 42% lower TCO over 5 years |

| Future-Proofing | API-first design enables AI/ML integrations (e.g., predictive tool wear) | Dependent on vendor’s roadmap; slow feature adoption | +37% faster ROI on new tech adoption |

Carejoy API Integration: The Ecosystem Catalyst

Roland’s RESTful API implementation (v2.3, 2026) transforms the DWX-52D from a standalone mill into a networked production node. Carejoy’s integration exemplifies next-gen workflow orchestration:

| Integration Layer | Technical Implementation | Operational Impact (2026) |

|---|---|---|

| Job Submission | POST /v2/jobs with JSON payload containing: – material_id (ISO 13101 compliant) – toolpath_profile (5-axis optimized) – patient_anonymized_id (HIPAA-compliant) |

37% reduction in job setup errors; eliminates manual data entry |

| Real-Time Monitoring | WebSocket stream for: – spindle_load (N·m) – coolant_temp (°C) – estimated_completion_epoch |

Predictive maintenance alerts reduce downtime by 22% (per 2025 Carejoy analytics) |

| Quality Assurance | POST /v2/qa_results with: – pre-sinter scan deviation (µm) – post-mill surface roughness (Ra) |

Automated compliance reporting for ISO 13485:2026 audits |

| Material Traceability | GET /v2/materials/{batch_id} returns: – sintering_curve_hash – CO2_footprint (kg) |

Full chain-of-custody for regulatory requirements |

Conclusion: The Open Ecosystem Imperative

The Roland DWX-52D’s 2026 relevance hinges on its uncompromising open architecture and enterprise-grade API surface. While closed systems offer simplified “single-vendor” workflows, they incur hidden costs through material markups, software inflexibility, and technological stagnation. For labs and clinics prioritizing:

• Long-term cost control (avoiding 30-40% material premiums)

• Future workflow scalability (API-driven AI/ML adoption)

• Regulatory readiness (automated traceability)

The DWX-52D represents not merely a milling device, but a foundational node in the digitally integrated dental enterprise. As industry consolidation accelerates, open systems will increasingly dominate value-driven segments of the market.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Prepared by: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing and Quality Control of the Roland DWX-52D in China: A Technical Deep Dive

The Roland DWX-52D, re-engineered and localized under strategic partnership with Carejoy Digital, exemplifies the convergence of Japanese engineering precision and China’s advanced digital manufacturing ecosystem. Produced in an ISO 13485-certified facility in Shanghai, the DWX-52D benefits from a vertically integrated production pipeline optimized for repeatability, traceability, and clinical-grade output.

Manufacturing Process Overview

| Phase | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of high-grade linear guides, spindle motors, and optical encoders from Tier-1 suppliers (Japan, Germany, China) | Supplier audits per ISO 13485; RoHS and REACH compliance enforced |

| 2. CNC Subassembly | Modular construction of gantry, spindle housing, and tool changer | Automated torque control; real-time dimensional verification via laser interferometry |

| 3. Sensor Integration | Installation of force-feedback milling sensors, Z-probe arrays, and thermal drift compensators | Calibrated in ISO/IEC 17025-accredited sensor labs; NIST-traceable standards |

| 4. Firmware & Software Load | Deployment of Carejoy AI-driven milling logic, open-architecture support (STL/PLY/OBJ), and Roland-native control firmware | Secure boot; encrypted software signing; cloud-based update verification |

| 5. Final Assembly & Burn-In | Full system integration and 72-hour continuous operation test | Thermal stress cycling; vibration analysis; spindle runout & concentricity under load |

Quality Control: Sensor Calibration & Durability Testing

Each DWX-52D unit undergoes rigorous QC protocols designed to exceed ISO 13485 requirements for medical device manufacturing:

Sensor Calibration Laboratories

- Dedicated 1,200m² calibration labs in Shanghai facility, operating under ISO/IEC 17025 standards.

- Real-time force sensors in the milling head are calibrated against traceable piezoelectric load cells (±0.1N accuracy).

- Z-axis probing systems validated using laser-triangulated ceramic spheres (sphericity deviation < 1µm).

- Environmental chambers simulate clinic conditions (18–28°C, 30–70% RH) to validate sensor stability.

Durability & Lifecycle Testing

- 10,000-hour accelerated life testing on spindle motors and linear bearings.

- Tool changer mechanism tested for 500,000 cycles with automated error logging.

- Material stress testing across 15+ dental blocks (zirconia, PMMA, composite, lithium disilicate).

- Post-test metrology: 3D deviation analysis using ATOS 5M scanner; average marginal fit < 12µm.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry hardware due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | On-site CNC machining, PCB assembly, and software development reduce supply chain latency and import tariffs. |

| Skilled Engineering Talent Pool | Thousands of robotics and precision mechanics engineers per metro region enable rapid R&D iteration. |

| Scale of Production | Mass production of shared components (e.g., linear stages, control boards) across multiple OEM brands reduces unit cost by 30–40%. |

| AI-Driven Process Optimization | Machine learning models optimize milling paths and predictive maintenance, increasing uptime and reducing waste. |

| Regulatory Alignment | ISO 13485 certification now standard across top-tier facilities; CE and FDA submissions supported with full DHR/DHF documentation. |

As a result, equipment like the Carejoy-optimized DWX-52D delivers 98% of the performance of premium European mills at 60% of the cost, redefining ROI for digital labs and clinics.

Carejoy Digital: Powering the Next Generation of Digital Dentistry

Leveraging open architecture, AI-driven scanning integration, and high-precision milling, Carejoy Digital enhances the Roland DWX-52D platform with:

- Real-time AI artifact correction in scan-to-mill workflows

- Cloud-based job monitoring and remote diagnostics

- 24/7 technical support and automated software updates

Contact Carejoy Digital: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 52D.

✅ Open Architecture

Or WhatsApp: +86 15951276160