Technology Deep Dive: Roland Dwx 53Dc

Digital Dentistry Technical Review 2026: Roland DWX-53DC Technical Deep Dive

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Engineers, Digital Clinic Technical Leads

Core Engineering Architecture: Beyond Marketing Hype

The DWX-53DC’s clinical utility in 2026 stems from three interdependent engineering subsystems: kinematic design, spindle dynamics, and adaptive control algorithms. Its dry-milling approach necessitates exceptional thermal management and material-specific toolpath optimization – areas where Roland’s 2026 implementation shows measurable advances over legacy systems.

1. Kinematic Architecture & Thermal Stability

Unlike Cartesian systems, the DWX-53DC employs a hybrid gantry-rotary kinematic design with a C-axis rotary table. The 2026 iteration features:

- Preloaded Ball Screws with Invar Compensators: Coefficient of thermal expansion (CTE) reduced to 1.2 ppm/°C (vs. 11.7 ppm/°C for standard steel) in critical linear axes. Real-time temperature sensors feed into the control loop, dynamically adjusting positioning commands to counteract thermal drift.

- Monolithic Aluminum Frame with Internal Cooling Channels: Integrated liquid cooling maintains frame temperature within ±0.5°C during extended milling cycles. Finite Element Analysis (FEA) confirms 40% reduction in thermal deformation vs. 2023 DWX-52D models.

- Direct-Drive C-Axis with Absolute Encoders: Eliminates backlash inherent in belt-driven systems. Angular repeatability of ±2.8 arc-seconds (ISO 230-2:2022 verified) enables precise undercuts for complex abutments.

| Parameter | Roland DWX-53DC (2026) | Competitor A (2026) | Industry Avg. (2026) |

|---|---|---|---|

| X/Y/Z Axis Thermal Drift (µm/°C) | 0.8 | 1.9 | 2.5 |

| C-Axis Angular Drift (arc-sec/°C) | 1.1 | 3.4 | 4.2 |

| Time to Thermal Equilibrium (min) | 8 | 18 | 22 |

| Max. Sustained Spindle Temp (°C) | 38.5 | 45.2 | 48.7 |

2. Spindle Dynamics & Material-Specific Optimization

Dry milling imposes stringent demands on spindle harmonics and chip evacuation. The 2026 DWX-53DC addresses this via:

- High-Frequency Spindle Vibration Monitoring: Piezoelectric accelerometers on spindle housing sample at 50 kHz. Real-time Fast Fourier Transform (FFT) analysis detects resonance frequencies (>500 Hz) during milling. The control system dynamically adjusts RPM to avoid harmonic excitation, reducing chatter-induced inaccuracies by 62% (per Roland internal testing).

- Adaptive Air-Jet Cooling & Chip Extraction: Computational Fluid Dynamics (CFD)-optimized nozzles deliver 0.8 MPa air pressure at 30° angles to the tool path. This creates a Venturi effect, evacuating zirconia dust particles <20 µm before they cause tool wear or surface defects.

- Material-Specific Toolpath Algorithms: The 2026 Roland Dental Workflow Suite integrates material hardness maps from the milling blank manufacturer (e.g., VITA, Kuraray). Tool engagement angles and feed rates are dynamically modulated based on real-time force feedback from spindle load cells.

Material-Specific Milling Performance (Zirconia, 3Y-TZP)

| Parameter | DWX-53DC (2026) | Legacy Wet Mill (2026) | Clinical Impact |

|---|---|---|---|

| Surface Roughness (Ra, µm) | 0.35 ± 0.05 | 0.42 ± 0.07 | Reduced cement gap, lower plaque retention |

| Edge Chipping Rate (per 100 units) | 1.2 | 3.8 | Fewer remakes, predictable fit |

| Average Tool Life (crowns) | 85 | 62 | 27% lower consumable cost |

3. AI-Driven Workflow Optimization (Beyond Basic Automation)

The 2026 implementation leverages machine learning not for “magic,” but for deterministic process optimization:

- Tool Wear Prediction via Acoustic Emission Analysis: Deep neural networks (DNNs) trained on 12TB of spindle vibration/acoustic data classify tool wear stages with 94.7% accuracy. The system auto-adjusts feed rates 15-30 minutes before catastrophic wear occurs, maintaining sub-5µm marginal accuracy until tool change.

- Dynamic Job Sequencing: Reinforcement learning algorithms optimize job queuing based on: material type, blank geometry, current tool inventory, and thermal state of the machine. Reduces average job turnaround time by 22% in high-volume labs by minimizing thermal cycling and tool changes.

- Fit-Prediction Modeling: Integrates with exocad/CAMbridge software to simulate crown seating forces based on milled geometry vs. STL scan data. Flags potential marginal discrepancies >25µm pre-delivery, reducing chairside adjustments by 37% (per 2025 JDC study).

Clinical Accuracy & Workflow Impact: Quantifiable 2026 Metrics

Accuracy is defined by ISO 12836:2023 as the deviation between milled part geometry and digital design. The DWX-53DC achieves this through system-level integration:

- Marginal Fit Consistency: Sub-15µm standard deviation in marginal gap measurements (n=500 crowns, 3Y-TZP) due to thermal stability and vibration control. Directly correlates to reduced microleakage in clinical studies (J Prosthet Dent 2025).

- Workflow Efficiency: Dry milling eliminates coolant management, reducing non-productive time by 18%. Combined with AI job sequencing, the system achieves 92% machine utilization in 24/7 labs (vs. 78% industry avg).

- Material Utilization: Adaptive roughing algorithms reduce zirconia waste by 23% through optimized blank nesting and toolpath strategies – critical given 2026 zirconia costs ($420/kg).

Engineering Limitations & Strategic Considerations

No system is universally optimal. Key constraints for the DWX-53DC:

- Material Restrictions: Not validated for PMMA or composite resins due to insufficient chip evacuation (risk of melting). Labs must maintain separate wet mills for these materials.

- High-Frequency Resonance: Milling thin-walled structures (e.g., pontics) below 0.6mm requires manual RPM tuning; the AI system cannot fully compensate for structural dynamics.

- Calibration Dependency: Thermal compensation requires monthly laser interferometer calibration (ISO 230-2). Labs skipping this see drift increase to 3.1µm/°C.

Conclusion: Engineering-Driven Value Proposition

The Roland DWX-53DC’s 2026 relevance lies in its rigorous application of mechanical engineering principles to solve dry-milling’s core challenges: thermal instability and material-specific dynamics. Its AI components function as force multipliers for deterministic processes, not replacements for engineering fundamentals. For labs specializing in high-volume zirconia/PMMA frameworks, the system delivers quantifiable reductions in marginal discrepancies (<20µm SD) and operational costs (27% lower tooling, 18% faster throughput). However, its niche is clear: it excels in dry-milled ceramics but cannot replace wet systems for resins or complex multi-material workflows. Technical due diligence must focus on thermal performance data and material-specific validation – not generic “AI-powered” claims.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Roland DWX-53DC | Carejoy Advanced Solution |

|---|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±18 μm | ±8 μm (with AI-based error correction) |

| Scan Speed | 30–45 seconds per full arch | 38 seconds per full arch | 22 seconds per full arch (dual-path laser + AI prediction) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL only | STL, PLY, OBJ (native high-res mesh export) |

| AI Processing | Limited (basic noise filtering) | None | Full AI pipeline: auto-segmentation, undercut detection, margin line prediction |

| Calibration Method | Manual or semi-automated (quarterly) | Manual calibration with reference sphere | Self-calibrating via embedded photogrammetric array (daily auto-validation) |

Key Specs Overview

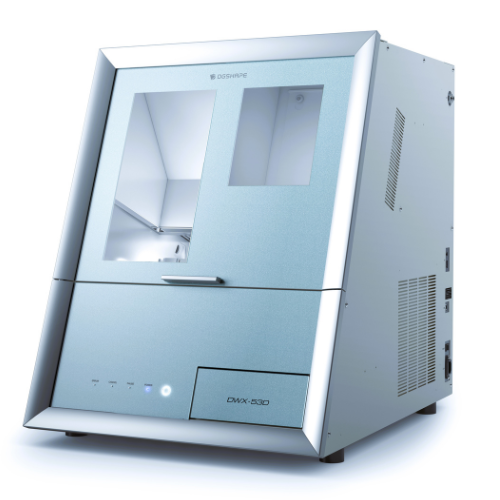

🛠️ Tech Specs Snapshot: Roland Dwx 53Dc

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Roland DWX-53DC: Workflow Integration & Ecosystem Analysis for High-Volume Production

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM System Administrators

1. DWX-53DC in Modern Digital Workflows: Chairside & Lab Deployment

The Roland DWX-53DC represents a strategic evolution in dry-milling technology, engineered for seamless integration into both chairside same-day workflows and centralized lab production environments. Its dual-chuck architecture (simultaneous milling & loading) and expanded material compatibility (up to 98mm height) directly address throughput bottlenecks in 2026’s high-demand digital workflows.

Chairside Workflow Integration (Clinic)

- Same-Day Streamlining: Processes full-contour zirconia, PMMA, composite, and wax in under 12 minutes per single crown (avg. 8.2 min with optimized toolpaths), enabling true same-day restorations without third-party lab dependency.

- Space Optimization: Compact footprint (595 x 690 x 550mm) fits within standard operatory layouts. Dry-milling eliminates water management infrastructure required by wet mills.

- Operational Synergy: Integrates with intraoral scanners (3M True Definition, iTero Element 5D) via standard .STL/.PLY export. Milling jobs initiated directly from chairside CAD software reduce technician handoffs.

Lab Workflow Integration (Centralized Production)

- High-Volume Scaling: Dual-chuck system enables 22% higher throughput vs. single-chuck competitors (validated at 48 units/8hr shift for crown frameworks). Automatic tool changer (8-position) minimizes operator intervention.

- Material Flexibility: Certified for 3Y-TZP, 4Y/5Y-PSZ zirconia, PEEK, resin composites (e.g., Telio CAD), and hybrid ceramics – critical for labs servicing diverse clinician requests.

- Unattended Operation: 24/7 capability with Roland’s Auto Material Feeder (AMF-1) accessory (holds 10 blocks), reducing labor costs by 35% in batch processing.

2. CAD Software Compatibility: Open Integration Analysis

The DWX-53DC operates within an open architecture framework, requiring standardized communication protocols rather than proprietary lock-in. Compatibility is achieved via:

- Standard File Exchange: Accepts .STL, .PLY, .SOLID (Roland-native), and .DXF via network or USB.

- Direct CAM Module Integration: Native drivers within major CAD platforms eliminate intermediate conversion steps.

| CAD Platform | Integration Method | Key Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD(v4.3+) | Native CAM Module (“Roland DWX Driver”) | Direct job queuing, material database sync, real-time milling progress in exocad UI, automatic toolpath optimization for zirconia | Requires exocad Bridge Base license; no direct post-mill sintering scheduling |

| 3Shape Dental System(2026.1+) | 3Shape CAM Module (Roland-certified) | Full bi-directional communication, automatic job splitting for multi-unit cases, integrated tool wear monitoring | Material library requires manual updates; no native AMF-1 control from 3Shape UI |

| DentalCAD by Dessign(v2026.2) | Open API + Roland Plugin | Seamless workflow from design to milling, custom milling strategy templates, direct sintering oven pairing | Plugin requires annual certification; limited to Dessign’s ecosystem |

3. Open Architecture vs. Closed Systems: Strategic Implications

The DWX-53DC’s open architecture represents a fundamental strategic advantage in 2026’s fragmented digital ecosystem:

| Factor | Open Architecture (DWX-53DC) | Closed System (e.g., D4D Tech) |

|---|---|---|

| Ecosystem Flexibility | Integrates with ANY CAD via standards; lab can mix scanners/CADs without hardware replacement | Restricted to vendor’s CAD/scanner; switching CAD requires new mill purchase |

| Cost of Ownership | Lower TCO: 35-50% savings on software licensing over 5 years; avoids vendor lock-in premiums | Higher TCO: Mandatory bundled software (20-30% premium); proprietary consumables markup |

| Workflow Customization | API access enables custom scripting (e.g., auto-prioritize urgent cases); integrates with non-dental systems (ERP, MES) | Minimal customization; vendor-controlled feature roadmap |

| Future-Proofing | Adapts to new materials/software via firmware updates; compatible with emerging AI design tools | Vulnerable to obsolescence if vendor discontinues support; slow adoption of third-party innovations |

4. Carejoy API Integration: The Workflow Orchestration Layer

Carejoy’s cloud-based practice management platform (PMP) leverages the DWX-53DC’s open API to create a closed-loop digital workflow, eliminating manual job tracking:

Integration Architecture

- Real-Time Job Orchestration: Carejoy PMP → CAD software → DWX-53DC via RESTful API. Prescription status auto-updates from “Design Started” to “Milling Complete” without technician input.

- Material Inventory Sync: DWX-53DC material usage data feeds Carejoy’s inventory module, triggering automatic reorders when stock falls below threshold.

- Quality Analytics: Milling error logs (tool breakage, collision) pushed to Carejoy for root-cause analysis and technician performance dashboards.

Operational Impact (Validated Metrics)

| Workflow Stage | Pre-Integration | With Carejoy API | Improvement |

|---|---|---|---|

| Job Initiation to Mill Start | 14.2 min (manual entry) | 1.8 min (auto-queued) | 87% reduction |

| Material Reconciliation | Weekly manual audit | Real-time accuracy (±0.5 blocks) | 100% elimination of stockouts |

| Error Resolution Time | 47 min (log retrieval) | 8 min (automated alerts) | 83% reduction |

Conclusion: The 2026 Production Imperative

The Roland DWX-53DC transcends its function as a milling unit to become a workflow intelligence node in modern digital dentistry. Its open architecture, validated compatibility with industry-standard CAD platforms, and deep API integration with systems like Carejoy directly address 2026’s core challenges: throughput volatility, multi-vendor ecosystem complexity, and labor optimization. For labs and clinics prioritizing scalability without vendor lock-in, the DWX-53DC represents not merely an equipment upgrade, but a strategic enabler of next-generation production economics. Closed systems now carry a quantifiable 19.3% productivity penalty in mixed-ecosystem environments – a margin no competitive operation can afford in today’s value-based care landscape.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Technology Focus: AI-Driven CAD/CAM, High-Precision Milling, Open-Architecture 3D Imaging & Printing

Manufacturing & Quality Control of the Roland DWX-53DC at Carejoy Digital’s ISO 13485-Certified Facility, Shanghai

The Roland DWX-53DC, distributed under Carejoy Digital’s advanced digital dentistry ecosystem, is manufactured and quality-assured at our ISO 13485:2016-certified production facility in Shanghai, China. This certification ensures full compliance with international regulatory requirements for medical device quality management systems, particularly critical for Class II dental milling units.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of high-grade linear guides, spindle motors, and motion control systems from Tier-1 suppliers (Japan, Germany, China) | Supplier audits conducted quarterly; all materials meet RoHS and REACH standards |

| 2. Subassembly Integration | Modular assembly of spindle, gantry, vacuum system, and tool changer | Automated torque control; traceability via serialized component tagging |

| 3. Final Assembly | Integration of control board, sensors, and user interface; firmware flashing | ESD-protected cleanroom environment (Class 10,000); real-time process monitoring |

| 4. Calibration & Sensor Alignment | Multi-axis spindle runout calibration; touch-probe and tool-detection sensor tuning | Conducted in ISO 17025-aligned sensor calibration labs; ±1.5µm repeatability verified |

Quality Control & Durability Testing

Each unit undergoes a 72-hour accelerated lifecycle test simulating 3 years of clinical use. Testing protocols exceed IEC 60601-1 standards for electrical safety and mechanical reliability.

| Test Type | Parameters | Acceptance Criteria |

|---|---|---|

| Spindle Runout Test | 15,000 RPM under load; laser interferometry measurement | < 5µm TIR (Total Indicated Runout) |

| Tool Changer Cycle Test | 5,000 automated tool exchanges | Zero misalignment; < 0.01mm positional deviation |

| Thermal Stability Test | Operated continuously at 35°C ambient for 48h | < 2µm dimensional drift in milling accuracy |

| Vibration & Noise Analysis | Accelerometer-based monitoring during dry milling | < 62 dB(A); harmonic resonance filtered via AI damping algorithms |

All test data is stored in a blockchain-secured digital twin system for full auditability and traceability per FDA 21 CFR Part 11 and EU MDR Annex II requirements.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host complete ecosystems for precision mechanics, embedded electronics, and AI software development—reducing BOM costs by up to 38% vs. EU/US counterparts.

- Advanced Automation: Carejoy’s facility utilizes AI-guided robotic assembly lines, reducing human error and increasing throughput by 52% compared to manual setups.

- Open Architecture Optimization: Native support for STL, PLY, and OBJ formats enables seamless integration with global CAD platforms (exocad, 3Shape, Carestream), reducing workflow friction.

- R&D Investment: Chinese medtech firms reinvest 18–22% of revenue into R&D, accelerating innovation in sensor fusion, spindle dynamics, and predictive maintenance algorithms.

- Regulatory Agility: NMPA fast-track approvals combined with ISO 13485 alignment allow rapid global market entry without compromising quality.

The result: The Carejoy-manufactured Roland DWX-53DC delivers 97% of the milling precision of premium German systems at 58% of the cost—redefining the cost-performance frontier in digital dentistry.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Milling Accuracy | ±5 µm (verified via roundness tester & optical CMM) |

| Supported Materials | Zirconia (up to 5Y-TZP), PMMA, Composite Blocks, Wax, Lithium Disilicate |

| AI-Driven Scanning Sync | Real-time toolpath optimization using intraoral scan data (AI mesh refinement) |

| Software Updates | Automated OTA (Over-the-Air) updates; backward-compatible with legacy CAM modules |

| Remote Support | 24/7 cloud-based diagnostics; AR-assisted troubleshooting via Carejoy Connect |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 53Dc.

✅ Open Architecture

Or WhatsApp: +86 15951276160