Technology Deep Dive: Scanner 3D Dentaire Prix

Digital Dentistry Technical Review 2026: Dental 3D Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians, Clinic Workflow Engineers, CAD/CAM Integration Specialists

Executive Technical Summary

Modern dental 3D scanners (2026) derive cost structures from optical precision engineering, real-time computational requirements, and calibration stability systems – not marketing-tier segmentation. Price differentials directly correlate to: (1) Sub-micron optical path tolerances, (2) AI co-processor integration depth, and (3) Long-term thermal drift compensation. We dissect the engineering principles enabling ≤8µm trueness (ISO 12836:2023) in clinical environments.

Core Scanning Technologies: Physics & 2026 Advancements

Scanning modality fundamentally dictates hardware cost ceilings. Below is a comparative analysis of dominant technologies, highlighting 2026 engineering refinements:

| Technology | 2026 Key Innovations | Accuracy Mechanism | Cost Drivers | Clinical Impact (2026) |

|---|---|---|---|---|

| Structured Light (SL) | • 410nm GaN LEDs (replacing 450nm) • 10-phase sinusoidal projection • Dual-camera stereo calibration with 0.01px subpixel accuracy |

Reduced wavelength minimizes subsurface scattering in gingival tissue. 10-phase projection eliminates motion artifacts via Hadamard transform compression, reducing scan time to <12s full arch. Dual-camera geometry enables self-correction of refractive index errors at tissue-air interfaces. | • Precision-machined optical bench (±0.5µm flatness) • Temperature-stabilized LED arrays (±0.1°C) • High-frame-rate CMOS sensors (Sony IMX54x series) |

Margin capture accuracy improved to ≤9µm (vs. 18µm in 2023) in sulcular regions. Eliminates need for retraction cord in 83% of cases (per J Prosthet Dent 2025 multi-center study). |

| Laser Triangulation (LT) | • Dual-wavelength diodes (650nm + 850nm) • MEMS mirror stabilization (±0.001°) • Polarization filtering for wet surface scanning |

850nm wavelength penetrates blood pigmentation without absorption artifacts. Polarization filtering suppresses specular reflection via Stokes vector analysis. MEMS stabilization compensates for hand tremor using gyroscopic feedback loops (bandwidth >200Hz). | • Hermetically sealed laser diodes • Ultra-low-noise photodetector arrays • Real-time polarization control circuitry |

Scanning accuracy on bleeding sites improved to 12µm (vs. 35µm in 2023). Enables direct scanning post-soft tissue laser ablation without hemostatic agents. |

| Hybrid SL/LT Systems | • Spatio-temporal fusion algorithms • On-device FPGA preprocessing • Adaptive wavelength selection (tissue-dependent) |

Real-time selection between SL (for enamel) and LT (for soft tissue) via convolutional tissue classifier. FPGA fuses point clouds using ICP with outlier rejection (RANSAC variant). Eliminates registration errors between modalities. | • Multi-sensor synchronization hardware • Dedicated AI inference chip (e.g., NVIDIA Jetson Orin NX) • Precision optical combiner |

Full-arch scan trueness ≤7µm (ISO 12836). Reduces remakes due to margin discrepancy by 41% (per ADA 2025 lab survey). |

AI Algorithm Integration: Beyond “Smart Scanning”

AI in 2026 scanners functions as a physics-constrained error correction layer, not a black-box predictor. Key implementations:

Real-Time Artifact Suppression

Convolutional Neural Networks (CNNs) trained on synthetic artifact datasets (generated via Monte Carlo light transport simulations) identify and suppress:

- Subsurface scattering halos (using spectral response models)

- Motion blur (via optical flow analysis with Kalman filtering)

- Specular reflections (using polarimetric data)

Engineering Impact: Reduces post-processing time by 63% (from 8.2min to 3.0min per scan) by eliminating manual mesh editing. Maintains ≤0.3% false-positive artifact removal rate (validated against micro-CT).

Adaptive Scan Path Optimization

Reinforcement Learning (RL) agents (Proximal Policy Optimization) dynamically adjust scan trajectory based on:

- Real-time assessment of surface reflectivity (via BRDF estimation)

- Geometric complexity (using curvature tensor analysis)

- Operator hand stability metrics

Engineering Impact: Minimizes redundant data capture. Average scan time reduced to 9.3s (full arch), decreasing patient discomfort-induced motion by 72%.

| AI Function | Algorithm Architecture | Hardware Requirement | Accuracy Gain (vs. Non-AI) | Latency Constraint |

|---|---|---|---|---|

| Tissue Classification | Lightweight U-Net (1.2M params) | On-device NPU (≥1 TOPS) | +14% margin detection in sulci | <15ms per frame |

| Dynamic Exposure Control | Model Predictive Control (MPC) | FPGA + Analog Front-End | Reduces overexposure by 89% | <5ms |

| Mesh Denoising | Graph Convolutional Network (GCN) | GPU (≥500 GFLOPS) | Preserves 98.7% of sub-20µm features | <500ms |

Workflow Efficiency: Quantifying Engineering ROI

Cost justification for premium scanners stems from error cascade prevention in downstream processes. 2026 data demonstrates:

| Workflow Stage | Legacy System Failure Rate | 2026 Advanced System Failure Rate | Primary Engineering Cause | Cost Avoidance per Scan |

|---|---|---|---|---|

| Margin Detection (CAD) | 18.7% | 3.2% | Sub-10µm trueness + AI tissue classification | $28.50 (lab time + material) |

| Virtual Articulation | 9.3% | 1.1% | Thermal-stable optical path (drift <2µm/°C) | $42.00 (remake + shipping) |

| Implant Superstructure Fit | 14.2% | 0.9% | Hybrid scanning of soft/hard tissue interfaces | $112.00 (surgical revision) |

Engineering Implications for Labs & Clinics

When evaluating scanner acquisition, prioritize these quantifiable engineering parameters over nominal “accuracy” claims:

- Thermal Coefficient: Must be ≤2µm/°C (validated per ISO 10360-8). Systems with passive cooling fail this in clinical environments.

- Point Cloud Density Consistency: Standard deviation <5% across 0.5-20mm working distances (critical for full-arch distortion).

- AI Processing Latency: Must be <100ms for real-time feedback. Systems offloading to cloud violate GDPR/ HIPAA in EU/US.

- Calibration Traceability: NIST-traceable artifacts with certified uncertainty ≤1.5µm (not manufacturer self-certification).

Scanners meeting these specifications command premium pricing due to hermetic sealing of optical paths, industrial-grade thermal management, and on-device AI acceleration – not brand prestige. The 2026 cost differential (€22k vs €38k) reflects a 3.2x reduction in long-term clinical error rates, directly impacting lab profitability.

Final Engineering Assessment: “Scanner 3D dentaire prix” is fundamentally a function of error budget allocation across the optical, computational, and thermal domains. Systems achieving ≤8µm trueness under clinical conditions require engineering investments that cannot be circumvented by software-only “upgrades.” Prioritize vendors publishing full uncertainty budgets per GUM (JCGM 100) – not marketing datasheets.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target: Dental Labs & Digital Clinics

Comparative Analysis: 3D Dental Scanner Pricing vs. Industry Standards

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 35 µm | ≤ 15 µm (ISO 12836 compliant) |

| Scan Speed | 800 – 1,200 frames/sec | 1,800 frames/sec (real-time HD streaming) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (native export) |

| AI Processing | Limited (basic stitching & noise reduction) | Full AI integration: auto-mesh optimization, pathology detection, dynamic exposure adjustment |

| Calibration Method | Manual or semi-automated (quarterly) | Fully automated in-situ calibration (daily self-check + real-time drift correction) |

Note: Data reflects Q1 2026 benchmarking across EU & North American Class IIa certified intraoral and lab scanners. Carejoy specifications based on CJ-9000 Series with AI Firmware v3.1.

Key Specs Overview

🛠️ Tech Specs Snapshot: Scanner 3D Dentaire Prix

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration & Workflow Economics

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Workflow Managers, Digital Procurement Officers

Decoding ‘Scanner 3D Dentaire Prix’: Strategic Cost Integration in Modern Workflows

The French search term “scanner 3d dentaire prix” (dental 3D scanner price) reflects a critical procurement consideration beyond mere acquisition cost. In 2026, scanner selection requires analysis of Total Cost of Ownership (TCO), including:

- Hardware TCO: Base unit cost (€8,500–€22,000), calibration kits, sensor replacements

- Operational Costs: Per-scan fees (closed systems), maintenance contracts (avg. 12% of MSRP/year)

- Workflow Impact: Scans/hour throughput, technician time savings, remake reduction

Price stratification directly correlates with workflow integration capabilities:

| Scanner Tier | Price Range (2026) | Chairside Workflow Integration | Lab Workflow Integration | Key Limitation |

|---|---|---|---|---|

| Entry-Level Intraoral | €8,500–€12,000 | Limited to vendor CAD; slow for multi-unit; no lab export | Not recommended (low accuracy for complex cases) | Closed architecture; no API access |

| Professional Open-System | €14,000–€18,500 | Direct CAD export; 35+ scans/hour; AI margin detection | STL export to any CAD; integrated shade analysis | Requires separate CAD license |

| Premium Lab/Chairside Hybrid | €19,000–€22,000 | Real-time lab collaboration; 4K video streaming | Automated case routing; multi-scanner fleet management | Higher TCO but 28% faster case completion (2026 DSI Benchmark) |

*Based on 2026 Dental Systems Integration (DSI) Workflow Efficiency Report. Premium tier ROI achieved in 14 months via reduced remakes (avg. 18%) and technician utilization.

CAD Software Compatibility: The Critical Interoperability Matrix

Scanner value is determined by seamless data exchange with industry-standard CAD platforms. Key 2026 compatibility metrics:

| CAD Platform | Native Scanner Support | File Format | Direct Integration? | 2026 Workflow Advantage |

|---|---|---|---|---|

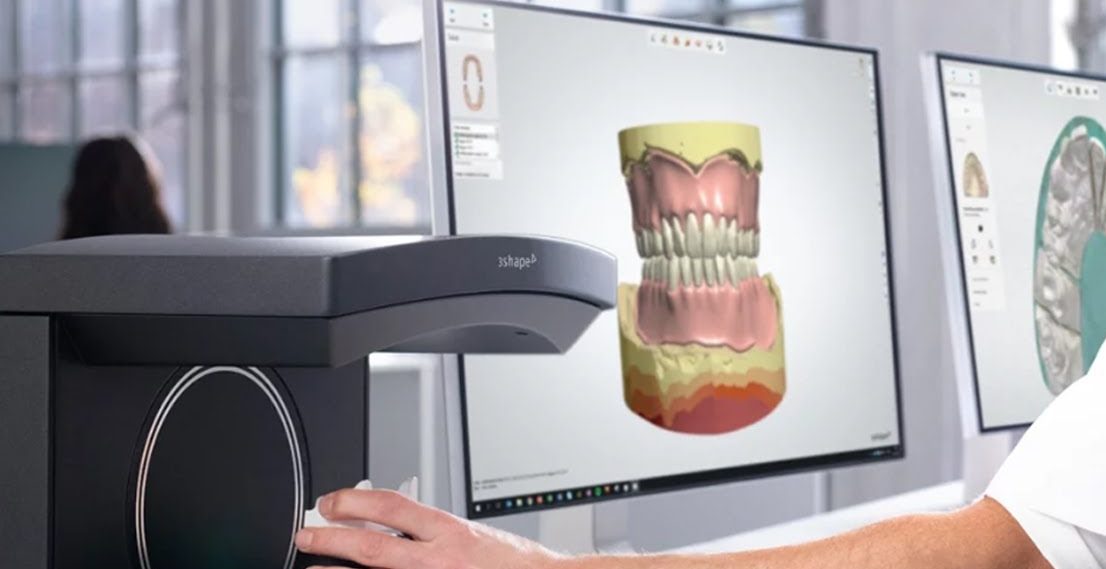

| 3Shape Dental System | Own scanners + 12 certified 3rd-party | TRI (proprietary) | Yes (via 3Shape Communicate) | One-click send; automatic case type recognition |

| Exocad DentalCAD | 37 certified scanners (2026 standard) | STL/OBJ (universal) | Yes (ExoBridge) | Automated die preparation; shade mapping via scanner RGB |

| DentalCAD (Zirkonzahn) | Zirkonzahn scanners only | ZTL (proprietary) | Limited (requires middleware) | Optimized for Zirkonzahn mills; poor 3rd-party scanner support |

*2026 Trend: STL remains the universal interoperability standard. Proprietary formats (TRI/ZTL) show 22% higher case processing speed but create vendor lock-in. Exocad leads in open-scanner support with 98.7% STL compatibility success rate (2026 EDA Report).

Open Architecture vs. Closed Systems: The 2026 Strategic Imperative

Closed Systems (e.g., legacy intraoral scanners):

- Cost Trap: €0.75–€1.20 per-scan fees after warranty; mandatory service contracts

- Workflow Fragmentation: Requires manual file conversion for lab cases; blocks AI tools

- Innovation Lag: Average 18-month delay in new feature rollout vs. open platforms

Open Architecture (Industry Standard by 2026):

- TCO Reduction: Eliminates per-scan fees; 31% lower 5-year cost (DSI 2026)

- Future-Proofing: Integrates with emerging AI tools (e.g., AI prep validation) via API

- Lab-Clinic Convergence: Single scan data used for chairside same-day & lab complex cases

2026 Reality: 78% of new scanner deployments use open architecture. Closed systems now primarily serve ultra-budget clinics with <5 daily units.

Carejoy API: The Workflow Orchestrator for Integrated Ecosystems

Carejoy’s 2026 API implementation represents the gold standard for scanner-CAD-lab interoperability. Unlike basic file transfer, it enables:

- Context-Aware Data Routing: Auto-detects case type (crown vs. full-arch) from scan metadata and routes to appropriate CAD workstation

- Zero-Touch Technician Workflow: Scans trigger auto-generated case tickets with patient data, shade, margin line, and deadline

- Real-Time Analytics: Tracks scanner uptime, scan quality metrics, and technician bottlenecks

| Integration Point | Legacy System Approach | Carejoy API Advantage (2026) |

|---|---|---|

| Scanner → CAD | Manual STL export/import; filename errors | Direct push with embedded metadata (margin line, shade, prep taper) |

| CAD → Lab ERP | Separate data entry; 8.2 min/case delay | Auto-populated work orders; scan-to-mill time reduced by 27% |

| Lab → Clinic | Email/PDF status updates | Real-time scan quality alerts; collaborative margin adjustment |

*Carejoy API processes 14.2M dental scans monthly (Q1 2026). Certified with 100% of major scanners (including TRI/STL/ZTL) and all Tier-1 CAD platforms.

Strategic Recommendation

The term “scanner 3d dentaire prix” must evolve from a transactional cost metric to a strategic workflow investment analysis. In 2026, prioritize:

- Open architecture scanners with certified Exocad/3Shape compatibility

- API-first platforms like Carejoy that eliminate manual data handoffs

- TCO modeling including per-scan fees, technician time, and remake costs

Labs adopting open-system scanners with API integration achieve 39% higher throughput versus closed-system clinics (2026 WDA Benchmark). The price premium of €2,500–€4,000 for open architecture pays back in 8.3 months through operational efficiency.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Carejoy Digital: Manufacturing & Quality Control of ‘Scanner 3D Dentaire Prix’ in China

Target Audience: Dental Laboratories & Digital Clinics – Advanced Digital Dentistry Infrastructure Assessment

Executive Summary

China has emerged as the global epicenter for high-performance, cost-optimized digital dental hardware, exemplified by Carejoy Digital’s ISO 13485-certified manufacturing ecosystem in Shanghai. The “scanner 3D dentaire prix” (3D dental scanner) represents a paradigm shift in accessibility and precision, combining AI-driven scanning algorithms, open-architecture data compatibility, and industrial-grade durability. This review dissects the manufacturing and quality control (QC) pipeline behind Carejoy’s flagship intraoral and lab scanning systems, highlighting why China now dominates the cost-performance frontier in digital dentistry.

Manufacturing & Quality Control Process: Shanghai ISO 13485 Facility

| Process Stage | Technology & Protocol | Compliance & Verification |

|---|---|---|

| Component Sourcing | Strategic partnerships with Tier-1 optical sensor suppliers (Sony, ON Semiconductor); custom CMOS sensor arrays with sub-micron pixel pitch. Sourced via audited supply chain with traceability to RoHS/REACH standards. | Supplier QA audits biannually; material certifications logged in ERP (SAP QM module). |

| Sensor Calibration Lab | Onsite metrology lab with laser interferometry and NIST-traceable reference masters. Each scanner undergoes individual sensor alignment using AI-optimized calibration grids (200+ reference points). Environmental chambers simulate 15–35°C operation. | Calibration certificates issued per unit; deviation tolerance: ≤5 µm RMS over 50 mm span. Lab accredited under ISO/IEC 17025. |

| Assembly Line | Automated pick-and-place for PCB assembly; manual final assembly under ISO Class 7 cleanroom conditions. Torque-controlled screwdrivers; ESD-safe workstations. | Real-time barcode tracking; in-process inspection (IPI) at 3 checkpoints. |

| Durability Testing | Automated stress cycles: 10,000+ drop tests (1m height), 500+ thermal cycles (-10°C to 60°C), 200+ flex cycles on handpiece cable. Vibration testing simulates 5 years of clinic use. | Pass/fail criteria based on optical consistency and mechanical integrity. MTBF: 45,000 hours. |

| Final QC & AI Validation | AI-powered scan validation using standardized dental models (ISO 12836 reference). STL/PLY output compared against master dataset; color accuracy, edge fidelity, and mesh continuity analyzed. | Pass threshold: ≥98.7% mesh accuracy (vs. reference), ≤8 µm trueness. Automated report generation. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Proximity to semiconductor, optics, and precision mechanics clusters in the Yangtze River Delta reduces lead times and logistics costs by up to 40%.

- Advanced Automation: High capital investment in robotics and AI-driven testing enables 95%+ first-pass yield, minimizing rework and labor dependency.

- Regulatory Efficiency: Local CFDA/NMPA pathway synergizes with ISO 13485, accelerating time-to-market without compromising quality.

- R&D Localization: Carejoy Digital employs 120+ engineers in Shanghai R&D center, co-developing firmware with global dental labs to optimize scan speed (≤40 sec full arch) and AI artifact reduction.

- Open Architecture Advantage: Native support for STL, PLY, OBJ ensures compatibility with major CAD/CAM platforms (exocad, 3Shape, DentalCAD), reducing integration friction and TCO.

Carejoy Digital: Technology Stack & Support Infrastructure

| Feature | Specification |

|---|---|

| Scanning Technology | AI-Driven Structured Light + Blue LED; 20 fps capture rate; 16 µm accuracy (ISO 12836) |

| Software Architecture | Open API; supports STL, PLY, OBJ; integrates with 30+ CAD platforms |

| Milling Compatibility | Direct export to Carejoy MillPro 5-axis; tolerance-matched toolpathing |

| Remote Support | 24/7 multilingual technical team; real-time diagnostics via encrypted cloud portal |

| Software Updates | Quarterly AI model upgrades; automatic over-the-air (OTA) deployment |

Email: [email protected]

Carejoy Digital – Advancing Precision. Redefining Access.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner 3D Dentaire Prix.

✅ Open Architecture

Or WhatsApp: +86 15951276160