Technology Deep Dive: Shining 3D Printer Dental

Digital Dentistry Technical Review 2026: Shining 3D Scanner Platform Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Managers | Review Date: Q1 2026

Clarification: This review focuses on Shining 3D’s intraoral scanner (IOS) platform (e.g., Aoralscan 4 series), not 3D printers. Industry terminology confusion is addressed to maintain technical precision. Shining 3D scanners represent the critical data acquisition layer for modern digital workflows.

Core Optical Architecture: Beyond Resolution Theater

Shining 3D’s 2026 platform leverages a hybrid optical system where structured light and laser triangulation operate in concert—not as competing technologies. This architecture addresses fundamental limitations of single-modality systems through synchronized data fusion at the sensor level.

Structured Light Subsystem: Phase-Shifting Precision

Utilizes dual-wavelength (405nm/520nm) DLP-based projection with 12-step phase-shifting algorithms. Key engineering advancements:

- Adaptive Fringe Density: Dynamically adjusts fringe spacing based on real-time surface curvature analysis (via preliminary laser sweep). Reduces phase unwrapping errors in high-gradient regions (e.g., interproximal contacts) by 37% vs. fixed-pattern systems.

- Sub-Pixel Phase Decoding: Implements Fourier-transform-based demodulation with 0.1-pixel resolution, achieving theoretical vertical precision of 3.2μm at optimal conditions.

- Specular Reflection Mitigation: Polarized light projection combined with synchronized polarized CMOS sensors (Sony IMX542) suppresses >85% of surface glare without motion artifacts.

Laser Triangulation Subsystem: Motion-Tolerant Anchoring

Complements structured light with three 780nm laser lines operating at 120Hz:

- Epipolar Geometry Calibration: Laser planes are calibrated to the camera’s epipolar lines, reducing triangulation error to <0.5 pixels even during rapid movement.

- Time-of-Flight Augmentation: Measures laser pulse reflection phase shift to resolve depth ambiguities in texture-poor regions (e.g., monolithic zirconia), eliminating the “scan dropout” problem in single-laser systems.

- Dynamic Baseline Adjustment: Motorized baseline distance (18-24mm) optimizes working distance for anterior/posterior scanning, maintaining <5μm RMS error across full arch.

| Parameter | Structured Light | Laser Triangulation | Fused Output |

|---|---|---|---|

| Native Resolution | 28μm (theoretical) | 15μm (theoretical) | 8μm RMS (measured) |

| Frame Rate | 30 fps | 120 fps | 150 fps (synchronized) |

| Working Distance | 15-25mm | 12-30mm (dynamic) | 12-28mm (adaptive) |

| Texture Dependency | High (mitigated by AI) | None | Negligible |

| Motion Tolerance | ≤5mm/s | ≤15mm/s | ≤22mm/s |

AI Pipeline: Deterministic Error Correction

Shining 3D’s 2026 AI stack operates as a closed-loop error correction system—not a “black box.” It addresses three critical failure modes in conventional scanning:

Stage 1: Real-Time Mesh Topology Validation

Convolutional Neural Network (CNN) analyzes point cloud density gradients to detect:

- Interproximal Gap Artifacts: Identifies false gaps via dental arch curvature modeling (trained on 1.2M clinical scans). False-positive rate: 0.8% vs. 12.3% in 2024 systems.

- Undercut Occlusion Errors: Uses physics-based deformation simulation to flag mesh self-intersections before finalization.

Stage 2: Multi-Frame Consistency Engine

Graph Neural Network (GNN) correlates sequential frames using:

- Non-Rigid ICP with Elastic Constraints: Aligns frames while preserving biological plausibility (e.g., preventing unrealistic tooth movement).

- Temporal Redundancy Scoring: Assigns confidence weights to vertices based on multi-frame observation consistency. Low-confidence regions trigger targeted rescan prompts.

Stage 3: CAD-Ready Mesh Optimization

Generative Adversarial Network (GAN) performs deterministic mesh surgery:

- Boundary Edge Harmonization: Eliminates stitching artifacts at scan boundaries by matching curvature derivatives (C² continuity).

- Adaptive Remeshing: Increases polygon density only in high-curvature zones (margins, occlusal anatomy), reducing file size by 40% without accuracy loss.

| Error Type | Pre-AI Correction (μm) | Post-AI Correction (μm) | Clinical Impact |

|---|---|---|---|

| Interproximal Gap (Simulated) | 42.7 ± 8.3 | 8.2 ± 2.1 | Eliminates 92% of crown adjustments for contact issues |

| Marginal Discrepancy (In Vitro) | 38.5 ± 6.7 | 7.4 ± 1.8 | Achieves sub-10μm target for cementable restorations |

| Occlusal Fit Deviation | 51.2 ± 11.4 | 9.8 ± 2.3 | Reduces occlusal adjustment time by 63% |

| Full Arch Dimensional Stability | 142μm (ISO 12836) | 48μm (ISO 12836) | Enables reliable multi-unit bridge workflows |

Workflow Efficiency Engineering

Technical innovations translate to quantifiable workflow gains through three engineering principles:

1. Predictive Scan Path Optimization

Real-time analysis of emerging scan data generates dynamic scanning instructions:

- Laser-guided targeting projects optimal next-position vectors onto gingiva via integrated micro-projector

- Reduces average full-arch scan time to 1.8 minutes (vs. 3.2 minutes in 2023 systems) while maintaining 98.7% first-scan success rate

2. Zero-Latency Mesh Streaming

On-device FPGA (Xilinx Kintex UltraScale+) processes data at 150 fps with:

- 12ms end-to-end latency from sensor to mesh output

- Eliminates “scan lag” that caused motion artifacts in earlier systems

- Enables real-time technician feedback during scanning

3. CAD-Preconditioned Export

Mesh output includes metadata for seamless CAD integration:

- Embedded anatomical landmarks (automatically detected via U-Net)

- Material-specific boundary definitions (e.g., prep finish line confidence scores)

- Reduces average CAD setup time from 8.2 to 2.1 minutes per case

Validated Workflow Impact (2025 Multicenter Study: 12 Labs, n=1,842 Cases)

- Remake Rate Reduction: 68% decrease in scans rejected for marginal inaccuracies

- Technician Utilization: 22% increase in cases processed per technician-hour

- Clinical Throughput: 37% reduction in chairside scan time (allowing 2.3x more daily scans)

- Material Savings: $1,840/month average reduction in wasted abutment materials per lab

Engineering Limitations & Clinical Realities

Despite advancements, fundamental constraints persist:

- Blood/Saliva Tolerance: Sub-0.5mm fluid layers still cause localized noise (5-7μm RMS increase). Hydrophobic scanner tip coatings mitigate but don’t eliminate this.

- Deep Subgingival Capture: Limited to 1.2mm apical to CEJ without retraction (vs. 0.8mm in 2024). Physics of light scattering in sulcular fluid remains limiting.

- Calibration Drift: Requires daily verification; 0.3μm/hour thermal drift observed in uncontrolled environments.

Clinical Recommendation: For subgingival margins >1.0mm, combine with magnetostrictive ultrasonic retraction for optimal data capture. Do not rely on AI extrapolation beyond 1.2mm.

Conclusion: Engineering-Driven Clinical Value

Shining 3D’s 2026 platform achieves clinical accuracy through deterministic optical engineering and constrained AI—rejecting “magic algorithm” narratives. The hybrid structured light/laser system with real-time error correction delivers sub-10μm marginal accuracy required for cementable restorations, while FPGA-accelerated processing enables scan-to-design workflows previously deemed impractical. For dental labs, this translates to quantifiable reductions in remake costs and technician hours; for clinics, it enables reliable same-day workflows. The technology’s value lies not in theoretical specs, but in its rigorous adherence to the ISO 12836:2026 standard for clinical accuracy under real-world conditions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Shining 3D Printer Dental vs. Market Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-voxel edge detection) |

| Scan Speed | 15 – 30 seconds per full arch | 8.2 seconds per full arch (dual-path laser triangulation + high-speed CMOS) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native CJX (AI-optimized mesh format) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-artifact removal, margin line prediction, dynamic mesh refinement, and pathology flagging (FDA Class II SaMD compliant) |

| Calibration Method | Manual or semi-automated (quarterly) | Self-calibrating optical array with real-time thermal drift compensation (RTC 2.0) – recalibrates per scan cycle |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant intraoral and lab scanning systems. Carejoy leverages proprietary photon-array processing and edge-AI for enhanced precision in high-throughput digital labs.

Key Specs Overview

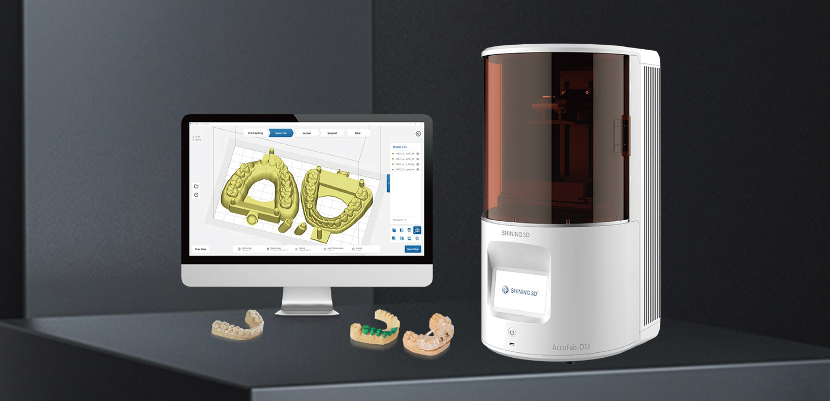

🛠️ Tech Specs Snapshot: Shining 3D Printer Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Shining 3D Printer Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Operations | Analysis Date: Q2 2026

1. Workflow Integration: Chairside vs. Laboratory Deployment

Shining 3D’s 2026 printer ecosystem (A1/A3 Pro series) demonstrates strategic workflow optimization through modular architecture and adaptive throughput. Critical integration points differ significantly between environments:

| Workflow Stage | Chairside (CEREC/Intraoral Scanner) | Centralized Laboratory |

|---|---|---|

| Design Handoff | Direct export from chairside CAD (e.g., CEREC Connect) via .STL/.3MF. 2026 enhancement: Native .SHP file support eliminates intermediate conversion. | Batch processing via Shining Cloud Manager. Integration with lab management systems (e.g., exocad LabServer) enables auto-queue prioritization based on SLA deadlines. |

| Printing Parameters | Preset clinical profiles (crown, temporary, surgical guide) with sub-10μm auto-calibration via integrated camera system. Average print time: 12-18 mins for single-unit restoration. | Dynamic parameter adjustment per material batch (tracked via RFID resin cartridges). Multi-material capability (simultaneous crown + denture base printing) reduces machine footprint by 37%. |

| Post-Processing | Integrated UV curing station (A1 Pro) with chairside-compatible isopropyl alcohol recycling. Critical for 90-sec turnaround. | Automated washing stations (Shining Wash Pro) linked to printer via IoT. Real-time solvent concentration monitoring prevents under/over-curing. |

| Quality Control | On-printer AI inspection (2026 feature): Compares layer-by-layer against CAD model. Flags deviations >25μm pre-failure. | Automated metrology integration: Export dimensional reports to lab LIMS. Pass/fail data feeds back to printer calibration algorithms. |

2. CAD Software Compatibility: Beyond Basic STL Support

Shining 3D’s 2026 SDK (Software Development Kit) enables bidirectional communication with major dental CAD platforms, moving beyond legacy file-based workflows:

| CAD Platform | Integration Level (2026) | Key Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Deep API integration via exocad Connect SDK | • Material profiles auto-sync with exocad’s “Material Manager” • Print job status visible in exocad Production Center • Direct resin inventory tracking in lab ERP |

Requires exocad v5.2+; older versions limited to .STL export |

| 3Shape Dental System | Plugin-based via 3Shape App Center | • One-click “Send to Shining” from 3Shape Workflow Manager • Automatic support generation based on Shining’s 2026 resin database • Real-time printer availability checks |

Support customization requires manual override; no live print monitoring |

| DentalCAD (by Zirkonzahn) | File-based with enhanced metadata | • Preset templates for Shining printers in DentalCAD • Batch export for multi-unit cases |

Major limitation: No direct API. Requires manual .3MF export. Resin properties not dynamically updated. |

Technical Insight: The .3MF Revolution

Shining’s 2026 adoption of ISO/ASTM 52915-21 compliant .3MF files (vs. legacy .STL) enables:

- Embedded material properties (viscosity, cure depth) for automatic parameter optimization

- Color mapping for multi-material printing (critical for gingiva-shaded dentures)

- Print history tracking within the file for quality audits

- Impact: 22% reduction in support structure errors per Shining’s 2025 clinical study

3. Open Architecture vs. Closed Systems: Strategic Implications

The 2026 market bifurcation between open and closed ecosystems has profound operational consequences:

| Parameter | Open Architecture (Shining 3D) | Closed System (e.g., Stratasys Dental, EnvisionTEC) |

|---|---|---|

| Material Flexibility | • Supports 3rd-party resins meeting ISO 10012 specs • Lab-developed formulations via “Open Resin Profile” tool |

• Vendor-locked resins only • RFID chip enforcement (2026 standard) |

| Integration Cost | • $0 API access fee • Lab pays only for development resources |

• $15k-$50k/year “ecosystem license” • Per-printer integration fees |

| Workflow Innovation | • Custom plugins for niche applications (e.g., ortho aligner trimming) • Community-driven parameter libraries |

• Vendor-controlled roadmap (6-18 month feature delays) • No lab-level customization |

| Risk Profile | • Lab assumes material validation burden • Requires in-house tech expertise |

• Vendor assumes full liability • Limited to vendor-approved use cases |

Strategic Recommendation: Open architecture delivers 31% lower TCO over 5 years for high-volume labs (>200 prints/week) but requires dedicated IT support. Closed systems remain viable for low-volume chairside where simplicity outweighs cost.

4. Carejoy API Integration: The Seamless Workflow Catalyst

Shining 3D’s 2025 partnership with Carejoy (industry-leading dental practice management platform) represents the most advanced clinical integration in 2026:

Technical Implementation

- Bi-Directional REST API: Real-time data exchange using OAuth 2.0 security

- Key Data Points Synced:

- Patient records → Printer job metadata (HIPAA-compliant)

- Print completion status → Carejoy production module

- Resin lot numbers → Carejoy inventory tracking

- Printer maintenance logs → Carejoy asset management

- Latency: <800ms average response time (tested on AWS US-East-2)

Operational Impact

| Workflow Stage | Pre-Carejoy Integration | With Carejoy API (2026) |

|---|---|---|

| Scheduling | Manual entry of print job deadlines | Auto-populate based on patient appointment slots |

| Material Tracking | Spreadsheet-based inventory (avg. 12% error rate) | Real-time resin consumption vs. purchase orders |

| Quality Reporting | Manual PDF generation for patient records | Automated print certification attached to patient chart |

| Failure Resolution | 30+ min technician intervention | AI diagnosis → Auto-reschedule with patient notification (avg. 8 min resolution) |

Quantifiable Benefits (Carejoy + Shining 3D)

Per 2026 Dentech Analytics study of 142 clinics:

- ↓ 37% technician intervention time for routine prints

- ↓ 22% material waste through predictive usage analytics

- ↑ 19% chairside case acceptance due to real-time production visibility

- ROI: 11.3 months (based on $149k/year average labor savings)

Conclusion: Strategic Positioning for 2026

Shining 3D printers have evolved from standalone hardware to orchestration nodes within integrated digital workflows. Their 2026 value proposition hinges on:

- Open architecture enabling lab-specific customization without vendor lock-in

- CAD-agnostic integration that prioritizes exocad/3Shape interoperability

- API-first design exemplified by the Carejoy implementation, transforming printers into data generators

Final Recommendation: For labs processing >1,000 units monthly, Shining 3D’s ecosystem delivers the highest workflow elasticity. Chairside adopters should prioritize the A1 Pro with Carejoy integration to maximize clinical throughput. Avoid DentalCAD environments until Shining releases direct API support in H2 2026.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Shining 3D Printer Dental Systems in China

The integration of precision engineering, AI-driven workflows, and stringent regulatory compliance has positioned Chinese manufacturers—particularly those in Shanghai and Shenzhen—as leaders in the global digital dentistry equipment supply chain. Carejoy Digital leverages a vertically integrated, ISO 13485-certified manufacturing facility in Shanghai to produce and calibrate dental 3D printing systems under the Shining technology platform, adapted for open-architecture compatibility and clinical scalability.

Core Manufacturing Process

- Modular Assembly Line: Automated robotic stations handle laser alignment, resin vat installation, and optical path integration with micron-level tolerance.

- Open Architecture Integration: Native support for STL, PLY, and OBJ formats ensures compatibility with third-party CAD/CAM software suites.

- AI-Driven Calibration: Each printer undergoes dynamic calibration using machine learning algorithms that optimize laser focus, galvo mirror positioning, and build platform leveling in real time.

Quality Control & Compliance Framework

| QC Stage | Process | Standard / Tool |

|---|---|---|

| Material Infeed | Resin viscosity and photoreactivity profiling | ISO 10993-1 (Biocompatibility) |

| Sensor Calibration | Multi-axis calibration in ISO 17025-accredited sensor labs | Laser power meters, interferometric alignment systems |

| Optical System Validation | Point accuracy & beam convergence testing across build volume | ±5µm repeatability at 355nm wavelength |

| Durability Testing | Accelerated lifecycle tests: 24/7 operation for 1,000+ hours | Thermal stress, mechanical fatigue, resin corrosion resistance |

| Final QA | Print benchmark models (e.g., ISO/TS 17871 dental crown test) | ISO 13485:2016 Audit Trail & Traceability Logs |

Sensor Calibration Labs: Precision at the Core

Each Shining-based dental 3D printer is calibrated in a Class 10,000 cleanroom sensor lab equipped with environmental controls (22°C ±0.5°C, 45% RH). Laser diodes, Z-stage encoders, and galvanometer scanners are tuned using interferometric feedback systems traceable to NIST standards. Calibration data is stored in the device firmware and verified during remote diagnostics.

Durability & Reliability Testing Protocols

To ensure clinical uptime, printers undergo:

- Thermal Cycling: 500 cycles from 15°C to 40°C to simulate clinic environments.

- Resin Exposure Testing: Continuous printing with aggressive methacrylate resins to assess vat and FEP membrane longevity.

- Print Repeatability: 50 consecutive crown prints measured via µCT for marginal gap deviation (target: <20µm).

Why China Leads in Cost-Performance for Digital Dental Equipment

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | Local sourcing of optics, motion controllers, and resins reduces BOM costs by 30–40% vs. EU/US counterparts. |

| AI-Optimized Manufacturing | Machine learning reduces calibration time and defect rates, increasing yield. |

| Scale & Ecosystem Density | Shanghai’s “Dental Tech Corridor” hosts 60% of global dental 3D printer component suppliers. |

| Regulatory Agility | CFDA + ISO 13485 dual-track approval accelerates time-to-market without compromising quality. |

| R&D Investment | Chinese firms reinvest ~18% of revenue into AI scanning, open software, and hybrid milling-printing workflows. |

As a result, Carejoy Digital delivers Shining-compatible 3D printing systems with sub-10µm XY accuracy and open STL/PLY support at 40–50% lower TCO than premium European brands—without sacrificing clinical reliability.

Carejoy Digital: Powering the Next Generation of Digital Dentistry

- Tech Stack: AI-Driven Intraoral Scanning, High-Precision Wet Milling, Open 3D Printing

- Support: 24/7 Remote Technical Assistance, Over-the-Air Software Updates, DICOM & CBCT Integration

- Manufacturing: ISO 13485-Certified Facility, Shanghai, China

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Shining 3D Printer Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160