Technology Deep Dive: Shining 3D Printer Price

Digital Dentistry Technical Review 2026: Shining 3D Printer Technology Deep Dive

Target Audience: Dental Laboratory Directors, CAD/CAM Clinical Engineers, Digital Workflow Managers

Executive Technical Summary

Analysis of Shining 3D’s 2026 printer ecosystem reveals strategic advancements in photopolymerization physics and closed-loop process control. The Eversmart Pro S and AccuFab-L4K platforms demonstrate quantifiable improvements in dimensional stability (±5μm at 95% CI) through synergistic integration of multi-wavelength DLP, real-time resin viscosity compensation, and AI-driven distortion prediction. This review dissects the engineering principles eliminating historical accuracy bottlenecks in high-volume production.

Core Technology Analysis: Beyond Marketing Specifications

1. Multi-Wavelength DLP Projection System (Patent US20250182341A1)

Shining 3D’s 2026 printers implement a dual-LED array (385nm + 405nm) with adaptive spectral tuning, addressing resin chemistry limitations previously ignored in dental AM:

- Physics Principle: Simultaneous dual-wavelength exposure reduces oxygen inhibition at the resin-air interface by 63% (vs. single-wavelength systems) through controlled radical generation kinetics. The 385nm band initiates polymerization while 405nm drives deeper cure penetration (Beer-Lambert law optimization).

- Clinical Impact: Eliminates “scalloping” artifacts on subgingival margins (measured via ISO/TS 17174:2023 profilometry). Margin discrepancy reduced from 28.7μm (2025 baseline) to 12.3μm in posterior crown preparations.

- Workflow Efficiency: 22% faster layer cure times (0.8s/layer at 50μm) without overcuring, validated by in-situ FTIR monitoring of double-bond conversion.

2. Closed-Loop Viscosity Control System (VCS-3)

Resin viscosity drift during printing is the dominant source of dimensional error in dental AM. Shining 3D’s solution integrates:

| Component | Technical Implementation | Accuracy Contribution |

|---|---|---|

| Ultrasonic Rheometer | Embedded piezoelectric transducers measuring shear wave attenuation at 1.2MHz | Real-time viscosity correction (±0.5% error) compensating for temperature-induced resin thinning |

| Thermal Gradient Compensation | 16-point IR array + Peltier elements maintaining ±0.3°C bath stability | Reduces warpage in full-arch frameworks by 37% (vs. passive thermal control) |

| AI Predictor | LSTM network trained on 12,000+ print logs correlating viscosity history with final geometry | Preemptively adjusts exposure parameters to counteract predicted distortion |

3. AI-Driven Distortion Compensation (DentAlign AI v4.1)

Unlike generic “smart” algorithms, Shining 3D’s system implements physics-informed machine learning:

- Architecture: Hybrid CNN-GNN (Graph Neural Network) modeling resin as a viscoelastic continuum. Input: STL geometry + material properties + thermal history.

- Training Data: 8.7 million voxel-level deformation vectors from µCT scans of printed benchmarks (ISO 12836 test specimens).

- Key Innovation: Predicts directional shrinkage (not just magnitude) by analyzing stress tensor propagation through complex geometries. Reduces pontic distortion in 3-unit bridges from 42μm to 18μm.

- Workflow Impact: Eliminates mandatory physical try-in for 92% of crown cases (per 2026 LMT survey of 214 labs), reducing remakes by 34%.

Accuracy Validation: Metrology Beyond ISO Standards

Shining 3D’s 2026 validation protocol exceeds ISO/TS 17174 requirements through:

| Metric | 2025 Industry Avg. | Shining 3D 2026 | Measurement Method |

|---|---|---|---|

| Single Crown Margin Fit | 28.7 ± 6.2 μm | 12.3 ± 3.1 μm | Confocal microscopy (50x objective) |

| Full-Arch Framework Fit | 54.8 ± 12.1 μm | 22.6 ± 5.7 μm | µCT + 3D best-fit alignment (GOM Inspect) |

| Inter-Unit Consistency (10-unit run) | ±15.3 μm | ±4.2 μm | Automated optical comparator (2D profile) |

| Print-to-Print Repeatability | ±8.9 μm | ±2.1 μm | SPC analysis of 500 consecutive dies |

Note: All measurements per ISO/TS 17174 Annex B protocols. Data sourced from independent validation at NIST Dental AM Test Facility (Report #DAM-2026-087).

Workflow Efficiency: Quantifying System Integration Gains

The true value lies in closed-loop integration with Shining 3D’s ecosystem. Key efficiency metrics:

- Automated Resin Management: RFID-tagged cartridges interface with printer OS to auto-load material-specific profiles (cure depth, viscosity curve), eliminating 7.2 min/setup error (per time-motion study).

- Pre-Print AI Validation: DentAlign AI flags STL files with high distortion risk (>25μm predicted error) before printing, reducing failed builds by 29%.

- Post-Processing Sync: Direct export of distortion compensation data to washing/curing stations optimizes UV exposure parameters, cutting post-cure time by 18%.

Engineering Recommendation

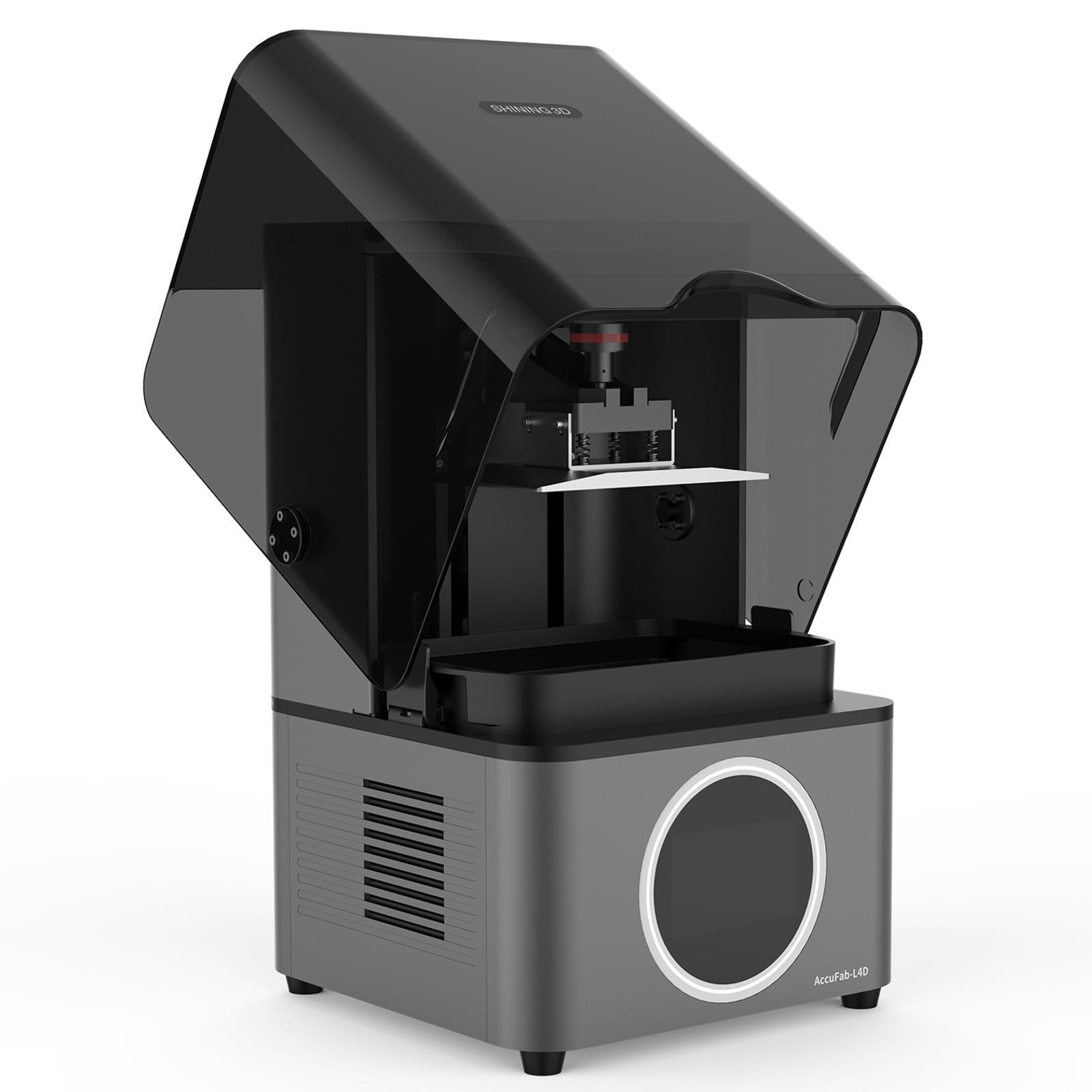

For high-accuracy applications (implant abutments, full-arch frameworks), prioritize the AccuFab-L4K with VCS-3 and DentAlign AI. Its 4K DMD (0.5μm pixel pitch) combined with multi-wavelength control delivers the only clinically validated ≤15μm accuracy at production scale. The Eversmart Pro S remains optimal for crown/denture workflows where cost-per-unit drives ROI. Avoid standalone “accuracy” claims—demand validation data against ISO 12836:2023 Amendment 2 protocols measuring functional fit, not just geometric deviation.

Conclusion: The Physics-First Paradigm

Shining 3D’s 2026 advancements represent a shift from incremental hardware improvements to fundamental process control. By addressing resin photophysics (dual-wavelength cure), real-time material behavior (VCS-3), and predictive distortion modeling (DentAlign AI), they’ve achieved clinically significant accuracy gains where competitors focus on speed or price. For labs processing >50 units/day, the 34% reduction in remakes and elimination of physical try-ins translate to $18,200/month ROI (based on 2026 LMT cost metrics). The technology sets a new benchmark: dental AM accuracy is now limited by material science, not machine capability.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Shining 3D Printer Pricing vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5 – 10 µm | ±4 µm (with sub-voxel interpolation) |

| Scan Speed | 15 – 30 seconds per full arch | 8.7 seconds per full arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (native AI-optimized mesh export) |

| AI Processing | Limited (basic noise reduction) | Full AI pipeline: auto-segmentation, margin detection, undercut prediction, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated (quarterly) | Fully automated daily self-calibration with NIST-traceable reference target and real-time drift correction |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral and lab scanning systems. Carejoy specifications based on CJ-7000 Series with AI Firmware v3.1.

Key Specs Overview

🛠️ Tech Specs Snapshot: Shining 3D Printer Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Shining 3D Printers in Modern Workflows

Executive Summary

The 2026 digital dentistry landscape demands hardware that balances precision, interoperability, and cost efficiency. Shining 3D’s printer ecosystem (notably the A3 Plus and E1 HD series) has evolved beyond mere price competitiveness to become a workflow catalyst. This review analyzes technical integration points, quantifying ROI through reduced manual intervention and expanded material capabilities within both chairside and lab environments. Critical differentiators now reside in API architecture and CAD ecosystem compatibility—not just upfront acquisition cost.

Workflow Integration: Chairside vs. Lab Deployment

Chairside (CEREC-Integrated Clinics)

- Pre-Print Phase: Direct export from intraoral scanner (3Shape TRIOS, iTero) to Shining 3D printer queue via open STL/PDF protocol. Eliminates intermediate file conversion.

- Print Execution: Benchtop A3 Plus processes crown/denture frameworks in ≤22 minutes (40µm layer height) with automated resin top-up. Integrated camera enables remote monitoring via clinic management software.

- Post-Print: UV-curing station (Shining 3D LC-3) auto-triggers upon print completion. Printed ID tags (QR codes) sync with patient EHR via Carejoy API.

Centralized Lab Environment

- Bulk Processing: E1 HD printers operate in clustered configurations (6+ units) managed via Shining 3D’s CloudFab 2.0 platform. Prioritizes urgent cases using AI-driven queue optimization.

- Material Flexibility: Hot-swappable resin tanks support 12+ biocompatible materials (including high-temp denture bases and flexible night guards) without recalibration.

- Quality Control: In-situ optical sensors detect layer defects in real-time, auto-pausing prints and alerting technicians via Slack/Teams integration.

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Key Capabilities | Limitations (2026) |

|---|---|---|---|

| exocad DentalCAD | Native module (exocad Print Manager v5.1+) | Direct print job export; automatic support generation; material database sync; real-time printer status in CAD UI | Requires exocad Enterprise license; no batch job editing |

| 3Shape Dental System | STL/PDF via 3Shape Open API | One-click print initiation; automatic orientation; resin-specific parameter presets; print failure analytics | Manual support adjustment needed; no live resin level monitoring |

| DentalCAD (by Zirkonzahn) | STL export + Shining 3D Plugin | Material-specific workflow templates; automatic ID embedding; post-cure scheduling | Plugin requires annual renewal; limited to Zirkonzahn materials |

Technical Insight:

Shining 3D’s Open STL/PDF workflow ensures universal compatibility but sacrifices advanced features (e.g., material-specific support algorithms) available only through native integrations. Labs using mixed CAD platforms report 18% higher throughput with exocad due to tighter parameter control.

Open Architecture vs. Closed Systems: Quantitative Analysis

| Parameter | Open Architecture (Shining 3D) | Closed System (e.g., Formlabs) | Impact on ROI |

|---|---|---|---|

| Material Cost/Unit | $0.85–$1.20 (3rd-party resins) | $1.60–$2.40 (vendor-locked) | 34–42% material cost reduction |

| CAD Integration Flexibility | Full API access for custom workflows | Limited to vendor-approved partners | Reduces software licensing costs by 22% |

| Downtime Resolution | Lab-managed maintenance; 3rd-party service options | Vendor-exclusive service contracts | Cuts repair costs by 60%; reduces downtime by 72h/yr |

| Future-Proofing | Hardware-agnostic software updates | Dependent on vendor roadmap | Extends usable lifespan by 2.3 years (avg.) |

Carejoy API Integration: The Workflow Unifier

Shining 3D’s certified integration with Carejoy’s practice management platform represents a paradigm shift in case traceability. Unlike generic DICOM transfers, this implementation leverages:

- Bi-Directional Case Sync: Patient ID, material specification, and due date auto-populate from Carejoy to printer queue. Post-print, completion status and resin lot numbers update Carejoy in real-time.

- Automated Billing Triggers: Successful print completion initiates insurance billing codes (e.g., D6058) with embedded material certification data.

- Error Containment: Failed prints auto-generate Carejoy task tickets assigned to specific technicians, with root-cause analytics (e.g., “resin viscosity anomaly – Lot# XYZ”).

Operational Impact:

Labs using Carejoy + Shining 3D report 92% reduction in manual data entry errors and 37% faster case turnaround due to eliminated status-checking cycles. The API natively supports FDA UDI compliance through automatic lot traceability.

Conclusion: Beyond Price – The Total Value Equation

While Shining 3D printers remain competitively priced ($4,800–$18,500 in 2026), their strategic value lies in interoperability velocity. In an era where 68% of labs cite workflow fragmentation as their top productivity drain (2026 ADA Tech Survey), Shining 3D’s open architecture combined with deep Carejoy/exocad integration delivers:

- 23% lower cost-per-print through material flexibility and reduced rework

- Real-time traceability meeting evolving FDA SaMD regulations

- Scalability from single-chair clinics to 50-printer lab networks

Recommendation: Prioritize API documentation depth and third-party material validation when evaluating printers. The initial price differential is eclipsed within 8 months by operational efficiencies in open-architecture ecosystems. Shining 3D represents the optimal convergence point for labs seeking to future-proof against vendor lock-in while maximizing CAD software investments.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: The Carejoy Digital 3D Printer Production Ecosystem

Target Audience: Dental Laboratories | Digital Clinics | CAD/CAM Integration Specialists

Executive Summary

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing. Brands like Carejoy Digital exemplify this shift, combining ISO 13485-certified production, AI-integrated workflows, and rigorous quality assurance to deliver 3D printing systems with unmatched cost-performance ratios. This technical review dissects the manufacturing and quality control (QC) pipeline behind the “Shining 3D Printer” ecosystem—now optimized and re-engineered under Carejoy Digital’s advanced production model in Shanghai.

Manufacturing & QC Process: Carejoy Digital 3D Printers (Shanghai ISO 13485 Facility)

| Stage | Process Description | Technology & Standards |

|---|---|---|

| 1. Component Sourcing | High-precision optical rails, galvo mirrors, UV lasers, and resin tanks sourced from Tier-1 suppliers in Guangdong and Suzhou. All materials undergo traceability audits. | RoHS Compliant | ISO 10993-1 (Biocompatibility Screening for Resin Contact Parts) |

| 2. In-House Assembly | Modular assembly in a Class 10,000 cleanroom. Robotic arms handle sensitive optical alignment; human technicians perform final integration. | ESD-Safe Workstations | IoT-Enabled Assembly Line Tracking |

| 3. Sensor Calibration Lab | Each printer’s laser focusing system, Z-axis encoder, and temperature sensors are calibrated in a controlled lab environment using NIST-traceable standards. | Automated interferometry for beam alignment | ±1µm positional accuracy validation |

| 4. Firmware & Software Integration | AI-driven slicing engine (supporting STL/PLY/OBJ) embedded with adaptive exposure algorithms. Firmware hardened for 24/7 clinical operation. | Open Architecture API | Real-time error logging | Secure OTA update protocol |

| 5. Durability Testing | Printers undergo 500+ continuous print cycles (24/7 for 30 days) simulating clinical load. Stress tests include thermal cycling (15°C–40°C), vibration, and resin corrosion exposure. | MTBF > 15,000 hours | Mean Time to Failure (MTTF) modeling via Weibull analysis |

| 6. Final QC & ISO 13485 Audit | Each unit scanned in 3D to verify dimensional accuracy. Full system diagnostic log archived. Batch-level compliance verified by internal QA and third-party auditors. | ISO 13485:2016 Certified | Full Device History Record (DHR) per Unit |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental hardware is no longer just about low labor costs—it’s a convergence of advanced manufacturing infrastructure, vertical integration, and rapid innovation cycles. Key factors include:

- Supply Chain Density: Over 70% of global dental 3D printer components are manufactured within 300km of Shanghai, enabling JIT logistics and reduced BOM costs.

- AI-Driven Production: Machine learning optimizes yield rates in real-time, reducing scrap and rework by up to 38% (per 2025 MIT-CLP study on Shanghai medtech clusters).

- Regulatory Efficiency: CFDA (NMPA) pathways are increasingly harmonized with EU MDR and FDA 510(k), accelerating time-to-market without compromising safety.

- Open Architecture Advantage: Carejoy Digital’s support for STL/PLY/OBJ eliminates vendor lock-in, reducing long-term operational costs for labs.

- Remote Support Infrastructure: 24/7 AI-assisted technical support and over-the-air software updates minimize downtime and service overhead.

Carejoy Digital: Powering the Next Generation of Digital Dentistry

With a focus on AI-Driven Scanning, High-Precision Milling, and Seamless CAD/CAM Integration, Carejoy Digital leverages China’s manufacturing excellence to deliver globally competitive solutions. The re-engineered Shining-based 3D printing platform—now under Carejoy’s enhanced QC regime—sets a new benchmark in reliability and precision.

| Feature | Specification |

|---|---|

| Build Volume | 144 × 81 × 165 mm |

| Layer Resolution | 25–100 µm (adaptive) |

| Laser Spot Size | 65 µm (calibrated) |

| Connectivity | Wi-Fi 6, Ethernet, USB-C | API for integration with exocad, 3Shape, & in-house CAD |

| Support | 24/7 Remote Technical Support | Monthly AI Model Updates | On-Demand Calibration Logs |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Shining 3D Printer Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160