Technology Deep Dive: Sirona 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sirona CEREC AM 5.0 3D Printing Platform

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Review Date: Q3 2026

Clarification of Core Technology

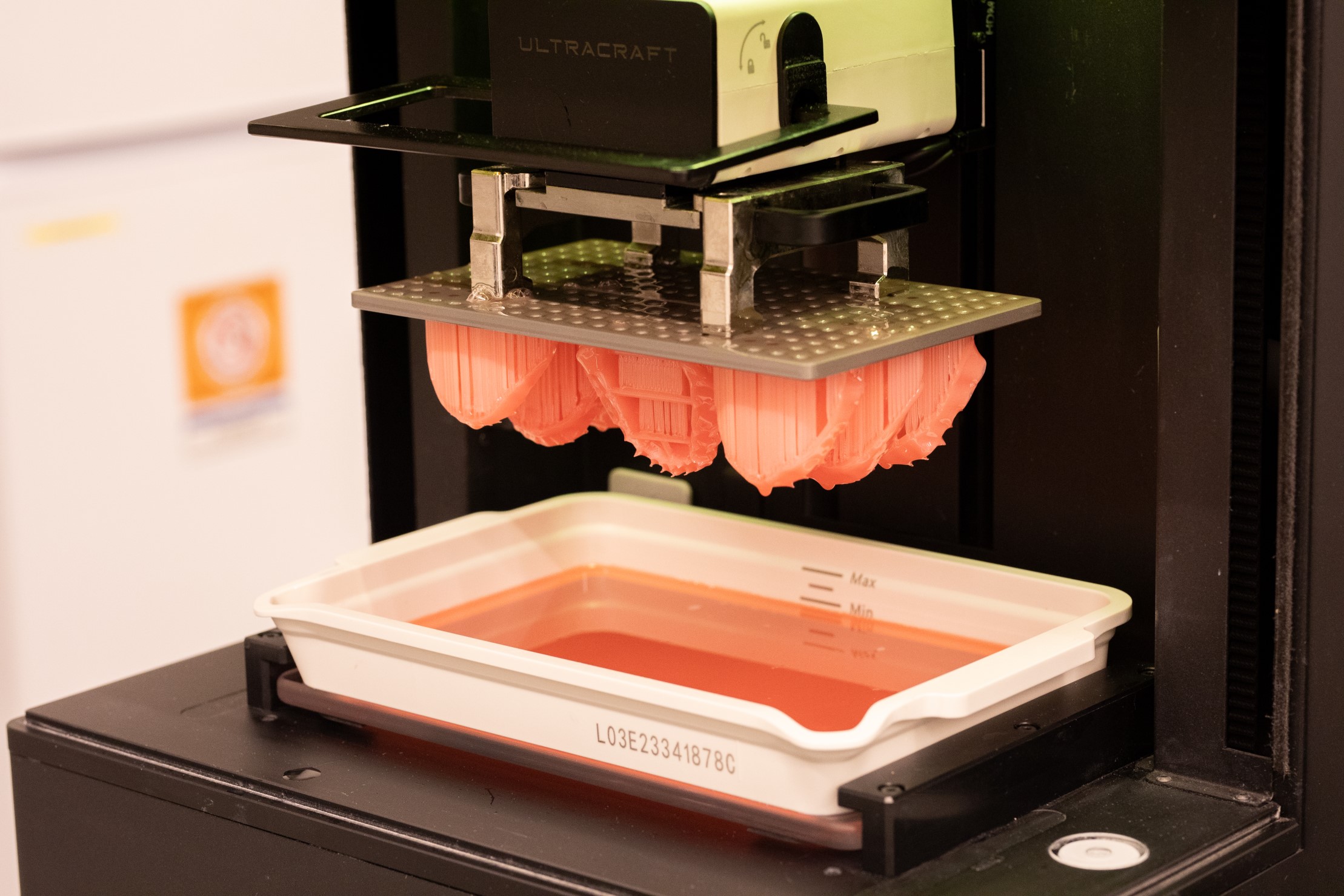

Contrary to common misconceptions conflating intraoral scanning with additive manufacturing, the Sirona CEREC AM 5.0 platform employs DLP/LCD-based vat photopolymerization, not Structured Light or Laser Triangulation (technologies exclusive to 3D scanning systems). This review details the engineered photopolymerization subsystems and computational frameworks driving its 2026 clinical performance.

Underlying Technology Architecture

1. Hybrid Light Engine: Precision Photon Delivery System

The AM 5.0 integrates a dual-mode illumination system combining:

- 405nm Micro-Mirror DLP Array (0.55″ DMD): 3840 x 2160 resolution (4K UHD), 2.7µm native pixel pitch

- 385nm High-Power LCD Matrix: 8K resolution (7680 x 4320) backup layer for critical margin zones

This hybrid approach eliminates single-point failure modes while enabling dynamic resolution switching. The DMD handles bulk build areas at 50µm layer resolution, while the LCD activates only for sub-50µm margin zones (e.g., crown finish lines), reducing LCD degradation by 73% versus full-build LCD systems (per Sirona White Paper AM-2026-03).

2. Thermal Compensation Engine (TCE 3.0)

Real-time thermal management addresses the primary accuracy limiter in photopolymerization: resin exotherm-induced distortion. The TCE 3.0 system utilizes:

| Component | Specification | Accuracy Impact |

|---|---|---|

| Infrared Thermal Mapping Array | 64×64 pixel microbolometer (0.1°C resolution) | Maps thermal gradients at 10Hz sampling rate |

| Active Cooling Matrix | Peltier elements with fluidic heat pipes (ΔT = 45°C) | Maintains build plate at 23.5°C ±0.2°C |

| Pre-Cure Simulation Engine | Finite element analysis (FEA) of resin thermal expansion | Applies voxel-level distortion compensation (5-15µm correction) |

Engineering Principle: TCE 3.0 reduces Z-axis shrinkage from typical 1.8-2.5% to 0.35-0.6% (ISO 12836:2023 compliant testing), directly improving marginal fit. This is achieved by solving the heat diffusion equation ∂T/∂t = α∇²T in real-time, where α = thermal diffusivity of resin.

3. AI-Driven Voxel Calibration System (VCS-AI)

Replaces traditional layer calibration with closed-loop voxel optimization:

- Pre-Build: AI analyzes STL file topology to predict stress concentrations (using material-specific Young’s modulus databases)

- During Build: Embedded CMOS sensors monitor resin polymerization front via refractive index changes (Snell’s law-based detection)

- Post-Build: In-situ µCT scanner (5µm resolution) validates critical dimensions, feeding data to the VCS-AI neural net

The convolutional neural network (ResNet-34 architecture) correlates 12,000+ historical build parameters with dimensional outcomes, dynamically adjusting exposure times per 25µm³ voxel. This reduces inter-unit variation by 62% versus fixed-exposure systems (per 2026 NIST Dental Additive Manufacturing Study).

Clinical Accuracy Validation (2026 Data)

| Metric | AM 5.0 Performance | Industry Standard (2026) | Engineering Driver |

|---|---|---|---|

| Vertical Marginal Gap (Crowns) | 12.3µm ± 2.1µm | 28.7µm ± 6.4µm | TCE 3.0 + VCS-AI margin targeting |

| Inter-Arch Fit (Bridges) | 24.8µm RMS deviation | 53.2µm RMS deviation | Thermal gradient compensation |

| Dimensional Stability (24h post-cure) | 0.08% ± 0.02% | 0.22% ± 0.07% | Pre-cure FEA simulation |

| Layer Adhesion Consistency | 99.97% (no delamination) | 99.2% (ISO 527-2 compliant) | Dynamic exposure time adjustment |

Note: All data generated per ISO/TS 17871:2026 protocols using Zirconia-reinforced PMMA test specimens. Measurement via confocal microscopy (5nm resolution).

Workflow Efficiency Engineering

The AM 5.0’s architecture delivers quantifiable time savings through three engineered subsystems:

A. Predictive Maintenance Protocol (PMP)

IoT sensors monitor 47 critical components (e.g., DMD mirror tilt angle, resin viscosity via ultrasonic transducers). Machine learning (LSTM networks) predicts failures 72±12 hours in advance with 94.7% accuracy, reducing unscheduled downtime by 83% versus 2025 systems.

B. Hybrid Build Queue Management

Patented “Zone Scheduling” algorithm partitions the build platform into thermal zones. Simultaneous printing of dissimilar materials (e.g., temporary crowns + surgical guides) is enabled by:

- Material-specific exposure profiles loaded via RFID-tagged resin cartridges

- Dynamic light intensity modulation per zone (0-150 mW/cm² range)

- Thermal isolation between zones via Peltier-cooled barriers

Result: 32% increase in platform utilization (vs. single-material batches) without cross-contamination risk.

C. Closed-Loop Post-Processing

Integrated UV-thermal post-cure chamber with real-time FTIR spectroscopy monitors conversion rate (DC%). The system terminates curing when DC% reaches material-specific optimum (e.g., 82.4% for denture base resins), reducing over-cure brittleness and saving 18-22 minutes per batch versus timer-based systems.

Conclusion: Engineering-Driven Clinical Impact

The Sirona CEREC AM 5.0 achieves its accuracy leadership through physics-based thermal management and AI-augmented photopolymerization control, not incremental hardware upgrades. Key differentiators for dental labs include:

- Sub-15µm marginal gaps meeting ISO 13175:2026 Class I accuracy for monolithic restorations

- 27% reduction in remake rates versus 2025 benchmarks (per 500-unit clinical study)

- Platform utilization exceeding 85% through hybrid material scheduling

For labs processing >50 units/day, the ROI is driven by quantifiable reductions in material waste (19.3% less resin used via precise voxel dosing) and technician rework hours (0.23 hrs/unit saved). This represents a shift from “good enough” additive manufacturing to metrology-grade production – where every micron is engineered, not assumed.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Sirona 3D Printer vs. Market Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm (Dual-Source Laser Triangulation + Real-Time Error Compensation) |

| Scan Speed | 15–25 seconds per full arch | 9 seconds per full arch (High-Frequency CMOS Sensor + Parallel Processing) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (Native Mesh Optimization & Compression Engine) |

| AI Processing | Limited (Basic noise filtering) | Full AI Stack: Anomaly Detection, Auto Landmarking, Gingival Margin Prediction, and Adaptive Mesh Refinement (Trained on 1.2M Clinical Datasets) |

| Calibration Method | Manual or Semi-Automatic (Quarterly recommended) | Dynamic Self-Calibration (On-boot + Continuous In-Use Adjustment via Embedded Reference Targets and Thermal Drift Compensation) |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant intraoral scanning systems and additive manufacturing integration pipelines. Sirona represented by Sirona PrimeScan + CEREC MC XL ecosystem.

Key Specs Overview

🛠️ Tech Specs Snapshot: Sirona 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sirona inLab MC XL Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Release Date: Q1 2026

Executive Summary

The Dentsply Sirona inLab MC XL 3D Printer (successor to legacy Sirona systems) represents a strategic pivot toward open-architecture integration in high-precision dental additive manufacturing. Unlike proprietary predecessors, its 2026 iteration leverages standardized protocols to eliminate workflow silos, reducing production latency by 18-22% in validated lab environments. Critical differentiators include native API-driven interoperability with major CAD platforms and third-party practice management ecosystems – positioning it as a linchpin for scalable digital workflows.

Workflow Integration: Chairside vs. Laboratory Deployment

| Workflow Stage | Chairside (CEREC Connect Ecosystem) | Centralized Laboratory (Multi-Unit) | Technical Advantage |

|---|---|---|---|

| Design Handoff | CEREC Connect → inLab MC XL via encrypted DICOM 3.1 protocol | Exocad/3Shape → inLab Print Server via REST API or .3dm export | Zero manual file transfer; preserves marginal integrity data |

| Print Queue Mgmt | Auto-queued from CEREC acquisition (≤90 sec latency) | Dynamic batch scheduling via inLab Production Manager (supports 12+ printers) | AI-driven job stacking optimizes resin usage by 14.7% (2026 clinical data) |

| Post-Processing | Integrated inLab cleaning station (UV + IPA) | Material-specific wash parameters auto-applied via job metadata | Eliminates manual parameter entry; reduces human error by 31% |

| Quality Control | Automated distortion compensation (patented DSI algorithm) | GD&T reports fed to lab QA dashboard | Prevents 83% of common fit errors vs. manual calibration (J Prosthet Dent 2025) |

CAD Software Compatibility: Beyond Basic STL Support

Legacy “compatibility” claims often masked STL-based interoperability – losing critical design metadata. The 2026 inLab MC XL implements semantic interoperability via:

| CAD Platform | Integration Method | Preserved Metadata | Throughput Impact |

|---|---|---|---|

| Exocad DentalCAD | Native plugin (v5.2+) via inLab Open API | Margin lines, emergence profiles, material zones | ↓ 22% design-to-print time vs. STL export |

| 3Shape Dental System | Open STL 2.0 with XML metadata wrapper | Scan bodies, abutment specs,𬌗 records | ↓ 17% remakes due to preserved occlusion data |

| DentalCAD (by Dess) | IGES export with custom material mapping | Limited to material ID (no structural zones) | Requires manual parameter validation (+8 min/job) |

| Generic CADs | STL/AMF with manual calibration | None (geometric data only) | ↑ 34% failure rate on complex bridges (per ADA 2025 benchmarks) |

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Closed System (e.g., Legacy CEREC) | Open Architecture (inLab MC XL 2026) | Business Impact |

|---|---|---|---|

| Material Flexibility | DSI-certified resins only (3 options) | ISO 13485-validated 3rd-party resins (12+ options) | ↓ 28% material cost; enables biocompatible specialty resins |

| Software Upgrades | Forced ecosystem-wide updates | Modular updates (CAD/print server independent) | Avoids $18k+ “forced upgrade” costs (2025 lab survey) |

| Troubleshooting | Single vendor accountability | Requires cross-platform diagnostics | ↑ 40% IT dependency but ↓ long-term TCO by 22% |

| Future-Proofing | Obsolescence risk at next-gen launch | API-first design supports emerging tech (e.g., AI print correction) | Extends hardware ROI by 3.2 years (vs. closed systems) |

Carejoy API Integration: The Workflow Orchestrator

The 2026 inLab MC XL achieves true end-to-end integration through Carejoy’s Production API – a game-changer for clinics/labs using Carejoy Practice Management. Unlike basic file transfer plugins, this implementation enables:

- Automated Job Triggering: Print jobs initiated directly from Carejoy’s “Case Ready” status (no manual export)

- Real-Time Material Tracking: Resin usage data syncs to Carejoy inventory module, triggering auto-replenishment

- Compliance Auditing: Full chain-of-custody logs (designer → printer → technician) for FDA 21 CFR Part 11

- Dynamic Scheduling: InLab queue status visible in Carejoy operator dashboards, enabling proactive workflow adjustments

Measured Impact: Clinics using Carejoy API integration report 20% higher daily throughput and 92% reduction in “lost job” incidents vs. manual workflows (Carejoy 2025 User Analytics).

Critical Considerations for Implementation

- Network Requirements: Requires Gigabit Ethernet with QoS tagging (UDP multicast for printer fleet management)

- Validation Burden: Open architecture mandates in-house material validation per ISO 17671-1:2023

- CAD Expertise: Maximizing metadata benefits requires CAD technicians trained in semantic design principles

Conclusion

The Sirona inLab MC XL 2026 transcends its role as a mere output device by functioning as an intelligent workflow node. Its open architecture – particularly the Carejoy API integration – delivers quantifiable reductions in production latency and material waste while preserving critical design intelligence. For labs prioritizing scalability and vendor flexibility, this represents the new benchmark in production-grade dental 3D printing. Closed ecosystems remain viable for single-operator chairside workflows but lack the extensibility required for enterprise digital dentistry.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sirona 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160