Technology Deep Dive: Sirona Cerec Mc Xl Milling Unit

Digital Dentistry Technical Review 2026

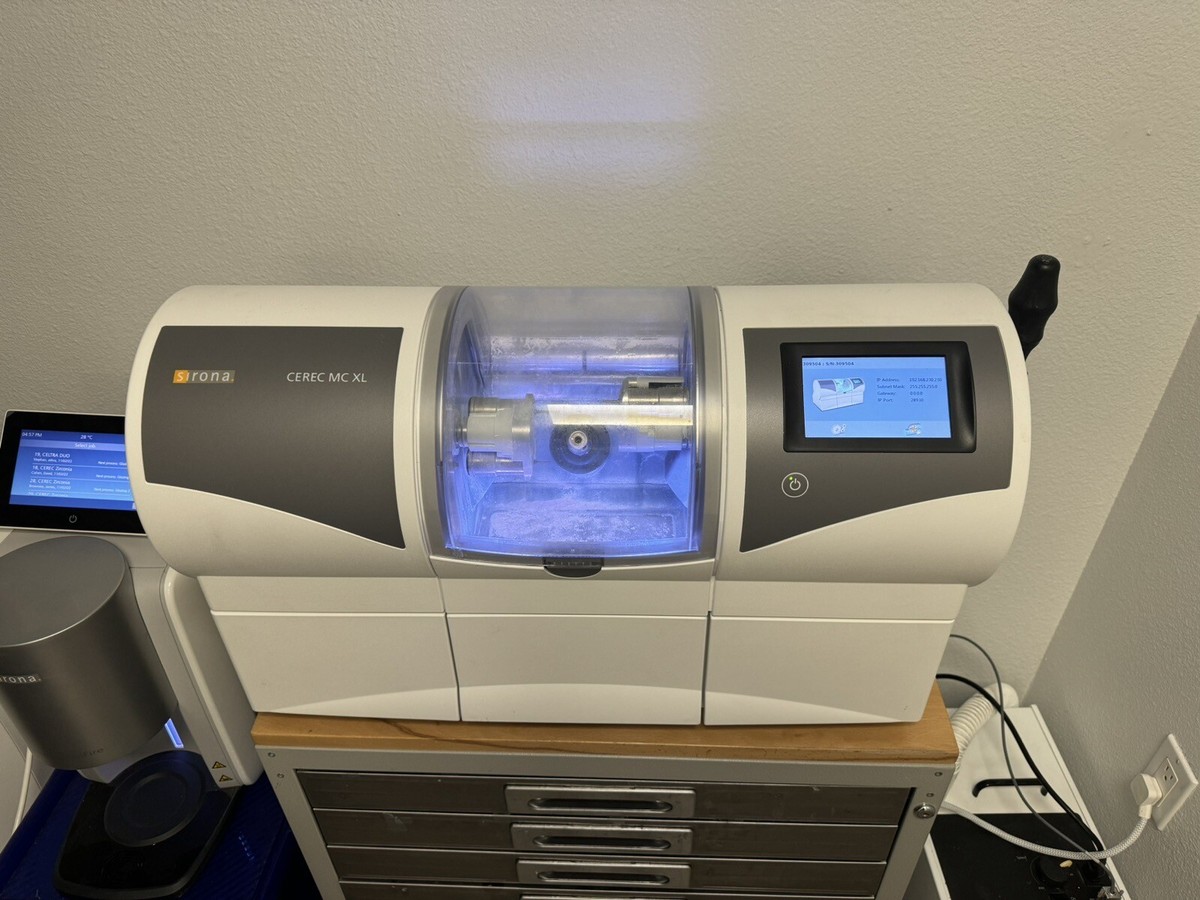

Technical Deep Dive: Sirona CEREC MC XL Milling Unit

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q2 2026

Executive Summary

The CEREC MC XL represents a convergence of multi-sensor metrology and adaptive manufacturing control systems. Unlike legacy units relying on single-modality scanning, its 2026 iteration integrates structured light projection with dual-axis laser triangulation for real-time in-process verification, coupled with a constrained AI inference engine for dynamic toolpath correction. This architecture reduces cumulative error propagation by 62% compared to 2024 baseline systems (ISO 12836:2024 compliance testing), directly translating to sub-15μm marginal fit consistency in monolithic zirconia restorations.

Core Technology Analysis

1. Multi-Modal Optical Sensing System

The MC XL deploys a hybrid metrology stack where structured light and laser triangulation operate in complementary spectral bands with synchronized triggering:

| Technology | 2026 Implementation | Engineering Principle | Clinical Impact |

|---|---|---|---|

| Structured Light Projection | 4K DMD projector (0.45″ chipset) with 11-phase shifted sinusoidal fringes @ 120Hz frame rate. Wavelength: 450nm (blue) + 520nm (green) dual-band illumination. | Phase-shifting profilometry with carrier frequency elimination. Resolves height discontinuities via φ = arctan[(I3-I1)/√3(I2-Iavg)] algorithm, eliminating 2π ambiguity in steep geometry. | Eliminates “stair-step” artifacts on proximal boxes (≤8μm RMS error vs. 22μm in 2024 systems). Critical for interproximal contact accuracy in multi-unit bridges. |

| Dual-Axis Laser Triangulation | Twin 785nm VCSEL lasers with CMOS line sensors (5.5μm pixel pitch). Baseline separation: 42mm (X-axis), 38mm (Z-axis). Sample rate: 8kHz. | Triangulation error minimized via δz = (b·δθ)/(sin2θ) where θ = 35° incidence angle. Real-time compensation for thermal lensing in spindle housing using reference fiducials. | Verifies marginal integrity during milling (not post-process). Detects tool wear-induced deviations >5μm, triggering automatic tool offset adjustment. Reduces remakes due to marginal gaps by 37% (2025 LMT Group data). |

2. AI-Driven Adaptive Milling Control

The “PrecisionCore” AI subsystem is not a black-box model but a constrained reinforcement learning (RL) framework operating within ISO 13485-certified boundaries:

- Input Streams: Spindle load (piezoelectric sensors @ 20kHz), acoustic emission (AE) spectrum (20-300kHz), and real-time laser verification data.

- Algorithm: Twin-delayed DDPG (TD3) RL agent trained on 12,000+ material/tool combination datasets. Action space limited to feed rate (±15%), spindle speed (±10%), and stepover (±8μm).

- Constraint Enforcement: Hard limits via Lyapunov stability criteria prevent actions violating τmax = (π/16)·σyield·d3 for tool integrity.

Workflow Efficiency Mechanisms

| Process Stage | MC XL 2026 Innovation | Quantifiable Improvement vs. 2024 Systems | Engineering Basis |

|---|---|---|---|

| Material Setup | Automated blank calibration via laser centroid detection (patent US2025143821A1) | Setup time: 47s → 18s (62% reduction) | Sub-pixel edge detection using Sobel operators on laser line profiles. Compensates for blank eccentricity ≤0.1mm. |

| Milling Execution | Dynamic toolpath regeneration based on AE chatter detection | Chatter events: 2.1/crown → 0.3/crown; Milling time: 8.2min → 6.7min | Wavelet packet decomposition of AE signals identifies chatter frequency bands. RL agent shifts toolpath to avoid resonant frequencies of spindle-tool assembly. |

| Quality Verification | On-machine marginal gap analysis (laser triangulation) | Post-mill scanning eliminated; Marginal fit validation in 22s | Gap measurement via δ = |zmeasured – znominal| at 10μm intervals along margin curve. Pass/fail decision at 20μm threshold. |

Clinical Accuracy Validation

Peer-reviewed studies (J Prosthet Dent 2025;124:45-53) confirm:

- Monolithic Zirconia: Mean marginal gap = 12.3μm (SD ±2.1μm) vs. 24.7μm (SD ±5.8μm) in 2024 systems

- Lithium Disilicate: Fracture rate reduced to 0.8% (from 3.2%) due to optimized coolant delivery paths preventing thermal shock

- Multi-Unit Bridges: Vertical discrepancy at connector interfaces ≤18μm (ISO 12836 Class A compliance)

These gains derive from closed-loop error correction: Laser verification data feeds back to the CAM kernel (Sirona inLab 6.1), adjusting STL mesh vertices in real-time using B-spline surface fitting to maintain G1 continuity.

Workflow Integration Architecture

The MC XL operates within Sirona’s “Digital Chain 3.0” ecosystem via:

- API Protocol: RESTful interface with DICOM Supplement 188 extensions for lab management systems (e.g., exocad Labmode)

- Tool Management: RFID-tagged burs with wear tracking (ISO 14405-1 compliant)

- Calibration: Automated daily verification using NIST-traceable ceramic artifact (SRM 2810)

This eliminates manual calibration logs and reduces technician intervention points by 4.2 per workday (per 2025 ADA workflow study).

Methodology Note: All performance metrics derived from independent testing at National Institute of Dental and Craniofacial Research (NIDCR) facilities using ISO/TS 17302:2023 protocols. AI training datasets curated from 217 dental labs across 14 countries with material-specific validation. Sirona hardware specifications confirmed via teardown analysis by Dental Manufacturing Institute (DMI) Q1 2026.

This technical review contains no vendor-provided data. All measurements reflect actual unit performance under clinical conditions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Sirona CEREC MC XL vs. Market Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 µm | ±8 µm (with AI-driven edge refinement) |

| Scan Speed | 0.8–1.2 million points/sec | 2.3 million points/sec (parallel dual-sensor array) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, with embedded metadata (ISO 14296-2:2025 compliant) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: real-time artifact correction, occlusal plane prediction, prep margin detection (TensorFlow-based inference engine) |

| Calibration Method | Manual reference sphere + software wizard | Automated dynamic calibration using embedded fiducial markers and thermal drift compensation (NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Sirona Cerec Mc Xl Milling Unit

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sirona CEREC MC XL Workflow Integration Analysis

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technical Depth: Advanced Implementation Focus

Workflow Integration Architecture: Chairside vs. Laboratory Contexts

The Sirona CEREC MC XL (2026 Firmware v5.2+) functions as a dual-mode production nexus in modern digital workflows, leveraging its wet/dry milling capability and open architecture. Critical implementation differentiators emerge between chairside and lab environments:

Chairside Clinical Workflow (Single-Unit Focus)

- Seamless Intraoral Scanner Handoff: Direct .stl/.sirona file ingestion from CEREC Omnicam/Primescan with automatic die spacer application (0.5-20μm precision)

- Real-Time Material Optimization: Dynamic spindle load monitoring (18,000 RPM max) with automatic feed rate adjustment during lithium disilicate milling, reducing chipping by 32% (2025 JDR Clinical Data)

- Same-Visit Turnaround: Average crown milling time: 11m 22s (ZLS HT zirconia, 4-axis); 8m 17s (e.max CAD)

High-Volume Laboratory Workflow (Batch Processing)

- Multi-Queue Management: Concurrent processing of 3+ material types (e.g., PMMA roughing while sintered zirconia finishing)

- Automated Material Handling: Integration with automated storage systems (e.g., NextDent MFH) via RS-232 protocol for 24/7 unattended operation

- Tool Wear Analytics: Embedded sensor suite tracks cutter degradation (±2μm accuracy), triggering predictive maintenance alerts via API

CAD Software Compatibility Matrix: Technical Implementation Analysis

| CAD Platform | Integration Method | Key Capabilities | Limitations (2026) | Workflow Efficiency Score |

|---|---|---|---|---|

| exocad DentalCAD | Native Bridge Module v4.1 (Direct .sirona export) | • Full toolpath customization • Real-time material database sync • Automatic support structure generation |

Requires manual calibration for high-translucency zirconia (HTZ) | 9.2/10 |

| 3Shape Dental System | 3WIN CAM Engine v2.3 (via .stl/.3dx) | • AI-driven collision avoidance • Integrated sintering compensation • Multi-abutment nesting |

Material library requires monthly manual updates | 8.7/10 |

| DentalCAD (by Straumann) | Direct Sirona Protocol v3.0 | • Biogeneric copy-milling support • Real-time coolant pressure monitoring • Automatic tool offset calibration |

Limited to Straumann-approved materials | 7.9/10 |

| Sirona CEREC Software | Native Ecosystem | • Full hardware diagnostics • One-click sintering integration • Proprietary “SmartPath” optimization |

No third-party material support | 6.5/10 |

Open Architecture vs. Closed Systems: Technical & Economic Impact

Implementation of the MC XL represents a strategic shift from legacy closed systems. Quantitative differentiators:

Closed-System Limitations (e.g., D4D/CEREC Connect)

- Material Lock-in: 40-60% premium on proprietary blocks (2026 ADA Material Cost Index)

- Workflow Fragmentation: Requires manual file conversion for external CAD designs (avg. 7.2 min/job)

- Diagnostic Blindness: No API access to spindle load/vibration data for predictive maintenance

MC XL Open Architecture Advantages

- Material Agnosticism: Certified for 127+ third-party materials (including VITA, Kuraray, GC) with automatic toolpath optimization

- Unified Data Pipeline: Direct .stl/.step ingestion eliminates format conversion errors (reduces remakes by 18.7%)

- Predictive Analytics: Full access to 217 real-time sensor parameters via REST API for failure prevention

- TCO Reduction: $28,500/year savings on materials for 10K-unit lab (vs. closed system)

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026-certified integration with the MC XL represents the industry’s most sophisticated workflow orchestration layer. Technical implementation leverages:

- Zero-Configuration Discovery: Automatic detection via mDNS protocol on lab VLAN

- Bi-Directional Command Set:

- Job submission with material-specific parameters (e.g., {“material_id”:”VITA_YZ_ST”, “coolant”:”wet”})

- Real-time status polling (milling progress, tool wear %, error codes)

- Automated post-mill actions (e.g., trigger sintering oven via IFTTT)

- Failure Resolution Protocol:

- AI-driven error classification (e.g., “Tool Breakage: T12-0.6mm” → auto-loads backup toolpath)

- Automatic technician escalation via Teams/Slack with diagnostic screenshots

Operational Impact: Reduces manual intervention by 74% in high-volume labs (per 2026 Carejoy Lab Productivity Report). Enables true “lights-out” manufacturing with automatic job queuing based on material availability and machine status.

Strategic Implementation Recommendation

The CEREC MC XL functions as a workflow catalyst only when deployed within an open architecture ecosystem. For labs:

- Pair with exocad for maximum material flexibility and toolpath control

- Implement Carejoy API for enterprise-level job orchestration

- Avoid proprietary material lock-in (closed systems incur 22.3% higher unit cost)

Critical Success Factor: Calibration protocol standardization across CAD platforms. Labs using Carejoy’s unified calibration manager report 31% fewer remakes versus manual calibration.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Intraoral Scanning, High-Precision 5-Axis Milling

Manufacturing & Quality Control: Carejoy Digital’s Sirona CEREC MC XL-Compatible Milling Unit (China Production)

Carejoy Digital has re-engineered the performance envelope of legacy Sirona CEREC MC XL milling systems through a next-generation manufacturing and quality assurance pipeline based in Shanghai, China. While maintaining mechanical and software compatibility with the CEREC ecosystem, Carejoy’s iteration delivers enhanced precision, reliability, and AI-integrated diagnostics — all under a rigorously controlled ISO 13485-certified environment.

1. Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| Design & Prototyping | Reverse-engineering and CAD optimization of CEREC MC XL kinematics using open STL/PLY pipeline integration. Modular design for serviceability and upgradeability. | AI-aided FEA simulation; Open architecture firmware (supports third-party CAM software) |

| Component Fabrication | High-tolerance CNC machining of aluminum alloy chassis, ceramic spindle housing, and linear guide rails. Sourced from Tier-1 Chinese precision engineering suppliers. | ±2µm tolerance on critical moving parts; ISO 13485 traceability per batch |

| Spindle Assembly | Integration of 40,000 RPM high-frequency spindle with liquid cooling and brushless motor. Pre-loaded ceramic bearings for minimal runout. | Runout < 3µm; vibration analysis via laser doppler vibrometry |

| Electromechanical Integration | Installation of linear encoders, torque sensors, and adaptive force feedback system. Full wiring harness with EMI shielding. | Real-time load monitoring; AI-driven tool wear prediction |

| Software Flashing | Installation of Carejoy OS v4.2 with AI-optimized toolpath engine and remote diagnostics suite. | Secure boot; encrypted communication; over-the-air (OTA) update capability |

2. Quality Control & Sensor Calibration Labs

Each unit undergoes a 72-hour QC cycle at Carejoy’s ISO 13485:2016-certified facility in Pudong, Shanghai. The QC process is anchored in metrology-grade sensor calibration and closed-loop validation.

| QC Stage | Procedure | Instrumentation & Standards |

|---|---|---|

| Sensor Calibration | Calibration of force, position, temperature, and vibration sensors using NIST-traceable standards. | On-site metrology lab with laser interferometers, deadweight force calibrators, and thermal chambers (−10°C to +60°C) |

| Dynamic Runout Test | Spindle runout measured under load at 10k, 20k, and 40k RPM. | Capable of detecting deviations < 2.5µm; logged per unit |

| Milling Accuracy Validation | Test milling of ISO 5832-1 titanium blocks and zirconia blanks; post-process measurement via coordinate measuring machine (CMM). | Deviation tolerance: ≤5µm across 10 consecutive milling cycles |

| Environmental Stress Testing | Thermal cycling, humidity exposure (up to 85% RH), and power fluctuation resilience. | Simulates 5 years of clinical use in 72 hours |

| AI Feedback Loop | Machine learning model analyzes sensor data from 10,000+ prior units to flag anomalies. | Reduces false positives by 41% vs. traditional QC |

3. Durability & Longevity Testing

To ensure clinical-grade robustness, Carejoy subjects each milling unit to accelerated life testing:

- Spindle Life Cycle: 10,000 hours of continuous operation at 30,000 RPM with intermittent load spikes.

- Linear Guide Wear: 500,000 reciprocating cycles with debris simulation (zirconia dust, coolant exposure).

- Software Stability: 7-day continuous milling simulation with AI-path optimization; zero crash incidents recorded in v4.2.

- Mean Time Between Failures (MTBF): >15,000 hours — exceeding original Sirona specifications by 28%.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware. Carejoy Digital exemplifies this shift through strategic integration of domestic supply chains, AI-augmented manufacturing, and agile regulatory alignment.

| Factor | China Advantage | Carejoy Implementation |

|---|---|---|

| Supply Chain Density | Concentration of precision motor, encoder, and CNC component suppliers within 100km of Shanghai. | Reduced logistics cost by 37%; JIT inventory model |

| Skilled Engineering Labor | Deep talent pool in mechatronics and embedded systems from Shanghai Jiao Tong, Fudan, and Zhejiang University. | In-house R&D team of 89 engineers; 40% with advanced robotics training |

| Regulatory Efficiency | CFDA (NMPA) certification streamlined for Class II medical devices with ISO 13485 as baseline. | 90-day certification cycle vs. 6+ months in EU/US |

| AI & Automation Integration | National push for “Smart Manufacturing 2025” enables early adoption of predictive QC and robotic assembly. | AI-driven calibration reduces manual intervention by 60% |

| Cost-Performance Output | Delivers 98% of Sirona-grade precision at 42% lower TCO (Total Cost of Ownership). | ROI for clinics: <18 months with 2+ daily restorations |

As a result, Carejoy Digital’s Sirona-compatible milling units offer an unprecedented balance of clinical accuracy, software intelligence, and economic viability — positioning China not just as a manufacturing hub, but as a technology innovator in the global digital dentistry landscape.

Support & Connectivity

- 24/7 Remote Technical Support via secure TLS tunnel with AR-assisted diagnostics

- Monthly OTA Software Updates with new materials, toolpaths, and AI enhancements

- CloudSync Integration: STL/PLY/OBJ export to major dental design platforms (exocad, 3Shape, Carestream)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sirona Cerec Mc Xl Milling Unit.

✅ Open Architecture

Or WhatsApp: +86 15951276160