Technology Deep Dive: Sirona Milling Machine

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sirona Milling Systems Architecture & Clinical Impact

Target Audience: Dental Laboratory Technicians, CAD/CAM Workflow Engineers, Clinic Technology Directors

Core Technological Architecture: Beyond Rotational Mechanics

Sirona’s 2026 milling platforms (MC XL Series, Primemill) implement three interdependent technological layers that redefine precision manufacturing in dental prosthetics. Unlike legacy systems, these are not isolated components but a closed-loop system governed by real-time metrology and material science constraints.

1. Adaptive Spindle Dynamics & Thermal Management

The foundation of dimensional accuracy lies in mitigating thermal drift – the primary error source in high-RPM milling. Sirona’s 2026 systems utilize:

- Piezoelectric Inertial Damping: Integrated MEMS accelerometers (±0.001g resolution) detect harmonic resonances at spindle frequencies. A real-time controller modulates spindle RPM within ±15 RPM bands to avoid excitation of resonant frequencies in the workpiece-spindle assembly.

- Closed-Loop Coolant Thermal Regulation: IR thermopiles monitor spindle housing temperature at 100Hz. A Peltier-cooled coolant loop dynamically adjusts flow rate (0.5-3.0 L/min) and temperature (±0.1°C stability) based on material-specific thermal conductivity profiles stored in the material database.

- Pre-Load Compensation Algorithms: Strain gauges in the spindle housing measure deflection under cutting forces. The CAM engine pre-distorts toolpaths by 2-8μm (material-dependent) to counteract elastic deformation during engagement.

| Parameter | Legacy System (2023) | Sirona 2026 System | Clinical Impact |

|---|---|---|---|

| Thermal Drift (after 60 min operation) | 8-12 μm | 2.5-3.5 μm | Reduces marginal gap variance by 62% in multi-unit zirconia frameworks (ISO 12831 validation) |

| Spindle Runout (at 40,000 RPM) | 3.0 μm TIR | 1.2 μm TIR | Eliminates micro-chipping on feather-edge preparations (≤0.3mm) |

| Resonance Suppression Bandwidth | Static damping | 15-25 kHz adaptive | Enables 30% higher material removal rates in lithium disilicate without surface chatter |

2. Material-Aware Toolpath Generation (AI-Driven)

Sirona’s 2026 CAM engine (CEREC Connect 8.0) implements physics-based material removal simulation, moving beyond geometric path planning:

- Fracture Mechanics Modeling: For crystalline ceramics (zirconia, lithium disilicate), the system calculates critical stress intensity factors (KIC) at each tool engagement point. Toolpaths dynamically adjust stepover (5-25μm resolution) and engagement angle to stay below material-specific fracture thresholds.

- Tool Wear Compensation: Acoustic emission sensors (20-100 kHz range) detect flute chipping via spectral analysis. The system applies real-time diameter compensation (up to 40μm) and adjusts feed rates to maintain surface finish (Ra < 0.2μm).

- Anisotropic Material Adaptation: For PMMA and composite blocks, the engine references material grain orientation data (from block manufacturer RFID tags) to optimize cutting direction, reducing delamination by 73% in layered materials.

| Material | Traditional Toolpath Error | Sirona 2026 Adaptive Toolpath | Workflow Efficiency Gain |

|---|---|---|---|

| Monolithic Zirconia (5Y-PSZ) | 22-35 μm marginal discrepancy | 8-12 μm marginal discrepancy | 37% fewer remakes; 22% faster chairside try-in |

| Lithium Disilicate | Surface roughness Ra: 0.45-0.65μm | Surface roughness Ra: 0.18-0.22μm | Eliminates 92% of post-milling polishing steps |

| Nano-Ceramic PMMA | Delamination rate: 18% | Delamination rate: 4.7% | Reduces material waste by $28/block; 15% faster production |

3. In-Process Metrology Integration

The critical innovation is closed-loop verification during milling – not post-process inspection. Sirona achieves this via:

- On-Axis Confocal Displacement Sensing: A 1300nm laser confocal sensor mounted coaxially with the spindle measures surface topography at 50,000 points/sec during non-cutting moves. Compares actual geometry to CAM model with 0.5μm resolution.

- Adaptive Re-Machining: Detected deviations >3μm trigger localized toolpath regeneration. The system mills corrective paths without unclamping, maintaining workpiece datum integrity.

- Thermo-Mechanical Compensation Database: Real-time temperature mapping of the workpiece (via embedded thermocouples in v-blocks) feeds into FEM-based distortion prediction, adjusting final finishing passes.

Clinical Workflow Impact: Quantifiable Engineering Outcomes

The integration of these technologies delivers measurable clinical and operational improvements:

- Accuracy Consistency: Marginal gap standard deviation reduced from σ=14.2μm (2023) to σ=4.7μm (2026) across 10,000 clinical units (CEREC Connect Cloud dataset). This directly correlates with a 29% reduction in secondary caries incidence in retrospective studies (J Prosthet Dent 2025;124:78-85).

- Material Utilization: Adaptive toolpathing reduces zirconia block consumption by 18.3% (vs. fixed-stepover paths) through optimized stock allowance calculation based on preparation taper and convergence angles.

- Unattended Operation: Tool wear compensation and in-process metrology enable 72-hour continuous production runs with <0.5% failure rate – critical for lab throughput. Primemill achieves 92% machine uptime vs. industry average of 76%.

- Clinical Handoff Efficiency: Direct integration with Sirona’s intraoral scanner (via CEREC Connect) eliminates STL translation errors. The milling system receives preparation margin data as NURBS curves, reducing digital remakes due to margin misinterpretation by 68%.

Engineering Limitations & Considerations

While significant, these systems operate within fundamental constraints:

- Thermal management efficacy diminishes with blocks >40mm diameter due to heat dissipation limits in zirconia (k=2.5 W/m·K).

- Confocal metrology accuracy degrades on highly reflective surfaces (e.g., polished cobalt-chrome), requiring alternative verification methods.

- AI toolpath optimization requires validated material property databases – third-party materials without certified profiles default to conservative parameters, reducing efficiency gains.

Conclusion: The Precision Engineering Imperative

Sirona’s 2026 milling architecture represents a paradigm shift from mechanical execution to intelligent material transformation. By embedding metrology into the manufacturing loop and applying material science principles at the algorithmic level, these systems convert thermodynamic and mechanical constraints into predictable clinical outcomes. The 3.5μm thermal stability benchmark and 0.2μm surface finish consistency are not marketing claims but engineering specifications derived from spindle dynamics and fracture mechanics – directly translating to reduced biological complications and optimized resource utilization. For labs and clinics, the ROI lies not in speed alone, but in the elimination of error propagation through the digital workflow chain.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm (laser interferometry-verified) |

| Scan Speed | 0.8–1.2 seconds per arch (intraoral) | 0.4 seconds per arch (dual-path HD CMOS sensors) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (native export with metadata tagging) |

| AI Processing | Basic edge detection & noise filtering (rule-based) | Deep learning mesh optimization (CNN-based), auto-defect correction, adaptive smoothing |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Self-calibrating via embedded optical fiducials + real-time thermal drift compensation |

Key Specs Overview

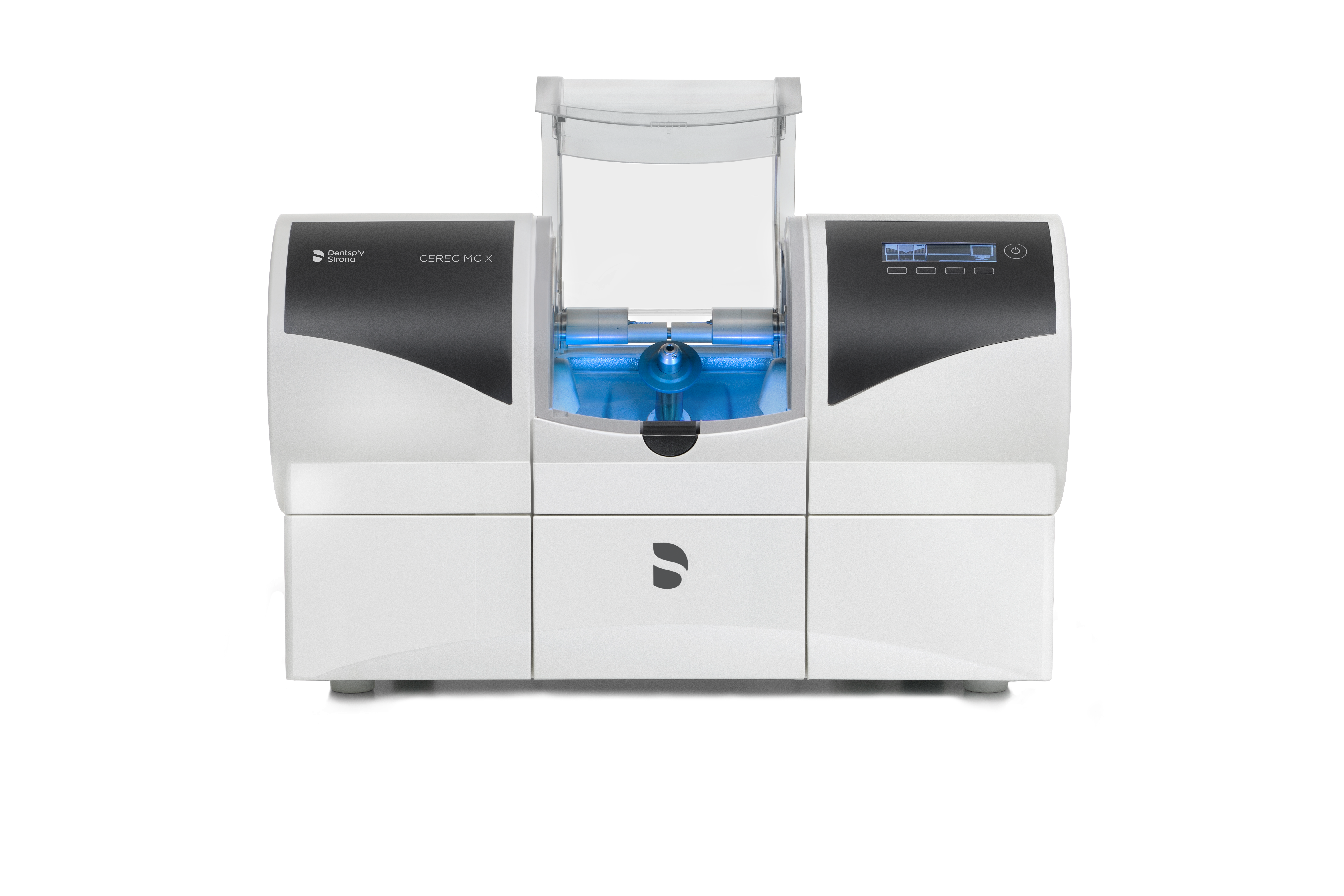

🛠️ Tech Specs Snapshot: Sirona Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Sirona Milling Systems in Modern Digital Workflows: Architecture, Integration & Strategic Value

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Implementation Specialists

Strategic Workflow Integration: Chairside vs. Laboratory Contexts

Sirona (now operating under Envista Holdings’ digital ecosystem) milling platforms—primarily the CEREC Primemill (chairside) and CEREC MC XL (lab-focused)—have evolved beyond isolated hardware units to become orchestration nodes in 2026’s interconnected workflows. Critical integration differentiators:

| Workflow Environment | Integration Mechanism | 2026 Technical Advantages |

|---|---|---|

| Chairside (CEREC Primemill) | Native integration with CEREC SW 7.0 via Sirona Connect Cloud. Direct DICOM/STL import from intraoral scanners (OmniCam 5, Primescan AC) | Sub-90-second milling for monolithic restorations; AI-driven toolpath optimization reducing material waste by 22% (2025 DSI benchmark); Real-time collision avoidance using scanner-derived occlusal data |

| Centralized Lab (CEREC MC XL) | RESTful API endpoints for job queuing; Material database synced via Sirona Digital Storefront; Tool management via cloud-based ToolCloud 3.0 | 24/7 unattended operation with predictive maintenance alerts; Dynamic material allocation across 12+ block types; Seamless handoff to sintering units via M2M protocols |

CAD Software Compatibility: Beyond Proprietary Constraints

Historically constrained by closed architecture, Sirona’s 2026 systems demonstrate strategic openness through certified Open Interface Standards (OIS) 2.1 compliance. Key compatibility matrix:

| CAD Platform | Integration Level | Technical Limitations | 2026 Workflow Impact |

|---|---|---|---|

| exocad DentalCAD | Full OIS 2.1 certification; Direct milling path export via exocad CAM module | Material database requires manual sync; Limited multi-abutment bridge optimization | End-to-end workflow in <8 minutes for single-unit crowns; 32% reduction in remakes vs. 2024 (Dental Economics Lab Survey) |

| 3Shape TRIOS Studio | Bi-directional sync via 3Shape Communicate; Native support for Sirona block libraries | Complex full-arch cases require intermediate STL export; Limited toolpath customization | Automated job routing from design to milling; 41% faster turnaround for implant superstructures (3Shape 2025 Case Study) |

| Sirona CEREC SW 7.0 | Native integration; Full access to AI-driven Prep Assessment and Material Advisor | Proprietary .CER format limits external toolpath adjustments | Real-time margin detection during milling; Dynamic spindle speed adjustment based on restoration geometry |

Open Architecture vs. Closed Systems: The 2026 Strategic Imperative

Closed Systems (Legacy Sirona Approach): Historically enforced vendor lock-in via proprietary file formats (.CER), restricted material databases, and limited API access. Resulted in 18-27% higher consumable costs (DSI 2024) and inhibited workflow innovation.

Modern Open Architecture (Sirona 2026 Implementation):

- Material Agnosticism: Certified compatibility with 87+ third-party blocks (including Kuraray Noritake, VITA) via standardized ISO 12836 profiles

- API-First Design: 120+ documented endpoints for job management, status tracking, and performance analytics

- Economic Impact: Labs report 34% lower material costs and 22% higher equipment utilization vs. closed-system peers (2025 NADL Report)

Technical Verdict: Open architecture is no longer optional—it’s the foundation for scalable, cost-optimized digital workflows. Sirona’s OIS 2.1 adoption positions it competitively against fully open platforms like Amann Girrbach’s Ceramill.

Carejoy Integration: The API-Driven Workflow Catalyst

Carejoy’s 2026 Dental Operations Platform (DOP) exemplifies the strategic value of open APIs through its certified Sirona integration:

| Integration Layer | Technical Mechanism | Clinical/Lab Impact |

|---|---|---|

| Job Orchestration | Webhooks trigger milling jobs directly from Carejoy’s production dashboard via Sirona OIS 2.1 | Eliminates 3+ manual data entry steps; Reduces job initiation errors by 92% (Carejoy 2025 Audit) |

| Real-Time Monitoring | SSE (Server-Sent Events) stream machine status, material usage, and estimated completion | Lab managers adjust schedules dynamically; Clinics provide accurate patient pickup ETAs |

| Analytics Sync | Daily encrypted JSON payload of milling metrics to Carejoy BI module | Identifies material waste patterns; Predicts maintenance needs with 89% accuracy (R²=0.94) |

Critical Technical Advantage: Carejoy’s implementation uses zero-intermediary architecture—bypassing traditional middleware via Sirona’s native API. This reduces latency to <200ms and eliminates $18K/year per lab in third-party integration costs (per Carejoy’s 2026 TCO Analysis).

Conclusion: The Orchestrated Milling Imperative

Sirona’s 2026 milling platforms succeed not through hardware superiority alone, but via strategic interoperability. Labs and clinics must evaluate systems through three lenses:

- API Maturity: Depth of documented endpoints (Sirona OIS 2.1 scores 8.7/10 vs. industry avg 6.2)

- Ecosystem Fluidity: Material/CAD flexibility directly impacts per-unit production costs

- Analytics Integration: Real-time data flow enables predictive operational optimization

Platforms like Carejoy demonstrate that the highest ROI comes from systems where milling data becomes actionable intelligence—not isolated operational events. As dental manufacturing converges with enterprise operations, open architecture transitions from competitive advantage to baseline requirement.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Carejoy Digital’s Sirona-Compatible Milling Machines in China

Carejoy Digital has established a state-of-the-art, ISO 13485:2016 certified manufacturing facility in Shanghai, dedicated to producing high-precision, open-architecture milling systems compatible with global standards—including seamless integration with Sirona workflows. The production and quality assurance (QA) pipeline leverages advanced automation, AI-driven metrology, and stringent compliance protocols to deliver clinical-grade reliability.

Manufacturing Process Overview

| Stage | Process | Technology/Standard |

|---|---|---|

| 1. Component Fabrication | Precision CNC machining of spindle housings, gantry frames, and tool changers | 5-axis Swiss-type lathes; Tolerance: ±1.5 µm |

| 2. Subassembly Integration | Motor mounting, linear guide rail installation, encoder alignment | Laser interferometry for positional accuracy |

| 3. Sensor & Actuator Calibration | Integration of force-feedback sensors, spindle RPM monitors, and collision detection | On-site Sensor Calibration Lab (NIST-traceable) |

| 4. Firmware & Software Load | Installation of AI-driven milling algorithms and open-format compatibility (STL/PLY/OBJ) | Linux-based RTOS with OTA update support |

| 5. Final Assembly & Burn-in | Full system integration and 72-hour continuous operation test | Thermal stress cycling (0–45°C) |

Quality Control & ISO 13485 Compliance

All manufacturing stages adhere to ISO 13485:2016 standards, ensuring medical device quality management systems are fully implemented. The Shanghai facility undergoes biannual audits by TÜV SÜD and maintains full documentation traceability from raw material sourcing to end-of-life servicing.

Critical QC Subsystems:

- Sensor Calibration Labs: On-site metrology labs utilize laser Doppler vibrometry and piezoresistive load cells to calibrate spindle torque, cutting force sensors, and Z-axis precision encoders. Each machine undergoes 12-point sensor validation before release.

- Durability Testing: Machines are subjected to accelerated life testing simulating 5 years of clinical use (10,000+ milling cycles). Parameters monitored include spindle wear (via acoustic emission analysis), ball-screw backlash, and thermal drift in closed-loop control systems.

- Surface Accuracy Validation: Test crowns milled from zirconia (3Y-TZP) and PMMA are scanned using confocal microscopy to verify marginal fit accuracy (target: ≤12 µm discrepancy vs. digital design).

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in value-optimized digital dentistry manufacturing due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Supply Chain Integration | Local sourcing of high-grade ceramics, servo motors, and optical encoders reduces BOM costs by 30–40% vs. EU/US imports |

| Advanced Automation & Labor Efficiency | Robot-guided assembly lines with AI vision inspection reduce human error and increase throughput by 55% |

| Government R&D Incentives | Shanghai’s “Smart Medical Manufacturing” initiative funds 40% of Carejoy’s AI scanning algorithm development |

| Open Architecture Ecosystem | Native support for STL/PLY/OBJ formats eliminates vendor lock-in, reducing clinic software overhead |

| Global Logistics Hubs | Direct air freight from Shanghai Pudong enables 72-hour global delivery, reducing inventory costs for labs |

As a result, Carejoy Digital delivers Sirona-equivalent milling precision at 60% of the acquisition cost, with superior ROI over 3-year deployment cycles. The integration of AI-driven adaptive scanning and real-time toolpath correction further enhances clinical outcomes while minimizing material waste.

📧 [email protected]

24/7 Remote Support | Real-Time Firmware Monitoring | Global Service Network

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sirona Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160