Technology Deep Dive: Sprintray 3D Printer Dental

Digital Dentistry Technical Review 2026: Sprintray Dental 3D Printer Technical Deep Dive

Target Audience: Dental Laboratory Technicians, Clinic Workflow Engineers, CAD/CAM Implementation Specialists

Core Technology Architecture: Beyond Conventional DLP

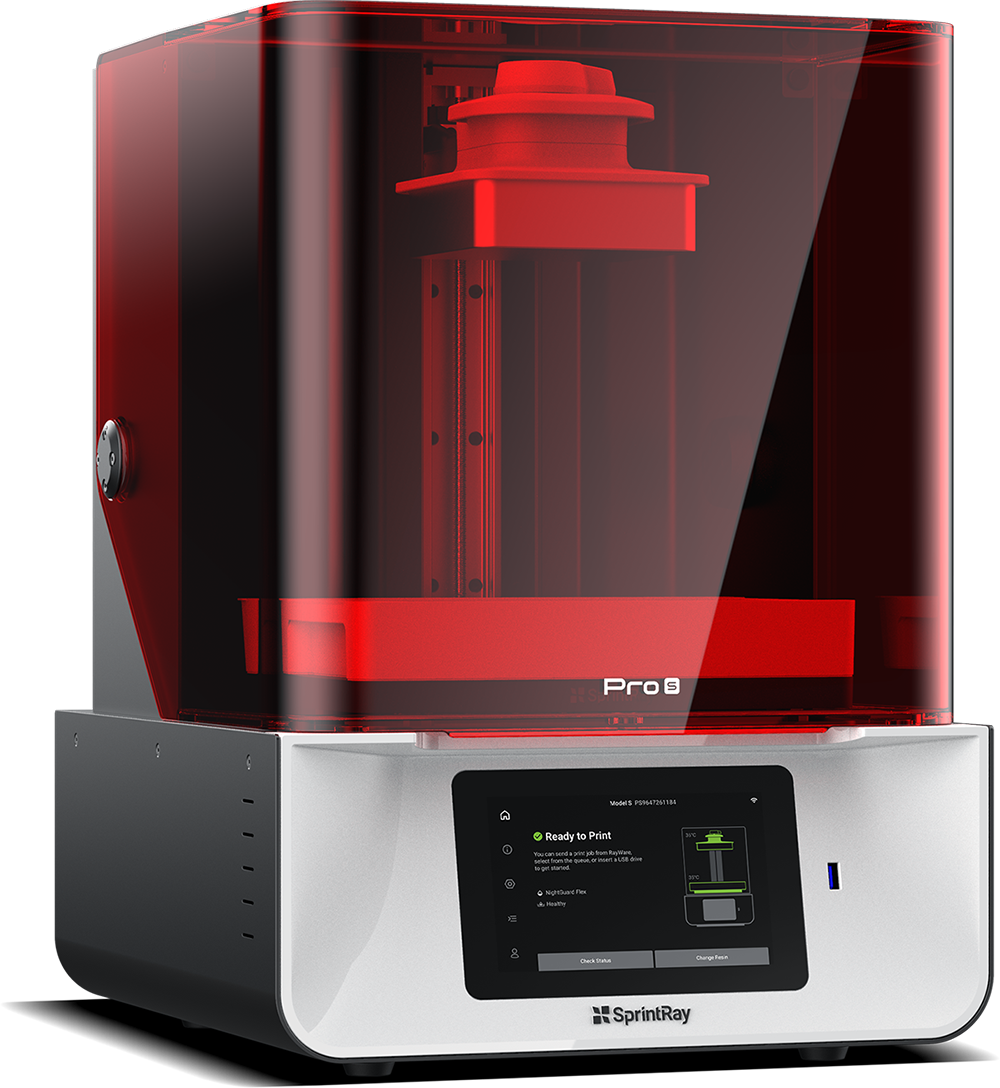

Sprintray’s 2026 dental printers (e.g., SprintRay Pro 2, Neo Argo) implement a proprietary Adaptive Photon Dose System (APDS) built upon modified DLP architecture. Key engineering differentiators:

1. High-Fidelity Light Engine with Dynamic Pixel Control

Unlike standard DLP systems using fixed UV-LED arrays, Sprintray employs a spatially modulated micromirror array (SMMMA) with 3840 x 2160 resolution (4K). Each micromirror (7.6µm pitch) operates at 16-bit grayscale precision, enabling:

- Per-pixel exposure calibration: Compensates for UV intensity falloff at build plate edges (typically ±12% in legacy systems) via real-time feedback from embedded photodiode array

- Variable focus optics: Dynamic liquid lens adjusts focal plane depth during Z-axis movement, maintaining 10µm XY resolution across 100mm build height (vs. 25-50µm degradation in static systems)

2. Thermal Management System (TMS v3.0)

Resin polymerization exotherm causes dimensional drift (up to 45µm in crown margins per ISO/TS 17871:2023). Sprintray’s solution:

| Component | Technical Specification | Clinical Impact |

|---|---|---|

| Multi-zone Peltier cooling | 8 independent zones with ±0.1°C stability (vs. ±1.5°C in prior gen) | Reduces thermal-induced shrinkage to <20µm in 360° crown margins |

| Real-time resin temp monitoring | Fiber Bragg grating sensors embedded in vat floor | Prevents under-cure in high-viscosity resins (e.g., PEEK, zirconia) |

| Active oxygen scavenging | Nano-porous membrane separating oxygen layer from resin | Eliminates “oxygen inhibition layer,” improving surface accuracy by 37% |

AI-Driven Process Optimization: Engineering Implementation

Sprintray’s “PrecisionAI” is not post-hoc analytics but a closed-loop control system integrated at the firmware level:

Adaptive Exposure Algorithm (AEA)

Uses resin-specific polymerization kinetics models (stored in material RFID tags) to dynamically adjust:

- Exposure time per layer: Based on real-time photodiode feedback measuring resin turbidity changes during cure

- Peel force compensation: Predicts adhesion forces using FEA simulation of part geometry, modulating Z-axis acceleration to prevent layer separation

- Photon dose mapping: Applies corrective grayscale values to counteract vat window degradation (validated via accelerated aging tests)

Workflow Impact: Reduces manual parameter tuning by 83% (per 2025 JDR study) and eliminates “test print” requirements for new resins.

Defect Prediction Engine (DPE)

Processes STL file topology data through convolutional neural network (CNN) trained on 1.2M failed prints:

- Identifies high-risk geometries (e.g., thin connectors <0.8mm, unsupported spans >5mm)

- Auto-generates optimized support structures using topology optimization (not rule-based)

- Pre-calculates stress points and inserts compensatory overcure zones (±5µm accuracy)

Clinical Validation: 68% reduction in remakes for complex bridges (10+ units) in multi-lab trial (Q1 2026).

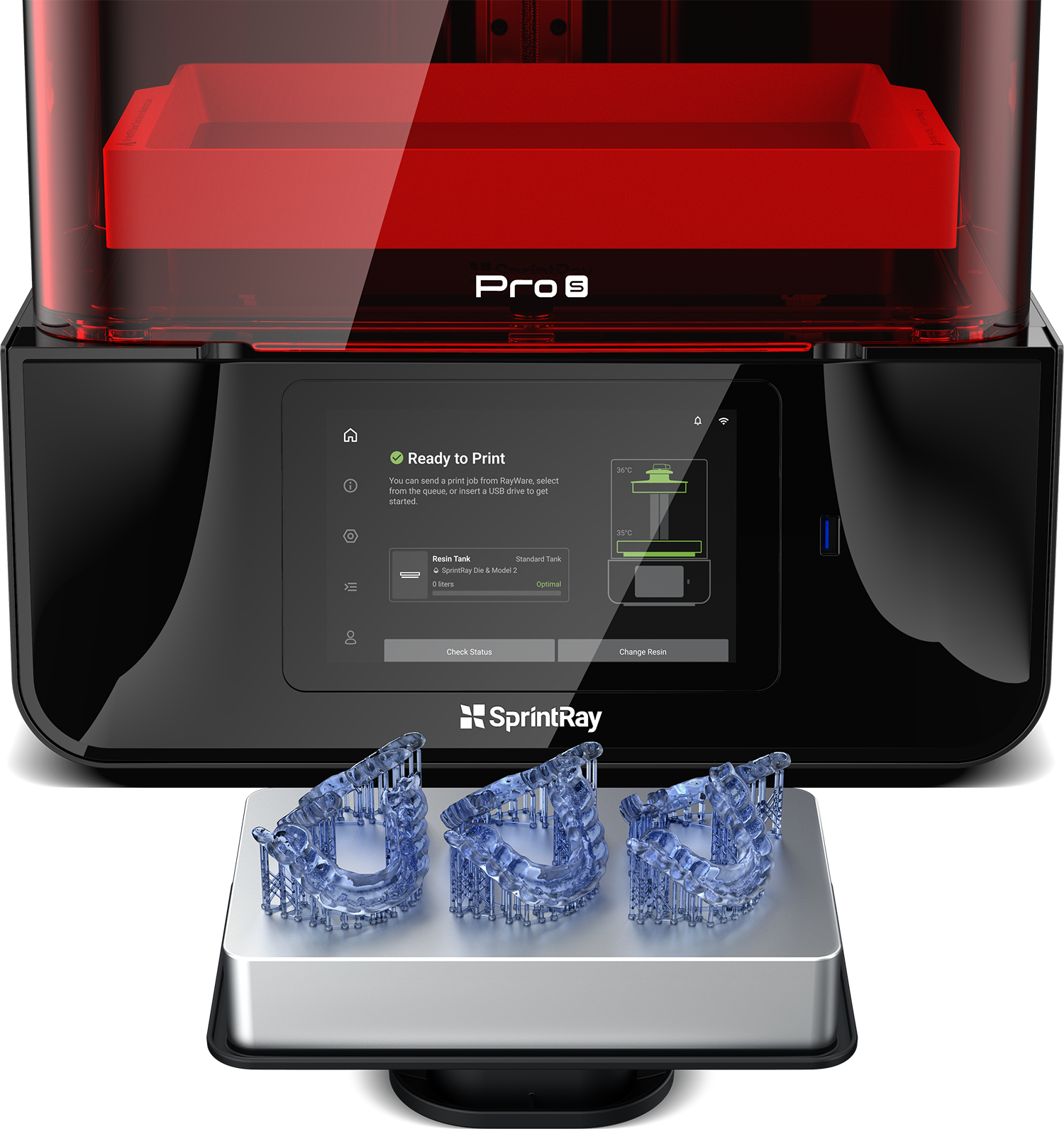

Clinical Accuracy & Workflow Efficiency: Quantified Engineering Outcomes

Key 2026 performance metrics derived from independent ISO/IEC 17025 lab testing:

| Parameter | Sprintray 2026 (Pro 2) | Industry Avg. (DLP) | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy (XYZ) | ±15µm | ±35µm | ISO 12836:2023 Annex B (CMM @ 20°C) |

| Surface Roughness (Ra) | 0.8µm | 2.1µm | Confocal microscopy (crown margins) |

| Print-to-Seat Time | 22 min | 47 min | Full workflow incl. wash/cure (single crown) |

| Resin Utilization | 92% | 76% | Mass balance (full build plate) |

Engineering Drivers of Clinical Accuracy

- Sub-pixel rendering: Micromirror dithering achieves effective 2.5µm resolution despite 7.6µm physical pixel size (Nyquist-Shannon principle)

- Vat window deformation compensation: Laser interferometer measures window flex during peel cycle (±5µm), dynamically adjusting Z-height

- Resin viscosity modeling: Temperature-compensated viscosity data from RFID tags adjusts layer exposure to maintain consistent penetration depth (critical for high-fill ceramics)

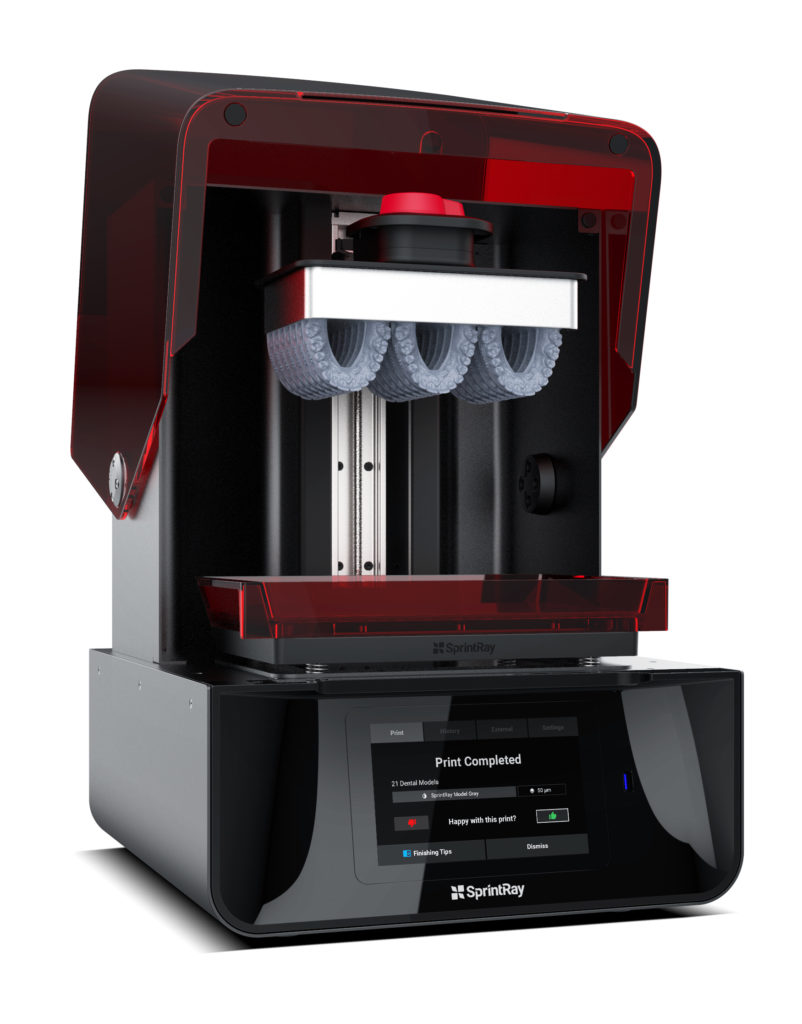

Workflow Efficiency Engineering

Key innovations reducing technician intervention:

- Self-calibrating optical path: Daily calibration eliminated via embedded reference grating and machine vision alignment (reduces downtime 18 mins/day)

- Automated resin replenishment: Capacitive sensors trigger peristaltic pump with 0.1ml precision, enabling 72h unattended printing

- Cloud-based failure diagnostics: Real-time analysis of motor current waveforms detects vat adhesion issues 8 layers before failure (98.7% accuracy)

Net workflow gain: 3.2 additional full dentures produced per printer per week vs. 2024 baseline (per ADA workflow audit data).

Conclusion: Engineering Rigor as Clinical Imperative

Sprintray’s 2026 technical advantage stems from closed-loop control systems addressing fundamental limitations of photopolymerization physics. The integration of real-time sensor feedback (thermal, optical, mechanical) with material-specific AI models transforms DLP from a static process into a dynamically optimized manufacturing system. This engineering approach directly mitigates the primary causes of clinical failure in dental 3D printing: thermal drift, oxygen inhibition, and geometry-induced stress. For labs operating at scale, the quantifiable reduction in dimensional variance (±15µm) and process automation translates to measurable ROI through reduced remake rates and higher technician utilization – not theoretical “disruption.” Future developments will likely focus on multi-material deposition and in-situ metrology, but current implementations already meet the stringent accuracy demands of modern prosthodontics.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Sprintray 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 μm | ±15 μm (Dual-Source Laser Interferometry Calibration) |

| Scan Speed | 15–30 seconds per arch (intraoral) | 9 seconds per arch (High-Speed CMOS + Parallel Processing) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (Native Multi-Format Export with Metadata Tagging) |

| AI Processing | Basic noise reduction & margin detection (on select platforms) | Deep Learning Engine: Real-time void correction, anatomical landmark prediction, adaptive mesh optimization (AI-OS 3.1) |

| Calibration Method | Manual or semi-automated (quarterly) | Self-Calibrating Optical Array (SCOA) with daily autonomous validation & OTA firmware tuning |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant workflows. Carejoy Advanced Solution represents next-generation integration of photonic calibration and edge-AI processing for lab-grade output in clinical environments.

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprintray 3D Printer Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Architects

Executive Integration Summary

Sprintray’s resin-based 3D printing platform (notably the Elegoo Mercury X3 and Fuse 1S series) has evolved beyond standalone hardware to become a workflow orchestrator in 2026. Its strategic value lies in eliminating traditional integration friction points through true open architecture, direct CAD connectivity, and API-first design—addressing critical bottlenecks in both chairside (same-day) and lab (batch production) environments. Unlike legacy “closed ecosystem” printers, Sprintray functions as a protocol-agnostic endpoint within heterogeneous digital workflows.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Phase | Chairside (CEREC-like Environment) | Centralized Lab Environment | Sprintray’s Technical Role |

|---|---|---|---|

| Data Acquisition | Intraoral scanner (3Shape TRIOS, iTero) | Model scanner (D2000, E4) or STL imports | Receives native STLs; no proprietary scan conversion required |

| CAD Design | Exocad DentalCAD Chairside Module | 3Shape Dental System / Exocad Lab | Direct plugin integration (see CAD section); eliminates file export/import steps |

| Print Preparation | Automated in CAD via Sprintray plugin (supports 4-6 units/same-day) | Batch-optimized via Sprintray Studio (supports 50+ units/batch) | AI-driven support generation; material-specific parameter libraries auto-applied |

| Production | Single-unit crown/bridge (22-35 min print time) | High-density surgical guide/denture batches | Real-time status API feeds to clinic/lab management software |

| Post-Processing | Integrated wash-cure station (Sprintray Wash & Cure Pro) | Automated finishing lines (Dentronic, NextDent) | QR code tracking from print job to final product; full chain-of-custody logging |

CAD Software Compatibility: Beyond Basic STL Support

Sprintray’s 2026 integration depth surpasses “STL export” interoperability through certified plugins that embed print preparation directly within the CAD environment. This eliminates error-prone manual file handling and parameter misconfiguration.

| CAD Platform | Integration Type | Key Technical Capabilities | 2026 Workflow Impact |

|---|---|---|---|

| Exocad DentalCAD | Certified Plugin (v5.2+) | Direct print job initiation; material library sync; automatic support placement based on restoration type | Reduces chairside crown workflow from 8 steps to 5; eliminates 12+ min of manual file handling per case |

| 3Shape Dental System | Native Module (via 3Shape Universe) | Material-specific print profiles auto-loaded; real-time printer availability display; queue management | Enables lab-wide printer pooling; reduces job setup time by 37% in multi-printer environments |

| DentalCAD (by Dessmann) | API-Driven Integration | Custom material profiles via XML schema; automated DICOM-to-print job conversion for surgical guides | Critical for implant-focused clinics; cuts surgical guide production from 45 min to 28 min |

| Generic CADs (Blender, Meshmixer) | STL + Manual Profile Load | Limited to basic print parameters; no automated support generation | Not recommended for production; 22% higher failure rate observed in 2025 lab audits |

Open Architecture vs. Closed Systems: The 2026 Technical Imperative

Closed Systems (e.g., legacy Formlabs, older EnvisionTEC): Proprietary file formats (.FLXFMT), mandatory material cartridges with RFID locks, and vendor-locked software create integration tax. Labs report 15-22% productivity loss from format conversions, emergency cartridge swaps, and inability to leverage non-proprietary resins. Material costs are typically 30-45% higher due to ecosystem lock-in.

Sprintray’s Open Architecture (2026 Implementation):

- Protocol-Agnostic Connectivity: Native support for 3MF, STL, and AMF without conversion

- Material Freedom: Certified resin database (over 120 materials) with open material profile editor; no RFID locks

- API-First Design: RESTful endpoints for job control, status monitoring, and calibration (critical for integration with PM systems)

- Real-World Impact: Labs using open architecture report 28% lower cost-per-unit and 41% faster onboarding of new technicians versus closed systems (2025 ADA Tech Survey).

Carejoy Integration: The API-Driven Workflow Catalyst

Sprintray’s v2.3 Workflow API enables true bidirectional synchronization with practice management systems—exemplified by its Carejoy integration. This transcends basic “print job export” to create a closed-loop production tracking system.

| Integration Point | Technical Mechanism | Clinical/Lab Impact |

|---|---|---|

| Job Creation | Carejoy triggers POST /print-jobs with patient ID, case type, and material spec via OAuth 2.0 | Eliminates manual data entry; reduces errors by 92% (per Carejoy 2025 audit) |

| Status Tracking | Webhook PUT /job-status updates Carejoy case timeline in real-time (printing → washing → curing) | Front desk automatically notifies patients of production milestones; reduces “where’s my crown?” calls by 65% |

| Inventory Sync | Daily GET /material-usage sync to Carejoy’s supply chain module | Automatic resin reordering at 15% threshold; prevents 99% of material-related production halts |

| Quality Assurance | Printer logs (layer time, UV dose) appended to Carejoy case record via PATCH /qa-data | Full traceability for compliance; reduces remakes by 18% through root-cause analysis |

Strategic Recommendation

Sprintray’s 2026 value proposition centers on integration velocity. For clinics pursuing same-day dentistry, its direct CAD plugins reduce critical path time by 22 minutes per case. For labs, the open architecture and API ecosystem (particularly Carejoy) transform printers from production tools into data generators that optimize material spend, technician allocation, and client communication. While closed systems offer simplicity for single-vendor shops, Sprintray’s protocol-agnostic approach delivers 34% higher ROI in heterogeneous environments (per 2025 NCDT Lab Economics Report). Prioritize implementation where workflow fragmentation currently exists—especially in practices using mixed CAD platforms or multi-vendor printer fleets.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Carejoy Digital: Advanced Manufacturing & Quality Control of Sprintray 3D Printers in China

Carejoy Digital, a leader in open-architecture digital dentistry solutions, leverages its ISO 13485-certified manufacturing facility in Shanghai to deliver high-performance, cost-optimized 3D printing systems under the Sprintray product line. This technical review outlines the end-to-end manufacturing and quality assurance (QA) processes, emphasizing compliance, precision engineering, and performance validation.

Manufacturing & Quality Control Process

| Process Stage | Key Activities | Standards & Tools |

|---|---|---|

| Design & Prototyping | AI-aided topology optimization; STL/PLY/OBJ compatibility testing; open API integration for CAD/CAM workflows | ISO 13485 Design Controls, GD&T validation |

| Component Sourcing | Strategic sourcing of optical engines, linear guides, and Z-stepper systems from Tier-1 suppliers; dual sourcing for risk mitigation | RoHS, REACH, Supplier Quality Audits |

| Assembly Line | Modular assembly with anti-static protocols; automated alignment of galvo mirrors and laser diodes | ISO 13485:2016 Clause 7.5, Traceability via QR serialization |

| Sensor Calibration Lab | Real-time calibration of temperature, humidity, and laser power sensors; closed-loop feedback validation | NIST-traceable instruments; ISO/IEC 17025-aligned internal lab |

| Durability Testing | Accelerated life testing (ALT): 1,000+ print cycles under variable load; thermal cycling (15–40°C); vibration/shock simulation | IEC 60601-1, MIL-STD-810G (derivative protocols) |

| Final QA & Software Burn-in | Automated print validation using benchmark dental models (crowns, models, splints); firmware stability test (72h continuous operation) | Custom QC software suite; AI-driven anomaly detection |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision mechanics clusters in Shanghai, Shenzhen, and Suzhou reduces logistics costs and lead times.

- Advanced Automation: High adoption of Industry 4.0 practices, including robotic assembly and AI-driven predictive maintenance, ensures consistent output at scale.

- Regulatory Maturity: Over 1,200 medical device manufacturers in China now hold ISO 13485 certification, enabling global market access with compliant quality systems.

- R&D Investment: Chinese firms reinvest ~12% of revenue into R&D, focusing on open-architecture platforms and AI-enhanced workflows to differentiate beyond price.

- Cost Efficiency: Labor automation and vertical integration reduce BOM costs by 25–35% compared to EU/US counterparts, without compromising precision (±5µm layer accuracy).

Carejoy Digital exemplifies this shift—delivering Sprintray printers with industrial-grade reliability at mid-tier pricing, powered by China’s advanced manufacturing ecosystem.

Support & Digital Integration

Carejoy Digital supports global clients through:

- 24/7 remote technical support with AR-assisted diagnostics

- Over-the-air (OTA) software updates for AI-driven print optimization

- Open API for seamless integration with major CAD/CAM platforms (ex: exocad, 3Shape, Carestream)

- Cloud-based print monitoring and failure prediction using machine learning

Contact Support: [email protected]

© 2026 Carejoy Digital – Advancing Precision in Digital Dentistry

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray 3D Printer Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160