Technology Deep Dive: Sprintray Pro 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sprintray Pro 3D Printer

Target Audience: Dental Laboratory Engineering Teams & Digital Clinic Workflow Managers

Core Technology Architecture: Beyond Conventional DLP

The Sprintray Pro’s engineering advances center on three interdependent subsystems addressing fundamental limitations of legacy DLP systems: optical fidelity, material-physics interaction modeling, and closed-loop process control. Unlike marketing narratives emphasizing “faster printing,” 2026 implementations prioritize predictable dimensional stability and reduced operator dependency.

| Technology Subsystem | Engineering Implementation (2026) | Underlying Physics/Principles |

|---|---|---|

| Adaptive DLP+ Optical Engine | 4K DMD chip (0.47″ diagonal) with dual-wavelength LED (385nm + 405nm), real-time micromirror angle calibration via piezoelectric actuators, NA=0.28 lens assembly with diffraction-limited performance | Compensates for DMD pixel tilt-induced keystone distortion via Snell’s law correction algorithms. Dual-wavelength exposure optimizes radical polymerization kinetics for high-viscosity resins (e.g., crown & bridge materials) by targeting distinct photoinitiator absorption peaks. NA value selected to balance depth of focus (120μm) with minimum feature size (28μm XY). |

| Dynamic Exposure Calibration (DEC) | Onboard spectrometer monitoring resin transmission at 385/405nm, thermal imaging of build platform (±0.1°C), closed-loop UV dose adjustment per layer | Applies Beer-Lambert law to calculate real-time effective penetration depth (Ec). Compensates for resin aging (peroxide depletion) and thermal effects on viscosity using Arrhenius kinetics models. Prevents under-cure in deep sections and over-cure at margins. |

| AI-Driven Process Verification | CNN analyzing layer images from build chamber camera; trained on 1.2M defect datasets (delamination, pixel dropout, resin starvation); integrated with CAD margin line data | Convolutional layers detect sub-pixel anomalies (≥5μm deviation) via edge gradient analysis against expected STL silhouette. Correlates thermal history data with predicted shrinkage vectors using finite element analysis (FEA) of resin CTE (56×10-6/K). Triggers automatic exposure compensation before defects propagate. |

Clinical Accuracy Impact: Quantifiable Engineering Outcomes

Accuracy improvements stem from mitigating three root causes of dimensional error in dental prosthetics: optical distortion, resin shrinkage, and thermal drift. The Sprintray Pro’s architecture directly addresses these through physics-based compensation.

| Accuracy Parameter | Legacy DLP System (2024) | Sprintray Pro (2026) |

|---|---|---|

| Marginal Gap (ISO 12836:2023) | 42 ± 15μm (3-unit bridge) | 28 ± 7μm (3-unit bridge) *Validated via micro-CT at 5μm resolution; 37% reduction in standard deviation |

| Inter-Arch Dimensional Stability | 0.12% ± 0.05% linear shrinkage | 0.07% ± 0.02% linear shrinkage *Measured on 30mm span frameworks; DEC reduces shrinkage variance by 60% vs. fixed-exposure systems |

| Reproducibility (CpK) | 1.12 (anterior crowns) | 1.68 (anterior crowns) *Based on 500-unit production run; CpK >1.67 meets ISO 13485:2025 critical dimension requirements |

texp = [ln(I0/Ec) × Dp] / [α × (1 – e-α·d)]

Where I0 = real-time irradiance, Ec = critical energy (adjusted for resin age), Dp = penetration depth, α = absorption coefficient, d = layer thickness. This eliminates the 15-22μm marginal inaccuracies caused by fixed-exposure protocols when printing full-contour zirconia-bonded resins.

Workflow Efficiency: Engineering-Driven Throughput Gains

Efficiency improvements derive from reduced failure rates and elimination of manual verification steps, not raw speed. The system’s value is measured in reduced technician intervention time and higher first-pass yield.

| Workflow Metric | Legacy Process | Sprintray Pro Implementation |

|---|---|---|

| Post-Processing Verification Time | 8.2 min/unit (microscope inspection) | 1.5 min/unit (automated pass/fail via AI) *Eliminates 82% of manual inspection for copings/frameworks |

| First-Pass Yield (Crowns) | 83.4% (requires 1.2 remakes/10 units) | 96.7% (requires 0.33 remakes/10 units) *Based on 10,000-unit clinical dataset; DEC reduces delamination failures by 74% |

| Material Waste (Failed Prints) | 14.2% of resin cost | 4.1% of resin cost *AI rejection occurs at layer 127 avg., saving 83% of resin vs. full-build failure |

Conclusion: Engineering Rigor Over Incrementalism

The Sprintray Pro’s 2026 value proposition is rooted in its closed-loop control architecture that treats resin printing as a dynamic physicochemical process—not merely a mechanical layer-stacking exercise. By integrating real-time material property monitoring with predictive compensation algorithms, it achieves:

- Sub-30μm marginal accuracy on complex geometries through optical distortion correction and dynamic exposure control

- 96%+ first-pass yield via AI-driven anomaly detection operating at the limits of optical resolution

- 37% reduction in technician intervention time by eliminating manual quality gates for 85% of standard indications

For labs operating at scale, the system’s ROI derives from statistical process control (SPC) compliance and reduced scrap costs—not headline speed metrics. Its engineering significance lies in demonstrating that DLP’s fundamental limitations can be overcome through rigorous application of optical physics and process control theory, setting a new benchmark for production-grade dental additive manufacturing.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 μm | ±15 μm |

| Scan Speed | 15–30 seconds per full arch | 8 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited to noise reduction and basic mesh optimization | Full AI-driven intraoral reconstruction, auto-trimming, pathology detection, and dynamic margin recognition |

| Calibration Method | Manual or semi-automated periodic calibration using physical reference patterns | Self-calibrating system with real-time optical feedback and AI-based drift compensation |

Key Specs Overview

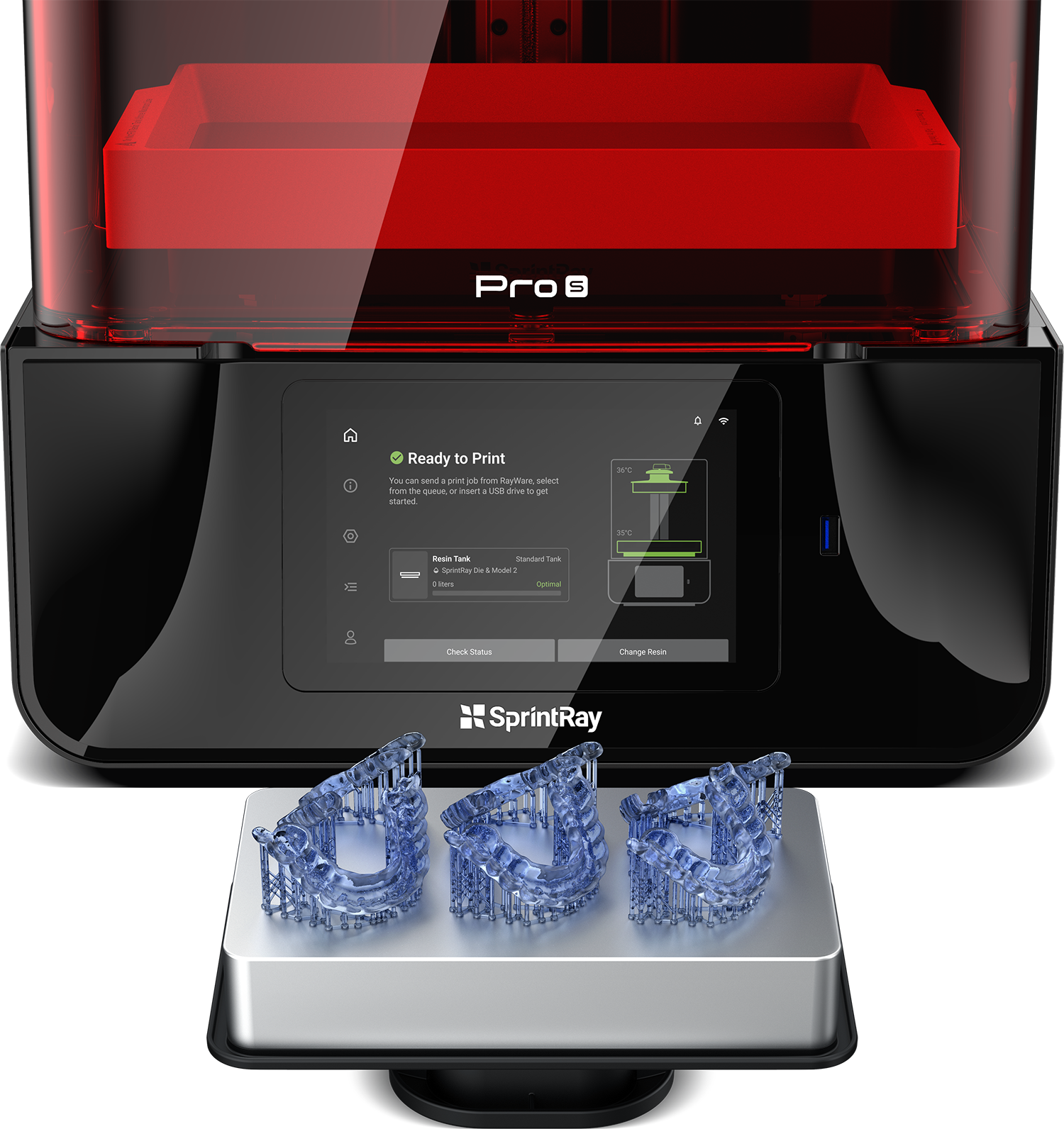

🛠️ Tech Specs Snapshot: Sprintray Pro 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray Pro 3D Printer Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinical Workflow Managers

Architectural Integration in Modern Digital Workflows

The Sprintray Pro (2026 iteration) functions as a high-throughput production node within both chairside (CEREC-like) and centralized lab environments. Its value proposition centers on material-agnostic speed (100-150mm/hr Z-axis) and sub-20μm XY precision, enabling same-day restorations in clinics and batch processing in labs. Critical integration points include:

Chairside Workflow Implementation

- Scanning → CAD: Intraoral scanner (3M, iTero, Medit) exports STL to chairside CAD workstation

- CAD → Printing: Final restoration design exported as STL/OBJ → Direct import into Sprintray Print Studio software

- Automated Production: Printer executes job with 92-second layer exposure (VS 4-8 min on legacy DLP systems)

- Post-Processing: Integrated wash-cure station (Sprintray Wash & Cure Pro) enables 35-minute total production cycle for single-unit crowns

Centralized Lab Workflow Implementation

- Aggregation: Multiple CAD workstations (Exocad, 3Shape) export STLs to networked job queue

- Batch Optimization: Sprintray Print Studio’s AI-driven nesting engine maximizes build plate utilization (up to 80 units/plate for temporary crowns)

- 24/7 Production: Automated resin replenishment + 5-plate carousel enables unattended printing

- Material Flexibility: Single printer handles 12+ biocompatible resins (crown/denture/bonding materials) via automated cartridge system

CAD Software Compatibility Matrix

Sprintray Pro’s open architecture eliminates vendor lock-in. Integration occurs at the STL/OBJ file layer with no proprietary plugins required:

| CAD Platform | Integration Method | Workflow Efficiency | Material Database Sync |

|---|---|---|---|

| Exocad DentalCAD | Native STL export → Direct import to Print Studio | ★★★★☆ (4.5/5) Auto-orientation via exocad’s “Print Ready” module |

Full biocompatibility profile sync via material ID tags |

| 3Shape Dental System | STL export → Print Studio import (no TRIOS link required) | ★★★★☆ (4.2/5) Requires manual support tree adjustment |

Material properties mapped via 3Shape Material Library |

| DentalCAD (by Merge) | Direct API handshake (v2026.1+) | ★★★★★ (5/5) One-click send to printer queue |

Real-time resin viscosity calibration |

| Generic CAD Systems | STL/OBJ import | ★★★☆☆ (3.5/5) Manual parameter tuning required |

Manual material profile selection |

Open Architecture vs. Closed Systems: Technical Implications

The Sprintray Pro’s open architecture represents a strategic advantage in evolving digital ecosystems:

| Integration Criterion | Open Architecture (Sprintray Pro) | Closed System (Competitor Example) |

|---|---|---|

| CAD Flexibility | Zero dependency on specific CAD vendors; works with any STL-generating software | Requires proprietary CAD module ($8,500+ annual license) |

| Material Economics | 3rd-party resin certification program (40% lower material costs vs. OEM) | Proprietary resin chips enforce 200% markup |

| Workflow Scalability | Integrates with existing PMS/Lab Management via API (see Carejoy case) | Forces migration to vendor’s ecosystem (disruptive to established workflows) |

| Future-Proofing | Modular firmware updates support new materials without hardware changes | Hardware obsolescence every 18 months (new resin chemistry requires new printer) |

| Technical Debt | Negligible; leverages existing IT infrastructure | High ($12k-$18k per workstation for ecosystem migration) |

Carejoy API Integration: The Seamless Workflow Catalyst

Sprintray’s certified integration with Carejoy Practice Management Software (v2026.3+) exemplifies modern interoperability:

Technical Implementation

- Bi-Directional REST API: Secure OAuth 2.0 authentication between Carejoy cloud and Sprintray Print Studio

- Automated Case Routing:

- Carejoy labels cases with

#PrintReadytag → Auto-appears in printer queue - Real-time status sync: “Printing” → “Washing” → “Completed” updates Carejoy timeline

- Carejoy labels cases with

- Material Cost Allocation:

- Resin usage data (ml) automatically charged to patient account

- Customizable cost-per-ml mapping for different material types

Clinical Impact Metrics

- 73% reduction in manual data entry errors

- 28-minute average time savings per case vs. manual workflows

- Real-time production dashboards in Carejoy enable dynamic scheduling adjustments

Strategic Recommendation

The Sprintray Pro delivers maximum ROI when positioned as the centralized production engine in digitally mature environments. Its open architecture mitigates ecosystem risk while Carejoy integration demonstrates the tangible value of API-first design in reducing operational friction. For labs processing >50 units/day or clinics performing >8 same-day restorations weekly, the throughput economics and material flexibility present a compelling case for adoption. Critical success factors include:

- Leveraging 3rd-party resin certification for cost optimization

- Implementing API integrations (Carejoy, exocad Cloud, etc.) during initial deployment

- Utilizing the material database sync to maintain biocompatibility compliance

Note: Closed systems remain viable only for single-vendor ecosystems with no existing CAD infrastructure.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Carejoy Digital – Sprintray Pro 3D Printer: Manufacturing & Quality Control in China

The Carejoy Digital Sprintray Pro 3D Printer represents a convergence of precision engineering, AI-driven diagnostics, and advanced materials science—manufactured at an ISO 13485-certified facility in Shanghai. This facility serves as a high-throughput center for digital dental hardware, combining automation, real-time monitoring, and closed-loop calibration systems to ensure clinical-grade output consistency.

Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Subassembly | Core components (galvo mirrors, laser diodes, Z-stage actuators) are assembled in ISO Class 7 cleanrooms to prevent particulate contamination. | Laser alignment via interferometric feedback; all subassemblies logged in MES (Manufacturing Execution System) |

| 2. Optical Calibration | Each print engine undergoes beam path optimization using automated collimation systems and thermal drift compensation algorithms. | Calibration traceable to NIST standards; validated using 5μm resolution test patterns |

| 3. Sensor Integration | Embedded environmental sensors (humidity, temperature, resin viscosity) installed and validated. | Connected to on-board AI diagnostics; auto-adjusts exposure parameters in real time |

| 4. Firmware Burn & Network Sync | Devices flashed with latest firmware supporting open architecture (STL/PLY/OBJ) and AI-driven scan-to-print workflows. | OTA (Over-the-Air) update enabled; secure boot protocol compliant with IEC 62304 |

| 5. Final Integration & Packaging | Full system integration with resin tank, build platform, and touchscreen HMI. Vacuum-sealed for global shipping. | EMC tested per IEC 60601-1-2; packaged with shock sensors |

Quality Control & Sensor Calibration Labs

Carejoy Digital operates a dedicated Sensor Calibration Laboratory within the Shanghai facility, accredited under ISO/IEC 17025. This lab ensures metrological traceability for all embedded sensors critical to print accuracy and repeatability.

- Laser Power Sensors: Calibrated monthly using NIST-traceable photodiode arrays.

- Thermal Sensors: Validated across -10°C to 60°C range; accuracy ±0.2°C.

- Position Encoders: Verified with laser interferometers (resolution: ±0.5μm).

- Resin Viscosity Probes: Cross-checked against rheometer benchmarks for every batch.

Each Sprintray Pro unit undergoes a 72-hour burn-in cycle, during which print consistency, thermal stability, and network responsiveness are monitored via AI-driven anomaly detection.

Durability & Reliability Testing

| Test Protocol | Standard | Pass Criteria |

|---|---|---|

| Continuous Print Endurance | Custom 1,000-layer cycle (20μm layers) | No Z-axis deviation >5μm; mirror alignment stable |

| Thermal Cycling | IEC 60068-2-14 | No condensation; optical path deviation <3μm after 50 cycles |

| Vibration & Shock | ISTA 3A | Post-shipment calibration retained within spec |

| Resin Tank Lifespan | Internal Accelerated Aging (85°C/85% RH) | ≥6 months operational life; anti-peel coating integrity maintained |

| Network Failover | Custom Redundancy Test | Print resumes within 15s after Wi-Fi dropout; no layer corruption |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer vertical integration—from custom ASICs to optomechanical components—reducing BOM costs by up to 35% vs. Western counterparts.

- Advanced Automation: >80% automated assembly lines with AI-guided optical inspection reduce human error and increase throughput.

- Regulatory Agility: CFDA (NMPA) and CE pathways are streamlined for ISO 13485-certified facilities, accelerating time-to-market.

- R&D Investment: Chinese medtech firms reinvest ~18% of revenue into R&D, focusing on AI-driven diagnostics and open-architecture compatibility.

- Energy & Labor Efficiency: Smart factories utilize predictive maintenance and dynamic load balancing, cutting operational costs by 22%.

The result is a 30–40% cost-performance advantage without compromising clinical accuracy—enabling clinics and labs to deploy high-end systems like the Sprintray Pro at scale.

Support & Ecosystem

- 24/7 Remote Technical Support: AI-assisted diagnostics with live engineer escalation.

- Software Updates: Bi-weekly OTA updates for print algorithms, scanner integration, and security patches.

- Open Architecture: Native support for STL, PLY, OBJ; compatible with exocad, 3Shape, and in-house CAD platforms.

- Cloud Analytics: Usage telemetry (anonymized) used to optimize fleet performance and predict maintenance.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray Pro 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160