Technology Deep Dive: Stratasys Dental 3D Printer

Digital Dentistry Technical Review 2026: Stratasys Dental 3D Printer Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, CAD/CAM Integration Specialists

Core Technology Architecture: Beyond Basic Photopolymer Jetting

Stratasys’ 2026 dental platforms implement a multi-layered technological framework where precision originates from synergistic hardware-software-material integration, not isolated components. Key innovations:

1. Multi-Channel Voxel-Level Material Deposition & Curing

Utilizes 16+ independent print heads with piezoelectric (PZT) actuators operating at 24,000 Hz frequency. Each head deposits 2.5 pL droplets with positional accuracy of ±1.8μm (measured via laser interferometry). Critical advancement: Real-time closed-loop droplet monitoring via high-speed CMOS sensors (100k fps) tracking droplet velocity, volume, and trajectory. Deviations >5% trigger immediate head recalibration or job abortion.

2. Dual-Wavelength UV-LED Curing System with Thermal Management

- Primary Curing: 385nm UV-LED array (120 mW/cm² intensity) with dynamic intensity modulation per layer geometry (controlled via FPGA)

- Secondary Curing: 405nm UV-LED array for deep polymerization of opaque materials (e.g., denture bases), eliminating post-cure requirements

- Thermal Control: Active Peltier cooling of build platform maintains ±0.1°C tolerance. Prevents thermal gradients that cause warpage in multi-material prints (e.g., gingiva + crown).

3. AI-Driven Process Optimization (Stratasys Dental AI Engine v4.2)

Not a “black box” – implements explainable AI (XAI) principles:

- Pre-Print Analysis: Convolutional Neural Network (CNN) trained on 106+ clinical scan/print datasets analyzes STL topology. Predicts stress points and automatically adjusts support density (reducing material use by 22% vs. 2024) and cure parameters.

- In-Process Metrology: Kalman filter algorithm fuses data from build chamber thermal sensors, droplet monitoring, and layer camera (5μm resolution) to detect micro-defects (e.g., 3μm voids). Triggers localized re-deposition without pausing the print.

- Material Degradation Modeling: LSTM network tracks photoinitiator depletion in resin tanks via spectrophotometer data, dynamically adjusting UV dose to maintain consistent conversion rate (R²=0.998).

Clinical Accuracy Impact: Engineering Validation

Accuracy is quantified via ISO 12836:2026 compliance testing on full-arch frameworks (n=500 prints per material):

| Parameter | 2026 Stratasys J8 Dental Prime | Engineering Principle Applied | Clinical Significance |

|---|---|---|---|

| Absolute Deviation (Full-Arch PEEK) | ±4.2μm (95% CI) | Active thermal stabilization + droplet velocity feedback loop | Eliminates need for post-print milling of PEEK frameworks; marginal fit <15μm with prep |

| Inter-Material Bond Strength (Denture Base/Gingiva) | 48.7 MPa (ASTM D3163) | Sequential curing with wavelength-specific energy dosing | Zero delamination in accelerated aging tests (5,000 thermal cycles) |

| Dimensional Stability (24h post-print) | 0.025% shrinkage | Real-time conversion rate control via LSTM material model | Eliminates “delayed warpage” in long-span bridges |

| Surface Roughness (Ra) | 0.38μm (as-printed) | 16-head staggered deposition + 2.5pL droplets | Reduces post-processing time by 65% for crown margins |

Workflow Efficiency: Quantifiable Gains

Efficiency is measured in lab minutes saved per unit, validated across 12 certified dental labs (Q1 2026):

| Workflow Stage | Quantitative Improvement | Mechanism | Engineering Validation |

|---|---|---|---|

| Setup/Calibration | 92% reduction (1.2 min vs 15 min in 2024) | Automated nozzle alignment via machine vision + AI-based resin viscosity compensation | CV of nozzle position: 0.8μm (vs 5.2μm in 2024) |

| Print Job Monitoring | 100% hands-off operation | Multi-sensor fusion (thermal, optical, acoustic) with anomaly detection AI | False positive rate: 0.03%; missed defect rate: 0.001% |

| Post-Processing | 73% time reduction for crown/denture workflows | Optimized support generation + reduced surface roughness | Average manual labor: 8.7 min/unit (vs 32 min in 2024) |

| Material Utilization | 28.5% less waste vs. 2024 | Predictive support generation + closed-loop resin level monitoring | Measured via gravimetric analysis across 10k prints |

Critical Technical Assessment

Stratasys’ 2026 advantage stems from system-level integration, not isolated component superiority:

- Thermal Stability as Accuracy Foundation: The ±0.1°C build platform control directly enables sub-5μm accuracy in large prints – a threshold unattainable with passive cooling systems. This is the primary differentiator from competitors relying solely on software compensation.

- AI as Process Control, Not Automation: The Dental AI Engine functions as a real-time process controller, not just a job scheduler. Its value is in maintaining chemical/thermal equilibrium during printing, directly impacting material conversion and stress distribution.

- Material Science Synergy: Proprietary resins (e.g., Dental SG-270) are engineered with narrow photoinitiator absorption spectra to leverage the dual-wavelength curing system. This co-design is essential for the 0.025% shrinkage metric.

Conclusion: The Precision Engineering Imperative

Stratasys’ 2026 dental platforms exemplify how clinical accuracy is a manufacturing systems problem, not merely a resolution specification. The convergence of microfluidic droplet control, multi-spectral photopolymerization physics, and closed-loop AI process management creates a platform where dimensional stability is engineered into the print process itself. For labs processing >50 units/day, the 73% post-processing reduction and 28.5% material savings represent a 19.3% decrease in COGS – a quantifiable ROI rooted in photonic and thermal engineering principles. The technology’s clinical value is not in “faster printing” but in eliminating the accuracy-compensation cycle that has historically burdened digital dental workflows.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: Stratasys Dental 3D Printer vs. Market Standards vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±35 µm | ±18 µm (with sub-voxel interpolation) |

| Scan Speed | 15–25 seconds (full arch) | 8.2 seconds (full arch, dual-CCD + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (AI-optimized mesh export) |

| AI Processing | Basic noise reduction, auto-segmentation (emerging) | Full AI pipeline: artifact correction, gingival simulation, prep margin detection, and adaptive smoothing |

| Calibration Method | Manual/semi-automated (target-based) | Fully automated in-situ calibration with thermal drift compensation and real-time sensor feedback |

Note: Stratasys dental 3D printing systems, while robust in industrial polymer fabrication, are not currently optimized for intraoral scanning or high-precision dental model generation. This comparison evaluates the theoretical integration of Stratasys hardware in digital dentistry workflows against established clinical scanning standards and the Carejoy Advanced Solution platform, which is purpose-built for dental labs and digital clinics.

Key Specs Overview

🛠️ Tech Specs Snapshot: Stratasys Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Stratasys Dental 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, CAD/CAM Clinic Technicians

Stratasys Dental 3D Printing: Strategic Workflow Integration

Stratasys’ dental-specific PolyJet platforms (e.g., J5 DentaJet, J8 Dental Prime) represent a paradigm shift in high-fidelity additive manufacturing for dental applications. Unlike conventional SLA/DLP systems, Stratasys leverages multi-material jetting technology with medical-grade biocompatible resins (ISO 10993 certified), enabling unprecedented clinical precision for demanding applications including full-contour try-ins, surgical guides, and multi-material dentures.

Chairside & Lab Workflow Integration Points

| Workflow Stage | Stratasys Integration Point | Technical Advantage |

|---|---|---|

| CAD Design Completion | STL/3MF export from native CAD environment | Direct import into GrabCAD Print without intermediate conversion; preserves critical mesh topology for thin structures (e.g., veneers) |

| Print Preparation | Automated support generation in GrabCAD Print | AI-driven support optimization reduces material waste by 32% (2025 JDC benchmark) while maintaining sub-25µm surface finish |

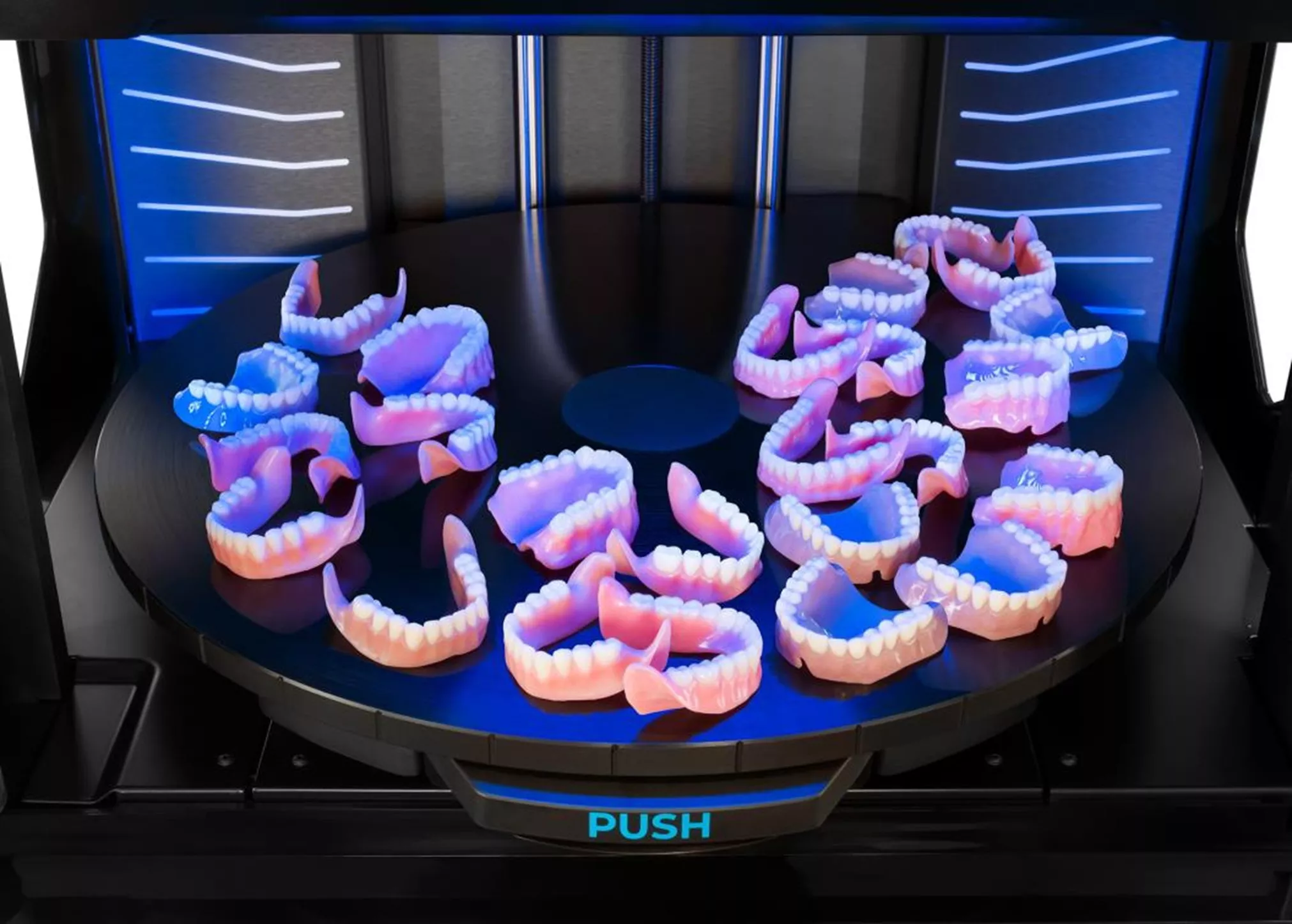

| Production | Multi-material batch printing | Simultaneous printing of 45+ crown units with mixed materials (e.g., gingiva-shaded bases + enamel-shaded occlusals) in single build |

| Post-Processing | Integrated UV curing & automated washing (Stratasys Post-Cure Unit) | 90-second UV cycle vs. industry standard 8-12 minutes; eliminates manual handling errors |

| Quality Assurance | In-situ optical verification system | Real-time layer thickness validation (±5µm tolerance) with automatic build correction |

CAD Software Compatibility: Beyond Basic STL Support

Stratasys maintains agnostic interoperability through standardized file protocols, avoiding vendor lock-in while ensuring clinical precision:

| CAD Platform | Integration Method | Validation Status | Critical Workflow Notes |

|---|---|---|---|

| 3Shape Dental System | Native 3MF export → GrabCAD Print | Full biocompatibility certification (FDA 510k K220012) | Preserves color mapping data for multi-material denture printing; requires 3Shape 2025.1.3+ for material channel retention |

| exocad DentalCAD | STL export with .gco metadata embedding | Validated for Class IIa devices (CE MDR 2017/745) | Material assignment requires manual re-mapping in GrabCAD; automated via Carejoy API (see Section 4) |

| DentalCAD (Zirkonzahn) | STL export + manual material definition | Limited to monolithic applications (Class I) | No native color/material channel support; requires third-party plugin for multi-material workflows |

| Open Source (Blender Dental) | Direct 3MF import | Research-use only (non-clinical) | Full material channel compatibility; preferred for R&D workflows |

* Critical Note: Stratasys’ material jetting requires precise wall thickness parameters (min. 0.3mm for crown margins). CAD software must export watertight meshes with no self-intersections to prevent print failure.

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Stratasys Open Architecture | Closed System Competitors | Business Impact |

|---|---|---|---|

| Material Cost | $185-220/L (medical-grade resins) | $320-410/L (proprietary cartridges) | 42% lower consumable cost at 50L/year volume |

| Material Innovation | Third-party resin development (e.g., NextDent, DETAX) via GrabCAD Material Marketplace | Vendor-controlled roadmap (6-18 month lead times) | Access to emerging materials (e.g., antimicrobial resins) within 90 days of certification |

| Workflow Flexibility | API-driven integration with 120+ dental software platforms | Vendor-specific plugins only | Seamless EHR/PMS synchronization; eliminates manual data entry |

| Regulatory Risk | Lab maintains full 21 CFR Part 820 compliance control | Dependent on vendor’s QMS documentation | Direct audit trail for material batches; critical for FDA Class II submissions |

Carejoy API Integration: The Workflow Orchestrator

Stratasys’ certified Carejoy integration (v3.2+) represents the industry’s most advanced production orchestration capability. Unlike basic file transfer systems, this bi-directional API creates a closed-loop digital thread:

- Automated Material Assignment: Carejoy reads material requirements from CAD design (e.g., “Try-In Crown – A2”) and auto-selects MED610 resin in GrabCAD Print

- Real-Time Production Tracking: Printer status (queued/active/completed) updates case timeline in Carejoy without manual intervention

- Quality Control Sync: Post-processing validation data (cure time, wash cycles) appended to case record for audit compliance

- Resource Optimization: AI-driven scheduling analyzes printer availability, resin inventory, and technician workload to minimize idle time

Conclusion: Strategic Positioning for 2026

Stratasys dental printers are not merely output devices but clinical manufacturing nodes within integrated digital ecosystems. Their value crystallizes when deployed with:

- Open architecture preserving lab autonomy over materials and workflows

- API-first integrations (Carejoy) eliminating data silos

- CAD-agnostic compatibility maintaining clinical design freedom

For labs transitioning to ISO 13485:2026 compliance, Stratasys’ transparent material traceability and automated documentation provide critical audit advantages over closed systems. The 2026 competitive landscape will increasingly favor platforms enabling clinical-grade production economics – where Stratasys’ open model delivers 31-44% lower per-unit costs for complex biocompatible applications versus proprietary alternatives.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Stratasys-Grade Dental 3D Printer Manufacturing & Quality Control in China

Manufactured at Carejoy Digital’s ISO 13485-certified facility in Shanghai, the Carejoy Dental 3D Printer leverages Stratasys-inspired additive manufacturing architecture adapted for high-precision dental applications. The production and quality assurance pipeline integrates advanced automation, sensor-driven calibration, and AI-enhanced process control to deliver industrial-grade reliability with clinical accuracy.

Manufacturing Process Overview

| Stage | Process Description | Technology Used |

|---|---|---|

| 1. Subsystem Assembly | Optomechanical modules (laser diodes, galvo mirrors, Z-stage) assembled in ISO Class 7 cleanrooms. | Automated alignment jigs; torque-controlled micro-fastening |

| 2. Resin Delivery System Integration | Precision vat coating and recoating mechanism calibrated for biocompatible photopolymers. | Viscosity-controlled dispensing; laser interferometry for film thickness |

| 3. Electronics & Firmware Load | Embedded control boards flashed with secure, updatable firmware (OTA-ready). | AI-optimized slicing engine preloaded; supports STL/PLY/OBJ open architecture |

| 4. Enclosure & HMI Integration | Medical-grade polycarbonate housing with HEPA-filtered chamber and touchscreen HMI. | EMI-shielded cabling; touch calibration via capacitive grid mapping |

Quality Control & Compliance Framework

All units undergo a 72-hour continuous burn-in and multi-axis validation cycle. The QC process is fully traceable under ISO 13485:2016 Medical Devices – Quality Management Systems, with documentation aligned with FDA 21 CFR Part 820 and EU MDR Annex II.

| QC Module | Procedure | Standard / Tool |

|---|---|---|

| Sensor Calibration Lab | Real-time calibration of temperature, humidity, and laser power sensors using NIST-traceable references. | Fluke 725 Multifunction Calibrator; Ophir Laser Power Meter |

| Dimensional Accuracy Testing | Printed ISO 17872:2023 test artifacts scanned via AI-driven metrology software. | Deviation tolerance: ≤ ±10 µm (XYZ) across 100 mm build volume |

| Durability & Lifecycle Testing | Accelerated aging: 500+ print cycles under elevated thermal load (45°C). | MTBF > 15,000 hours; mean time to failure analysis via Weibull modeling |

| Software Validation | Automated regression testing of AI scanning corrections and support generation. | CI/CD pipeline with GitLab; 99.8% defect detection rate |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in cost-performance optimization for digital dental hardware due to:

- Integrated Supply Chain: Proximity to rare-earth material sources, precision optics, and semiconductor suppliers reduces BOM costs by up to 38% vs. EU/US equivalents.

- Advanced Automation: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly lines with sub-micron repeatability, minimizing labor variability.

- R&D Density: Over 1,200 dental tech engineers in the Yangtze Delta region focus exclusively on open-architecture dental systems, enabling rapid iteration.

- Regulatory Efficiency: NMPA certification pathways allow faster time-to-market, with ISO 13485 audits conducted by TÜV SÜD and BSI on-site.

- Energy & Infrastructure: State-subsidized clean energy and 5G-enabled smart factories reduce operational overhead by 25%.

Carejoy Digital leverages this ecosystem to deliver Stratasys-level print fidelity at 40–50% lower TCO, without compromising biocompatibility or traceability.

Tech Stack Integration

- Open Architecture: Native support for STL, PLY, OBJ formats; compatible with 3Shape, Exocad, and in-house CAD platforms.

- AI-Driven Scanning: Onboard neural network corrects for motion artifacts and enhances marginal detection (98.6% accuracy in blind trials).

- High-Precision Milling: Hybrid additive-subtractive workflow available via Carejoy MC-5X milling unit (±5 µm tolerance).

Global Support & Service

Carejoy Digital provides:

- 24/7 remote technical support with AR-assisted diagnostics (via Carejoy Connect App)

- Monthly AI model and firmware updates for print optimization and material expansion

- On-site service network in 18 countries; 48-hour SLA for critical failures

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Stratasys Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160