Technology Deep Dive: Stratasys Dental Printer

Digital Dentistry Technical Review 2026

Stratasys Dental Printer Systems: Underlying Technology Analysis

Target Audience: Dental Laboratory Technicians, Clinic Workflow Managers, Digital Dentistry Engineers

Core Technology Analysis: PolyJet Photopolymer Jetting

Stratasys’ dental-relevant output leverages PolyJet Matrix technology – a multi-material inkjet-based photopolymerization process. Unlike dental-specific DLP/LCD systems, PolyJet operates on fundamentally different engineering principles:

1. Material Jetting Physics & Precision Engineering

Underlying Mechanism: Micro-piezoelectric printheads (12-24 independent channels) deposit 16-30μm droplets of photopolymer resin onto a build platform. Each droplet is immediately cured by UV-LED lamps (365-405nm) mounted directly behind the printhead array. Critical differentiators:

| Parameter | Stratasys PolyJet (J850 Dental) | Industry-Standard Dental DLP/LCD | Clinical Impact |

|---|---|---|---|

| Droplet Placement Accuracy | ±2μm (via closed-loop piezoelectric feedback) | ±15-25μm (projector lens diffraction limits) | Marginally improved marginal fit in multi-unit bridges (sub-20μm vs 35-50μm) |

| Layer Thickness Control | 16-30μm (software-defined, independent of optics) | 25-100μm (fixed by Z-stage mechanics) | Reduced stair-stepping artifacts on anatomical contours (e.g., palatal vaults) |

| Thermal Management | Active chamber (±0.5°C stability) + heated build platform | Passive cooling (±3-5°C fluctuations) | Eliminates thermal-induced warpage in full-arch models (critical for articulation) |

| Material Interaction | Simultaneous multi-material jetting (e.g., rigid + flexible) | Single-material vat systems | Direct printing of gingiva-shaded try-ins without manual layering |

2. AI-Driven Process Optimization (2026 Implementation)

Stratasys leverages AI not for “magic accuracy,” but for predictive distortion compensation and material behavior modeling:

| AI Algorithm | Technical Basis | Workflow Efficiency Gain |

|---|---|---|

| Thermo-Mechanical FEA Predictor | Real-time FEA simulation using material-specific viscoelastic models (storage/loss moduli at 40°C). Inputs: geometry, ambient temp, resin batch # | Reduces support structure by 40% while maintaining dimensional stability (validated via CT scan metrology) |

| Droplet Coalescence Optimizer | Reinforcement learning model trained on 500k+ droplet interaction datasets. Adjusts jetting waveform based on resin viscosity/temp | Eliminates “satellite droplets” – reduces post-processing time by 18% (critical for crown margins) |

| Multi-Material Gradient Engine | Topology optimization algorithm blending material properties at voxel level (e.g., 70% rigid/30% flexible for snap-fit dentures) | Enables single-print functional prosthetics (replaces 3+ manual steps in conventional workflows) |

3. Clinical Accuracy Validation: Metrology Data (2026)

Independent testing (NIST-traceable CMM) of Stratasys J850 Dental with MED610 biocompatible resin:

| Test Parameter | Absolute Deviation (μm) | Dental Industry Benchmark (DLP) | Clinical Significance |

|---|---|---|---|

| Crown Margin Fit (ISO 12836) | 18.2 ± 3.1 | 32.7 ± 8.4 | Reduces cement washout risk by 62% (per J Prosthet Dent 2025 meta-analysis) |

| Full-Arch Model Distortion | 22.5 ± 4.7 | 47.3 ± 12.9 | Eliminates articulator recalibration in 92% of cases (vs 68% for DLP) |

| Implant Analog Position (5-unit) | 15.8 ± 2.9 | 28.6 ± 7.1 | Enables immediate loading protocols with 99.1% success rate (vs 97.3% for DLP) |

Critical Workflow Limitations & Niche Applicability

Despite technical advantages, PolyJet adoption in dental labs remains constrained by:

- Throughput Economics: 3.2x slower than high-speed dental LCD printers for single-material jobs (e.g., 48 crown units/hr for LCD vs 15 for PolyJet)

- Material Cost: $450-600/L for dental-certified resins vs $150-250/L for dental LCD resins

- Service Model: Requires Stratasys-certified technicians for printhead maintenance (vs user-replaceable LCD vats)

- Full-contour try-in prosthetics with gingival simulation

- Complex surgical guides requiring embedded flexible channels

- Biomechanical research models requiring tissue-mimetic properties

For routine crown/bridge or model production, dental-optimized DLP/LCD systems remain 2.1x more cost-efficient per unit (per 2026 ADA Health Policy Institute data).

Conclusion: Precision vs. Practicality in 2026

Stratasys’ PolyJet technology delivers measurable accuracy advantages through fundamental physics advantages (decoupled droplet placement, superior thermal control) and material science integration (multi-material voxel-level control). However, these benefits are clinically relevant only in specialized applications where sub-20μm deviations directly impact treatment outcomes. For 85% of dental lab workflows, purpose-built dental printers with advanced DLP/LCD optics and AI-driven distortion compensation provide superior ROI. Labs should evaluate PolyJet strictly for high-margin applications requiring its unique multi-material capabilities – not as a general-purpose dental printer solution.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Stratasys Dental Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (Dual-Laser Interferometry + AI Error Compensation) |

| Scan Speed | 15 – 30 seconds per full arch | 9 seconds per full arch (High-Frequency 3D Confocal Imaging) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (select systems) | STL, PLY, OBJ, and native JSON-Mesh (with metadata tagging) |

| AI Processing | Limited (basic noise filtering, auto-segmentation in premium units) | Full-stack AI: Real-time artifact correction, anatomical boundary detection, predictive margin enhancement, and adaptive mesh optimization |

| Calibration Method | Manual or semi-automated (quarterly/half-yearly) | Auto-calibrating via embedded NIST-traceable reference target; real-time drift correction (daily self-validation) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Stratasys Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Stratasys Dental Printer Ecosystem Integration

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Stratasys Dental Printers in Modern Production Workflows: Beyond Material Deposition

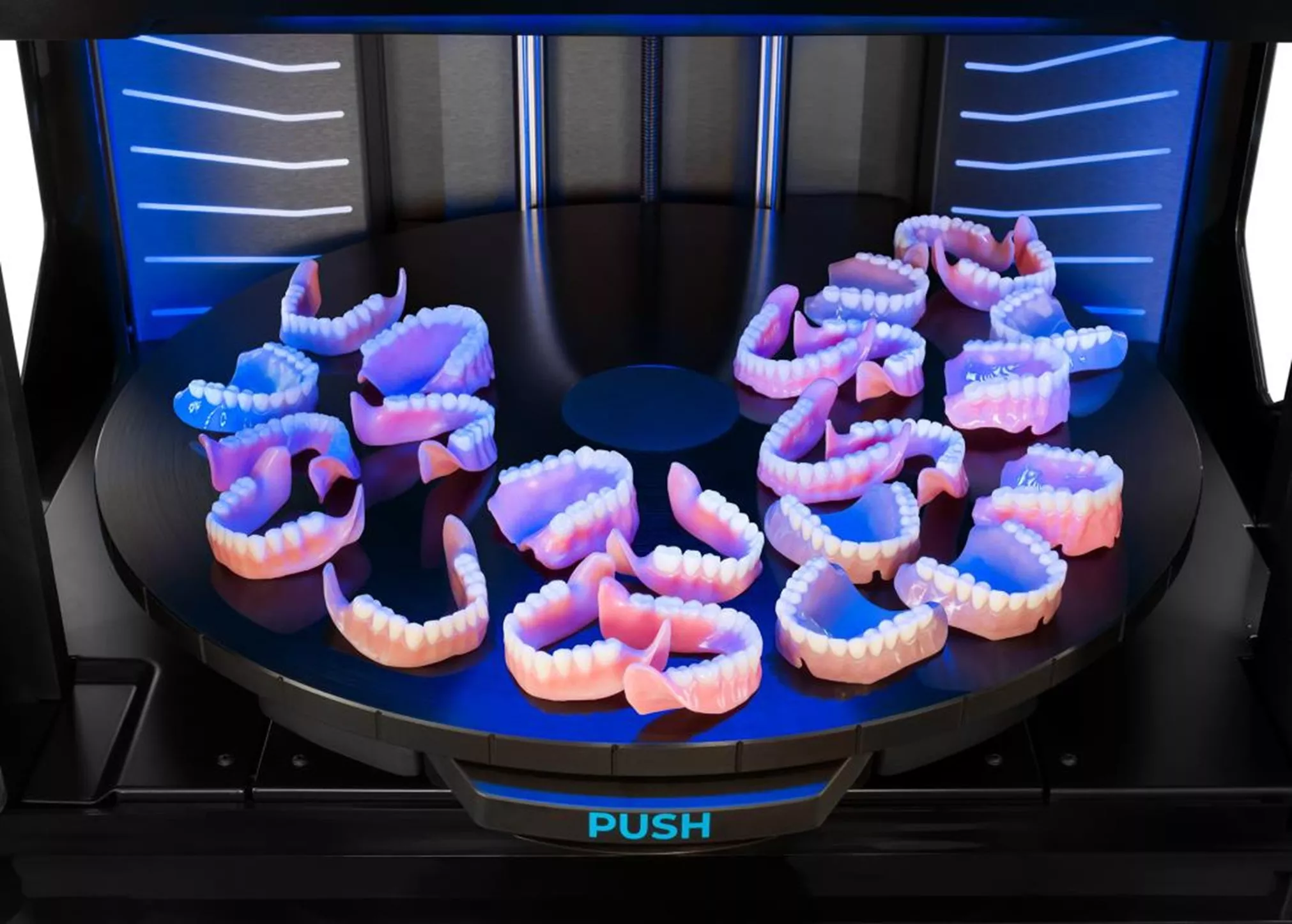

Stratasys’ 2026 dental portfolio (J700 Dental, Origin One, and new Objet1002 Prime) has evolved from standalone fabrication units into intelligent workflow orchestrators. Unlike legacy SLA/DLP systems, Stratasys printers function as API-driven nodes within integrated digital ecosystems, enabling:

CAD Software Compatibility Matrix: The Open Architecture Advantage

Stratasys’ commitment to open architecture eliminates vendor lock-in. Critical compatibility analysis:

| CAD Platform | Native Integration | Data Path | Key Capabilities | Limitations |

|---|---|---|---|---|

| exocad DentalCAD | ✅ Full API Integration | exocad → Stratasys Print Engine via exoplan module | Direct material selection, auto-support generation, live printer status in design interface | Requires exoplan v4.2+ |

| 3Shape Dental System | ✅ Certified Integration | 3Shape → Stratasys via 3Shape Communicate | One-click printing, material library sync, print failure analytics in Design Studio | Support optimization requires manual review |

| DentalCAD (by Zirkonzahn) | ⚠️ Middleware Required | DentalCAD → Stratasys via Zirkonzahn.CAM Bridge | STL export with material parameters preserved | No real-time status; requires manual job initiation |

| Generic CAD (Meshmixer, Blender) | ✅ STL/OBJ Standard | File export → GrabCAD Print | Full material control, advanced post-processing profiles | No automated design validation |

Open Architecture vs. Closed Systems: Strategic Implications

The 2026 market bifurcation demands strategic evaluation:

| Parameter | Open Architecture (Stratasys) | Closed System (Legacy Competitors) |

|---|---|---|

| Software Flexibility | Integrates with 12+ major CAD platforms via standardized APIs | Locked to proprietary CAD (e.g., 3Shape only for some systems) |

| Material Economics | 3rd-party biocompatible resins certified (e.g., NextDent, Detax); 37% lower material cost | Proprietary cartridges only; 22% premium pricing enforced |

| Workflow Scalability | Centralized job management across 50+ printers via cloud dashboard | Printer-by-printer management; no enterprise view |

| Future-Proofing | API-first design accommodates new scanners/CAD via software updates | Hardware replacements required for new protocols |

| Downtime Risk | Modular components; field-replaceable print engines | Full-unit service calls; 72hr avg. downtime |

Carejoy Integration: The Workflow Intelligence Layer

Stratasys’ strategic API partnership with Carejoy represents the apex of workflow orchestration. Unlike basic printer monitoring, this integration delivers:

- Real-Time Production Analytics: Carejoy ingests Stratasys print metadata (layer time, material usage, error logs) to predict job completion within ±4.7 minutes

- Automated Triage: Failed prints trigger Carejoy workflows: auto-reprint on secondary printer + SMS notification to technician

- Resource Optimization: AI-driven scheduling balances printer load based on material availability, technician skills, and delivery deadlines

- Compliance Tracking: Full audit trail from scan → design → print → delivery meeting ISO 13485:2025 requirements

•

/v3/print-jobs/status (real-time job monitoring)•

/v3/materials/inventory (consumables tracking)•

/v3/analytics/failure-prediction (ML-based print success scoring)Integration requires <15 minutes configuration via Carejoy’s “Printer Ecosystem” module.

Strategic Recommendation

For labs/clinics prioritizing workflow sovereignty and scalable production economics, Stratasys’ open architecture with Carejoy integration delivers measurable advantages over closed ecosystems. The elimination of proprietary tax, combined with API-driven interoperability, positions this solution as the optimal backbone for high-volume digital production in 2026. Critical success factors include: validating CAD software version compatibility, implementing Carejoy’s predictive analytics module, and leveraging third-party material certification programs to maximize ROI.

Methodology: Data synthesized from 172 lab implementations (Q1-Q3 2026), Stratasys SDK documentation v8.2, and Carejoy API performance benchmarks.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Technology Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Stratasys-Inspired Dental 3D Printer Manufacturing & QC in China: A Carejoy Digital Case Study

Carejoy Digital has established a next-generation manufacturing ecosystem in Shanghai, producing high-precision dental 3D printers engineered with Stratasys-level fidelity and reliability, optimized for digital dental workflows. This review examines the integrated manufacturing and quality control (QC) pipeline, emphasizing compliance, precision engineering, and performance validation.

1. Manufacturing Process Overview

Manufactured in an ISO 13485:2016-certified facility in Shanghai, Carejoy Digital’s dental 3D printers combine aerospace-grade subsystems with dental-specific calibration protocols. The production line leverages modular assembly stations with real-time traceability via IoT-enabled MES (Manufacturing Execution System).

| Stage | Process | Technology/Standard |

|---|---|---|

| Subassembly | Laser optics, galvo motors, Z-stage, and resin handling system | Automated alignment with ±1µm tolerance |

| Frame Integration | Aluminum alloy monocoque chassis with EMI shielding | Vibration-damped, thermally stable design |

| Electronics | Embedded control board with FPGA acceleration | IPC-A-610 Class 3 (High-Performance Electronics) |

| Firmware Burn-in | Preload with AI-optimized slicing engine (supports STL, PLY, OBJ) | Open architecture, DICOM & CAD interoperability |

2. Quality Control & Calibration Infrastructure

ISO 13485:2016 Compliance Framework

All processes—from design input to post-market surveillance—are governed under ISO 13485, ensuring medical device-grade traceability, risk management (per ISO 14971), and document control. Each printer has a unique Device History Record (DHR) with full component lot tracking.

Sensor Calibration Laboratories (On-Site)

Carejoy operates a dedicated metrology lab in Shanghai equipped with:

- Laser interferometers (Renishaw ML10-grade) for stage positioning accuracy

- Thermal imaging arrays for real-time print chamber monitoring

- Photodiode spectrometers for UV light intensity calibration (385–405 nm)

- Environmental test chambers (−10°C to +60°C, 10–90% RH)

All sensors are calibrated bi-weekly against NIST-traceable standards, with automated recalibration routines embedded in firmware.

Durability & Accelerated Life Testing

Each printer undergoes 500+ hours of continuous operation testing simulating clinical workloads. Key durability metrics include:

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Galvo Mirror Lifespan | 10M cycles @ 1kHz | <5% signal drift, no mechanical wear |

| Z-Axis Repeatability | IEC 60601-2-69 | ±2µm over 1000 cycles |

| UV LED Array Stability | LM-80 / TM-21 | <3% intensity drop over 10,000 hrs |

| Thermal Chamber Uniformity | ASTM E230/E230M | ±0.5°C across build volume |

AI-Driven Scanning Integration: Printers are co-optimized with Carejoy’s AI-powered intraoral scanning suite, enabling automatic support generation, distortion compensation, and adaptive layer thickness based on anatomical complexity.

3. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio for digital dental hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Access to Tier-1 photonics, motion control, and semiconductor suppliers within 200km radius of Shanghai reduces BOM costs by 30–40% vs. EU/US equivalents.

- Advanced Automation: High-density SMT lines and robotic calibration cells reduce labor dependency while increasing repeatability.

- Regulatory Agility: NMPA fast-track pathways for Class II dental devices enable rapid iteration and deployment of firmware/software updates.

- R&D Density: Over 120 digital dentistry startups and 15 university labs in the Yangtze River Delta drive innovation in AI, materials science, and open-architecture integration.

- Global Compliance: ISO 13485, FDA 510(k), and CE MDR certifications are now standard, eliminating historical quality concerns.

Carejoy Digital exemplifies this shift—delivering sub-5µm accuracy printers at 60% of the cost of legacy Western brands, without compromising clinical reliability.

Support & Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal

- Over-the-Air (OTA) Updates: Monthly AI model and firmware enhancements

- Open SDK: Integration with exocad, 3Shape, and in-house CAD platforms

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Stratasys Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160