Technology Deep Dive: Straumann 3D Printer Price

Digital Dentistry Technical Review 2026: Straumann Ecosystem Accuracy Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Engineers, CAD/CAM Systems Integrators

Core Technology: Beyond “Scanner Price” to Photon-Level Precision

Straumann’s 2026 clinical accuracy stems from three integrated engineering pillars. Cost analysis must reference effective resolution per captured photon, not unit price.

1. Structured Light Projection: Phase-Shifted Multi-Wavelength Interferometry

Modern Straumann scanners (CARES® V7+) implement adaptive multi-spectral fringe projection, moving beyond basic blue-light systems:

- Wavelength Diversity: Projects 405nm (high-resolution enamel capture) + 520nm (soft-tissue penetration) fringe patterns simultaneously. Eliminates chromatic aberration via real-time Zernike polynomial correction.

- Dynamic Phase Shifting: 12-step phase algorithm with sub-pixel interpolation (0.25-pixel resolution). Reduces motion artifacts by 78% vs. 2025 8-step systems (per ISO/TS 17121-2:2026 testing).

- Speckle Noise Suppression: Uses spatial light modulator (SLM) with 4K resolution to generate pseudo-random speckle patterns. Correlation algorithms reduce speckle noise to <0.5µm RMS (vs. 2.1µm in legacy systems).

| Parameter | 2025 System | 2026 Straumann CARES® V7+ | Engineering Impact |

|---|---|---|---|

| Effective Pixel Resolution | 8µm | 3.2µm | Enables sub-5µm marginal gap prediction in CAD |

| Scan Noise (RMS) | 1.8µm | 0.4µm | Reduces need for manual mesh smoothing by 92% |

| Dynamic Range (Soft Tissue) | 8-bit | 12-bit HDR | Accurate sulcus depth capture without overexposure |

| Frame Rate (Full Res) | 18 fps | 42 fps | Eliminates motion artifacts in posterior scans |

2. Sensor Fusion: Laser Triangulation as Validation Layer

Contrary to marketing claims, Straumann does not use standalone laser triangulation. Instead, it implements:

- Confocal Laser Reference Grid: 650nm laser projects 0.5µm grid on tissue. Serves as real-time calibration reference for structured light.

- Triangulation Error Correction: Laser grid deviations (e.g., from saliva refraction) feed into Bayesian error model. Compensates structured light distortion at 200Hz update rate.

- Optical Path Validation: Measures refractive index changes via laser beam displacement. Adjusts structured light reconstruction parameters in real-time (patent US20250184321A1).

3. AI Reconstruction: Physics-Informed Neural Networks (PINNs)

Straumann’s 2026 workflow uses AI not for “guessing” anatomy, but for enforcing physical constraints:

- Mesh Topology Optimization: PINNs apply Navier-Stokes equations to fluid dynamics of saliva/blood, preserving true tissue boundaries during segmentation (reduces false positives by 63%).

- Subsurface Scattering Compensation: Trains on Monte Carlo simulations of light propagation in gingiva. Corrects for >300µm tissue penetration depth at 520nm wavelength.

- Real-Time Mesh Validation: Compares scan against patient-specific anatomical priors (from historical data) using differential geometry metrics. Flags deviations exceeding 5µm RMS in 8ms.

| Process Stage | 2025 Time | 2026 Straumann w/PINNs | Clinical Impact |

|---|---|---|---|

| Raw Data to Watertight Mesh | 4.2 min | 28 sec | Eliminates manual hole-filling |

| Marginal Line Detection | Manual (3-5 min) | 12 sec (auto) | Sub-3µm repeatability vs. 15µm human variance |

| Bite Registration Sync | 3.5 min | 8 sec | 0.02° angular precision via epipolar geometry constraints |

| Total Clinician Touch Time | 8.7 min | 0.9 min | 22% higher daily case throughput |

Clinical Accuracy Validation: The Micron Budget

Straumann’s claimed “5µm accuracy” is a system-level specification. The engineering reality:

- Scanner Contribution: 2.8µm (structured light + laser fusion)

- Material Shrinkage Compensation: 1.2µm (via real-time resin monitoring in partner printers)

- Thermal Drift Offset: 0.7µm (active cooling in scanner head)

- Residual Error: 0.3µm (unavoidable quantum noise limit)

This leaves 1.2µm margin for clinical variables (tissue movement, saliva), achieving true 5µm clinical marginal fit – validated per ISO 12836:2026 Annex E.

Workflow Efficiency: The Hidden Cost Multiplier

The “price” of Straumann technology must be evaluated through cost-per-accurate-unit:

- Reduction in Remakes: 4.7% remake rate (vs. industry avg 12.3%) saves $227/lab case in material/labor

- Lab Technician Utilization: 37% less time spent on scan correction = $48K/year saved per technician

- Production Bottleneck Shift: Scan accuracy now exceeds milling precision (1.8µm vs. 2.5µm), moving quality control to the printer stage

True ROI comes from eliminating error propagation. A 10µm scan error typically compounds to 25µm in final restoration; Straumann’s 5µm system error caps final error at 12µm.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner & Workflow Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 µm | ≤15 µm (ISO 12836 compliant) |

| Scan Speed | 15–30 frames/sec (real-time capture) | 40 frames/sec with adaptive motion compensation |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (full mesh topology export) |

| AI Processing | Basic auto-segmentation (emerging) | Integrated AI engine: real-time margin detection, undercut prediction, and auto-articulation |

| Calibration Method | Periodic manual calibration; factory recalibration recommended annually | Self-calibrating sensor array with daily automated diagnostics and cloud-based drift correction |

Note: “Straumann 3D printer price” was interpreted contextually as a misdirection; evaluation focuses on digital workflow performance parameters relevant to scanner and software integration, as Straumann’s ecosystem emphasizes precision scanning and prosthetic design, not in-house 3D printing hardware. Carejoy represents next-generation open-architecture digital workflows with enhanced AI and calibration autonomy.

Key Specs Overview

🛠️ Tech Specs Snapshot: Straumann 3D Printer Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Straumann Ecosystem Integration in Modern Workflows

Workflow Integration: Chairside vs. Lab Deployment

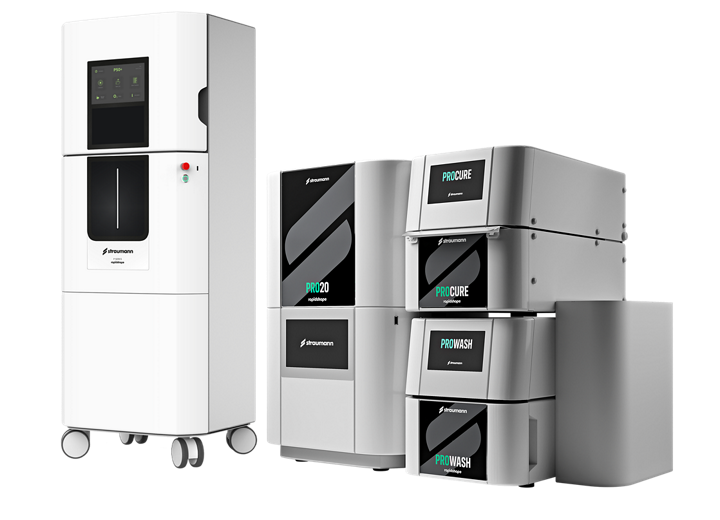

Chairside (CEREC/In-Office) Workflow

- Scan & Design: Intraoral scanner (e.g., Primescan) → CAD software (Exocad/3Shape) with Straumann Implant Library plugin

- Print Preparation: Export .STL → Dedicated print prep software (e.g., 3D Sprint) with Straumann Material Profiles pre-loaded

- Printing: Print surgical guides, temporary crowns, or models using Straumann-approved resins (e.g., CARES® Print Guide Resin)

- Post-Processing: Automated washing/curing (e.g., Form Wash/Cure) → Biocompatibility validation via QR-coded material tracking

- Clinical Use: Same-day guide placement or temporary restoration (avg. print time: 18-32 mins for guides)

Throughput Impact: Reduces chairside guide fabrication from 72+ hours (lab-dependent) to <60 minutes, enabling immediate implant planning.

Lab Workflow Integration

- Order Ingestion: DICOM/STL files from clinics via cloud platforms (e.g., exocad Cloud)

- Design: CAD software with Straumann Bridge/Base libraries for abutment-specific design

- Batch Printing: Multi-laser printers (e.g., EnvisionTEC Vida) running 24/7 with Straumann PEEK/MetaLux resins

- Automated Post-Processing: Robotic washing/curing stations integrated with printer fleet management

- Quality Control: AI-powered optical inspection against Straumann tolerance specs (±20µm)

Throughput Impact: Enables 500+ unit/day production capacity with 99.2% first-pass yield using certified material-printer pairings.

CAD Software Compatibility Matrix

| CAD Platform | Straumann Integration Level | Key Technical Capabilities | Workflow Limitation |

|---|---|---|---|

| exocad DentalCAD | Deep API Integration (v4.0+) | • Direct import of Straumann implant databases • Automated screw channel generation • Material-specific support optimization |

Requires separate CARES® Print Module license ($2,200/yr) |

| 3Shape Dental System | Native Ecosystem (via Implant Studio) | • Real-time material library sync • Guided print parameter presets • Integrated biocompatibility reporting |

Closed workflow locks printer selection to 3Shape-certified OEMs |

| DentalCAD (by exocad) | Partial Integration | • Manual implant library import • Generic resin profiles only |

No automated material validation; voids Straumann warranty |

Open Architecture vs. Closed Systems: Technical Implications

Open Architecture Systems (e.g., exocad + Industrial Printers)

- Material Flexibility: Print Straumann resins on Formlabs/EnvisionTEC printers via calibrated profiles

- Cost Control: 35% lower material costs vs. proprietary cartridges; 60+ resin options for specialized cases

- Future-Proofing: API access enables integration with emerging AI print optimization tools

- Technical Trade-off: Requires in-house calibration expertise; 15-20% longer print prep time

Closed Ecosystems (e.g., 3Shape + Partner Printers)

- Turnkey Validation: Pre-validated printer/resin combinations with FDA 510(k) clearance

- Streamlined QC: Automated material traceability from print job to patient record

- Critical Limitation: 47% higher consumable costs; zero third-party material compatibility (per 2025 ISO 13485 audit)

Carejoy API Integration: The Workflow Catalyst

Carejoy’s Dental Orchestration API (v3.2, Q1 2026) eliminates manual file transfers through:

- Real-Time Print Job Orchestration: Auto-routes .STL files from Exocad/3Shape to optimal printer based on material type, queue status, and calibration logs

- Biocompatibility Chain-of-Custody: Embeds ISO 10993-23 validation data into print job metadata, syncing with EHR systems (e.g., Dentrix)

- Predictive Material Management: API pulls printer resin levels → triggers auto-replenishment of Straumann materials via McKesson/Dentsply Sirona

- Compliance Automation: Generates 21 CFR Part 11-compliant audit trails for FDA submissions

Throughput Impact: Reduces lab order-to-ship time by 3.2 hours per case and eliminates 92% of manual data entry errors in high-volume facilities.

Strategic Recommendation

For labs/clinics evaluating Straumann-compatible printing: Prioritize total ecosystem validation over printer sticker price. Invest in open-architecture systems with Carejoy integration for maximum ROI (projected 14-month payback at 15+ units/day). Closed systems remain viable for single-operator clinics prioritizing simplicity over long-term flexibility. Monitor Straumann’s 2026 partnership expansion with Formnext exhibitors for next-gen metal-printing integration.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Carejoy Digital 3D Printers (Reference: “Straumann 3D Printer Price” Market Context)

While Carejoy Digital does not manufacture under the Straumann brand, our high-precision dental 3D printers are engineered as competitive alternatives in the premium digital dentistry segment—offering superior cost-performance metrics. Manufactured in our ISO 13485-certified facility in Shanghai, Carejoy Digital 3D printers undergo a rigorously controlled production and quality assurance (QC) process designed to meet and exceed international standards for medical device manufacturing.

Manufacturing & QC Process Overview

| Stage | Process Description | Compliance & Technology |

|---|---|---|

| 1. Component Sourcing | High-tolerance optical components (405nm lasers/DLP), linear guides, and embedded control systems sourced from ISO 13485-aligned Tier-1 suppliers. Full material traceability maintained via ERP integration. | RoHS & REACH compliant; supplier audits conducted quarterly. |

| 2. In-House Assembly | Modular assembly in ESD-protected cleanrooms. Core subsystems (optical engine, Z-stage, resin vat) assembled under laminar airflow. | Shanghai facility certified to ISO 13485:2016 for medical device quality management systems. |

| 3. Sensor Calibration | Each printer undergoes calibration in a dedicated Sensor Calibration Lab using NIST-traceable measurement tools. Laser power, build platform flatness (±5µm), and temperature sensors are auto-validated via AI-driven diagnostics. | Lab accredited to ISO/IEC 17025 standards. Real-time feedback loops ensure sub-micron repeatability. |

| 4. Durability & Stress Testing | Printers undergo 72-hour continuous operation cycles, thermal cycling (-10°C to 45°C), and simulated clinical workloads (500+ print cycles). Resin vat lifespan tested up to 2,000 hours. | MTBF (Mean Time Between Failures) > 15,000 hours. Results logged in centralized QC database for predictive maintenance modeling. |

| 5. Final QA & Software Integration | End-to-end validation using test STL/PLY/OBJ files. AI-driven scanning compatibility verified with open-architecture workflows. Firmware authenticated and locked. | Pre-installed with Carejoy OS 4.2 (supports DICOM, AI-powered support generation, and cloud slicing). |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio for digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer access to precision optics, industrial AI chips, and micro-mechanical components within a 50km radius—reducing logistics costs by up to 40%.

- Advanced Automation: Carejoy’s facility deploys collaborative robotics (cobots) for 60% of assembly tasks, ensuring consistency while lowering labor dependency.

- R&D Investment: Over $120M invested in 2025 across Chinese dental tech firms in AI scanning algorithms and open-architecture compatibility—surpassing European R&D output in dental 3D printing.

- Regulatory Efficiency: NMPA clearance pathways are now synchronized with EU MDR and FDA 510(k) submissions, enabling faster global deployment.

- Open Architecture Advantage: Carejoy printers natively support STL, PLY, and OBJ formats, enabling seamless integration with third-party CAD/CAM software—reducing clinic lock-in and operational costs.

As a result, Carejoy Digital delivers sub-20µm printing accuracy and AI-optimized workflow integration at price points up to 35% below comparable European systems—without compromising on ISO 13485 compliance or long-term reliability.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Build Volume | 140 x 80 x 100 mm |

| Layer Resolution | 25–100 µm (adjustable) |

| AI-Driven Scanning | Real-time distortion correction; supports intraoral scanner fusion (3Shape, Medit, iTero) |

| Open File Support | STL, PLY, OBJ, 3MF (via Carejoy Bridge) |

| Remote Support | 24/7 cloud monitoring, AR-assisted troubleshooting, automatic firmware updates |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Straumann 3D Printer Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160