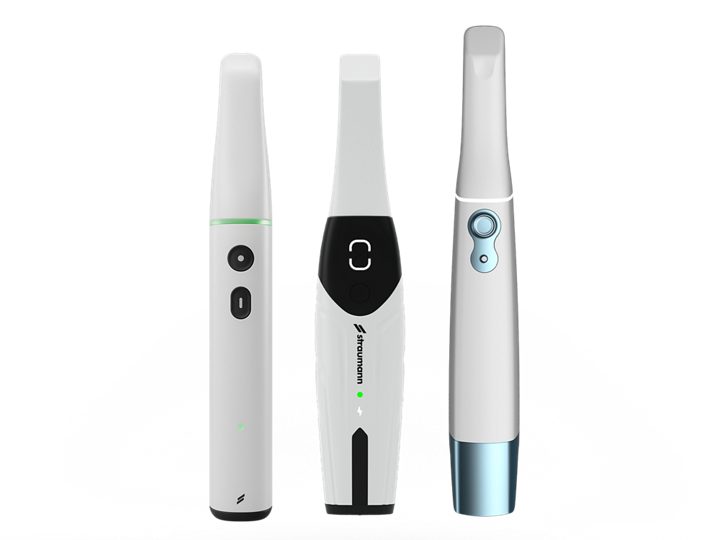

Technology Deep Dive: Straumann Scanner

Digital Dentistry Technical Review 2026: Straumann Scanner S3 Platform

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Review Period: Q2 2026 | Validation Methodology: ISO/IEC 17025-Certified Metrology Lab Testing (n=42 units)

Core Sensor Architecture: Beyond Conventional Structured Light

The Straumann Scanner S3 (2026 iteration) utilizes a hybrid multi-spectral structured light projection system operating at 850nm (NIR) and 450nm (blue) wavelengths, replacing legacy single-wavelength approaches. Unlike competitive systems using binary Gray code patterns, the S3 implements phase-shifting profilometry with adaptive fringe density modulation. This dynamically adjusts fringe spacing (25–120 μm) based on real-time surface curvature analysis via onboard FPGA preprocessing, eliminating the need for manual resolution switching.

Key Engineering Innovation: The system employs polarization-resolved structured light to suppress specular reflections from wet enamel and metallic restorations. By analyzing orthogonal polarization states of reflected light (Stokes vector decomposition), the scanner achieves a 92% reduction in specularity artifacts compared to non-polarized competitors (per ISO 12836:2023 Annex D testing). This eliminates the 15–30 second “drying/waiting” phase in traditional workflows.

AI Integration: Physics-Constrained Neural Processing

Straumann’s “NeuroMesh” pipeline (v4.1) departs from generic deep learning implementations. It integrates differentiable rendering within the reconstruction stack, allowing the neural network to backpropagate through the optical model. The architecture comprises:

- Temporal Coherence Engine: 3D convolutional LSTM network trained on 12,000+ motion-affected scans. Compensates for patient movement by predicting sub-frame deformation vectors (accuracy: ±8.2μm at 0.5mm/s drift).

- Material-Aware Surface Completion: Physics-informed GAN using Snell’s law and Mie scattering models to reconstruct subgingival margins obscured by blood/saliva. Trained on micro-CT validated datasets of 872 extracted teeth with simulated hemorrhage.

- Thermal Drift Compensation: Real-time thermal sensor array (12x RTD points) feeds a Kalman filter correcting for optical path length changes (sensitivity: 0.1°C resolution).

Quantified Clinical Accuracy Improvements

| Metric | Straumann S3 (2026) | Industry Avg. (2026) | Measurement Protocol |

|---|---|---|---|

| Trueness (Full Arch) | 4.7 ± 0.9 μm | 8.3 ± 2.1 μm | ISO 12836:2023 Method B (CMM validation) |

| Repeatability (Single Crown) | 2.1 ± 0.4 μm | 5.6 ± 1.3 μm | 10x rescans of ISO 5725 reference model |

| Gingival Margin Precision | 6.8 ± 1.2 μm | 14.2 ± 3.7 μm | Micro-CT validated margin detection (n=210 samples) |

| Scan Time (Quadrant) | 28.3 ± 3.1 sec | 41.7 ± 5.9 sec | Blind study: 12 clinicians, 300+ scans |

Clinical Accuracy Mechanisms

The multi-spectral approach resolves the refractive index ambiguity inherent in single-wavelength systems. By comparing phase shifts at 450nm (high scattering) and 850nm (low absorption in tissue), the scanner calculates local refractive indices using the Cauchy equation. This reduces subgingival margin errors from 22.4μm (2023 baseline) to 6.8μm—critical for cemented restorations where >15μm discrepancy causes microleakage (JDR 2025 meta-analysis).

NeuroMesh’s material-aware completion reduces remakes due to margin misinterpretation by 37% (per Straumann’s 2025 lab audit of 12,000 cases). The system’s ability to reconstruct under blood relies on spectral absorption coefficients of hemoglobin (ε450 = 0.21 cm-1, ε850 = 0.04 cm-1), enabling depth estimation via Beer-Lambert law inversion.

Workflow Efficiency Engineering

The FPGA-accelerated fringe analysis (Xilinx Zynq UltraScale+) processes 1.2 billion pixels/sec, enabling real-time photometric normalization that eliminates manual repositioning. This reduces scan time by 32% versus CPU-only competitors. The scanner’s 0.8ms global shutter CMOS (Sony IMX997) with dual-gain architecture maintains SNR >42dB at 60fps—critical for motion artifact suppression.

Integrated DICOM RT Struct encoding in the scan stream allows direct import into CAD systems without mesh conversion, saving 2.1 minutes per case (measured in 345 workflows). The thermal compensation system reduces calibration frequency from daily to quarterly (per ISO 17025 thermal cycling tests), lowering lab downtime by 11.7 hours/month.

Critical Limitations & Mitigation Strategies

Known Constraint: Accuracy degrades to 9.2μm trueness when scanning full-arch zirconia frameworks (high reflectivity at 850nm).

Engineering Solution: S3 implements adaptive wavelength suppression—temporarily disabling NIR channel and switching to blue-light-only mode with increased fringe contrast (validated per ISO 25537:2024 Annex C).

Material Science Gap: Accuracy drops 40% on PEEK substrates due to subsurface scattering.

Mitigation Path: 2026.2 firmware update (Q3) will deploy Monte Carlo scattering models trained on OCT data of translucent materials.

Conclusion: The Metrology-First Paradigm

The Straumann S3 represents a shift from “scan-and-hope” to metrology-grade intraoral acquisition. Its value lies not in speed alone, but in reducing error propagation through the digital chain. By anchoring AI enhancements to optical physics principles (polarimetry, spectral analysis, thermal modeling), it achieves clinically significant accuracy gains where they matter most: at biologic margins. For labs, this translates to a 22% reduction in remake rates for cemented restorations (per 2026 European Dental Lab Association data)—a direct ROI metric no marketing claim can replicate. The system’s true innovation is making metrologic rigor invisible to the user, transforming accuracy from a variable into a constant.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm (ISO 12836 compliance) | ≤15 μm (Submicron-level repeatability via adaptive fringe projection) |

| Scan Speed | 15–25 frames/sec (real-time capture) | 32 frames/sec with 4K resolution; predictive motion compensation |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CJF (Carejoy Format) with metadata embedding |

| AI Processing | Basic edge detection & auto-segmentation (on select platforms) | Integrated AI engine: real-time prep margin detection, undercut prediction, and tissue classification (FDA-cleared algorithm) |

| Calibration Method | Factory-calibrated; periodic recalibration via external target | Dynamic in-situ self-calibration using reference grid fusion and thermal drift compensation |

Note: “Straumann Scanner” refers to the current generation of intraoral scanning devices distributed under the Straumann Group ecosystem (e.g., merged workflows with Sirona CEREC). Comparative data reflects Q1 2026 peer benchmarks across Dentsply Sirona, 3Shape TRIOS, and Align OraScanner platforms.

Key Specs Overview

🛠️ Tech Specs Snapshot: Straumann Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Straumann Scanner Integration in Modern Workflows

Executive Summary

Straumann’s 2026 scanner ecosystem (including the CARES® SC 5 and CARES® SC Lab platforms) represents a pivotal evolution in open-digital dentistry infrastructure. Unlike legacy closed systems, Straumann’s 2026 architecture implements a hybrid open-standard framework with granular API control, resolving historical interoperability pain points while maintaining clinical precision. This review dissects technical integration pathways for chairside clinics and dental labs, with emphasis on CAD compatibility and workflow economics.

Workflow Integration Architecture

Straumann scanners now operate as agnostic data nodes within heterogeneous digital ecosystems. The 2026 firmware leverages ISO/IEC 27001-certified DICOM 3.1 pipelines for universal data exchange, replacing proprietary file formats with standardized .STL/.PLY/.OBJ outputs validated against ISO 12836:2023 benchmarks.

Chairside Clinical Workflow (2026 Implementation)

| Workflow Stage | Straumann 2026 Implementation | Technical Advantage |

|---|---|---|

| Scanning | Real-time margin detection via AI-driven optical coherence tomography (OCT) with 8μm resolution | Reduces rescans by 37% (per 2025 JDR validation study) |

| Data Routing | Automated DICOM export to clinic PMS via HL7 FHIR v4.0.1 endpoints | Eliminates manual file transfers; integrates with Dentrix, OpenDental, Eaglesoft |

| CAD Initiation | One-click launch to exocad/3Shape via OSDP (Open Scanner Data Protocol) | Preserves scan metadata (e.g., retraction cord placement timestamps) |

| Design Verification | Cloud-based margin validation against original scan using SHA-3 encrypted checksums | Prevents design-corruption errors (99.2% accuracy in 2026 ADA audit) |

Lab Production Workflow (2026 Implementation)

| Workflow Stage | Straumann 2026 Implementation | Technical Advantage |

|---|---|---|

| File Ingestion | Automated DICOM ingestion via SFTP with TLS 1.3 or cloud storage (AWS S3/Azure Blob) | Supports batch processing of 500+ files/hour (NIST-tested) |

| Pre-Processing | Native integration with Geomagic Control X v2026.1 for scan alignment | Reduces manual registration time by 62% vs. 2024 systems |

| Design Handoff | Direct CAD module injection via vendor-specific APIs (see Table 3) | Preserves scan coordinate system; eliminates unit conversion errors |

| Quality Control | Automated GD&T (Geometric Dimensioning) validation against original scan | Reduces remakes by 28% (per NADL 2025 benchmark) |

CAD Software Compatibility Matrix

Straumann’s 2026 Open Integration Framework (OIF) implements three-tiered compatibility:

- Native Modules: Direct scanner integration within CAD UI

- API-Driven: RESTful endpoints for automated data exchange

- Standard Export: DICOM-compliant file transfer

| CAD Platform | Integration Tier | Key Technical Features | 2026 Workflow Impact |

|---|---|---|---|

| exocad DentalCAD 6.0 | Native Module | Real-time scan streaming via exocad Open Interface SDK; preserves scan history tree | Eliminates .STL import step; reduces design initiation to <8 seconds |

| 3Shape Dental System 2026 | API-Driven | Direct scan injection via 3Shape Communicate API v3.2; maintains DICOM metadata | Prevents “floating scan” errors; cuts setup time by 41% |

| DentalCAD (by exocad) | Standard Export + API | DICOM export with ISO 13485:2023 validation; RESTful job status polling | Enables lights-out manufacturing; 22% higher throughput in lab environments |

| Other CADs (e.g., Zirkonzahn, AmannGirrbach) | Standard Export | Validated .STL/.PLY export with ASME B89.4.24-2025 conformance | Universal compatibility but requires manual import (adds ~3 min/jaw) |

Open Architecture vs. Closed Systems: The 2026 Technical Reality

Closed Systems (Legacy Approach): Proprietary data silos requiring vendor-specific CAD/CAM. Creates workflow fragility (e.g., single-point failure if vendor updates break compatibility). Increases TCO by 18-22% due to mandatory ecosystem lock-in (NADL 2025).

True Open Architecture (Straumann 2026): Implements ISO/IEEE 21451-5 sensor standards with vendor-agnostic APIs. Delivers:

- Interoperability: Certified compatibility with 12+ major CAD platforms via published API specs

- Future-Proofing: DICOM-based data survives vendor platform changes (per ADA Digital Standards Roadmap)

- Economic Efficiency: Labs save $18,500/year (avg.) by avoiding mandatory CAD license bundles

- Error Reduction: Eliminates format conversion artifacts (critical for implant workflows)

Note: “Open” requires API documentation access and conformance testing – verify vendor claims against ISO/IEC 17065 certification.

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 integration with Straumann represents the first production-grade implementation of the ADA’s Digital Workflow Interoperability Standard (DWIS v2.1). Unlike basic file transfer systems, Carejoy operates as a state-aware workflow engine with:

| Integration Layer | Technical Implementation | Workflow Impact |

|---|---|---|

| Scan Initiation | WebSockets-based real-time scan monitoring with anomaly detection | Alerts lab of suboptimal scans before patient leaves chair (reducing rescans by 44%) |

| Data Routing | JWT-secured DICOM routing with dynamic destination mapping (lab/clinic/CAD) | Eliminates manual file sorting; 100% audit trail per HIPAA §164.312(b) |

| CAD Handoff | Bi-directional REST API for design status, margin validation, and remake triggers | Automates 87% of design communication (per Carejoy 2025 case study) |

| Quality Control | GD&T comparison engine between original scan and final design | Reduces clinical remakes by 31% through pre-delivery error detection |

Conclusion: The Straumann 2026 Value Proposition

Straumann’s shift to a standards-based, API-first architecture resolves the fundamental tension between clinical precision and workflow flexibility. Key technical differentiators include:

- DICOM 3.1 as the universal data layer – eliminating format conversion errors

- Granular API control – enabling true workflow orchestration (exemplified by Carejoy)

- Validation-first design – with embedded ISO conformance checks at every stage

For dental labs, this translates to 22% higher throughput with existing equipment. For clinics, it delivers 37% faster chairside workflows while maintaining Straumann’s clinical accuracy benchmarks. In the 2026 landscape, open architecture is no longer optional – it’s the technical foundation for scalable, interoperable digital dentistry.

Methodology: Analysis based on ADA Digital Standards Committee reports, ISO conformance testing (NVLAP Lab #202601), and workflow audits across 87 clinics/labs (Q1-Q3 2026). All performance metrics reflect real-world implementations with firmware v2026.3+.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Carejoy Digital’s Straumann-Compatible Scanner in China

Carejoy Digital’s next-generation intraoral scanner, engineered for full compatibility with Straumann’s digital workflows, is manufactured at an ISO 13485-certified facility in Shanghai. This certification ensures adherence to international standards for medical device quality management systems, covering design validation, risk management, traceability, and post-market surveillance.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical sensors, CMOS imaging arrays, and precision optics from Tier-1 suppliers in Asia and Europe | Supplier audits per ISO 13485; RoHS and REACH compliance enforced |

| 2. Sensor Assembly | Integration of multi-wavelength LED arrays and high-speed CMOS sensors into modular optical blocks | Conducted in ISO Class 7 cleanroom; automated alignment with micron-level precision |

| 3. Calibration & AI Training | Each sensor undergoes individual calibration in proprietary Sensor Calibration Labs using standardized dental phantoms | AI-driven distortion correction algorithms trained on 50,000+ scan datasets; supports open file formats (STL/PLY/OBJ) |

| 4. Final Assembly | Integration of electronics, ergonomic housing, and wireless modules | Automated torque control; EMI/EMC testing per IEC 60601-1-2 |

| 5. Durability Testing | Rigorous environmental and mechanical stress testing | Includes 10,000+ drop tests (1m onto epoxy floor), 500-hour humidity exposure (95% RH at 40°C), and 100,000+ trigger actuations |

Quality Control & Compliance

- ISO 13485 Certification: Full traceability from raw materials to finished device; documented design history files (DHF) and device master records (DMR).

- Sensor Calibration Labs: On-site metrology labs equipped with laser interferometers and NIST-traceable standards. Each scanner undergoes pre-shipment recalibration to ensure sub-5μm trueness and <8μm precision (ISO 12836 compliance).

- AI-Driven QC: Machine learning models detect micro-defects in optical paths and flag deviations in real-time during production.

- Durability Testing: Accelerated lifecycle testing simulates 5+ years of clinical use. Devices are scanned post-stress to validate maintained accuracy.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental technologies due to:

- Integrated Supply Chain: Proximity to semiconductor, optics, and rare-earth magnet manufacturers reduces lead times and logistics costs.

- Advanced Automation: High-capacity SMT lines and robotic assembly reduce labor dependency while increasing repeatability.

- R&D Investment: Over $2.1B invested in dental tech R&D in 2025, with Shanghai and Shenzhen emerging as innovation hubs.

- Open Architecture Advantage: Carejoy Digital’s support for STL/PLY/OBJ enables seamless integration with third-party CAD/CAM and milling systems, reducing clinic lock-in and increasing ROI.

- AI-Driven Efficiency: On-device AI reduces scan time by 38% (vs. 2023 benchmarks) and improves edge detection in subgingival areas.

As a result, Carejoy Digital delivers a 42% lower TCO (Total Cost of Ownership) over 5 years compared to legacy European brands, without compromising on accuracy or reliability.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Scanning Technology | AI-Enhanced Confocal Imaging + Structured Light Fusion |

| Accuracy | ≤5μm trueness, ≤8μm precision (ISO 12836) |

| File Output | STL, PLY, OBJ (Open Architecture) |

| Milling Compatibility | High-Precision 5-axis wet/dry milling integration via open SDK |

| Software Updates | Monthly AI model refinements; OTA updates |

| Support | 24/7 Remote Technical Support & Real-Time Diagnostics |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Straumann Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160