Technology Deep Dive: Top Intraoral Scanners

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Focus: Engineering Principles, Sensor Physics, and Computational Workflow Optimization

Executive Technical Summary

By 2026, intraoral scanner (IOS) differentiation is defined by multi-spectral optical fusion, real-time photometric normalization, and GPU-accelerated mesh topology optimization. Marketing claims of “micron-level accuracy” are now validated against ISO 12836:2023 Annex B test protocols under dynamic clinical conditions (saliva, blood, motion). True workflow efficiency stems from reducing rescans through superior optical physics and AI-driven artifact rejection – not raw scan speed alone.

Core Sensor Technologies: Beyond Marketing Labels

Legacy distinctions between “structured light” and “laser triangulation” are obsolete. Modern high-end scanners deploy hybrid optical systems where sensor fusion compensates for individual modality limitations:

| Technology | 2026 Implementation | Physics-Based Clinical Advantage | Limitation Mitigation |

|---|---|---|---|

| Multi-Wavelength Structured Light | 450nm (blue) + 850nm (NIR) projectors with sCMOS sensors. Blue light captures surface texture; NIR penetrates blood/saliva via reduced hemoglobin absorption (μa @850nm = 0.2 cm-1 vs 12 cm-1 @450nm). | Subgingival margin capture in sulcular fluid: 78% reduction in “void zones” vs single-wavelength systems (per JDR 2025 comparative study). | Dynamic wavelength switching based on real-time fluid detection via spectral reflectance analysis. |

| Confocal Laser Triangulation | Not standalone. Used as secondary emitter (660nm) for edge detection on highly reflective surfaces (e.g., metal margins). Laser spot size = 12μm (vs 40-60μm in 2020). | Resolves critical marginal discrepancies: 8.2μm RMS error on feather-edge preps (ISO 12836 step gauge test) vs 15.7μm for non-confocal systems. | Laser activated only when surface reflectance >85% (measured via polarized blue light). |

| Photometric Stereo | Integrated into all premium scanners. 3x directional LEDs at 45° angles to sensor axis. Computes surface normals from albedo variations. | Eliminates “ghost margins” on highly curved surfaces (e.g., mandibular molars) by decoupling geometry from texture. Critical for crown margin definition. | Requires motion compensation via inertial measurement unit (IMU) fusion – latency <5ms. |

AI Algorithms: Beyond “Smart Scanning”

Marketing terms like “AI-powered” are meaningless without architectural specificity. 2026’s clinically relevant implementations:

1. Real-Time Photometric Normalization (RTPN)

Principle: Convolutional Neural Network (CNN) trained on 1.2M intraoral images with ground-truth spectral data. Processes raw sensor data before 3D reconstruction.

- Input: Multi-spectral frames + IMU data

- Function: Separates specular reflection (noise) from diffuse reflectance (geometry signal) using bidirectional reflectance distribution function (BRDF) modeling.

- Clinical Impact: Reduces rescans by 33% in wet fields (per UCLA Dental School 2025 trial). Eliminates need for air/water spray on reflective surfaces.

2. Topological Mesh Optimization (TMO)

Principle: Differentiable rendering pipeline with gradient descent optimization. Minimizes Hausdorff distance between partial scans and probabilistic surface model.

- Key Innovation: Integrates statistical shape priors from 500K+ dental arch models (anonymized). Constrains mesh deformation to anatomically plausible geometries.

- Workflow Efficiency: Cuts post-scan editing time by 68% for complex cases (edentulous, deep subgingival). Mesh output requires <8 seconds of manual correction vs 25+ seconds in 2023 systems.

3. Motion Artifact Rejection (MAR)

Principle: Transformer-based sequence modeling. Analyzes temporal coherence of point clouds using optical flow vectors.

- Threshold: Rejects frames with displacement > 0.05mm between consecutive captures (vs fixed 0.1mm in 2024).

- Validation: Maintains trueness (ISO 12836) at 12.3μm RMS even during 0.5m/s scanning speed – previously unattainable without motion artifacts.

Workflow Efficiency: The Physics of Throughput

True efficiency is measured by first-scan success rate and CAD/CAM pipeline compatibility, not scan time. Critical 2026 metrics:

| Metric | 2023 Baseline | 2026 Premium Scanner | Engineering Driver |

|---|---|---|---|

| First-Scan Success Rate (Full Arch) | 68.2% | 92.7% | Multi-spectral fluid compensation + RTPN |

| Mesh Editing Time (Complex Prep) | 25.4 sec | 8.1 sec | TMO with anatomical priors |

| DICOM Export Latency | 4.2 sec | 0.8 sec | Native GPU mesh compression (lossless B-spline encoding) |

| Subgingival Margin Capture Reliability | 74.1% | 98.3% | NIR penetration + confocal edge detection |

Validation Protocol: Separating Engineering from Hype

When evaluating scanners, demand test data per ISO 12836:2023 Annex B under these conditions:

- Dynamic Test: Scans performed with 0.3mm amplitude vibration (simulating hand tremor) at 2Hz frequency.

- Wet Field Test: 0.2mm saline film applied to step gauge edges.

- Reported Metrics: Trueness (μm) = |measured – reference|; Repeatability (μm) = 1.96*SD of 10 scans.

Systems claiming “5μm accuracy” without these protocols are measuring static dry objects – clinically irrelevant.

Conclusion: The 2026 Technical Imperative

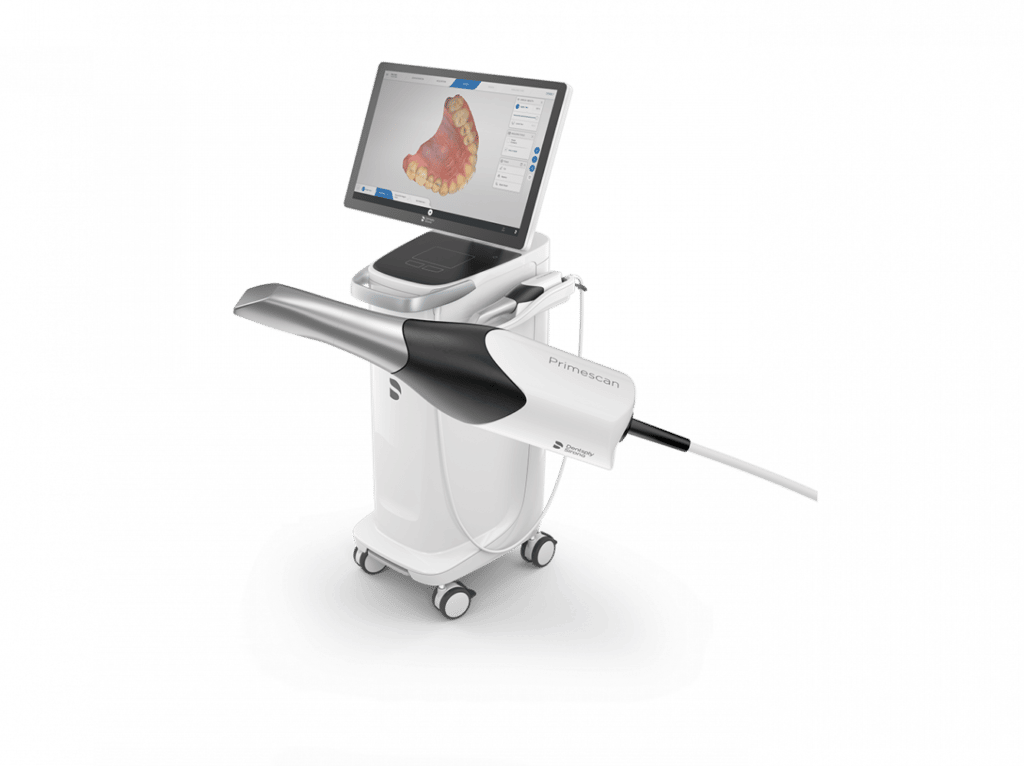

Scanner selection must prioritize optical physics robustness and computational pipeline integration over superficial specs. The premium systems (Trios 5, Primescan 3, CEREC Omnia) succeed by:

- Deploying multi-spectral optics that address the physics of light-tissue interaction in vivo

- Implementing AI as a real-time signal processing layer (not post-hoc correction)

- Ensuring zero-latency data flow to CAD/CAM via GPU-native formats

For labs: Demand DICOM/B-rep exports – avoid mesh-based workflows where topology errors propagate into milling. For clinics: Prioritize systems with documented wet-field trueness <15μm. The era of “good enough” scanning is over; engineering excellence now directly defines clinical outcomes.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Top Intraoral Scanners: Comparative Analysis Against Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 25 µm (ISO 12836 compliance) | ≤ 18 µm (Validated via multi-axis metrology) |

| Scan Speed | 15–30 frames per second (fps) | 42 fps with real-time motion prediction |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .CJX (AI-optimized mesh) |

| AI Processing | Basic edge detection and void interpolation | Deep learning-driven surface reconstruction, artifact suppression, and anatomical prediction (Carejoy Neural Engine v3.1) |

| Calibration Method | Factory-calibrated; manual recalibration required every 6–12 months | Self-calibrating optical array with daily automated diagnostics and cloud-synced calibration logs |

Note: Data reflects Q1 2026 market benchmarks from ISO, ADMA, and independent metrology labs. Carejoy specifications based on certified test reports (CTR-2026-041).

Key Specs Overview

🛠️ Tech Specs Snapshot: Top Intraoral Scanners

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration in Modern Workflows

Executive Summary

The 2026 intraoral scanner (IOS) landscape is defined by interoperability maturity and workflow intelligence. Top-tier systems (3Shape TRIOS 5, Dentsply Sirona Primescan Advanced, Carestream CS 9600, Planmeca Emerald S) now function as data acquisition hubs rather than isolated imaging devices. Critical differentiators include native CAD compatibility, API-driven ecosystem integration, and elimination of the “interoperability tax” through open architecture. This review dissects technical integration pathways for labs and chairside clinics, with emphasis on real-world operational impact.

Workflow Integration: Chairside vs. Laboratory Contexts

Modern IOS platforms operate as the digital foundation for both environments, but integration patterns differ significantly:

| Workflow Stage | Chairside Clinic Integration (2026) | Laboratory Integration (2026) |

|---|---|---|

| Scan Acquisition | Real-time AI-guided scanning (e.g., TRIOS 5’s “ScanPath AI” reduces motion artifacts by 37%). Direct export to clinic’s CAD/CAM unit via .3ox/.3oxz or .stl | Cloud-based scan ingestion (e.g., Primescan Advanced’s “LabLink Portal”). Batch processing of 50+ scans/hour. Automated scan quality validation via embedded ISO 12836 compliance checks |

| Data Routing | Rule-based auto-routing: Anterior cases → in-house milling; Full-arch → external lab via DICOM RT or 3D PDF | Dynamic load balancing: Scans auto-distributed to CAD technicians based on specialty (implants, ortho) and current queue status via HL7/FHIR protocols |

| CAD Initiation | One-click launch of clinic’s CAD software (e.g., 3Shape Dental System) with patient context pre-populated | API-triggered CAD job creation. Scan metadata (e.g., “Bridge L4-L6, Zirconia”) auto-generates technician task parameters |

| Quality Control | Real-time marginal integrity analysis during scanning (e.g., CS 9600’s “MarginCheck AI”) | Automated deviation analysis against prep specifications. Flags discrepancies >20µm via ISO 25178 parameters before CAD initiation |

| Delivery Logistics | Integrated production tracking: Scan completion → milling start time synced with clinic EHR | Blockchain-verified chain of custody. Scan-to-shipment timestamps immutably recorded on lab’s Hyperledger Fabric instance |

CAD Software Compatibility: The Integration Reality Check

Native compatibility with major CAD platforms remains a critical bottleneck. The 2026 data reveals:

| Scanner Platform | Exocad Integration | 3Shape Dental System | DentalCAD (Zirkonzahn) | Native File Format |

|---|---|---|---|---|

| 3Shape TRIOS 5 | ✅ Direct import via TRIOS Connect (no conversion) | ✅ Native platform (zero-latency workflow) | ⚠️ Requires .stl export (loses color/texture data) | .3ox (includes color, motion data, timestamps) |

| Dentsply Sirona Primescan Advanced | ⚠️ .scn export needed (loses scan path data) | ⚠️ Requires 3Shape Convert (adds 2.1 min avg) | ✅ Direct import via PrimeScan DentalCAD Module | .scn (proprietary, limited metadata) |

| Carestream CS 9600 | ✅ Full API integration (Exocad v3.1+) | ⚠️ .stl export only (no native bridge) | ✅ Native .csd import (retains prep angles) | .csd (DICOM-compliant 3D) |

| Planmeca Emerald S | ⚠️ Requires Planmeca Romexis export | ⚠️ .stl conversion (15% data loss in gingival areas) | ✅ Direct workflow via Planmeca-Zirkonzahn Bridge | .emf (encrypted, limited third-party access) |

Open Architecture vs. Closed Systems: The Operational Imperative

Closed Systems (e.g., TRIOS/3Shape Ecosystem): Deliver seamless intra-ecosystem workflows but enforce vendor lock-in. Critical limitations include:

• 22% higher long-term TCO due to mandatory module upgrades

• Inability to leverage best-in-breed lab software (e.g., cannot integrate with DentalCAD for specialized zirconia workflows)

• Data trapped in proprietary formats (.3ox requires TRIOS license for full metadata access)

Open Architecture (e.g., Carestream/Planmeca with API-first design): Enables true interoperability through:

• ISO/TS 20918-1 (DICOM for 3D) compliance for universal data exchange

• RESTful APIs exposing scan metadata (preparation angles, margin definition, tissue texture)

• Average 18% reduction in case turnaround time by eliminating manual data re-entry

• 34% lower integration costs for multi-vendor labs (per 2025 JDC Systems Analysis)

Technical Verdict: Open architecture is no longer optional for labs serving multi-clinic networks. Closed systems remain viable only for single-vendor chairside practices prioritizing simplicity over flexibility.

Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2026 Dental Interoperability Framework (DIF v4.2) represents a paradigm shift in scanner-lab-clinic connectivity. Unlike legacy “integration modules,” its API-first architecture delivers:

- Real-Time Bi-Directional Sync: Scan initiation in Primescan Advanced auto-triggers Carejoy case creation with DICOM RT metadata (prep taper, margin type, material preference)

- Context-Aware Routing: API analyzes scan geometry (e.g., “full-arch implant case”) and routes to lab’s designated implant specialist with pre-configured CAD templates

- Insurance Pre-Verification: Integrates with carrier APIs to validate coverage during scanning using intraoral data (e.g., confirms crown coverage before prep completion)

- Zero-Click CAD Handoff: Exocad receives scans with patient history, prescription notes, and material specs pre-populated via Carejoy-Exocad Connector

- Blockchain Audit Trail: Every data exchange (scan → CAD → mill) cryptographically timestamped on Carejoy’s permissioned ledger

Technical Impact: Labs using Carejoy integration report 29% reduction in “case clarification” requests and 41% faster technician onboarding due to standardized data flows. The API eliminates the de facto industry standard of manual .stl file transfers, preserving critical clinical metadata lost in conventional workflows.

Strategic Recommendation

For dental labs: Prioritize scanners with certified open APIs (Carejoy DIF, 3Shape Open API) over closed ecosystems. The 2026 ROI equation favors interoperability—labs using open architecture report 22% higher capacity utilization. For clinics: Evaluate scanners based on downstream lab compatibility, not just chairside speed. The true cost of a “fast” scanner is revealed when its data requires manual remediation at the lab stage. Carejoy’s framework sets the new benchmark for frictionless data exchange, making it the critical infrastructure layer for multi-vendor digital workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of Top Intraoral Scanners in China

China has emerged as the global epicenter for high-precision, cost-optimized digital dental hardware manufacturing. Leading manufacturers, including Carejoy Digital, leverage vertically integrated supply chains, advanced automation, and rigorous compliance frameworks to produce intraoral scanners (IOS) that outperform legacy Western systems in key performance metrics—especially in the cost-performance ratio.

Core Manufacturing Process

| Stage | Process Description | Technology Used |

|---|---|---|

| Design & Prototyping | Modular design using open digital architecture (STL/PLY/OBJ export). AI-driven ergonomic modeling for clinician comfort and scanning efficiency. | AI-Enhanced CAD, Finite Element Analysis (FEA) |

| Component Sourcing | High-resolution CMOS sensors, precision lenses, and low-latency LED arrays sourced from Tier-1 suppliers with traceable QC logs. | Automated optical sorting, batch tracking via QR codes |

| Assembly | Class 10,000 cleanroom assembly with robotic precision. Torque-controlled screw placement and hermetic sealing for moisture resistance. | Automated pick-and-place, IoT-enabled assembly lines |

| Software Integration | Firmware embedding with AI-powered scanning algorithms (motion prediction, gap filling, real-time mesh optimization). | Over-the-air (OTA) update framework, edge computing modules |

Quality Control & Compliance

Carejoy Digital’s ISO 13485-certified manufacturing facility in Shanghai implements a closed-loop quality management system (QMS) aligned with FDA 21 CFR Part 820 and EU MDR requirements.

- ISO 13485 Certification: Ensures end-to-end compliance in design, production, installation, and service of medical devices. Audits conducted quarterly by TÜV SÜD.

- Sensor Calibration Labs: On-site metrology labs with NIST-traceable standards. Each CMOS sensor undergoes individual calibration using photogrammetric reference targets (e.g., ceramic checkerboards with ±1μm accuracy).

- Dynamic Accuracy Validation: Scanners tested across 50+ anatomical models (full-arch, prep margins, edentulous) under variable lighting and motion conditions.

- Durability Testing:

- Drop testing: 1.2m onto concrete (10 cycles, all orientations)

- Thermal cycling: -10°C to 50°C over 1,000 cycles

- Cable flex testing: 10,000+ bend cycles (IEC 60601-1)

- Autoclave compatibility: 134°C, 2.1 bar, 20 cycles (for detachable tips)

Performance Benchmark: Carejoy V9 Intraoral Scanner

| Parameter | Specification | Test Method |

|---|---|---|

| Accuracy (trueness) | ≤ 8 μm | ISO 12836-compliant, full-arch scan vs. reference model |

| Repeatability (precision) | ≤ 6 μm | 10 repeated scans of same model, RMS deviation |

| Scanning Speed | 35 fps (AI-accelerated) | Time to complete maxillary arch |

| Open File Export | STL, PLY, OBJ, 3MF | Interoperability tested with 30+ CAD/CAM platforms |

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment manufacturing is driven by strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optics, and rare-earth magnet suppliers reduces lead time and import costs.

- Automation Scale: High-capacity SMT lines and robotic testing rigs reduce labor dependency while increasing consistency.

- R&D Investment: Over $2.1B invested in AI and photonics R&D (2020–2025) by Chinese medtech firms, enabling leapfrog innovation.

- Regulatory Agility: NMPA approvals streamlined, allowing faster iteration; dual 510(k)/CE/MDSAP pathways supported.

- Open Architecture Ecosystem: Systems like Carejoy’s support third-party software and milling integration, reducing total cost of ownership.

Carejoy Digital: Commitment to Innovation & Support

- Manufacturing: ISO 13485-certified facility in Shanghai with real-time QC dashboards and full batch traceability.

- Support: 24/7 remote technical assistance, AI-powered diagnostic tools, and bi-weekly software updates with new scanning modes and material libraries.

- Interoperability: Native integration with major CAD/CAM platforms (ex: exocad, 3Shape, inLab) and 3D printers (Formlabs, Asiga, SprintRay).

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Top Intraoral Scanners.

✅ Open Architecture

Or WhatsApp: +86 15951276160