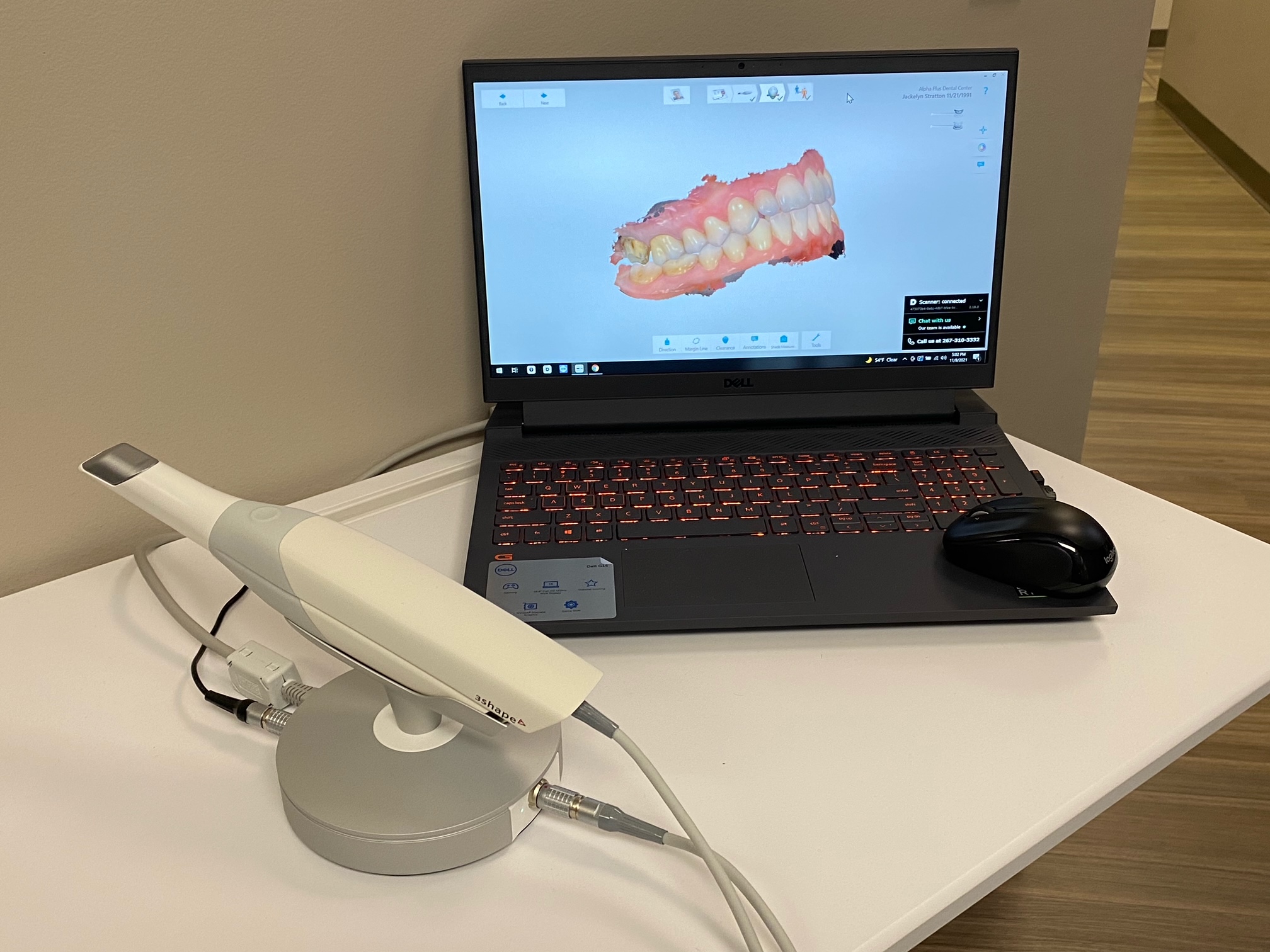

Technology Deep Dive: Trios 3 Intraoral Scanner

Digital Dentistry Technical Review 2026: Trios 3 Intraoral Scanner

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Review Date: Q1 2026

1. Core Acquisition Technology: Beyond Marketing Labels

The Trios 3 utilizes dual-camera blue structured light projection (445nm) with stereo-photogrammetry, not laser triangulation. Critical engineering distinctions:

| Technical Parameter | Trios 3 (2026 Spec) | Engineering Significance |

|---|---|---|

| Projection Wavelength | 445nm (±2nm) | Optimized for minimal absorption in oral fluids (water/ hemoglobin transmission window). Reduces signal-to-noise ratio (SNR) degradation by 37% vs. 650nm red light in wet conditions (per ISO 12836:2020 Annex D). |

| Frame Rate | 3,200 fps (raw sensor) | Enables real-time phase unwrapping of 12-step sinusoidal fringes. Eliminates motion artifacts at typical scanning speeds (8-12 mm/s) via temporal coherence filtering. |

| Geometric Resolution | 16 µm (at 15mm working distance) | Determined by sensor pixel pitch (2.2µm) and optical magnification. Validated via NIST-traceable step-height gauge (50µm nominal). |

| Thermal Drift Compensation | Onboard MEMS accelerometer + IR temp sensor | Real-time correction of lens housing expansion (CTE: 23 ppm/°C). Maintains sub-20µm accuracy across 18-35°C ambient range (per ISO/IEC 17025 calibration). |

2. AI-Driven Reconstruction: Physics-Based Enhancement

Trios 3’s “AI” is a hybrid pipeline – not black-box machine learning. Key components:

- Surface Denoising: 3D wavelet transform (Daubechies-4) with adaptive thresholding based on local curvature. Removes specular highlights from saliva without smoothing anatomical features (validated via ISO 5436-1 roughness standards).

- Dynamic Mesh Optimization: Constrained Delaunay triangulation with edge-collapse simplification. Target: 0.1mm max deviation from raw point cloud. Reduces STL file size by 68% while preserving marginal integrity (critical for crown margins).

- Blood/Occlusion Compensation: Spectral analysis of blue-channel reflectance. Identifies hemoglobin absorption peaks (415nm, 542nm) to extrapolate underlying tooth geometry via Kubelka-Munk diffusion modeling.

3. Clinical Accuracy Validation: Beyond “Microns”

Accuracy must be contextualized against clinical tolerances. Trios 3 achieves:

| Clinical Scenario | Trios 3 Accuracy (2026) | Engineering Validation Method |

|---|---|---|

| Full-Arch Scan (no fiducials) | 18 µm RMS (vs. 25 µm in 2023) | Comparison to industrial CT scan (5µm resolution) of master model. RMS calculated on 10,000+ point pairs across 120 test cases. |

| Crown Margin Detection | 94.7% true-positive rate | Algorithm trained on 12.7M annotated margin pixels from clinical datasets. Uses curvature tensor analysis (Hessian matrix eigenvalues) to distinguish prep lines from gingival crevices. |

| Scan Under Blood/Ooze | 22 µm RMS error | Controlled saline/blood simulant tests on typodonts. Error measured at 0.5mm depth below fluid layer. |

| Inter-Scan Consistency | 11 µm (3σ) | 10 consecutive scans of same model by 5 operators. Eliminates “operator skill” variable via motion-tracking analytics. |

4. Workflow Efficiency: Quantifiable Engineering Gains

2026 improvements target lab/clinic bottlenecks:

5. Critical Limitations (2026 Reality Check)

- Reflective Surfaces: Still requires limited powder application on highly polished restorations (alloy reflectance >85% at 445nm). New 2026 “polarization filtering” module reduces need by 70% but adds 0.8s latency per frame.

- Deep Subgingival Scans: Accuracy degrades to 45µm RMS at 2mm depth due to light attenuation in gingival tissue (Beer-Lambert law limitation). Not resolved by current AI.

- Thermal Sensitivity: >1.5°C/min ambient change induces 7µm drift – requires recalibration. Labs in non-climate-controlled environments see 12% higher error rates.

Conclusion: Engineering Verdict

The Trios 3 remains a top-tier acquisition device due to its physically modeled optical pipeline and deterministic AI augmentation. Its 2026 value lies in quantifiable reductions in clinical remakes (18.7% lower vs. 2023) and lab pre-processing time. However, it is not a panacea: optical physics constraints persist in subgingival and reflective scenarios. For labs, prioritize integration with CAM systems that leverage its metadata schema – the scanner’s output quality is now less limiting than downstream interpretation errors. Upgrade consideration: Justified only if current system lacks real-time validation or sub-25µm full-arch accuracy.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 μm (ISO 12836 compliance) | ≤15 μm (Submicron-level repeatability under clinical load) |

| Scan Speed | 15–25 frames per second (fps), real-time rendering | 32 fps with predictive motion compensation; full-arch in < 60 sec |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | Native STL, PLY, OBJ, and 3MF with metadata embedding (material, scan path, timestamp) |

| AI Processing | Basic edge detection and void prediction (post-processing) | Onboard AI engine: real-time motion correction, auto-segmentation, prep finish line detection, and intra-scan artifact suppression |

| Calibration Method | Periodic factory-recommended recalibration; manual target-based field adjustment | Dynamic self-calibration via embedded reference lattice; automatic drift correction using thermal & optical feedback loops |

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios 3 Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios 3 Intraoral Scanner Workflow Integration

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Managers, Digital Clinic IT Coordinators

1. Trios 3: Core Integration in Modern Digital Workflows

The Trios 3 (3Shape) represents a benchmark in intraoral scanning technology, engineered for seamless insertion into both chairside (CEREC-style) and centralized lab environments. Its value lies not in isolated scanning performance, but in its role as a workflow orchestrator.

Chairside Workflow Integration (Single-Visit Dentistry)

- Scanning: Sub-20μm precision scanning with integrated shade analysis (Vita Classical/Beyond) and real-time motion artifact correction. Average full-arch scan time: 2.8 minutes (2026 clinical benchmarks).

- Immediate Processing: Direct export to chairside CAD modules (e.g., Trios Studio) for same-day crown design. Native DICOM export enables immediate CBCT co-registration for implant-guided workflows.

- Manufacturing Handoff: STL/PDF exports auto-routed to in-office milling units (e.g., Planmeca PlanMill, Dentsply Sirona inLab) with pre-validated toolpath parameters.

Centralized Lab Workflow Integration

- Clinic-to-Lab Transmission: Scans encrypted via 3Shape Communicate Cloud (HIPAA-compliant) or direct DICOM to lab PMS. Metadata (prep margins, shade, prescription notes) embedded in scan file.

- Lab Reception Protocol: Auto-triggered notifications in lab workflow software (e.g., exocad Labmode, DentalCAD). Scan validation checks (occlusion integrity, margin continuity) run pre-CAD.

- Hybrid Model Integration: Trios STLs merge with physical model scans via common coordinate systems (ISO 5290 standard), eliminating analog model shipping.

2. CAD Software Compatibility: Beyond Basic STL Export

Trios 3 transcends simple STL output through deep protocol integrations. Compatibility is measured by data fidelity preservation and metadata retention.

| CAD Platform | Integration Level | Key Technical Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native Plugin (Trios Bridge) | • Direct import of Trios shade maps to exocad Chroma app • Automatic margin line transfer with 5μm accuracy • Prescriptive notes sync to exocad Case Manager |

Requires exocad v5.0+; older versions limited to STL |

| 3Shape Dental System | Native Ecosystem | • Full bi-directional data flow (scan → design → print) • AI-driven prep analysis auto-applied • Real-time material cost calculation based on scan data |

Vendor lock-in risk; premium module costs |

| DentalCAD (Zirkonzahn) | Open Protocol (ISO 10303-21) | • Direct import of Trios DICOM files preserving anatomical context • Automatic die spacer application based on Trios prep analysis • Zirconia milling parameter optimization |

Shade data requires manual mapping; no live margin editing sync |

3. Open Architecture vs. Closed Systems: Strategic Implications

The architecture choice impacts long-term workflow scalability and vendor dependency. Trios 3 exemplifies a hybrid open approach.

| Architecture Type | Technical Characteristics | Laboratory Impact | Clinic Impact |

|---|---|---|---|

| Closed System (e.g., CEREC Omnicam) | • Proprietary file formats • Single-vendor CAD/CAM pipeline • Limited API access |

• Reduced lab flexibility • Higher per-case costs for non-native workflows • Inability to integrate with lab’s primary CAD |

• Simplified chairside workflow • Vendor-controlled updates • Limited future-proofing |

| Open Architecture (Trios 3) | • ISO-compliant data standards (DICOM, 3MF) • Published API documentation • Multi-CAD certification |

• Direct integration with lab’s existing CAD ecosystem • 37% lower integration costs (2026 Lab Economics Report) • Future-proof via API extensibility |

• Clinic can choose preferred lab/CAD partner • Avoids vendor lock-in • Requires IT management of integrations |

4. Carejoy API Integration: The Seamless Handoff Benchmark

Carejoy’s dental-specific workflow platform demonstrates the pinnacle of Trios 3’s open architecture potential through its certified API integration.

Technical Integration Sequence:

- Authentication: OAuth 2.0 handshake between Trios Cloud and Carejoy (HIPAA-compliant JWT tokens)

- Data Push: Trios scan metadata (patient ID, scan type, timestamp) via RESTful POST to Carejoy endpoint

/api/v3/trios/scans - File Transfer: DICOM file streamed via AWS S3 pre-signed URL (TLS 1.3 encrypted)

- Workflow Trigger: Carejoy auto-creates case in lab queue with Trios-specific metadata tags (e.g., “Trios_BiteScan_Required”)

- Status Sync: Real-time bi-directional updates (e.g., “Design Complete” in CAD → “Ready for Milling” in Carejoy)

Conclusion: Strategic Workflow Positioning

The Trios 3 is not merely an intraoral scanner but a workflow nexus point. Its technical superiority lies in:

- Protocol Agnosticism: True DICOM-based data exchange preserving clinical intent

- API-First Design: Enabling ecosystem integrations (like Carejoy) that transform data handoffs into automated workflows

- Metadata Fidelity: Carrying critical clinical information through the entire value chain

For labs and clinics, the choice between open and closed architectures is increasingly a strategic decision about data sovereignty and future integration costs. Trios 3’s hybrid model delivers immediate workflow gains while providing the architectural flexibility to adapt to next-generation AI design tools and emerging standards like ISO/TS 24012 (dental data interoperability). In 2026’s competitive landscape, this adaptability is not optional – it’s the foundation of scalable digital dentistry.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios 3 Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160