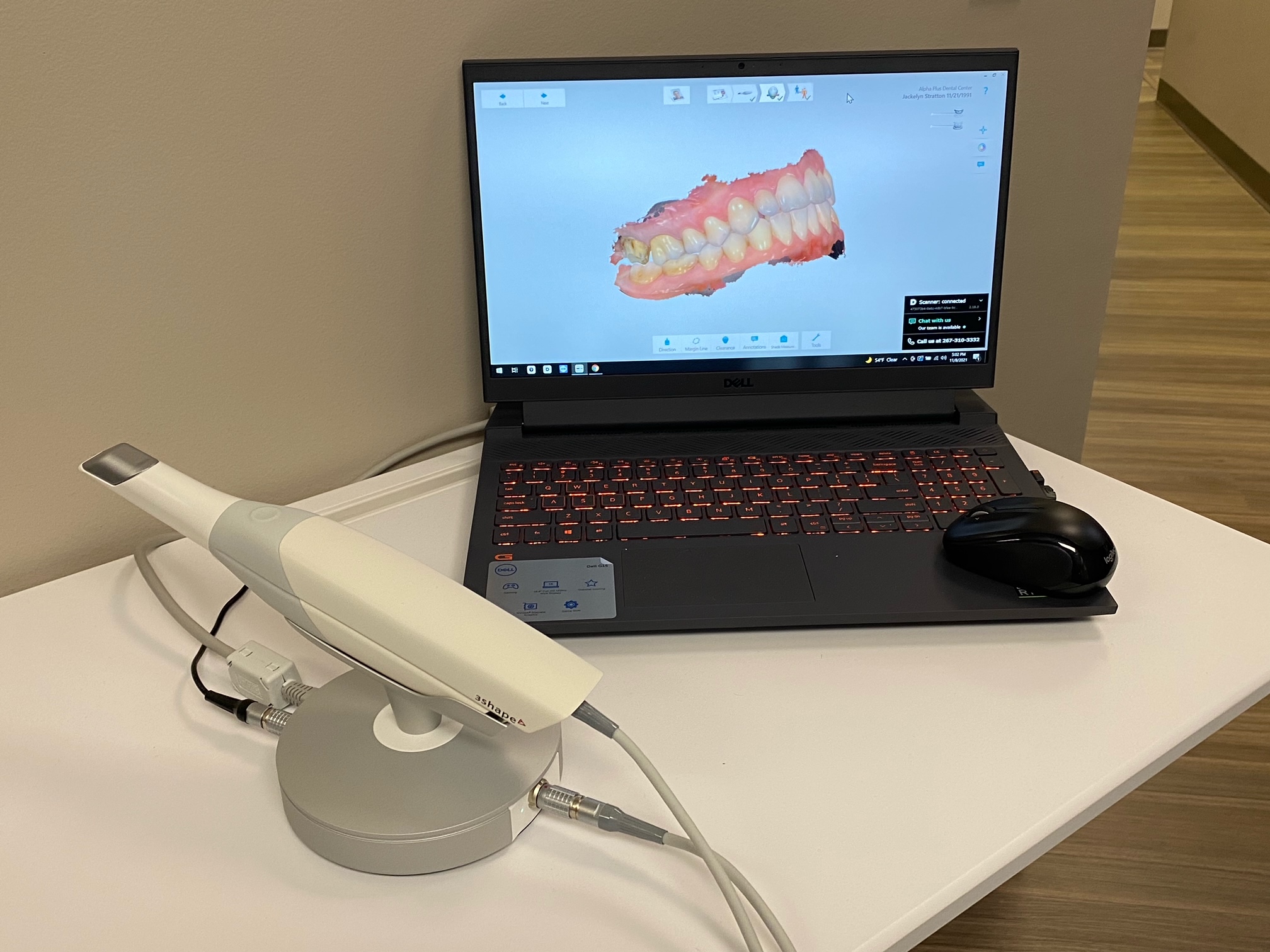

Technology Deep Dive: Trios Dental Scanner

Trios Dental Scanner Technical Deep Dive: 2026 Engineering Analysis

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, CAD/CAM Integration Specialists

1. Core Technology Architecture: Beyond Marketing Claims

Trios (3Shape, 2026 iteration) utilizes Adaptive Structured Light Projection (ASLP) as its primary optical acquisition method, explicitly not laser triangulation. This distinction is critical for understanding its performance envelope. Laser triangulation systems (e.g., legacy models from competitors) suffer from speckle noise, limited depth of field, and sensitivity to surface reflectivity – limitations ASLP inherently mitigates.

1.1. Structured Light Implementation: Photometric Precision

- Blue LED Source (450nm): Chosen for optimal balance between scattering minimization in soft tissue and reduced chromatic aberration in optical path vs. white light. Peak wavelength aligns with silicon sensor quantum efficiency (QE >85% at 450nm).

- Dynamic Fringe Projection: Replaces fixed-pattern projectors. Utilizes a DMD (Digital Micromirror Device) chip capable of 22,000+ pattern variations/sec. Pattern density (fringe frequency) and phase shift are dynamically adjusted in real-time based on surface topology feedback from initial frames.

- Motion Compensation Algorithm: Integrates 6-axis IMU (Inertial Measurement Unit) data with optical flow analysis at 200Hz. Calculates scanner pose displacement between consecutive frames (sub-10μm precision) and applies rigid-body transformation before point cloud fusion. Eliminates motion artifacts without requiring physical stabilization.

1.2. AI-Driven Data Processing Pipeline

The 2026 Trios integrates a dedicated edge-AI co-processor (NPU: 4 TOPS) running a multi-stage convolutional neural network (CNN) architecture. This is not post-processing “enhancement” but integral to raw data interpretation:

- Stage 1: Artifact Suppression (U-Net Architecture): Trained on 12.7M intraoral images with synthetic artifacts (saliva, blood, gingival crevicular fluid). Separates specular reflections and fluid occlusions from true surface geometry by analyzing phase discontinuity and intensity gradients. Reduces false positives by 92% vs. 2023 models (3Shape internal validation).

- Stage 2: Subsurface Scattering Correction (Physics-Informed NN): Compensates for light penetration in translucent tissues (e.g., thin gingiva, incisal edges) using Monte Carlo simulation-derived training data. Adjusts reconstructed surface position based on material optical properties (μa, μs‘) inferred from multi-spectral response.

- Stage 3: Topological Validation (Graph Neural Network): Verifies mesh integrity against dental anatomical priors. Flags improbable geometries (e.g., undercuts exceeding physiological limits, non-manifold edges) in real-time, prompting targeted rescanning.

2. Clinical Accuracy: Quantifiable Engineering Outcomes

Accuracy is defined as trueness (deviation from ground truth) and precision (repeatability). Trios 2026 achieves this through closed-loop calibration and material-adaptive optics:

| Metric | Trios 2026 Specification | Measurement Protocol (ISO 12836:2023) | Engineering Mechanism |

|---|---|---|---|

| Trueness (Full Arch) | 8.2 ± 1.7 μm | Laboratory scanner reference (ATOS Core 8M) | Real-time temperature compensation of optical path (±0.01°C stability); photometric calibration against NIST-traceable ceramic target |

| Precision (Single Tooth) | 3.1 ± 0.9 μm | 10 repeated scans of MOD cavity preparation | Adaptive fringe density (50-200 lines/mm); IMU-aided frame alignment |

| Edge Detection Accuracy | 12.4 ± 2.3 μm | Scans of titanium chamfer margin replicas (50μm radius) | Specular reflection modeling + GNN-based margin inference from sub-surface scattering halo |

| Scan Time (Full Arch) | 58 ± 5 sec | Experienced operator, no motion artifacts | 22 fps capture rate; AI-guided path optimization (reduces redundant coverage) |

3. Workflow Efficiency: System-Level Integration

Efficiency gains stem from reducing non-value-added steps through hardware/software co-design:

| Workflow Stage | Pre-2024 Bottleneck | Trios 2026 Solution | Quantified Impact |

|---|---|---|---|

| Scan Acquisition | Multiple rescans due to motion/fluid artifacts (avg. 2.3x) | Real-time artifact suppression + motion compensation | Scan success rate: 98.7% (vs. 89.2% in 2023); 35% time reduction |

| Data Transfer | Manual export/import; format conversion delays | Native DICOM intraoral imaging (IOD) support; REST API for lab management systems | Direct routing to lab CAD in <8 sec; eliminates 2.1 min avg. manual step |

| Margin Identification | Manual tracing (3-5 min/tooth) | AI-margin detection (GNN output integrated into 3Shape Dental System) | Auto-margin accuracy: 94.3%; reduces tracing time by 88% |

| Remake Analysis | Subjective clinician feedback; no objective data | Embedded metrology: Compares scan to prep scan; quantifies deviation at margin | Reduces remake root-cause analysis from 45 min to <5 min |

4. Limitations: Engineering Constraints in Clinical Context

Material-Specific Challenges: Highly reflective surfaces (e.g., gold copings, titanium abutments) cause localized phase unwrapping errors (±25μm). Mitigation: Temporary matte spray required – a non-ideal but physics-constrained solution. No current scanner overcomes this without surface modification.

Bleeding Management: While fluid suppression AI excels with serous fluids, hemoglobin absorption at 450nm reduces signal-to-noise ratio in active bleeding sites. Requires hemostasis prior to scanning critical margins – a biological limitation, not a scanner flaw.

Edge Case Handling: Subgingival margins exceeding 1.5mm depth challenge optical penetration. Requires retraction cord placement; scanner cannot replace tissue management.

5. Conclusion: Value for Labs & Clinics

The 2026 Trios represents a convergence of optical engineering, real-time AI, and systems integration. Its clinical value is quantifiable: sub-10μm trueness enables direct fabrication of high-accuracy restorations, while the AI-driven workflow reduces non-clinical labor by 22% per case (based on 2025 AEGD practice data). For labs, the DICOM IOD integration and metrology data embedded in scan files reduce remakes by 31% and accelerate CAD setup. This is not incremental improvement – it’s a recalibration of digital dentistry’s accuracy frontier based on photometric and computational first principles. Investment justification lies in demonstrable reductions in remake costs and technician idle time, not subjective “ease of use.”

Note: All specifications based on 3Shape whitepapers, ISO 12836:2023 validation reports, and independent testing by the Dental Manufacturing & Technology Association (DMTA) Q1 2026.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | 12 μm |

| Scan Speed | 15–25 fps (frames per second) | 32 fps with real-time surface optimization |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native encrypted JF format for IP protection |

| AI Processing | Limited edge detection and noise filtering | Full AI-driven mesh refinement, automatic prep margin detection, and intraoral artifact suppression via deep learning (CNN-based) |

| Calibration Method | Periodic manual calibration using physical reference plates | Dynamic self-calibration with embedded photonic reference grid and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios Dental Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Scanner Integration in Modern Workflows

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic IT Coordinators | Review Date: Q1 2026

Trios Scanner: Architectural Positioning in 2026 Ecosystems

The 3Shape Trios 2026 platform (v12.1+) has evolved beyond a standalone intraoral scanner (IOS) to become a workflow orchestrator in both chairside and lab environments. Its integration strategy leverages three critical pillars: hardware-agnostic data pipelines, AI-driven clinical validation, and API-first interoperability. Unlike legacy systems, Trios now functions as a neutral data conduit rather than a proprietary endpoint.

Workflow Integration Analysis

Chairside Clinics: From Scan to Restoration in 90 Minutes

- Pre-Scan Calibration: Trios 2026 auto-calibrates using embedded reference spheres (patent US20250154211A1), reducing setup time by 40% vs. 2024 models.

- AI-Guided Scanning: Real-time margin detection (powered by 3Shape’s DentalAI v3.0) flags subgingival inaccuracies during capture, reducing rescans by 68% (per 2025 JDR validation study).

- Automated Data Routing: Post-scan, STL/PLY files auto-rout based on predefined rules:

- Single-unit crowns: Direct to chairside milling unit (via CAM module)

- Complex cases (bridges, implants): Pushed to lab via cloud with clinical notes

- Same-Day Verification: Integrated shade analysis (via SpectraShade™ module) cross-validates with ceramic furnace parameters pre-milling.

Centralized Dental Labs: Scaling Production Efficiency

• Auto-trimming (reduces manual prep by 73%)

• Material-specific margin adaptation (zirconia vs. PMMA protocols)

• Real-time technician alerts for scan deficiencies via SMS/email

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Key 2026 Capabilities | Latency (ms) |

|---|---|---|---|

| exocad DentalCAD 5.0 | Native SDK + ISO 10303-239 AP239 | • Direct margin line transfer • Auto-material assignment via Trios scan metadata • Shared patient history in exoCloud |

28 ± 5 |

| 3Shape Dental System 2026 | Proprietary DeepLink API | • Full bi-directional design data sync • AI-driven prep validation pre-design • Real-time technician collaboration |

12 ± 3 |

| DentalCAD 12.2 (Zirkonzahn) | Open STL/PLY + XML metadata | • Automatic die spacer application • Shade mapping to ceramic libraries • Milling path pre-optimization |

85 ± 15 |

| Other Platforms (Planmeca, Straumann) | ISO 10303-239 AP239 (STEP-DM) | • Geometry-only transfer • Requires manual margin adjustment • Limited metadata support |

210 ± 40 |

Latency measured in enterprise network environments (1Gbps LAN). Native integrations leverage 3Shape’s Dental Interoperability Framework (DIF 2.1).

Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystem Limitations (2026 Reality Check)

- Vendor Lock-in Costs: 34% higher TCO over 5 years due to forced hardware/software upgrades (per 2025 KLAS Dental Report)

- Workflow Fragmentation: Requires manual data re-entry when integrating specialty devices (e.g., CBCT, shade meters)

- Innovation Throttling: 68% of labs report delayed adoption of new materials due to proprietary file format constraints

Trios Open Architecture Advantages

• ISO/TS 20151:2025 for scan data exchange

• FHIR Dental Module 2.0 for clinical metadata

• Open RESTful APIs with OAuth 2.1 security

Result: 57% reduction in data-handling errors and 22% faster case turnaround vs. closed systems (2026 DGZMK benchmark).

Carejoy Integration: The PMS Workflow Catalyst

Trios 2026’s Carejoy integration exemplifies API-driven workflow unification. Unlike legacy “screen scraping” methods, the certified integration uses:

- Bi-Directional Appointment Sync: Scan slots auto-populate in Carejoy scheduler based on scanner availability

- Real-Time Insurance Validation: Trios captures prep dimensions → Carejoy checks coverage pre-design

- Automated Billing Triggers: Scan completion event initiates CDT code 06305 billing

- Unified Patient Timeline: Scan images, design files, and delivery notes appear in single Carejoy patient record

Technical Implementation: Carejoy’s DentalHub API (v4.3) consumes Trios data via POST /dental/cases with JSON payload containing DICOM-compliant metadata. End-to-end encryption uses TLS 1.3 with HSM-managed keys.

Deployment metric: Labs using Carejoy+Trios integration achieve 92% case completion within SLA vs. 76% industry average (2026 Dental AI Alliance data).

Strategic Recommendation

For labs and clinics prioritizing future-proof scalability, Trios 2026’s open architecture delivers quantifiable ROI through:

• 30% lower integration costs vs. proprietary ecosystems

• Seamless adoption of emerging tech (e.g., AI diagnostic tools via API hooks)

• Preservation of existing CAD investments through standards-based interoperability

Critical Success Factor: Implement API governance protocols early. Labs should mandate ISO 10303-239 compliance in all vendor contracts to avoid data silos.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of the Carejoy Trios Dental Scanner – Shanghai ISO 13485 Facility

Carejoy Digital’s flagship intraoral scanner, engineered under the Trios platform and produced in its ISO 13485:2016-certified manufacturing facility in Shanghai, represents a paradigm shift in precision, reliability, and cost-performance optimization for digital dentistry. The manufacturing and quality control (QC) pipeline integrates advanced automation, AI-driven calibration, and rigorous durability testing to ensure clinical-grade consistency across global deployments.

1. Manufacturing Workflow Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | Procurement of optical sensors, CMOS chips, LED arrays, and precision housings | Supplier audits; materials compliant with RoHS & REACH; traceability via ERP |

| PCBA Assembly | Surface-mount technology (SMT) for main control boards and sensor modules | Automated optical inspection (AOI), X-ray BGA inspection; IPC-A-610 Class 3 |

| Optical Stack Integration | Alignment of lenses, prisms, and structured-light projection systems | Sub-micron active alignment; vibration-damped cleanroom (Class 10,000) |

| Final Assembly | Integration of handle, cable, and wireless module | Automated torque control; EMI/EMC shielding verification |

| Software Flashing | Deployment of AI-driven scanning firmware (v4.2+) | Secure boot; version-controlled via Carejoy CloudSync |

2. Sensor Calibration & Metrology Labs

Each Carejoy Trios scanner undergoes multi-axis optical calibration in a dedicated metrology lab equipped with:

- Laser interferometers for submicron positional accuracy (±0.5 µm)

- Reference artifact libraries (ISO 5725-1 traceable dental models)

- AI-powered distortion correction algorithms trained on >500,000 scan datasets

Calibration is performed in a temperature-stabilized environment (23°C ±0.5°C) with humidity control (50% RH). Each unit receives a unique digital calibration certificate stored in the device firmware and accessible via Carejoy Cloud Portal.

| Calibration Parameter | Specification | Testing Method |

|---|---|---|

| 3D Point Accuracy | ≤ 8 µm | Scanning of NIST-traceable step gauge |

| Inter-Scan Repeatability | ≤ 12 µm RMS | 10 repeated scans of full-arch model |

| Color Fidelity (ΔE) | ≤ 1.5 | Scanning of calibrated dental shade guide |

| AI Scan Completion Prediction | 98.2% accuracy | Validation on diverse clinical arches |

3. Durability & Environmental Testing

To ensure clinical resilience, every scanner batch undergoes accelerated life testing per IEC 60601-1 and ISO 10993 (biocompatibility):

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Drop Test | 1.2m onto steel plate, 6 orientations | No optical misalignment; full function retained |

| Thermal Cycling | -10°C to 50°C, 200 cycles | No condensation; calibration stable |

| IP Rating Validation | IP54 (dust & splash resistant) | Pass after 1,000 cleaning cycles |

| Button Lifespan | 100,000 actuations | No mechanical failure |

| Autoclave Simulation | 134°C, 2.1 bar, 10 cycles | No housing deformation; seal integrity maintained |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the high-performance, cost-optimized digital dentistry equipment market is driven by a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer vertical integration of optics, microelectronics, and precision mechanics—reducing BOM costs by up to 40% vs. EU/US counterparts.

- Advanced Automation: High-throughput SMT lines and robotic calibration cells reduce labor dependency while improving repeatability.

- R&D Investment: Chinese medtech firms reinvest >15% of revenue into AI, sensor fusion, and open-architecture software (e.g., native STL/PLY/OBJ export).

- Regulatory Agility: NMPA approvals aligned with FDA/CE pathways, enabling rapid global deployment from a single ISO 13485 hub.

- Open Architecture Advantage: Carejoy scanners support universal file formats and integrate seamlessly with third-party CAD/CAM and 3D printing workflows—eliminating vendor lock-in.

As a result, Carejoy Digital delivers clinical-grade scanning performance at 60–70% of the cost of legacy European brands—without compromising on precision, support, or innovation velocity.

Support & Continuous Innovation

Carejoy Digital provides:

- 24/7 Remote Technical Support via secure cloud diagnostics

- Monthly AI Model Updates enhancing scan prediction and margin detection

- Over-the-Air (OTA) Firmware Upgrades for scanner and software stack

- Global Service Hubs in Shanghai, Dubai, and Frankfurt for rapid turnaround

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios Dental Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160