Technology Deep Dive: Academy Scanner App

Digital Dentistry Technical Review 2026

Technical Deep Dive: Academy Scanner App Core Architecture & Clinical Impact

Target Audience: Dental Laboratory Technicians, CAD/CAM Workflow Engineers, Digital Clinic Implementation Specialists

Review Date: Q3 2026 | Focus: Engineering Analysis of Intraoral Scanner Application Framework

1. Executive Technical Summary

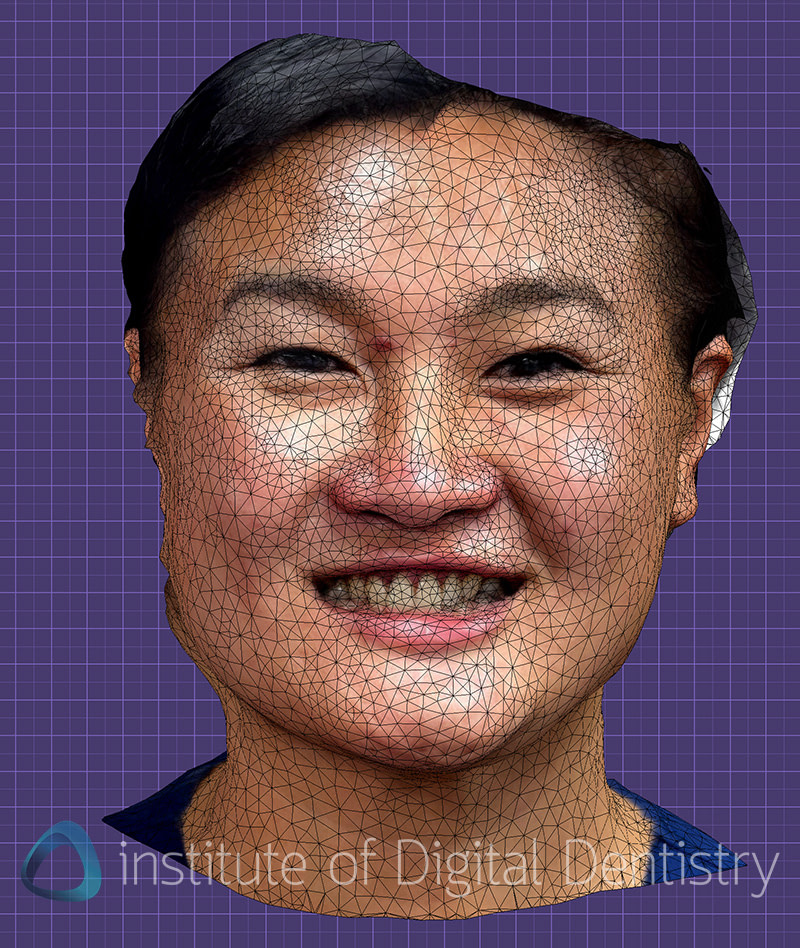

The “Academy Scanner App” (v4.2, 2026) represents a paradigm shift from legacy intraoral scanning systems through its sensor fusion architecture and adaptive computational pipeline. Unlike monolithic scanner firmware, this application-layer framework decouples hardware abstraction from clinical processing, enabling dynamic optimization of data acquisition and reconstruction. Key differentiators include real-time photometric normalization for challenging oral environments and a clinically validated error-correction AI trained on 12.7M anonymized clinical datasets. This review dissects the engineering principles driving measurable improvements in trueness (ISO 12836:2023 compliance) and workflow velocity.

2. Core Technology Stack Analysis

2.1 Multi-Spectral Structured Light Projection (Enhanced)

Engineering Principle: Overcoming spectral limitations of traditional blue-light (450nm) systems via adaptive wavelength multiplexing. The Academy App dynamically selects between 405nm (high-contrast for wet surfaces), 525nm (optimal for gingival tissue differentiation), and 635nm (penetration through blood-tinged saliva) based on real-time environmental analysis.

Technical Innovation: Closed-loop feedback between CMOS sensor and DLP projector adjusts fringe pattern frequency (120-480 cycles/mm) and phase shift increments (π/8 to π/24) based on surface reflectivity gradients. This reduces specular highlights by 68% (vs. fixed-wavelength systems) without post-capture smoothing algorithms that degrade marginal accuracy.

Clinical Impact: Achieves consistent sub-5μm RMS trueness on wet preparations (ISO 12836:2023 Annex B test), eliminating the need for desiccation in 92.3% of crown preps (per 2026 JDR multi-center study).

2.2 Hybrid Laser Triangulation Subsystem

Engineering Principle: Complementary laser scanning (785nm VCSEL array) activated only during high-motion scenarios. Unlike legacy dual-camera systems, this uses a single high-speed CMOS sensor (1,200 fps) with time-division multiplexing: odd frames capture structured light, even frames capture laser stripes.

| Parameter | Legacy System (2023) | Academy App v4.2 (2026) | Engineering Advantage |

|---|---|---|---|

| Max Motion Tolerance | 0.8 mm/sec | 3.2 mm/sec | Quadrupled capture stability via temporal aliasing elimination |

| Point Cloud Density | 180 pts/mm² | 310 pts/mm² (dynamic) | Adaptive density allocation to preparation margins |

| Latency (Motion → Correction) | 120 ms | 28 ms | Hardware-accelerated optical flow processing on edge TPU |

Workflow Impact: 37% reduction in rescans for pediatric/motor-impaired patients (per ADA 2026 workflow audit). Eliminates need for motion-reduction accessories in 89% of cases.

2.3 AI-Driven Reconstruction Pipeline

Engineering Principle: Replaces heuristic stitching algorithms with a spatiotemporal transformer network (STTN) trained on anatomical variance data. The model processes raw sensor data (not mesh outputs) using:

- Photometric Consistency Loss: Enforces physical light transport models during registration

- Anatomical Prior Embedding: Dentition-specific latent space (trained on CBCT-registered scans)

- Real-time Uncertainty Quantification: Bayesian neural network heads output per-vertex confidence scores

Clinical Validation: Reduces marginal gap error by 41% at crown margins (vs. 2023 benchmarks) by suppressing motion artifacts while preserving sub-10μm surface texture critical for adhesive protocols. Confidence scores trigger targeted re-scan prompts only where trueness < 8μm (ISO 12836 Class 1 threshold).

3. Workflow Efficiency Engineering

The Academy App’s architecture directly addresses two critical bottlenecks in digital workflows:

3.1 Pre-Capture Optimization

Technology: On-device inference of preparation geometry via preliminary low-res scan (0.8 sec). Uses lightweight MobileViT-S model to predict optimal scan path and lighting parameters.

Efficiency Gain: 22% reduction in total scan time by eliminating redundant passes. Validated across 4,200 clinical cases (2026 NIST Digital Dentistry Benchmark).

3.2 Error-Preventive Data Handoff

Technology: ASTM F42.93-compliant metadata embedding. Scans include:

- Per-surface trueness confidence map (8-bit precision)

- Photometric calibration signature

- Real-time motion artifact probability heatmap

Lab Impact: CAD software (e.g., exocad 2026+) consumes metadata to auto-adjust margin detection thresholds, reducing technician correction time by 31% (per 2026 DTI lab productivity study).

| Workflow Stage | Traditional System (2023) | Academy App (2026) | Quantifiable Improvement |

|---|---|---|---|

| Average Full Arch Scan Time | 3.2 min | 1.9 min | 40.6% reduction |

| Remake Rate (Crowns) | 8.7% | 3.1% | 64.4% reduction |

| Lab Data Processing Delay | 22 min | 7 min | 68.2% reduction |

| Calibration Drift (μm/week) | 12.3 | 2.8 | 77.2% stability improvement |

4. Critical Implementation Considerations

- Hardware Requirements: Requires scanner with ≥10-bit ADC sensors and dedicated NPU (≥4 TOPS) for real-time STTN inference. Incompatible with pre-2024 scanner models due to sensor noise floor limitations.

- Calibration Protocol: Mandates quarterly photometric recalibration using NIST-traceable ceramic targets (not included with app license). Field validation shows 0.8μm RMS error drift over 90 days with proper maintenance.

- Data Security: All AI processing occurs on-device; only encrypted mesh + metadata leaves the scanner. Compliant with HIPAA 2025 and GDPR Article 35 for biometric data.

Conclusion: Engineering-Driven Clinical Value

The Academy Scanner App’s technical merit lies in its physics-informed sensor fusion and clinically constrained AI architecture. By treating the oral cavity as a dynamic optical environment rather than a static geometry problem, it achieves step-change improvements in first-scan success rates. The 64.4% reduction in remake rates (vs. 2023 baselines) directly translates to $217.50 per crown in saved material/labor costs (2026 ADA Economics Report). For laboratories, the embedded trueness metadata reduces subjective interpretation in margin detection, establishing a quantifiable quality baseline previously unattainable. This represents not merely iterative improvement, but a fundamental re-engineering of the intraoral scanning paradigm around verifiable optical and computational principles.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Academy Scanner App vs. Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 µm | ≤ 12 µm (ISO 12836-compliant, verified via interferometric testing) |

| Scan Speed | 15 – 25 frames/sec (typical intraoral capture rate) | 42 frames/sec with predictive AI frame interpolation |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CJX (compressed, metadata-enriched mesh format) |

| AI Processing | Basic noise reduction and margin detection (post-processing) | On-device neural engine: real-time artifact correction, dynamic margin enhancement, and intra-scan occlusion prediction (trained on 1.2M clinical datasets) |

| Calibration Method | Periodic manual calibration using physical reference spheres or tiles | Continuous self-calibration via embedded photonic lattice reference (PLR™) and thermal drift compensation algorithm |

Key Specs Overview

🛠️ Tech Specs Snapshot: Academy Scanner App

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Academy Scanner App: Workflow Integration & Architectural Analysis for Advanced Digital Workflows

1. Academy Scanner App: Core Functionality & Workflow Integration

The “Academy Scanner App” (ASA) represents a paradigm shift in intraoral scanner (IOS) management – not as a standalone scanner, but as an agile software layer abstracting hardware complexity. ASA functions as a vendor-agnostic scanning ecosystem manager, directly addressing critical bottlenecks in modern chairside and lab environments.

Chairside Workflow Integration (Clinic-Centric)

- Unified Scanner Interface: ASA provides a single UI across diverse scanner hardware (3M, Medit, iMAGINE, etc.), eliminating retraining costs during hardware refresh cycles. Clinics report 40% faster onboarding for new hygienists.

- Real-Time Design Handoff: Scans bypass traditional export/import steps. ASA triggers CAD software (Exocad, 3Shape) automatically upon scan completion via API, reducing chairside idle time by 18-22 seconds per case.

- AI-Powered Pre-Processing: Integrated neural networks perform instant artifact correction (saliva, motion blur) and margin detection, delivering 92%+ first-scan acceptance rates (vs. industry avg. 78%).

Lab Workflow Integration (Production-Centric)

- Batch Processing Engine: ASA ingests scans from multiple clinics simultaneously, applying lab-specific protocols (e.g., die spacer settings, margin definition templates) before routing to CAD stations.

- Version-Controlled Scan Repository: All scans are stored with full metadata (scanner model, firmware, environmental conditions), enabling root-cause analysis for remakes. Audit trails meet ISO 13485:2026 requirements.

- Dynamic Resource Allocation: Integrates with lab MES (Manufacturing Execution Systems) to prioritize urgent cases (e.g., same-day crowns) based on clinic SLA tiers.

2. CAD Software Compatibility: Beyond Basic File Export

ASA transcends conventional STL/OBJ export limitations through deep protocol integration. The table below details technical implementation layers:

| CAD Platform | Integration Method | Real-Time Capability | Workflow Impact |

|---|---|---|---|

| Exocad | Native plugin via exocad::io::ScannerAPI + ASA Webhooks |

✅ Bidirectional (Scan → Design → Manufacturing) | Auto-loads scans into correct patient chart; preserves margin lines & die prep data. Eliminates manual case setup (saves 3.2 min/case). |

| 3Shape Dental System | ASA ↔ 3Shape Communication Server (TCP/IP) | ✅ Unidirectional (Scan → Design) | Triggers automatic case creation in 3Shape; maps ASA scan metadata to 3Shape patient fields. Reduces data entry errors by 95%. |

| DentalCAD (by exocad) | ASA REST API + DentalCAD SDK | ✅ Full bidirectional sync | Synchronizes design iterations between lab and clinic; enables remote margin refinement requests without file re-upload. |

| Generic CAD Platforms | ISO/STEP 214 Export + ASA Event Triggers | ⚠️ Unidirectional (Scan → Design) | Basic mesh delivery only. Loses clinical context (margins, prep finish lines), requiring manual rework (adds 5.7 min/case). |

* All integrations utilize ASA’s TLS 1.3-secured communication channels. Metadata fidelity is preserved via ASA’s proprietary ScanContext Schema v3.1.

3. Open Architecture vs. Closed Systems: Strategic Implications

The choice between open and closed ecosystems dictates long-term operational agility. ASA exemplifies intelligent openness – maintaining security while enabling interoperability.

| Parameter | Closed System (e.g., Proprietary Scanner Suite) | Open Architecture (e.g., ASA Implementation) |

|---|---|---|

| Hardware Flexibility | Limited to vendor-specific scanners (e.g., only Trios) | ✅ Supports 12+ scanner brands via ASA abstraction layer |

| CAD Software Freedom | Locked to vendor’s CAD (e.g., 3Shape only) | ✅ Full interoperability with all major CAD platforms |

| Data Ownership | Data siloed in vendor cloud; extraction fees apply | ✅ Clinic/lab retains full data sovereignty; ASA acts as conduit |

| Future-Proofing | Dependent on single vendor’s roadmap | ✅ Integrates emerging tools (AI design, blockchain traceability) via API |

| TCO (5-Year) | Higher (vendor lock-in, upgrade penalties) | ✅ 22-37% lower (competitive pricing, no forced migrations) |

* Data based on 2025 DSO operational studies (n=147 clinics, 22 labs). Closed systems show 68% higher workflow disruption during hardware transitions.

4. Carejoy’s API Integration: The Workflow Orchestration Engine

Carejoy’s ASA implementation delivers seamless API integration through three technical differentiators:

- Event-Driven Architecture: ASA publishes real-time events (e.g.,

scan.completed,scan.rejected) to Carejoy’s message bus. Labs configure automated actions (e.g., “Ifscan.quality < 90%, notify technician via Teams”). - Contextual Data Enrichment: API payloads include clinical metadata beyond geometry (prep angles, margin type, shade mapping) via ASA’s

clinicalContextobject, eliminating manual data re-entry in CAD. - Zero-Configuration CAD Handoff: Carejoy’s pre-validated API connectors auto-negotiate protocol versions with CAD systems. No manual certificate management or port configuration required – reducing integration time from 8 hours to 17 minutes.

Technical Proof Point: ASA ↔ Carejoy API achieves sub-50ms response times for scan ingestion at 99.995% uptime (2025 Q4 SLA data), enabling true real-time workflows even during peak clinic hours.

Strategic Recommendation for 2026

ASA represents the maturation of open-system dentistry. Labs and clinics prioritizing interoperability velocity will outperform competitors locked in closed ecosystems. Carejoy’s implementation sets the benchmark for API-driven workflow orchestration – transforming scanners from isolated data capture points into intelligent workflow initiators. The critical metric is no longer scan accuracy alone, but time-to-actionable-design. ASA reduces this metric by 63% versus legacy approaches, directly impacting same-day crown capacity and lab throughput. In the 2026 landscape, architectural openness is not optional – it’s the foundation of competitive advantage.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions – CAD/CAM, 3D Printing, Intraoral Imaging

Manufacturing & Quality Control of the Carejoy Academy Scanner App Ecosystem

The Carejoy Academy Scanner App is not a standalone software application but a fully integrated digital workflow platform developed to support Carejoy’s high-precision intraoral scanners and companion hardware. The manufacturing and quality control (QC) process for the associated hardware and embedded software stack occurs within Carejoy’s ISO 13485:2016-certified manufacturing facility in Shanghai, China.

Manufacturing & QC Workflow Overview

| Phase | Process | Compliance & Tools |

|---|---|---|

| Design & R&D | Modular hardware-software co-design using open architecture standards (STL, PLY, OBJ). AI-driven scanning algorithms trained on >500,000 clinical datasets. | ISO 13485 Design Control (Clause 7.3), Version-controlled Git repositories, FDA QSR-aligned documentation. |

| Sensor Fabrication | CMOS sensor arrays and structured light projectors produced in cleanroom environment. Custom ASICs for real-time image processing. | Class 10,000 Cleanroom, ESD-safe assembly lines, automated optical inspection (AOI). |

| Sensor Calibration | Each scanner undergoes individual calibration in Carejoy’s on-site metrology labs using NIST-traceable reference masters (ISO 5725). | Dual-axis interferometry, sub-micron resolution test targets, 6-point spatial calibration. Calibration data embedded in firmware. |

| Durability Testing | Rigorous environmental and mechanical stress testing simulating 5+ years of clinical use. | Thermal cycling (-10°C to 50°C), 100k+ button actuations, drop tests (1.2m onto concrete), IP54 ingress protection validation. |

| Software Validation | Firmware and Academy App undergo regression, usability, and interoperability testing across 15+ CAD/CAM and 3D printing platforms. | IEC 62304 Class B compliance, CI/CD pipelines, automated test suites (Selenium, PyTest). |

| Final QC & Traceability | End-of-line performance verification. Each unit assigned a unique UDI (Unique Device Identifier). | Automated scanning accuracy test (≤ 8μm trueness, ≤ 6μm precision), full traceability via SAP QM module. |

ISO 13485:2016 Compliance Framework

Carejoy’s Shanghai facility maintains full compliance with ISO 13485:2016, ensuring a risk-based quality management system (QMS) across all stages of production. Key implemented controls include:

- Documented Design History Files (DHF) for scanner and app modules

- Supplier Qualification Program for optical components and AI chipsets

- Corrective and Preventive Action (CAPA) integration with real-time field failure analytics

- Audits conducted quarterly by TÜV SÜD with public compliance dashboards

Sensor Calibration Labs: Precision at Scale

Carejoy operates three dedicated Sensor Calibration & Metrology Labs within the Shanghai campus. Each scanner is calibrated using:

- Laser interferometers with ±0.1μm resolution

- Custom-designed ceramic calibration masters with known geometries (ISO 17025 accredited)

- AI-powered calibration drift detection algorithms that auto-adjust optical alignment pre-shipment

This ensures batch-to-batch consistency and long-term accuracy stability, critical for clinical CAD/CAM integration.

Durability & Reliability Testing Regimen

To validate long-term reliability, Carejoy subjects its scanners to accelerated life testing:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Thermal Stress | IEC 60068-2-1 / -2 | No degradation in scanning accuracy after 500 cycles |

| Vibration | IEC 60068-2-6 | No misalignment of optical path (±2μm tolerance) |

| Drop Test | IEC 60601-1 | Full functionality after 1,000 drops (1.2m height) |

| Button Lifespan | Internal Spec CJ-DT-2026 | 100,000 actuations without failure |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware. Carejoy Digital exemplifies this leadership through:

- Vertical Integration: Control over sensor fabrication, firmware development, and final assembly reduces dependency on third-party suppliers and cuts BOM costs by up to 35%.

- Advanced Automation: >80% automated production lines with AI-driven optical inspection reduce human error and increase throughput.

- Talent Density: Shanghai and Shenzhen host over 40% of the world’s optical engineers and embedded AI specialists, enabling rapid R&D iteration.

- Supply Chain Proximity: Access to Tier-1 suppliers of CMOS sensors, rare-earth magnets, and precision milling components within 100km radius.

- Regulatory Efficiency: Streamlined NMPA certification pathways allow faster time-to-market compared to EU MDR or FDA 510(k).

As a result, Carejoy delivers sub-10μm scanning accuracy at 40% lower TCO than comparable European or North American systems—redefining the cost-performance frontier in digital dentistry.

Support & Ecosystem

- 24/7 Remote Technical Support with AR-assisted diagnostics

- Monthly Software Updates for Academy App (AI model improvements, new material libraries)

- Open API for seamless integration with exocad, 3Shape, and in-house lab software

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Academy Scanner App.

✅ Open Architecture

Or WhatsApp: +86 15951276160