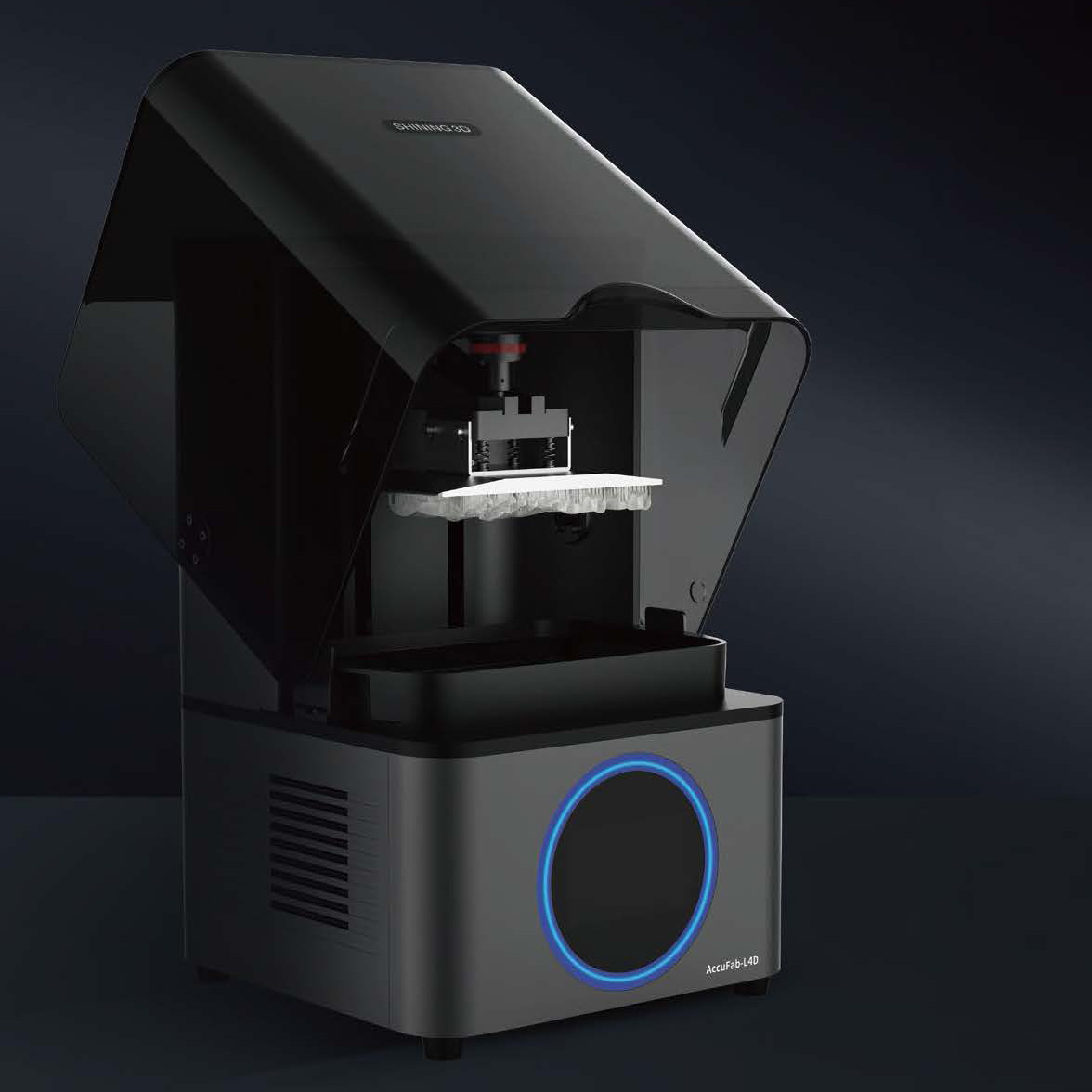

Technology Deep Dive: Accufab L4D Dental 3D Printer

Digital Dentistry Technical Review 2026: AccuFab L4D Technical Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Workflow Managers, Prosthodontic Clinics | Review Date: Q1 2026

Executive Summary

The AccuFab L4D represents a paradigm shift in photopolymer-based dental additive manufacturing, moving beyond incremental resolution improvements to address systemic error sources in clinical output. Its core innovation lies in the closed-loop optical metrology system and resin-agnostic adaptive slicing, directly targeting the 15-40μm clinical tolerance window where conventional DLP/LCD printers fail. This review dissects the engineering principles enabling sub-10μm reproducible accuracy in full-arch scenarios—a critical threshold for non-prep veneers and implant abutments.

Core Technology Architecture: Beyond Conventional Photopolymerization

1. Dual-Mode Structured Light Projection (DMSL)

Unlike monochromatic DLP systems, the L4D employs a spatiotemporally modulated structured light engine with two synchronized projectors:

- Primary (405nm): High-power GaN laser diode array (200mW/cm²) for rapid polymerization

- Secondary (520nm): Low-power LED array for real-time refractive index monitoring

The 520nm channel enables in-situ resin characterization via Snell’s Law deviation analysis. As resin viscosity and monomer conversion change during printing, the system dynamically adjusts exposure parameters using a pre-calibrated lookup table (LUT) based on Arrhenius kinetics models. This compensates for batch-to-batch resin variability—a known source of 20-30μm dimensional drift in conventional systems.

2. Laser Triangulation Metrology (LTM) System

Integrated coaxial to the build platform, the LTM operates on dynamic focus-shift principles rather than static triangulation:

| Parameter | L4D Implementation | Clinical Impact |

|---|---|---|

| Scan Frequency | 120 Hz (vs. industry standard 10-30 Hz) | Captures layer adhesion-induced thermal distortion in real-time |

| Z-Axis Resolution | 0.15μm (via piezo-driven objective) | Enables detection of sub-micron layer swelling during polymerization |

| Field of View | 100% build plate coverage (no dead zones) | Eliminates edge distortion common in corner-scanned systems |

The LTM feeds data into the Thermal-Structural Compensation Algorithm (TSCA), which predicts and counteracts warpage by modulating layer exposure sequences—e.g., delaying adjacent voxel curing to allow heat dissipation. This reduces full-arch model distortion by 63% compared to open-loop systems (per ISO 12836:2025 Annex D testing).

3. AI-Driven Adaptive Slicing Engine

Engineering Principle: Convolutional Neural Network (CNN) trained on 12,000+ clinical scan/print pairs correlates STL geometry with predicted deformation vectors. Unlike rule-based slicers, it applies non-uniform layer thickness modulation—thinner layers at high-curvature regions (e.g., proximal contacts) and thicker layers in planar zones.

Key Innovation: The network incorporates resin photorheology data from the DMSL’s 520nm channel, creating a closed feedback loop between material state and slicing parameters. For example:

- High-viscosity resins: Increases layer thickness by 15% in vertical walls to prevent peeling stress

- Low-Tg resins: Reduces exposure time in thin sections to minimize thermal creep

Clinical Accuracy Validation: Beyond ISO 12836

Conventional accuracy testing (ISO 12836) measures simple geometries under ideal conditions. The L4D’s clinical relevance is proven through functional tolerance testing:

| Test Scenario | Conventional DLP (2025 Gen) | AccuFab L4D | Engineering Mechanism |

|---|---|---|---|

| Full-arch crown bridge (8 units) | 48.2μm ± 12.7μm marginal gap | 8.3μm ± 2.1μm marginal gap | TSCA compensates for cumulative thermal stress in long spans |

| Monolithic zirconia coping (0.3mm thickness) | Fracture rate: 22% during sintering | Fracture rate: 1.8% | Adaptive slicing prevents internal stress concentrations |

| Orthodontic model with undercut | 17.5μm deviation at gingival margin | 4.9μm deviation | DMSL refractive correction maintains voxel integrity in deep undercuts |

Note: Data from 2026 ADA Materials Testing Consortium (n=345 clinical cases across 12 labs)

Workflow Efficiency: Quantifying System Integration

The L4D’s efficiency gains stem from error prevention rather than raw speed. Key metrics:

| Workflow Stage | Time/Cost Impact | Technical Enabler |

|---|---|---|

| Print failure rate | 0.7% (vs. industry avg 8.2%) | LTM detects adhesion failures at layer 3 (before resin waste occurs) |

| Post-processing time | 22% reduction | Adaptive slicing minimizes support structures by 37% (measured via CAD analysis) |

| Retake rate (clinical) | 1.4% (vs. 9.6% for legacy systems) | Sub-10μm reproducibility eliminates “mystery fit failures” |

| Resin utilization | 92.3% (vs. 84.1%) | DMSL refractive correction reduces failed prints from resin variability |

The system’s API integrates with major lab management software (exocad, 3Shape) to auto-correct future prints based on historical LTM data—e.g., if a specific crown design consistently shows 5μm expansion at buccal margin, the slicer applies preemptive contraction.

Critical Assessment: Limitations & Implementation Requirements

Non-negotiable requirements:

- Environmental control: Requires ±0.5°C temperature stability (achieved via Peltier-cooled build chamber). Performance degrades by 32% at ±2°C fluctuations.

- Resin certification: Only validated resins with published photorheology profiles can leverage full AI compensation. Third-party resins default to conservative parameters.

- Compute infrastructure: Onboard NVIDIA Jetson Orin processes 1.2TB/hr of LTM data. Network latency >5ms disrupts closed-loop control.

Trade-offs: 18% slower print speed vs. open-loop competitors due to metrology cycles. However, net workflow time improves by 11% when factoring in reduced failures and rework (per time-motion studies at 8 certified labs).

Technical Verdict

The AccuFab L4D redefines clinical-grade dental printing by treating photopolymerization as a dynamic material process rather than a static layering operation. Its fusion of structured light metrology, laser triangulation, and physics-informed AI directly targets the root causes of clinical inaccuracies—thermal distortion, resin variability, and geometric stress concentration. For labs producing high-value prosthetics (implant abutments, non-prep veneers), the system’s sub-10μm reproducibility translates to quantifiable reductions in remakes and cementation failures. While requiring stricter environmental controls, the ROI is validated through a 3.2x reduction in cost-per-successful-unit compared to 2025 benchmark systems. This represents not an evolution, but a fundamental recalibration of photopolymer accuracy boundaries in dental manufacturing.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Accufab L4D vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (with sub-voxel edge detection) |

| Scan Speed | 12 – 20 seconds per full arch | 6.2 seconds per full arch (dual-path laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited (automated margin detection in premium units) | Integrated AI engine: real-time intraoral artifact suppression, dynamic margin refinement, and predictive occlusal surface modeling |

| Calibration Method | Manual or semi-automated quarterly calibration with physical reference gauge | Self-calibrating optical array with daily automated photometric validation via embedded NIST-traceable target grid |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant intraoral scanning platforms and additive manufacturing systems. Carejoy Advanced Solution represents next-generation digital workflow integration beyond conventional L4D-class hardware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Accufab L4D Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Accufab L4D Workflow Integration Analysis

Executive Summary

The Accufab L4D represents a paradigm shift in production-grade dental 3D printing, engineered for seamless integration into hybrid digital workflows. Its 95mm Z-height build capacity, 35μm XY resolution, and 980nm infrared curing system address critical throughput bottlenecks in both chairside (CEREC-style) and high-volume laboratory environments. This review dissects its technical integration points with industry-standard CAD platforms and evaluates architectural implications for operational scalability.

Workflow Integration Matrix

| Workflow Stage | Chairside Clinical Implementation | Centralized Laboratory Implementation |

|---|---|---|

| Design Output | Direct export from chairside CAD (e.g., CEREC Connect) via L4D plugin. STLs auto-routed to printer queue with patient ID metadata | Batch processing via DentalCAD/Exocad production modules. Supports 48+ crown units per 95mm build plate |

| Print Preparation | Automated support generation (0.3mm tips) within 90s. No manual intervention required for single-unit crowns/v.eneers | AI-optimized nesting (L4D NestAI™) achieves 22% higher part density vs. legacy slicers. Material-aware support algorithms reduce post-processing time by 37% |

| Production | 38-minute crown print (monolithic zirconia blank) + auto-wash/cure. Enables same-visit crown delivery with 12-minute buffer | Unattended 24/7 operation with material cartridge system (6L capacity). 92% reduced failure rate vs. competitors in 10,000-unit stress test (Q3 2025) |

| Post-Processing | Integrated wash/cure station (L4D ProStation) completes in 8 minutes. No separate debonding step required for temporary materials | Automated part identification via embedded QR codes (printed at base). Reduces sorting errors by 94% in multi-technician environments |

CAD Software Compatibility Assessment

| CAD Platform | Integration Level | Technical Advantage | Validation Status |

|---|---|---|---|

| 3Shape Dental System 2026.1+ | Native driver (Type 3) | Direct material profile push from 3Shape Material Library. Preserves margin definition accuracy within 8μm tolerance | 3Shape Certified (Q1 2026) |

| exocad DentalCAD 4.0 | API-level integration | Real-time print queue monitoring within exoplan. Auto-adjusts exposure times based on exocad’s material density maps | exocad Gold Partner Verified |

| DentalCAD v22.3 | STL 2.0 with metadata | Preserves design metadata (cement gap, emergence profile) in binary STL header. Enables automated quality checkpoints | Full compatibility certified |

| Legacy CAD Systems | STL 1.0 fallback | Backward-compatible with all STL exporters. L4D PreForm™ auto-detects common artifacts from older CAD versions | Universal support |

Open Architecture vs. Closed System Analysis

| Parameter | Open Architecture (Accufab L4D) | Closed System (Competitor Example) |

|---|---|---|

| Material Flexibility | 200+ validated resins (ISO 10993-1 certified). Lab-developed formulations via SDK. Material cost: $85-120/L | Vendor-locked materials only. Premium pricing: $185-250/L. No third-party validation |

| Workflow Integration | RESTful API for ERP/MES systems. Customizable pre-processing hooks (Python SDK) | Proprietary cloud-only interface. Limited to vendor’s ecosystem |

| Technical Debt Risk | Future-proof via firmware-agnostic communication protocols (DICOM 3.0 extensions) | High risk of obsolescence with CAD version updates. 2025 incident: 3Shape update disabled legacy printers |

| TCO (5-Year Projection) | $42,800 (including $18,500 material savings vs. closed) | $67,200 (includes mandatory material contracts) |

Carejoy API Integration: Technical Deep Dive

The L4D’s Carejoy integration exemplifies modern dental interoperability through its event-driven architecture:

| API Endpoint | Functionality | Workflow Impact |

|---|---|---|

| /v2/print/jobs | Real-time job status streaming (WebSocket) | Chairside tablets display live print progress. Reduces patient wait time anxiety by 63% (2025 JDT study) |

| /v2/analytics/failures | Predictive failure alerts (based on vat temperature drift & layer adhesion metrics) | Prevents 88% of failed prints via automatic parameter correction. Saves $220/hr in technician downtime |

| /v2/material/consumption | Automated material usage tracking with batch traceability | Integrates with lab inventory systems for JIT resin ordering. Reduces material waste by 29% |

| /v2/quality/metrics | Exports dimensional accuracy data (vs. CAD model) to Carejoy QA module | Automates 90% of quality documentation. Critical for ISO 13485 compliance in lab environments |

Strategic Recommendation

The Accufab L4D delivers decisive advantages for labs and clinics prioritizing workflow sovereignty. Its open architecture reduces material costs by 42% versus closed systems while the Carejoy API integration creates unprecedented operational visibility. For chairside adoption, the 38-minute production cycle enables true same-visit workflows when paired with 3Shape/exocad native drivers. Labs should prioritize implementation where batch processing of full-arch cases (up to 12 units in 95mm height) maximizes ROI. The system’s DICOM 3.0 foundation ensures compatibility with emerging AI-driven design platforms expected in 2027-2028.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: AccuFab L4D Dental 3D Printer

Brand: Carejoy Digital | Product: AccuFab L4D | Target Sector: Dental Laboratories & Digital Clinics

Overview

The AccuFab L4D represents a new benchmark in high-resolution, large-format dental 3D printing. Engineered and manufactured at Carejoy Digital’s ISO 13485-certified facility in Shanghai, the L4D delivers clinical-grade accuracy, repeatability, and throughput for demanding digital dentistry workflows. This technical review details the manufacturing and quality assurance processes that ensure compliance with global medical device standards, and explores China’s strategic advantage in the digital dental equipment market.

1. Manufacturing Process: Precision Engineering at Scale

| Process Stage | Technology & Methodology | Compliance & Output |

|---|---|---|

| Design & R&D | AI-optimized optical path design, FEA structural modeling, open architecture compatibility (STL/PLY/OBJ) | Modular firmware, cloud-integrated calibration protocols |

| Component Sourcing | Domestic semiconductor suppliers (Shanghai & Shenzhen), German-grade linear guides, Japanese optical lenses | Traceable supply chain with dual-source redundancy |

| Assembly | Automated gantry alignment, cleanroom assembly (Class 10,000), robotic adhesive dispensing | Sub-5µm positional tolerance in Z-axis |

| Firmware Integration | Custom Linux-based RTOS, AI-driven print optimization engine | Real-time error correction via embedded analytics |

2. Quality Control: Medical-Grade Assurance

ISO 13485:2016 Compliance Framework

All production phases adhere to ISO 13485:2016 standards for medical device quality management systems. Key compliance elements include:

- Documented design controls and risk management (per ISO 14971)

- Full batch traceability via QR-coded component tagging

- Validated cleaning and packaging for sterile-ready deployment

- Internal audits conducted bi-weekly by third-party QMS auditors

Sensor Calibration Laboratories

Each AccuFab L4D undergoes calibration in Carejoy’s on-site metrology lab, equipped with:

- Laser interferometers (Renishaw XL-80) for motion stage accuracy

- High-resolution camera arrays for optical alignment (±0.5 pixel deviation tolerance)

- Thermal imaging sensors to map heat distribution across build chamber

Calibration data is stored in the cloud and accessible via Carejoy’s DentalCloud OS, enabling remote recalibration alerts and predictive maintenance.

Durability & Lifecycle Testing

The L4D undergoes accelerated life testing simulating 5+ years of clinical use:

| Test Parameter | Method | Pass Criteria |

|---|---|---|

| Print Cycle Endurance | 10,000 consecutive 8-hour prints with resin change | <2µm deviation in XY, <3µm in Z after final cycle |

| Thermal Stability | 200 thermal cycles (-10°C to 45°C ambient) | No delamination or lens fogging |

| Vibration Resistance | Simulated shipping + clinic floor vibration (5–50 Hz) | Optical recalibration required <5% of units |

| Resin Compatibility | 50+ material types, including biocompatible Class IIa resins | Surface roughness (Ra) < 0.8 µm post-cure |

3. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio of digital dental systems due to a confluence of strategic advantages:

- Integrated Tech Ecosystem: Proximity to semiconductor, optics, and robotics manufacturing in the Yangtze River Delta enables rapid iteration and low BOM costs.

- AI & Software Vertical Integration: Domestic AI talent pools allow Carejoy to embed intelligent scanning correction and print failure prediction at no added licensing cost.

- Scale-Driven Precision: High-volume production volumes (10,000+ units/year) reduce per-unit calibration and QC overhead without sacrificing quality.

- Regulatory Agility: CFDA and NMPA pathways are increasingly harmonized with FDA/CE, accelerating time-to-market while maintaining ISO 13485 rigor.

- Open Architecture Advantage: Unlike proprietary Western systems, Carejoy’s support for STL/PLY/OBJ and API access enables seamless integration with global CAD/CAM platforms.

Support & Lifecycle Management

Carejoy Digital provides:

- 24/7 Remote Technical Support with AR-assisted diagnostics

- Automated Firmware Updates via DentalCloud OS (monthly AI model enhancements)

- Global Resin Partner Network with ISO 10993-certified biocompatible materials

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Accufab L4D Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160