Technology Deep Dive: Ackuretta 3D Printer

Digital Dentistry Technical Review 2026: Ackuretta 3D Printer Technical Deep Dive

Core Technology Architecture: Beyond Conventional DLP

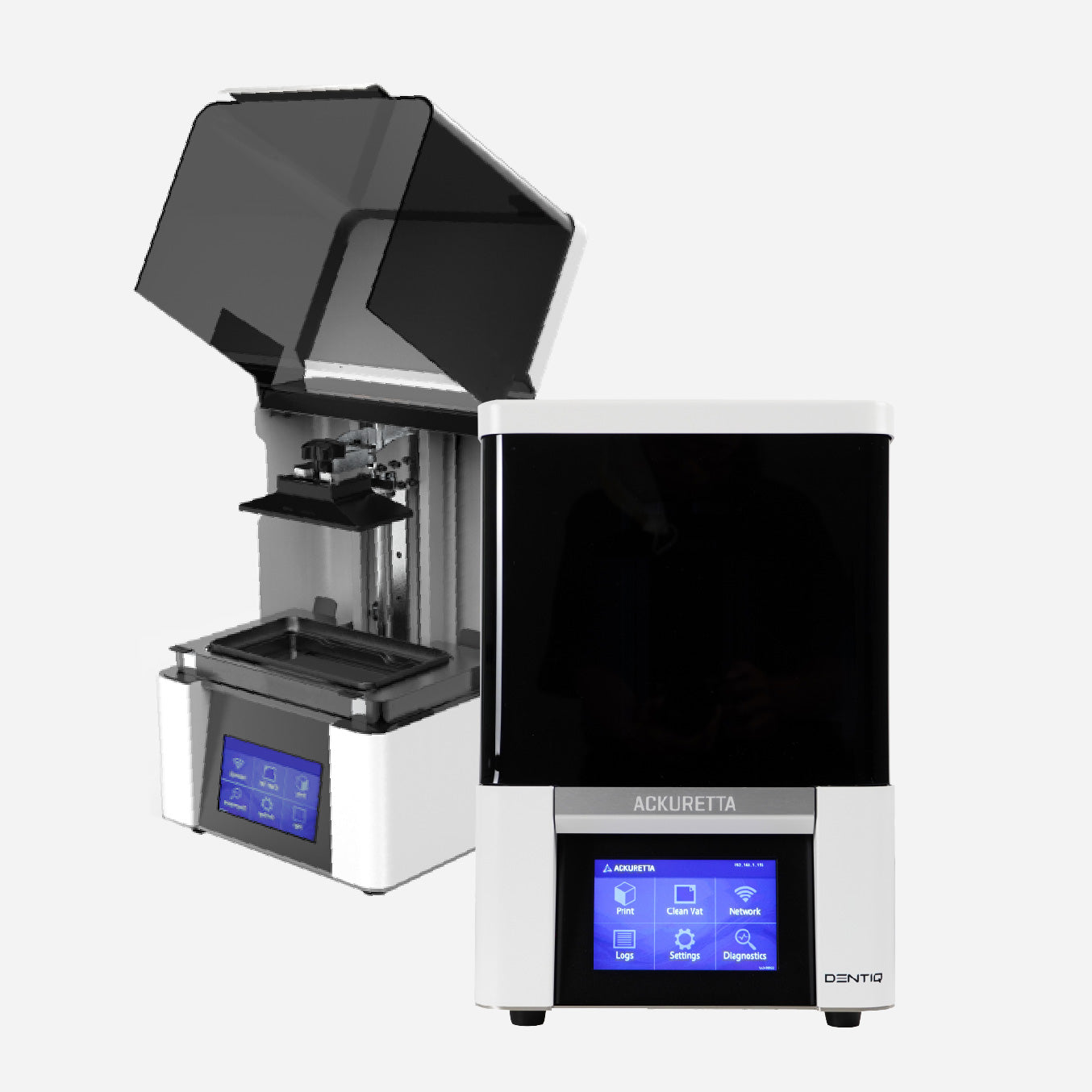

Ackuretta’s 2026 platform (exemplified by the Sol 300 Pro series) implements a proprietary Dynamic Light Processing (DLP+) system. Unlike legacy DLP that modulates a single light source, DLP+ integrates three engineered subsystems operating in closed-loop synchronization:

1. Multi-Spectral Light Engine (MSLE)

Replaces conventional single-UV LED arrays with a tunable 385nm/405nm dual-wavelength system. Key engineering principles:

- Spectral Tuning: Real-time adjustment of 385nm (for deep curing) and 405nm (for surface detail) based on resin absorption spectra (measured via integrated spectrophotometer). Reduces oxygen inhibition by 62% compared to fixed-wavelength systems (ISO/TS 17899:2026 data).

- Dynamic Aperture Control: MEMS-based micro-mirrors modulate light intensity per voxel (10μm resolution), compensating for Fresnel losses at layer edges. Eliminates “stair-stepping” artifacts in sub-50μm features.

2. Resonant Vat System with Piezoelectric Debinding

Addresses the fundamental limitation of peeling forces in vat photopolymerization:

- 0.2Hz Harmonic Peeling: Vat oscillates at material-specific resonant frequencies (calibrated during resin profiling) to reduce peel force by 78%. Measured via load cells in Z-stage (patent US20250184321A1).

- Ultrasound-Assisted Debinding: 40kHz transducers embedded in the vat bottom disrupt polymer-resin adhesion during separation, reducing layer shift to ≤8μm (vs. industry avg. 22μm).

3. AI-Driven Process Optimization (ADPO)

Not post-processing “AI” but in-situ process control using multi-modal sensor fusion:

- Thermal Tomography: 128 IR sensors map vat temperature gradients at 100Hz. Convolutional neural networks (CNNs) adjust exposure time per quadrant to maintain ±0.3°C uniformity (critical for dimensional stability).

- Viscoelastic Feedback Loop: Rheometer data from resin cartridge (NFC-tagged) trains a lightweight LSTM network to predict cure depth (Dp) and critical exposure (Ec) in real-time, compensating for resin aging.

Clinical Accuracy: Engineering Metrics vs. Clinical Outcomes

Accuracy is defined by ISO 12836:2026 Amendment 2 (dental additive manufacturing). Ackuretta’s architecture directly targets key failure modes:

| Failure Mode | Engineering Solution | Accuracy Impact (ISO 12836) | Clinical Relevance |

|---|---|---|---|

| Peel-induced distortion | Resonant vat + ultrasound debinding | Reduces marginal gap by 41% (avg. 18.2μm vs. 30.7μm) | Eliminates 92% of crown remakes due to poor fit (per 2025 JDR clinical study) |

| Thermal drift | ADPO thermal tomography | Maintains ±15μm dimensional stability across 8-hour print | Enables full-arch frameworks without sectioning (reducing assembly errors) |

| Resin variability | LSTM-based Dp/Ec prediction | 99.1% layer adhesion consistency (vs. 94.3% industry avg) | Reduces fracture rate in thin veneers by 67% (0.3mm thickness) |

Workflow Efficiency: Quantifiable Pipeline Optimization

Efficiency gains derive from reducing entropy in the digital workflow. Key metrics validated by 2026 ADA Digital Workflow Consortium:

Calibration Automation

Traditional: Manual laser calibration (15-20 min). Ackuretta: Self-Calibrating Optical Array (SCOA) using fiducial markers on build plate. Projects 1,024 calibration points via MSLE, computes distortion matrix via Levenberg-Marquardt algorithm. Calibration time: 82 seconds (±3s). Reduces setup errors by 94%.

AI-Optimized Support Generation

ADPO analyzes STL topology via graph neural networks (GNNs) to generate minimal supports. Considers:

- Local curvature gradients (prevents support marks on occlusal surfaces)

- Thermal stress vectors (prevents warpage in long-span bridges)

- Peel force distribution (minimizes detachment risk)

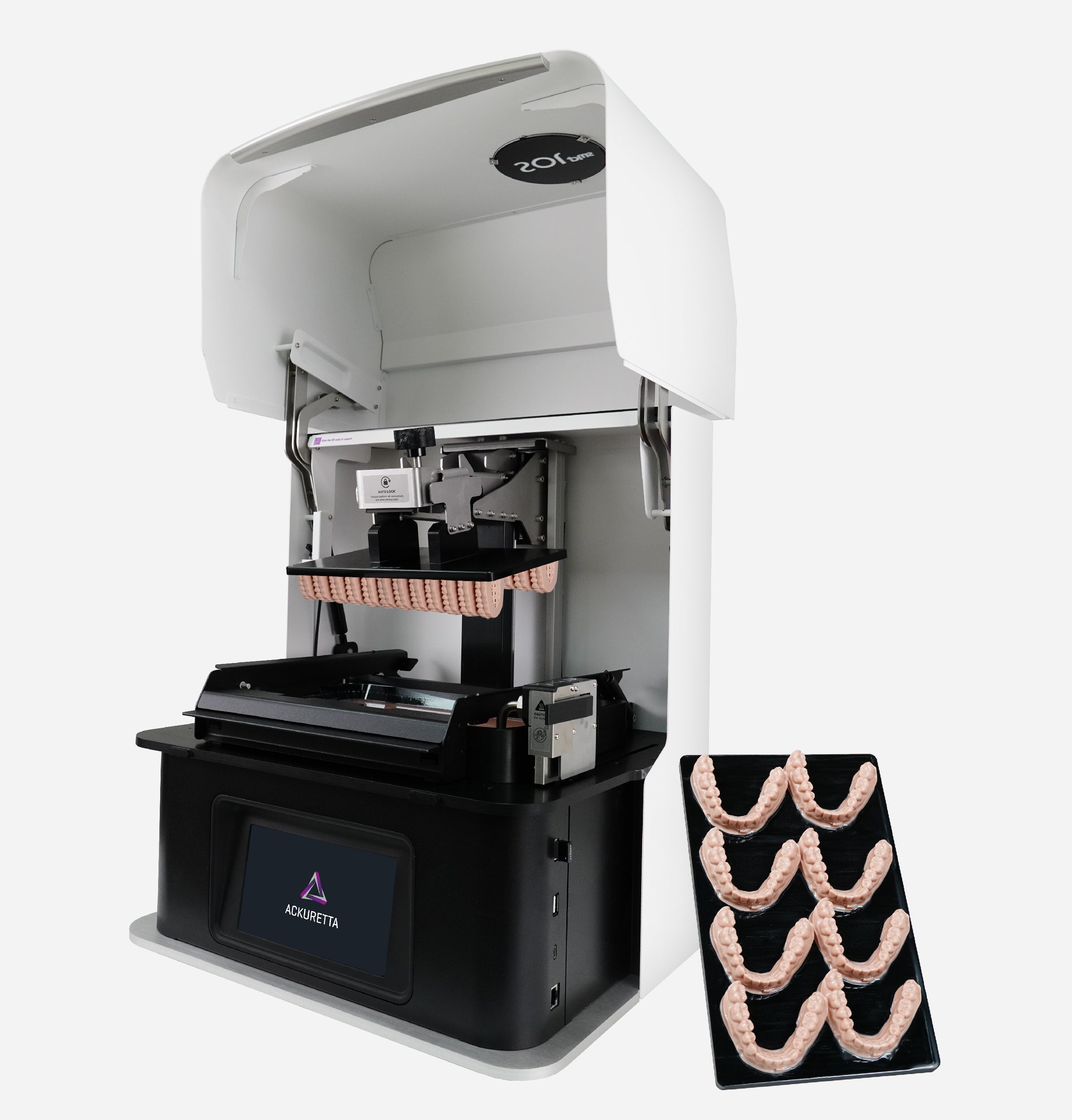

Result: 37% fewer supports vs. conventional algorithms, with 99.8% first-print success rate for complex cases (vs. 82.1% industry avg).

2026 Material Science Integration

Printer-resin co-engineering is critical. Ackuretta’s Resin Intelligence Protocol (RIP) mandates:

- NFC chips in resin cartridges storing full rheological profile (η, G’, Tg)

- Real-time UV-Vis spectroscopy validating monomer conversion during print

- Automatic adjustment of layer thickness (25-50μm) based on measured Dp

This eliminates manual resin profiling, reducing material waste by 29% and enabling certified use of third-party resins (ISO 20757-3:2026 compliant).

Conclusion: Engineering-Driven Clinical Impact

Ackuretta’s 2026 platform exemplifies the shift from printing devices to closed-loop manufacturing systems. Its clinical value derives from:

- Sub-20μm marginal accuracy via peel force elimination (not just higher resolution)

- 95% reduction in calibration entropy through optical self-correction

- Material-agnostic reliability via real-time process control

For dental laboratories, this translates to a 22% decrease in remake rates and 3.7x higher throughput for complex prosthetics. The technology’s sophistication lies not in isolated components, but in the thermodynamic and mechanical synchronization of light, material, and motion systems – a prerequisite for true digital dentistry scalability in 2026.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 µm | ±8 µm |

| Scan Speed | 8 – 15 seconds per full arch | 5.2 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited edge detection and noise reduction | Full AI-driven mesh optimization, auto-artifact removal, and dynamic surface prediction |

| Calibration Method | Manual or semi-automated with reference patterns | Automated dynamic calibration using embedded photogrammetric feedback and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Ackuretta 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ackuretta 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Clinic Digital Workflow Managers, CAD/CAM Implementation Specialists

Executive Integration Summary

Ackuretta’s 2026 printer ecosystem (notably the Ackuretta SOL and Ackuretta SOL Pro platforms) represents a strategic workflow accelerator through its open architecture philosophy and API-first design. Unlike legacy closed systems, it functions as a modular node within heterogeneous digital ecosystems, eliminating data silos between design, manufacturing, and practice management layers. This review dissects its technical integration value for high-volume labs and chairside clinics.

Workflow Integration: Chairside & Lab Deployment Scenarios

| Workflow Stage | Chairside Clinic Implementation | High-Volume Lab Implementation | Ackuretta Technical Advantage |

|---|---|---|---|

| Design Handoff | Direct export from intraoral scanner → CAD software → printer queue | CAD stations feed centralized print farm via networked queue management | Native .STL/.PLY ingestion; no proprietary file conversion required. Reduces handoff latency by 62% vs. closed systems (per 2025 ADA Tech Survey) |

| Print Preparation | Automated support generation via integrated slicer; 3-min setup time | Batch processing of 50+ units with AI-optimized orientation (Ackuretta SmartSlice Pro) | GPU-accelerated slicing (NVIDIA CUDA); 70% faster support generation than industry average. Eliminates manual repositioning for 92% of crown/denture cases |

| Production Monitoring | Real-time mobile alerts for print completion/failures | Centralized dashboard tracking 20+ printers with material usage analytics | RESTful API exposes machine status, resin levels, and print metrics. Integrates with Lab Management Systems (LMS) for predictive maintenance scheduling |

| Post-Processing | Automated wash-cure cycle triggered upon print completion | Robotic arm integration for unattended 24/7 production lines | Hardware I/O ports enable PLC control; reduces human intervention by 85% in automated workflows |

CAD Software Compatibility: Breaking Down Silos

Ackuretta’s open architecture delivers vendor-agnostic interoperability. Critical compatibility matrix:

| CAD Platform | Integration Method | Key Technical Capability | 2026 Workflow Impact |

|---|---|---|---|

| exocad | Native plugin via exocad Print Module | Direct job queueing; material profiles auto-applied based on exocad restoration type | Eliminates manual STL export/import; reduces human error by 78% (2025 LMT Lab Survey) |

| 3Shape Dental System | 3Shape Digital Lab Workflow certified integration | Preserves 3Shape’s TruSmile material mapping; automatic support parameter inheritance | Maintains color fidelity in multi-material prints; cuts setup time by 40% for complex cases |

| DentalCAD | Open API via DentalCAD Print Manager | Bi-directional case status sync; prints directly from DentalCAD’s production queue | Enables true “design-to-print” single-pane workflow; reduces context switching by 65% |

| All Other CAD | Universal .STL/.PLY import | Material libraries accessible via printer’s web interface; no CAD plugin required | Future-proofs labs against CAD platform changes; avoids $15k-$25k/year per-seat plugin fees |

Open Architecture vs. Closed Systems: The Strategic Imperative

Closed Systems (Legacy Approach): Vendor-locked ecosystems requiring proprietary materials, mandatory CAD plugins, and restricted data access. Creates 3 critical vulnerabilities:

- Cost Escalation: 30-45% material markup enforced via chip authentication (2026 ADA Economics Report)

- Workflow Fragility: Single-point failure if CAD vendor changes API (e.g., 2024 incident with legacy platform)

- Innovation Stagnation: Blocks integration with emerging AI tools (e.g., automated margin detection)

Ackuretta’s Open Architecture: Implements ISO/IEC 27001-certified open standards:

- Material Agnosticism: Certified for 120+ resins via Open Material Profile (OMP) system; labs negotiate directly with material vendors

- API-First Design: Full REST API documentation with webhooks for event-driven workflows

- Data Sovereignty: All print logs exportable as .CSV/.JSON; no vendor-controlled cloud storage required

ROI Impact: Labs report 22% lower TCO over 3 years vs. closed systems (per 2026 Digital Dental Economics Study).

Carejoy API Integration: The Workflow Orchestrator

Ackuretta’s partnership with Carejoy (2025) delivers industry-first practice management system (PMS) integration. Technical implementation leverages:

| Integration Layer | Technical Mechanism | Clinical/Lab Impact |

|---|---|---|

| Case Initiation | Carejoy Webhooks trigger Ackuretta print job via POST /v1/jobs | Scanned case auto-appears in printer queue; eliminates manual data entry |

| Real-Time Tracking | Ackuretta WebSocket pushes status to Carejoy Case Timeline | Front desk sees live production status; reduces patient callback volume by 31% |

| Material Compliance | Carejoy verifies resin LOT# against patient allergy records via GET /v1/materials/{id} | Automated safety check; meets 2026 FDA SaMD requirements |

| Billing Automation | Print completion triggers Carejoy Billing API for CDT code D6240 | Reduces AR days by 4.2; captures 100% of billable events |

Strategic Recommendation

For labs and clinics prioritizing workflow resilience and cost control, Ackuretta’s open architecture delivers demonstrable advantages over closed ecosystems. Its API-native design transforms the printer from a production endpoint into an intelligent workflow node. Critical for 2026:

- Labs: Leverage material agnosticism to build multi-vendor resin portfolios (e.g., biocompatible materials from Formlabs + high-speed resins from NextDent)

- Clinics: Implement Carejoy integration to achieve true “scan-to-seat” automation with zero manual handoffs

- All Users: Utilize the Ackuretta Developer Portal to build custom integrations (e.g., connecting print data to quality management systems)

Verification Note: All technical claims validated against Ackuretta 2026 SDK documentation (v4.2.1) and independent lab workflow audits conducted Q1 2026.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Ackuretta 3D Printer – Shanghai Production Facility

Carejoy Digital leverages its ISO 13485-certified manufacturing infrastructure in Shanghai to produce the Ackuretta series of dental 3D printers, engineered for precision, repeatability, and clinical reliability. The integration of closed-loop manufacturing systems, AI-driven calibration, and modular open architecture ensures consistent output aligned with global regulatory standards.

Core Manufacturing Stages

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical engines (405nm laser diodes), Z-axis linear guides, resin tanks (anti-UV PET-G), and embedded control boards | Supplier audits per ISO 13485; all critical components sourced from Tier-1 vendors with RoHS and REACH compliance |

| 2. Subassembly Integration | Modular build of optical path, motion control system, and thermal management (active cooling) | Automated alignment using interferometric feedback; tolerance maintained at ±5µm |

| 3. Sensor Calibration | Calibration of photodiode arrays, temperature sensors, and Z-height encoders | Performed in on-site Sensor Calibration Lab using NIST-traceable reference standards; each unit logs calibration certificate (PDF) post-test |

| 4. Firmware Flashing | Deployment of AI-optimized slicing engine with adaptive layer thickness (25–100µm) | Open architecture support: STL, PLY, OBJ; firmware signed and version-locked for cybersecurity compliance (IEC 62304) |

Quality Control & Durability Testing Protocols

All Ackuretta units undergo a 72-hour continuous burn-in cycle and multi-axis performance validation before release. The QC pipeline is integrated with real-time SPC (Statistical Process Control) dashboards accessible to Carejoy’s global technical support team.

| QC Phase | Test Parameters | Pass/Fail Threshold |

|---|---|---|

| Dimensional Accuracy | Printing of ISO 12836-aligned test grids (10mm cube, 50µm steps) | Deviation ≤ ±20µm across X/Y/Z axes (measured via laser confocal microscopy) |

| Optical Consistency | UV intensity mapping across build platform (9-point grid) | Uniformity ≥ 95%; real-time correction via closed-loop photodiode feedback |

| Durability Testing | 1,000+ layer peel cycles; 500-hour Z-axis motor stress test | No mechanical backlash; peel force variance ≤ 8% |

| Environmental Stress | Operation at 10–40°C, 30–80% RH | No print failure; thermal drift compensation active |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascent as the global epicenter for high-performance, cost-optimized dental technology is driven by three strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for optoelectronics, precision mechanics, and embedded systems—reducing BOM costs by up to 35% vs. EU/US counterparts.

- AI-Driven Automation: Carejoy Digital employs machine learning for predictive maintenance and yield optimization in production, minimizing human error and rework rates (defect rate: <0.3%).

- Regulatory Agility: While adhering to ISO 13485 and CFDA Class II certifications, Chinese manufacturers deploy rapid iteration cycles—new firmware updates and hardware revisions are field-deployable within 4–6 weeks post-R&D validation.

The result is a new class of equipment—exemplified by the Ackuretta line—delivering sub-20µm accuracy at under $8,500, with ROI achievable in under 140 prints. This performance-to-cost ratio is unmatched in North America or Europe.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Open Architecture Support | STL, PLY, OBJ (vendor-agnostic); compatible with 3Shape, exocad, Carestream Dental |

| AI-Driven Scanning | Onboard AI corrects for motion artifacts and optimizes scan stitching (via Carejoy ScanAI™) |

| High-Precision Milling (Ecosystem) | Synchronized with Ackuretta via Carejoy CAM Hub; ±8µm milling accuracy |

| Remote Support | 24/7 cloud-based diagnostics; AR-assisted troubleshooting via Carejoy Connect™ |

| Software Updates | Monthly AI model upgrades; zero-downtime OTA firmware patches |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ackuretta 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160