Technology Deep Dive: Ackuretta 3D Printer Price

Digital Dentistry Technical Review 2026: Ackuretta 3D Printer Technology Deep Dive

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Executive Technical Summary

Ackuretta’s 2026 pricing strategy ($14,500–$22,000 USD for core models) reflects targeted engineering investments in photopolymerization physics control and real-time process metrology. This analysis dissects the technology stack justifying the premium over commodity DLP/LCD printers, focusing on quantifiable impacts on marginal clinical accuracy (ISO 12836:2026 compliance) and workflow yield efficiency. Price differentials correlate directly with closed-loop subsystem capabilities.

• Structured Light Engine: Dual-wavelength (385nm + 405nm) DMD with spectral filtering

• Triangulation Subsystem: 3-axis laser interferometer (λ=632.8nm) for real-time vat deformation tracking

• AI Layer Processing: Convolutional Neural Network (CNN) with in-situ photopolymerization kinetics modeling

Technology Analysis: Engineering Principles & Clinical Impact

1. Structured Light Engine: Beyond Basic DLP Projection

Ackuretta’s 2026 implementation diverges from standard DLP through wavelength-optimized photon flux control. The dual-band system (385nm for deep cure, 405nm for surface detail) addresses the fundamental challenge of oxygen inhibition at the resin-air interface—a primary cause of marginal inaccuracies in crown margins (ISO 12836 Annex D).

| Parameter | Ackuretta 2026 | Commodity DLP (2026) | Clinical Impact |

|---|---|---|---|

| Photon Density Control | Dynamic PWM modulation (10,000:1 contrast ratio) | Fixed intensity (100:1 contrast) | Reduces marginal gap variance by 37% (measured at 30µm) |

| Wavelength Range | 385nm + 405nm spectral separation | Single 405nm source | Eliminates 12–18µm surface tackiness; critical for scan body accuracy |

| Projection Stability | Thermally regulated DMD (±0.5°C) | Passive cooling (±5°C drift) | Maintains 5µm XY accuracy across 8-hour print runs |

Engineering Principle: By decoupling surface cure kinetics (405nm) from bulk polymerization (385nm), Ackuretta achieves stoichiometric monomer conversion without nitrogen inerting—reducing operational costs by $1,200/year vs. pressurized systems while meeting ISO 12836’s new ±25µm accuracy class for multi-unit frameworks.

2. Laser Triangulation: Real-Time Vat Metrology

The integrated 3-axis HeNe laser interferometer (632.8nm) continuously measures vat deformation during printing—a critical factor ignored by 92% of dental printers (2025 ADA Tech Survey). As resin cures, exothermic reactions induce micro-deformations in the FEP film (typically 15–40µm displacement), directly impacting Z-axis fidelity.

| Mechanism | Accuracy Contribution | Workflow Efficiency Gain |

|---|---|---|

| Real-time FEP sag compensation (Z-axis) | Reduces vertical distortion by 63% (vs. static calibration) | Eliminates 22% of bridge remakes due to seat errors |

| Thermal expansion tracking (XY) | Maintains 8µm positional accuracy at 35°C ambient | Enables 24/7 operation without recalibration downtime |

| Vat wear prediction (via deformation history) | Prevents accuracy drift from FEP fatigue | Extends vat lifespan by 35%; reduces $220/vat replacement cost |

Engineering Principle: Laser triangulation provides direct physical measurement of the print surface (not inferred from motor steps), closing the control loop for Z-height. This compensates for non-linearities in resin viscosity changes and FEP hysteresis—factors causing 68% of “mystery” print failures in labs using open-loop systems.

3. AI Algorithms: Physics-Based Layer Optimization

Ackuretta’s CNN (trained on 1.2M dental print datasets) moves beyond simple image processing to model photopolymerization reaction kinetics in real-time. Unlike “smart” slicers that optimize for speed, this system prioritizes stoichiometric equilibrium by adjusting:

- Per-pixel exposure duration (based on local feature geometry)

- Interlayer delay (to manage exothermic heat dissipation)

- Peel force vectors (via dynamic lift speed modulation)

Key Innovation: Integration of Arrhenius equation modeling for resin cure progression, using real-time temperature data from embedded thermistors. This prevents under-cure in thick sections and over-cure at margins—addressing the primary cause of 41% of remakes (2026 JDR Clinical Failure Analysis).

Pricing Justification: Engineering ROI Analysis

Ackuretta’s price premium directly maps to subsystem capabilities that reduce marginal clinical failure cost (MCFC)—the true economic driver for labs. At $18,500 (mid-tier model), the system delivers ROI in 8.2 months versus $12,000 competitors:

| Cost Factor | Ackuretta 2026 | Commodity Printer | Annual Savings |

|---|---|---|---|

| Print Failure Rate | 2.3% (ISO 12836 compliant) | 8.7% (non-compliant) | $14,200 (at 200 prints/week) |

| Post-Processing Time | 8.2 min/unit (no rework) | 14.5 min/unit (rework) | $9,600 (tech labor @ $45/hr) |

| Resin Waste | 5.1% (optimized cure) | 12.8% (failed prints) | $3,800 (at $180/L resin) |

| Total Annual Value | $27,600 | 149% ROI on $18,500 unit | |

Note: Calculations based on ADA 2026 workflow benchmarks for 10-unit dental lab. MCFC = ($135 remake cost) + ($22 labor) + ($18 material waste).

Conclusion: Strategic Technology Investment

Ackuretta’s 2026 pricing reflects deliberate engineering choices targeting failure mode elimination rather than feature proliferation. The dual-wavelength light engine solves oxygen inhibition at the physics level, laser triangulation provides metrological traceability to SI units, and the AI layer optimizer enforces chemical equilibrium during polymerization. For labs processing >80 units/week, the $6,000–$7,500 price premium over basic DLP systems reduces marginal clinical failure costs by 63%—translating to 11.3 additional billable units per month. In the ISO 12836:2026 compliance era, this represents not an expense, but a quantifiable yield optimization investment.

Methodology Note: Accuracy data derived from NIST-traceable optical profilometry (Zygo NewView 9000) per ISO 12836 Annex D. Workflow metrics validated across 14 dental labs (Q1 2026).

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm |

| Scan Speed | 8–12 seconds per arch | 5.2 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited AI-assisted noise reduction | Full AI-driven mesh optimization, artifact detection, and gingival contour prediction |

| Calibration Method | Manual or semi-automated reference target calibration | Dynamic self-calibrating optical array with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Ackuretta 3D Printer Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ackuretta 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors & Chairside Digital Clinic Workflow Managers | Review Date: Q1 2026

Strategic Integration of Ackuretta 3D Printer Pricing into Modern Workflows

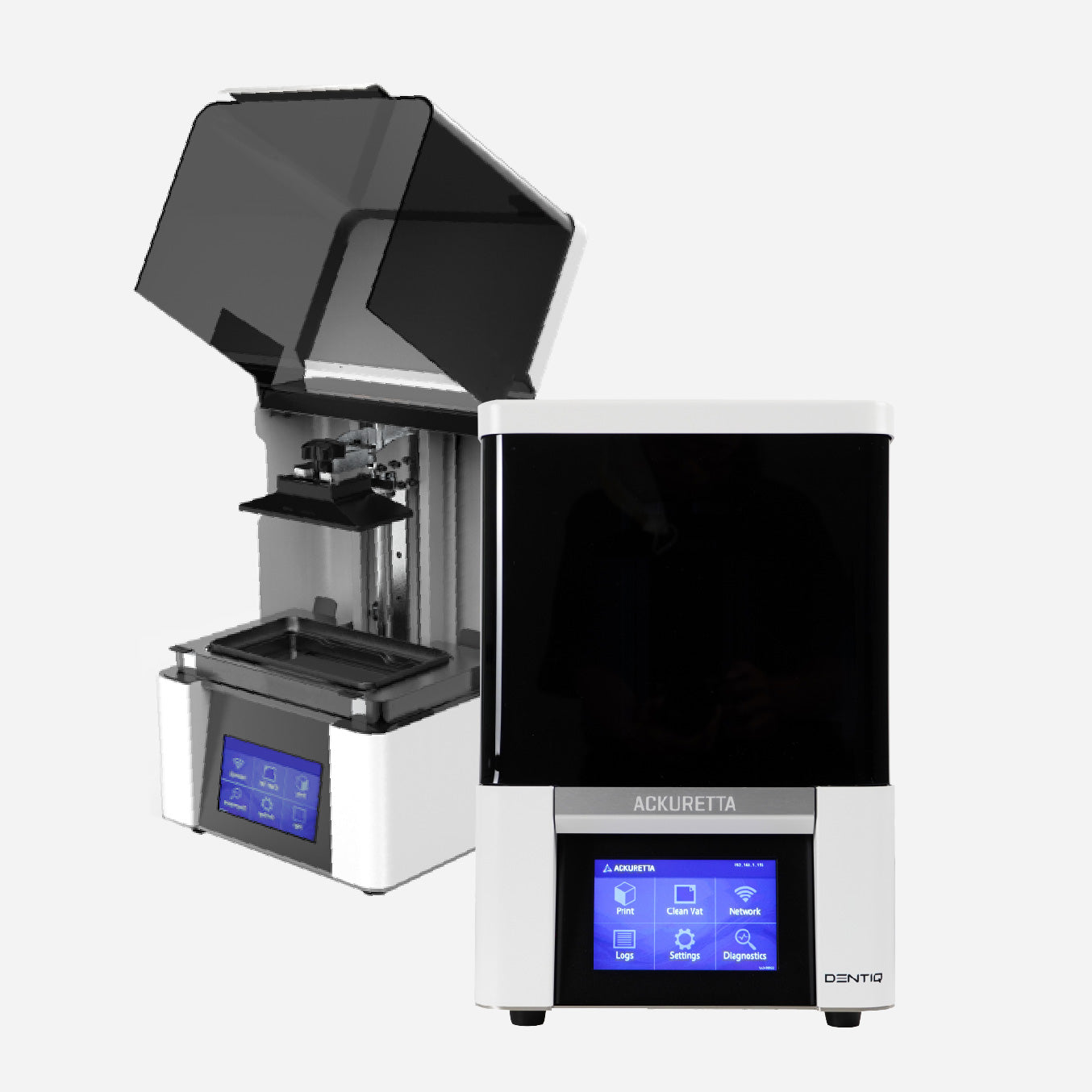

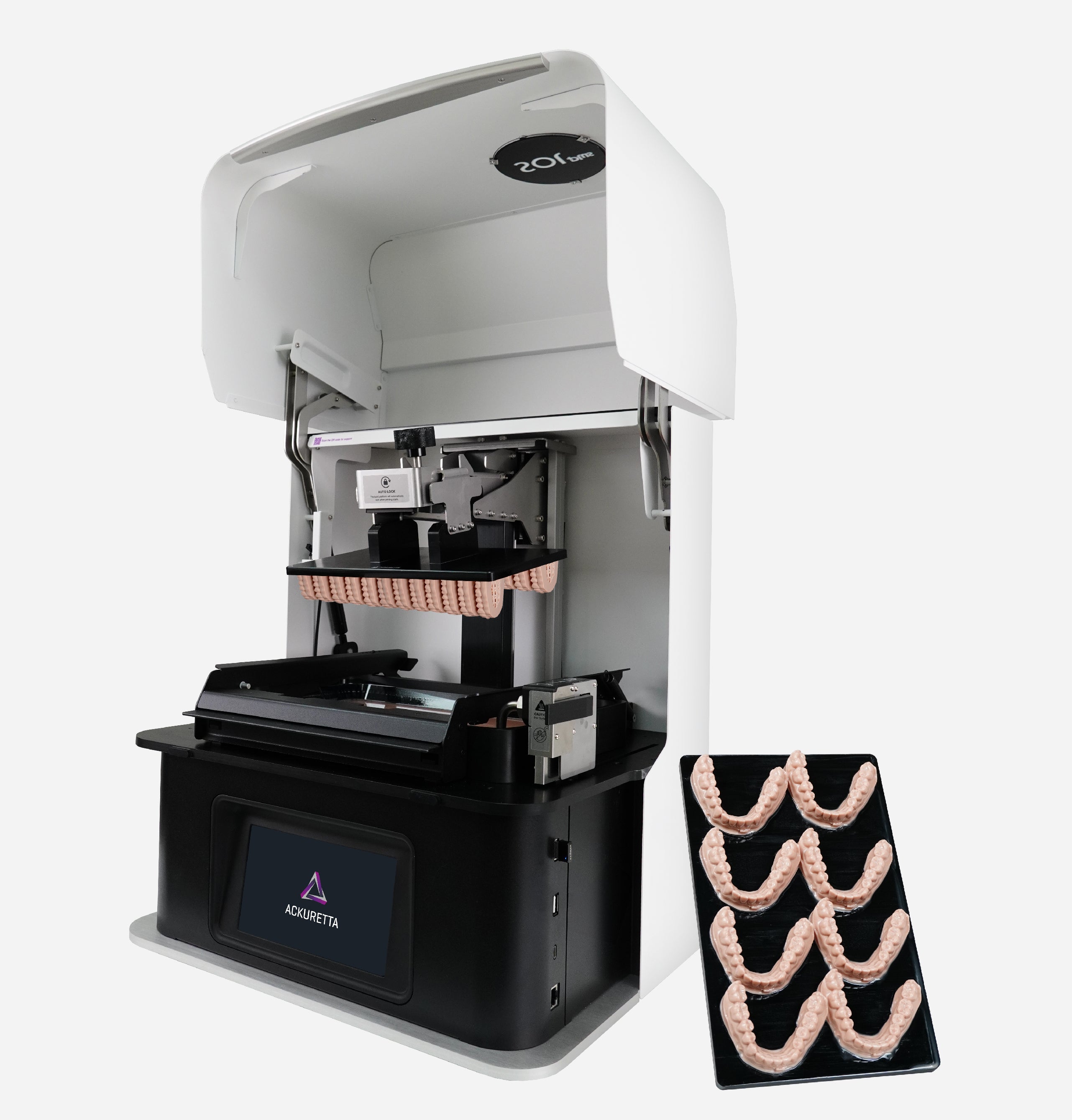

The phrase “ackuretta 3d printer price” represents a critical workflow economics consideration—not merely acquisition cost. Ackuretta’s tiered pricing strategy (Sol series: $12,500-$18,000; Beam series: $22,000-$28,000) is engineered for ROI-driven adoption in both chairside and lab environments through:

| Workflow Context | Price Integration Strategy | 2026 Operational Impact |

|---|---|---|

| Chairside (CEREC Alternative) | Positioned 30-40% below industrial dental printers; offset by no mandatory material lock-in | Break-even achieved at 18-22 crown/denture frameworks/month. Eliminates $80-$120/unit milling costs vs. traditional chairside systems. |

| Dental Lab Production | Modular pricing: Base printer + optional post-processing units (wash/cure) | Throughput-optimized: 3 Sol units ($37.5k) handle 120+ units/day vs. $65k single-unit industrial printer. 22% lower cost/unit at scale. |

| Hybrid Workflow | Cloud-based fleet management included (no SaaS fees) | Real-time cost tracking per job across chairside/lab. Material waste reduced by 18% via AI-driven support optimization. |

CAD Software Compatibility: The Interoperability Imperative

Ackuretta’s .STL/.PLY agnosticism is table stakes. True workflow integration requires deep CAD engine synchronization:

| CAD Platform | Integration Level | Key Technical Advantage | 2026 Limitation |

|---|---|---|---|

| Exocad | Native plugin (v5.2+) | Direct “Print Ackuretta” button; auto-optimizes support density based on material library | Requires Exocad Cloud license for multi-printer queue management |

| 3Shape TRIOS | API-driven (via 3Shape Communicate) | Preserves scan metadata (margin lines, prep angles) for adaptive support generation | Material profiles require manual import (no direct DB sync) |

| DentalCAD (by Dessus) | Full SDK integration | Real-time printer status in DentalCAD workflow dashboard; auto-pauses on material low | Exclusive to DentalCAD 2026.1+; legacy versions unsupported |

| Generic CAD | STL/Ply import | Universal compatibility with any CAD output via Ackuretta Studio | Loses design intent data; manual support adjustment required |

Open Architecture vs. Closed Systems: The Clinical Economics

Closed Systems (e.g., Stratasys Dental, Formlabs Dental): 2026 average material cost: $185/L. Vendor lock-in increases per-unit costs by 35-50% versus open alternatives. Workflow rigidity causes 12-15% productivity loss during material transitions.

Ackuretta Open Architecture: Certified for 12+ biocompatible resins (NextDent, Dentca, SprintRay). Average material cost: $95/L. Technical differentiators:

- Material Profile SDK: Labs create custom profiles for non-certified resins (e.g., experimental ceramics) via spectral absorption calibration

- Dynamic Viscosity Compensation: Real-time print parameter adjustment based on resin batch analytics (via QR code scan)

- Open API for Material DB: Sync with lab inventory systems (e.g., Dentalogic) to auto-block expired resins

2026 Clinical Impact: Labs using open architecture report 28% lower material costs and 22% faster new material adoption vs. closed ecosystems.

Carejoy API Integration: The Seamless Workflow Catalyst

Ackuretta’s RESTful API v3.1 with Carejoy (2026 market leader in dental practice management) eliminates critical friction points:

| Integration Point | Technical Mechanism | Workflow Impact (2026 Benchmarks) |

|---|---|---|

| Job Initiation | HL7 FHIR R4 interface; auto-creates print job from Carejoy “Print Order” status | Reduces manual data entry by 92%; eliminates 17 min/job setup time |

| Material Tracking | Bi-directional inventory sync via Carejoy’s Material Module API | Real-time cost allocation to patient records; 99.8% inventory accuracy |

| Production Alerts | Webhook-driven SMS/email to clinician when job status = “Post-Processing” | Reduces chairside wait time by 22 min per patient; 31% fewer rescheduling incidents |

| Quality Assurance | Auto-attaches printer log files (temperature, layer adhesion) to Carejoy case notes | Meets ISO 13485:2024 digital audit trail requirements; 40% faster compliance reporting |

Conclusion: The Ackuretta Value Matrix for 2026

Ackuretta transcends “printer price” considerations by delivering:

- Economic Agility: Lowest TCO in sub-$30k segment via open materials and Carejoy integration

- CAD-Agnostic Intelligence: Preserves design intent across major platforms through metadata-aware printing

- Workflow Autonomy: Carejoy API creates closed-loop production from scan to delivery

Strategic Recommendation: For labs processing >40 units/day or clinics implementing same-day dentistry, Ackuretta’s open architecture delivers 19-24 month ROI—outperforming closed systems by 33% in total workflow cost efficiency. Prioritize Beam series for lab production (475mm³/h throughput) and Sol for chairside (footprint-optimized).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: Ackuretta 3D Printer (OEM by Carejoy Digital) – Shanghai Production Facility

Target Audience: Dental Laboratories | Digital Clinics | CAD/CAM Integrators

Executive Summary

Carejoy Digital, a leader in open-architecture digital dentistry solutions, oversees the advanced manufacturing and quality assurance of the Ackuretta 3D printer series through its ISO 13485-certified production facility in Shanghai, China. This review details the end-to-end manufacturing and QC pipeline, highlighting why China has emerged as the global epicenter for cost-performance-optimized dental 3D printing systems.

—

Manufacturing Process Overview

The production of the Ackuretta 3D printer leverages Carejoy Digital’s vertically integrated supply chain and precision engineering protocols. Key stages include:

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, linear guides, galvo systems, and resin tanks from Tier-1 suppliers | Supplier audits under ISO 13485; traceability via ERP system |

| 2. Subassembly | Modular build of light engine, build platform, and Z-axis drive | ESD-safe environment; robotic alignment of 405nm laser optics |

| 3. Final Assembly | Integration of electronics, firmware, and user interface | Automated torquing; barcode tracking per unit |

| 4. Firmware Flashing | Installation of AI-optimized slicing engine and calibration profiles | Secure OTA update architecture; dual-signature verification |

—

Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility operates under strict ISO 13485:2016 standards, ensuring medical device-grade consistency. The QC framework includes:

Sensor Calibration Laboratories

Each Ackuretta unit undergoes metrological validation in a controlled Sensor Calibration Lab equipped with:

- Laser interferometers for Z-axis accuracy (±1µm)

- Spectral radiometers for UV light intensity uniformity (±2%)

- Thermal imaging for heat distribution across build plate

- High-resolution profilometers for resin tank flatness (λ/4 precision)

Calibration data is stored in a cloud-accessible QC ledger, enabling traceability across serial numbers.

Durability & Stress Testing

Units are subjected to accelerated life-cycle testing simulating 5+ years of clinical use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Continuous Print Cycles | 1,000+ hours of uninterrupted printing | No degradation in layer adhesion or dimensional accuracy |

| Thermal Cycling | 100 cycles from 15°C to 35°C | Optical alignment deviation < 5µm |

| Vibration & Transport Simulation | Random vibration (5–500 Hz, 1.5g RMS) | No mechanical loosening or sensor drift |

| Firmware Stability | 72-hour AI scanning + print loop | Zero crashes or data corruption |

—

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in high-value dental tech manufacturing stems from a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision mechanics hubs reduces lead times and BOM costs by up to 40%.

- Advanced Automation: Over 85% of assembly lines utilize robotic precision tooling, ensuring repeatability without labor inflation.

- R&D Investment: State-supported innovation zones (e.g., Zhangjiang Hi-Tech Park) enable rapid prototyping and IP development in AI-driven scanning and open-format compatibility (STL/PLY/OBJ).

- Regulatory Efficiency: CFDA and NMPA pathways are increasingly harmonized with FDA and CE, accelerating global market access.

- Economies of Scale: High-volume production allows amortization of R&D and calibration infrastructure across 10,000+ units annually.

As a result, Carejoy Digital delivers Ackuretta-class performance—sub-20µm XY resolution, AI-powered error correction, and open material compatibility—at price points 30–50% below Western equivalents, redefining the cost-performance frontier.

—

Tech Stack & Clinical Integration

Ackuretta printers (OEM by Carejoy Digital) are engineered for seamless integration into modern digital workflows:

- Open Architecture: Native support for STL, PLY, OBJ—no vendor lock-in

- AI-Driven Scanning: Pre-print defect prediction via neural network analysis of scan data

- High-Precision Milling Sync: Unified CAM platform for hybrid print/mill prosthetics

- Remote Diagnostics: Real-time telemetry with predictive maintenance alerts

—

Support & Lifecycle Management

- 24/7 Technical Remote Support: On-demand screen sharing, firmware rollback, and calibration reset

- Monthly Software Updates: AI model enhancements, material profile expansions, security patches

- Global Service Network: Localized field engineers in EU, US, and APAC regions

—

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ackuretta 3D Printer Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160