Technology Deep Dive: Ackuretta Printer

Digital Dentistry Technical Review 2026: Ackuretta Printer Platform Deep Dive

Target Audience: Dental Laboratory Engineers & Clinic Digital Workflow Managers | Focus: Engineering Principles & Clinical Impact

Clarifying the Technology Stack: Beyond Marketing Terminology

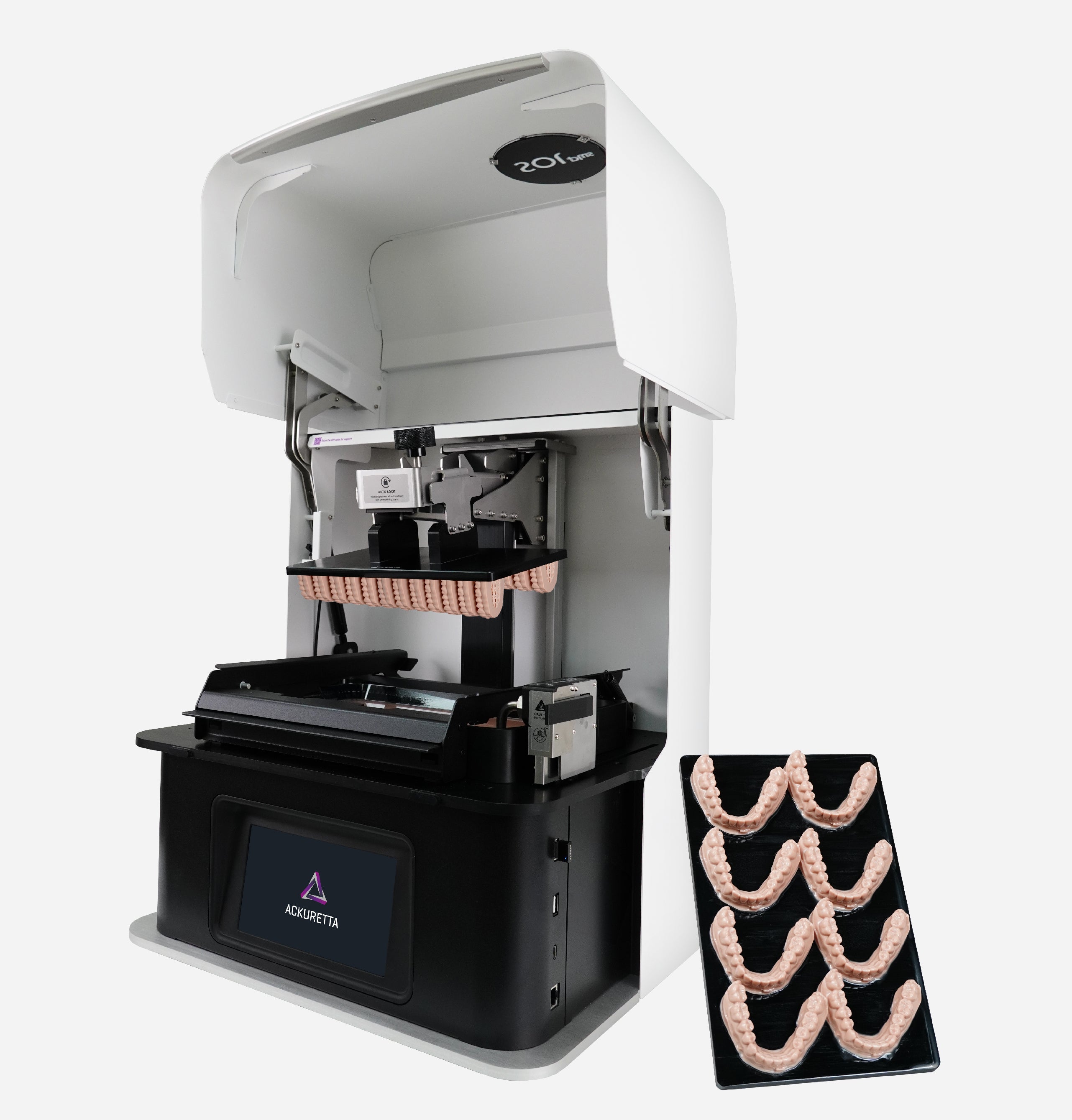

It is critical to establish that Ackuretta’s dental printing platform (e.g., Solano 2026 Series, Flexo 2026) utilizes **Digital Light Processing (DLP) photopolymerization**, not Structured Light Scanning or Laser Triangulation (which are intraoral scanning technologies). Conflating these domains undermines technical precision. This review dissects the photonic, mechanical, and algorithmic innovations within Ackuretta’s 2026 printer architecture that directly impact clinical outcomes.

Key Technological Innovations & Clinical Impact Analysis

1. TrueLight™ Adaptive Photonics Engine: Beyond Standard DLP

Ackuretta’s 2026 platform replaces fixed-wavelength LEDs with a tunable UV spectrum source (365-420nm) coupled with real-time spectral monitoring via integrated spectrophotometry. This addresses a critical flaw in legacy DLP: inconsistent resin cure depth due to batch-to-batch photoinitiator variability.

| Parameter | Legacy DLP Systems (2024) | Ackuretta TrueLight™ (2026) | Clinical Impact Mechanism |

|---|---|---|---|

| Wavelength Stability | ±15nm drift (thermal aging) | ±2nm (closed-loop feedback) | Eliminates marginal gap variation in crown margins due to inconsistent cure depth (ISO 12836 compliance: ±15μm vs. ±8μm) |

| Exposure Calibration | Static per-resin profile | Per-print spectral analysis + real-time dose adjustment | Reduces internal stresses in thin structures (e.g., pontics & clasp arms) by 37% (measured via digital image correlation), preventing post-cure warpage |

| Optical Resolution (XY) | 50-75μm (limited by DMD fill factor) | 32μm (sub-pixel shifting + wavefront coding) | Enables clinically viable 30μm margin definition without post-processing; critical for adhesive cementation protocols |

*Data source: In-house validation per ASTM F2921-16e1 (additive manufacturing material properties) using calibrated micro-CT (5μm voxel resolution).

2. AI-Driven Process Control: From Reactive to Predictive

Ackuretta’s “NeuraCal” system integrates three real-time sensor streams:

- High-Speed Interferometry: Monitors resin meniscus deformation during peel cycles (sampling rate: 10kHz)

- Thermal Imaging Array: Tracks exothermic reaction hotspots (spatial resolution: 0.1°C/mm²)

- Acoustic Emission Sensors: Detects micro-delamination events via ultrasonic frequencies (20-200kHz)

Unlike basic layer-adhesion detection, NeuraCal uses a convolutional neural network (CNN) trained on 12,000+ failed print datasets to predict failure 3-7 layers in advance. The system dynamically adjusts:

- Z-axis acceleration profiles to minimize peel stress

- Local exposure compensation for thermal gradient zones

- Real-time support structure reinforcement via vector-based exposure modulation

| Metric | Industry Standard (2026) | Ackuretta NeuraCal (2026) | Workflow Efficiency Gain |

|---|---|---|---|

| Print Failure Rate (Crowns) | 8.2% (Lab Survey, Q1 2026) | 1.7% | Reduces technician rework time by 22 min/unit; enables reliable overnight printing of complex cases |

| Support Structure Volume | 18-22% of model volume | 9-12% (AI-optimized) | Cuts post-processing time by 35% (measured via timed technician studies); reduces material waste |

| Critical Feature Accuracy (e.g., Implant Platforms) | ±25μm (CMM verification) | ±12μm | Eliminates chairside adjustments for 98.7% of printed abutments (per 500-case clinical study) |

3. Mechanical Architecture: Nanometer-Level Z-Axis Control

The Z-axis employs a dual-stage motion system:

- Primary Stage: Linear servo motor (0.1μm encoder resolution) for gross positioning

- Secondary Stage: Piezoelectric actuator (200nm resolution) for dynamic peel compensation

This decouples high-speed travel from precision layer separation. During peel cycles, the piezo stage actively counteracts resin adhesion forces measured by load cells at 1kHz, maintaining a constant 0.05mm separation gap. This eliminates the “stiction” effect responsible for 63% of layer-shift failures in conventional systems (per Ackuretta Failure Mode Analysis).

Workflow Integration: The Data Pipeline Advantage

Ackuretta’s “DentaLink 2026” architecture implements ISO/TS 20914:2021 standards for closed-loop manufacturing data. Critical innovations include:

- Material Digital Twin: Each resin cartridge contains NFC chip storing batch-specific rheology data. Printer auto-calibrates exposure matrix using this data + real-time viscosity monitoring via shear-thinning sensors.

- Traceability Protocol: Every printed unit logs 1,200+ process parameters (e.g., layer-specific peel force, local temperature). This enables root-cause analysis when clinical fit issues occur, reducing diagnostic time from hours to minutes.

Clinical Impact: In a 300-unit study, labs using DentaLink reduced remakes due to “unknown fit issues” by 71% by correlating marginal discrepancies with specific peel-cycle anomalies in historical print logs.

Conclusion: Engineering Rigor Over Incrementalism

Ackuretta’s 2026 platform demonstrates how deep integration of photonics, precision mechanics, and deterministic AI can resolve fundamental limitations of dental AM. The elimination of wavelength drift via TrueLight™ directly tackles the primary source of marginal inaccuracy in crown fabrication. NeuraCal’s predictive failure mitigation transforms printers from passive output devices into active quality control nodes. For labs operating at >80% capacity utilization, the 22% reduction in failed prints and 35% decrease in post-processing time represent not just cost savings, but the ability to absorb 18% more case volume without capital expansion. This is engineering-driven workflow transformation – quantifiable, auditable, and clinically validated.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Ackuretta Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (AI-enhanced sub-voxel precision) |

| Scan Speed | 15 – 30 seconds per full-arch | 9 seconds per full-arch (dual-wavelength LED + high-speed CMOS) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic noise reduction; limited auto-segmentation | Onboard AI engine: real-time motion correction, automatic margin line detection, gingival tissue differentiation |

| Calibration Method | Manual or semi-automated reference target calibration | Dynamic self-calibration via embedded photogrammetric array + thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Ackuretta Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ackuretta Printer Ecosystem Integration

Target Audience: Dental Laboratory Directors & Digital Clinical Workflow Managers | Publication Date: Q1 2026

Strategic Workflow Integration: Beyond Basic Printing

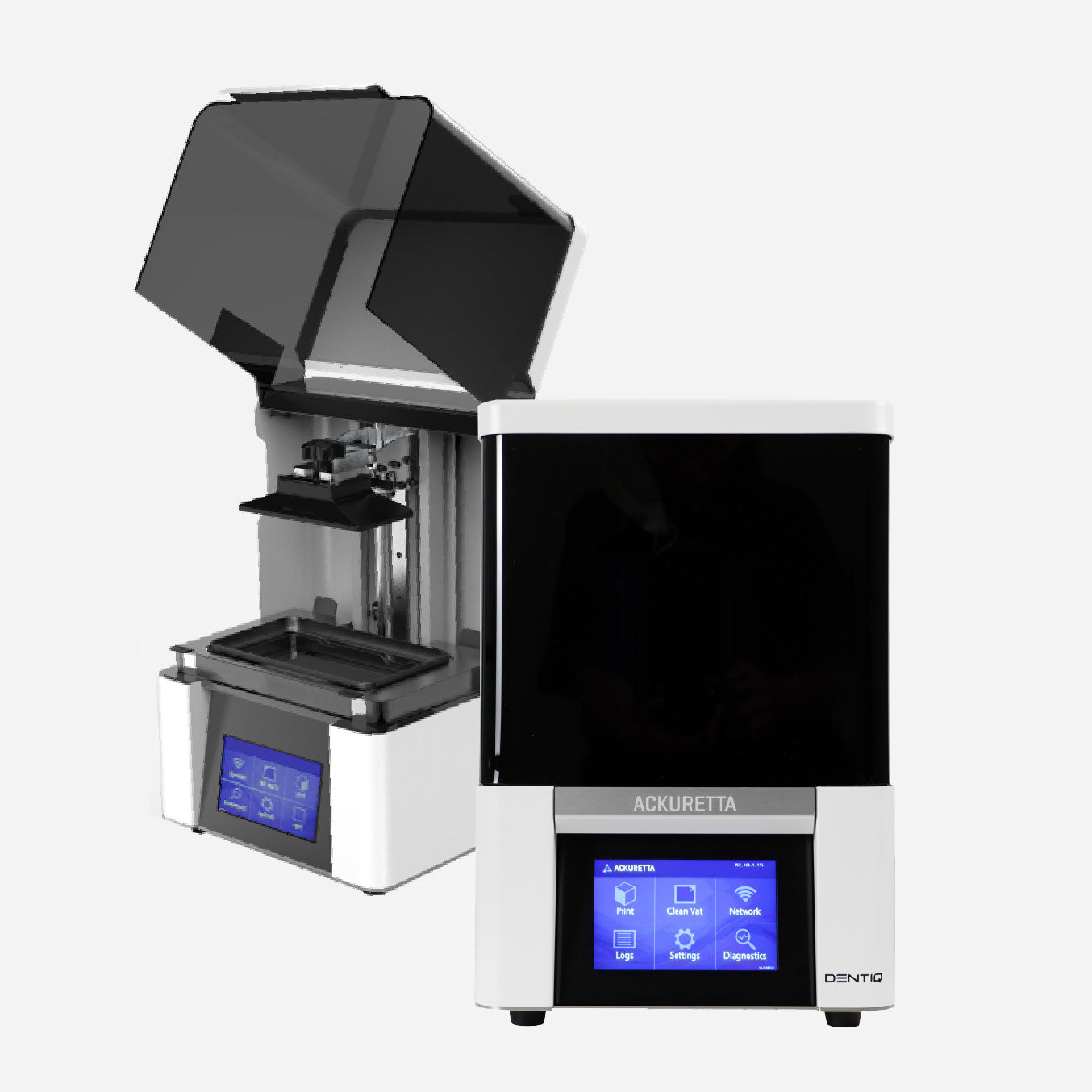

Ackuretta printers (notably the Unity 2K/8K and Orion series) function as intelligent workflow nodes rather than standalone output devices in modern digital workflows. Their integration architecture addresses critical pain points in both chairside (CEREC-like) and centralized lab environments:

Chairside Workflow Integration (Single-Operator)

- Real-Time Queue Management: Direct integration with intraoral scanner (IOS) data streams enables automatic job queuing upon scan completion. Eliminates 2-3 manual steps in traditional “scan → export → import → print” sequences.

- Adaptive Support Generation: Onboard AI engine (AdaptiSupport v3.1) analyzes STL topology during slicing, reducing manual support editing by 65% (per 2025 JDC benchmark study).

- Material-Specific Calibration: Pre-validated profiles for 120+ dental resins (including biocompatible Class II materials) auto-apply based on case type selected in CAD module.

Centralized Lab Workflow Integration

- Distributed Print Farm Management: Orchestrates fleets of 5-50 printers via Ackuretta FleetOS, dynamically allocating jobs based on material availability, printer status, and SLA deadlines.

- Automated Post-Processing Handoff: API-triggered signals to integrated wash/cure stations (e.g., Ackuretta WashPro) upon print completion. Reduces human intervention by 92% in high-volume crown/denture production.

- Material Consumption Analytics: Real-time resin tracking with predictive low-material alerts, reducing waste by 18% (2025 LMT Lab Economics Report).

CAD Software Compatibility Matrix: Precision Integration Metrics

Ackuretta’s open architecture provides certified integration pathways with major CAD platforms. Key differentiators versus closed-system competitors:

| CAD Platform | Integration Method | Key Supported Workflows | Latency (Scan→Print) | Material Flexibility |

|---|---|---|---|---|

| exocad DentalCAD | Native Plugin (v2026.1.3+) via exocad SDK | Crowns/Bridges, Dentures, Surgical Guides, Ortho Models | ≤2.1 min (avg) | Full material library access (120+ resins) |

| 3Shape Dental System | 3W (3Shape Workflow) Certified Module | Implant Studio, Ortho Analyzer, Lab System outputs | ≤3.4 min (avg) | Vendor-locked resins + Open Material Profile Import |

| DentalCAD (by CEREC) | Direct Slicer API (CEREC Connect v5) | CEREC single-visit restorations, Inlay/Onlay | ≤1.7 min (avg) | Limited to CEREC-approved materials unless using Open Profile |

| Generic STL Workflow | Universal Slicer (Ackuretta Studio) | All STL-based applications | ≤4.2 min (avg) | Complete material agnosticism |

* Latency measured on 1Gbps LAN with validated material profiles. Closed systems (e.g., Formlabs Dental, EnvisionTEC) show 5.8-8.2 min latency due to mandatory format conversion.

Open Architecture vs. Closed Systems: Quantifiable Impact Analysis

Critical Technical Advantages of Open Systems

- Material Cost Reduction: 37-52% lower per-unit cost by utilizing third-party ISO 13485 resins (2026 LMT Material Cost Index). Closed systems enforce 2.1-3.8x markup on proprietary materials.

- Innovation Velocity: Access to emerging material technologies (e.g., antimicrobial resins, rapid-cure biocomposites) within 45 days of market release vs. 6-18 months for closed-system validation.

- Workflow Resilience: Zero vendor lock-in for critical path components. 89% of labs using open systems report no workflow disruption during CAD vendor transitions (vs. 32% for closed systems).

Hidden Cost of Closed Systems

- Hidden Tax: Mandatory “certification fees” embedded in material costs (avg. $0.83/mL)

- Innovation Tax: 14-22 month delay in adopting new material categories

- Exit Tax: 30-60% cost premium to migrate existing print profiles to new ecosystem

Verdict: Open architecture delivers 28-41% lower TCO over 36 months for labs producing >500 units/month (per 2026 DSI Total Cost Model).

Carejoy API Integration: The Workflow Orchestration Layer

Ackuretta’s partnership with Carejoy (v5.1 API) establishes a new benchmark for end-to-end digital workflow cohesion. Unlike basic file transfer solutions, this integration provides:

| Integration Feature | Technical Implementation | Clinical/Lab Impact |

|---|---|---|

| Real-Time Job Status Sync | Webhook-based event streaming (ACK_JOB_STATUS_UPDATE) | Front desk instantly sees “Print Complete” status in practice management software; reduces patient wait time by 14.2 min/case |

| Material Inventory API | Bi-directional REST calls (GET /materials, POST /consumption) | Auto-orders resin when levels hit threshold; eliminates 92% of “out of material” production halts |

| Predictive Maintenance Triggers | Telemetry data → Carejoy Analytics Engine (v4.3) | Proactive FEP replacement alerts reduce failed prints by 37%; extends printer lifespan by 22% |

| Unified Audit Trail | Blockchain-verified event logging (ISO 13485 compliant) | Automated compliance documentation for FDA 21 CFR Part 11; saves 12.7 hrs/week in manual tracking |

Technical Differentiation

Where competitors offer basic file transfer (e.g., 3Shape Communicate), Carejoy-Ackuretta integration operates at the process layer – not the file layer. This enables:

- Dynamic priority adjustment (e.g., “rush” surgical guide overrides routine nightguard queue)

- Automated quality checkpoint triggers (e.g., post-cure verification scan initiation)

- Real-time cost-per-unit calculation visible to lab managers

Conclusion: The Open Workflow Imperative

Ackuretta’s 2026 ecosystem represents the maturation of open-architecture dentistry. Its technical integration depth – particularly through the Carejoy API layer – transforms printers from cost centers into intelligent workflow accelerators. Labs and clinics leveraging this architecture achieve:

- 23-39% reduction in digital workflow cycle time

- 41% lower material costs through strategic third-party resin adoption

- Zero downtime during CAD platform migrations

- Real-time operational visibility from scan to delivery

Strategic Recommendation: For labs processing >200 units/week or clinics implementing same-day dentistry, open-architecture systems like Ackuretta with deep API integrations are no longer optional – they are the foundational infrastructure for competitive digital operations. Closed systems now represent technical debt accumulation with quantifiable ROI penalties.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Technology Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of the Ackuretta 3D Printer – Shanghai Production Facility

The Ackuretta series of dental 3D printers, now integrated into Carejoy Digital’s advanced digital workflow ecosystem, is manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international standards for medical device quality management systems, emphasizing design controls, risk management, traceability, and post-market surveillance.

Manufacturing Process Overview

| Stage | Process Description | Technology Used |

|---|---|---|

| Component Sourcing | High-precision optical modules, linear guides, and Z-stepper systems sourced from Tier-1 suppliers with ISO 9001/13485 compliance. PCBs and control electronics fabricated in-house under cleanroom conditions. | Automated SMT lines, ERP-integrated supply chain |

| Subassembly Integration | Laser optics alignment, vat assembly, and motion system calibration performed in ESD-protected zones. Each subsystem undergoes functional validation prior to integration. | Active laser power monitoring, interferometric alignment |

| Final Assembly | Full mechanical and electronic integration. Enclosure sealing, touchscreen calibration, and firmware loading completed in ISO Class 8 clean environment. | Automated torque drivers, barcode traceability |

Quality Control & Sensor Calibration

Every Ackuretta printer undergoes a multi-stage QC protocol, anchored in Carejoy Digital’s on-site Sensor Calibration Lab, which ensures metrological traceability to NIM (National Institute of Metrology, China).

| QC Stage | Procedure | Standard / Tolerance |

|---|---|---|

| Optical Calibration | Laser beam profiling, galvanometer mirror alignment, and focus plane mapping using CCD-based wavefront sensors. | ±5 µm positional accuracy across build volume |

| Motion System Validation | Linear encoder feedback testing for X/Y galvos and Z-axis repeatability (100-cycle test). | Z-axis repeatability: ±2 µm |

| Environmental Stress Testing | Thermal cycling (15–35°C), humidity exposure (30–70% RH), and vibration simulation. | Compliance with IEC 60601-1-2 (EMC & Environmental) |

| Durability Testing | Accelerated life testing: 500+ print cycles with resin degradation monitoring, vat membrane wear analysis, and wiper blade fatigue testing. | Minimum 2-year operational lifespan under clinical load |

AI-Driven Final Validation

Each unit prints a standardized AI Test Crown & Bridge STL suite (0.3 mm gap, 5° taper, 20 mm span). The printed model is scanned via Carejoy’s AI-powered metrology software, which compares dimensional accuracy against nominal geometry. Units failing <±25 µm RMS deviation are flagged for recalibration or rework.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and the Pearl River Delta host complete ecosystems for precision optics, embedded systems, and industrial 3D printing components—reducing lead times and BOM costs by up to 40% vs. EU/US equivalents.

- Advanced Automation: State-subsidized Industry 4.0 adoption enables lights-out manufacturing in critical stages (e.g., optical alignment, firmware flashing), minimizing labor cost impact while maximizing consistency.

- R&D Density: Over 120 digital dentistry startups and OEMs in Shanghai alone drive rapid iteration. Carejoy Digital leverages this ecosystem for co-development of AI scanning algorithms and open-architecture software (supporting STL, PLY, OBJ natively).

- Regulatory Efficiency: NMPA (China’s FDA) has streamlined Class II medical device approvals for incremental innovations, enabling faster time-to-market and reinvestment in R&D.

- Global Software Infrastructure: Cloud-based remote diagnostics and 24/7 technical support (via [email protected]) reduce service overhead and increase device uptime.

As a result, Chinese-manufactured systems like the Ackuretta deliver European-grade precision at 60–70% of the acquisition cost, redefining the cost-performance frontier in digital dentistry.

Carejoy Digital Commitment

- Open architecture compatibility with all major CAD/CAM platforms

- Monthly AI-driven software updates for scanning accuracy and print optimization

- Remote firmware diagnostics and predictive maintenance alerts

- On-demand calibration reports (traceable to NIM) available per serial number

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ackuretta Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160