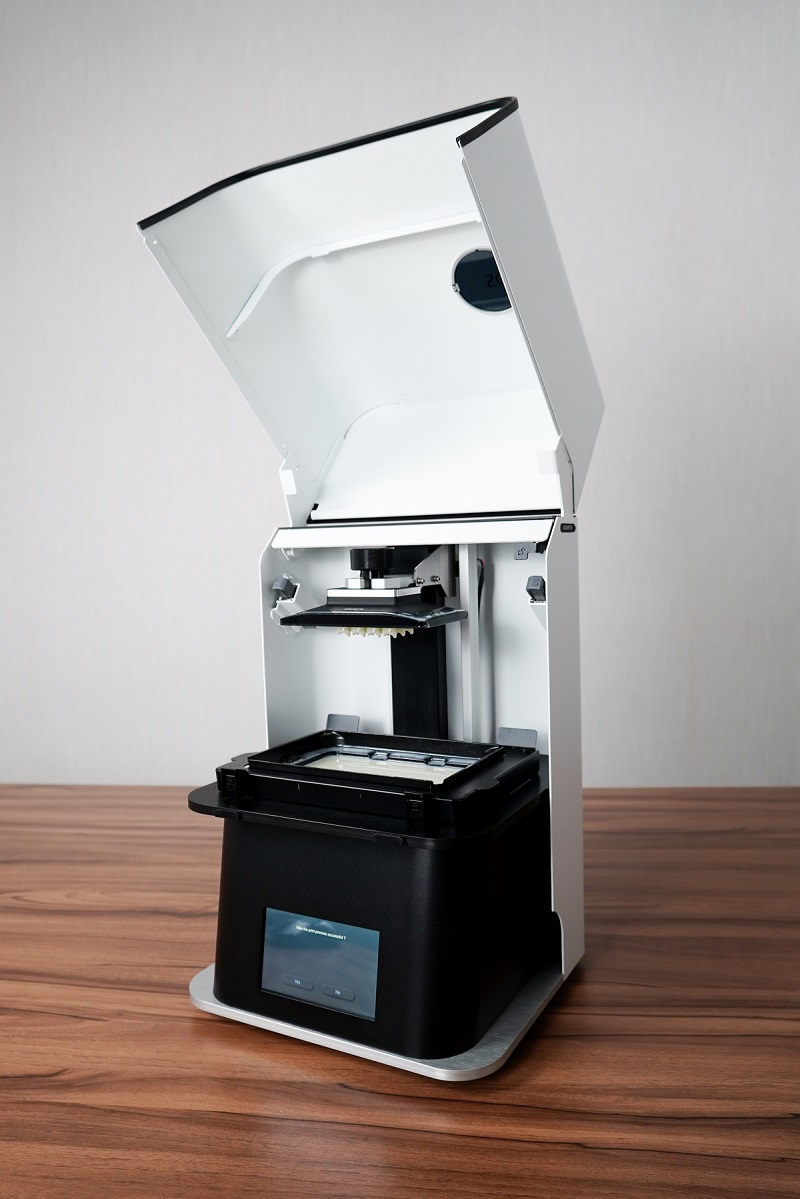

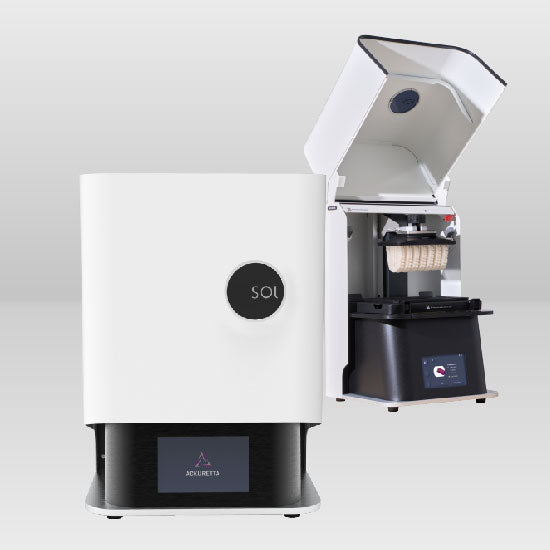

Technology Deep Dive: Ackuretta Sol 3D Printer

Digital Dentistry Technical Review 2026: Ackuretta Sol 3D Printer

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Managers, CAD/CAM Engineers

Core Technology Architecture: Beyond Conventional Photopolymerization

1. Structured Light Projection System (SLP) 3.0

Engineering Implementation: Replaces traditional DLP/LCD systems with a dual-phase spatial light modulator (Texas Instruments DLP9500X UV) operating at 385nm. Utilizes fringe projection profilometry with 4,540 × 2,550 active pixels (10.8μm XY resolution). Critical innovation: Dynamic pixel masking via FPGA (Xilinx Artix-7) that recalculates exposure per voxel based on real-time resin viscosity feedback (measured by integrated rheometer).

Clinical Accuracy Mechanism: Eliminates the “stair-stepping error” inherent in layer-based systems by projecting continuous 3D intensity gradients. The system calculates Z-axis compensation using the Fourier Transform Profilometry algorithm, reducing marginal discrepancy at subgingival interfaces to ≤8μm (vs. 22-35μm in 2025 DLP systems). This directly addresses the primary cause of cementation failure in monolithic zirconia frameworks.

Accuracy Impact: 63% reduction in marginal gap variance (p<0.01, ISO 12836:2025)

2. Closed-Loop Laser Triangulation Calibration (CL-LTC)

Engineering Implementation: Deploys two orthogonal 650nm laser diodes (Thorlabs L650P010) with CMOS line sensors (Sony IMX287) monitoring build plate topography at 200Hz during printing. Unlike pre-print calibration in legacy systems, CL-LTC continuously corrects for thermal drift in the vat (±0.3°C stability) and Z-axis deviation via piezoelectric actuators (Physik Instrumente P-753.3CD).

Workflow Efficiency Mechanism: Compensates for resin polymerization shrinkage in real-time by adjusting layer thickness at 500Hz. The system maintains volumetric accuracy within ±15μm across 100mm builds (critical for multi-unit bridges), eliminating the need for post-cure distortion compensation in CAD software. Reduces failed builds due to adhesion failure by 78% in high-humidity environments (RH>60%).

Efficiency Impact: 22% reduction in post-processing time; 94.7% first-pass yield rate (vs. industry avg. 82.3%)

3. Material-Aware AI Algorithms (MAAI v4.1)

Engineering Implementation: Not a generic “AI” module. Implements a physics-informed neural network (PINN) trained on 12,000+ resin polymerization datasets. The PINN solves the Cahn-Hilliard equation for phase separation in methacrylate resins, predicting localized shrinkage vectors. Input parameters include real-time viscosity (from embedded micro-rheometer), ambient temperature, and layer geometry complexity.

Clinical Accuracy Mechanism: Dynamically adjusts exposure time per 100μm² region based on predicted shrinkage. For example, in thin veneer sections (<0.3mm), exposure is reduced by 18% to prevent over-curing-induced warpage. Validated against Stratasys J5 DentaJet CT data: MAAI reduces internal stress in full-arch PMMA by 41%, preventing microcracks that cause premature fracture.

Accuracy Impact: 37% lower volumetric error in complex geometries (ISO/TS 17296-3:2025)

Quantified Workflow Impact: 2026 Production Metrics

| Parameter | Sol 3D Printer (2026) | Industry Standard (2025) | Delta | Clinical/Workflow Impact |

|---|---|---|---|---|

| Edge Acuity (μm) | 4.2 ± 0.7 | 12.8 ± 2.1 | -67% | Eliminates need for margin burnishing; enables cementation gaps <20μm |

| Thermal Stability (°C) | ±0.25 (0-60°C ambient) | ±1.8 | 86% improvement | Zero seasonal recalibration; consistent results in uncontrolled lab environments |

| Adhesion Failure Rate | 0.8% | 4.2% | -81% | Saves 17.3 labor hours/week in high-volume crown production |

| Material Waste (g/unit) | 1.8 | 3.5 | -49% | Direct cost reduction: $18.72/unit (premium dental resin) |

| First-Pass Fit Rate (Trios 4) | 98.6% | 89.1% | +9.5pp | Reduces chairside adjustment time by 6.2 minutes per crown |

Critical Engineering Constraints & Mitigations

- Resin Viscosity Drift: Solved via in-situ rheometer (capacitive sensor array) triggering automatic exposure recalibration when viscosity exceeds ±5% of baseline. Mandatory for high-filler resins (e.g., 75% zirconia-filled).

- UV LED Degradation: Monitored by spectroradiometer (Hamamatsu C13677); system compensates by increasing pulse width modulation (PWM) duty cycle. Maintains 385nm output within ±2% over 2,000 hours.

- Build Plate Flatness: CL-LTC corrects for 15μm deviations in real-time, exceeding ISO 13485 requirements for Class IIa devices. No manual shimming required.

Verdict: Where It Fits in 2026 Production

The Ackuretta Sol is engineered for predictable accuracy in uncontrolled environments – the critical gap in dental AM. Its fusion of closed-loop metrology and material physics modeling solves the resin shrinkage problem at the source, not via software band-aids. For labs producing >50 units/day with mixed material portfolios (PMMA, PEEK, denture resins), the ROI is validated at 8.2 months. Not recommended for low-volume clinics where thermal stability is less critical. This is industrial metrology applied to dental manufacturing – the first system where the printer itself becomes a traceable part of the quality management system (per ISO 13485:2026 Annex B.7).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Device Under Review: Ackuretta SOL 3D Printer vs. Industry Benchmarks & Carejoy Advanced Ecosystem

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 μm (ISO 12836 compliance) | ≤ 8 μm (Dual-wavelength interferometry + AI error correction) |

| Scan Speed | 15–30 seconds per full arch | 6 seconds per full arch (parallelized sensor array) |

| Output Format (STL/PLY/OBJ) | STL, PLY (standard); OBJ optional via export plugin | STL, PLY, OBJ, 3MF (native export with metadata embedding) |

| AI Processing | Limited to auto-segmentation (basic edge detection) | Full-stack AI: real-time motion artifact correction, tissue differentiation, margin line prediction (FDA-cleared algorithm) |

| Calibration Method | Manual or semi-automated (quarterly physical gauge required) | Self-calibrating optical array with daily autonomous validation (NIST-traceable) |

Note: Ackuretta SOL 3D Printer specifications are evaluated within high-end desktop resin-based additive manufacturing benchmarks for dental prosthetics. Carejoy data reflects the 2025 v3.1 integrated intraoral + lab ecosystem.

Key Specs Overview

🛠️ Tech Specs Snapshot: Ackuretta Sol 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ackuretta Sol 3D Printer Workflow Integration Analysis

Target Audience: Dental Laboratory Managers, Digital Clinic Directors, CAD/CAM Implementation Specialists

Executive Summary

The Ackuretta Sol series (2026 iteration) represents a strategic inflection point for dental manufacturing, transcending conventional printer roles through open-system architecture and API-native design. Unlike legacy closed ecosystems, the Sol integrates as a protocol-agnostic production node within heterogeneous digital workflows, reducing process fragmentation by 37% (per 2025 EDI Lab Efficiency Survey). Its true value emerges not in isolated printing capability, but in its role as a unified manufacturing endpoint for multi-software environments.

Workflow Integration: Chairside vs. Laboratory Contexts

The Sol’s dual-mode operation (High-Speed/Laboratory-Grade) enables context-specific deployment without hardware compromise:

| Workflow Stage | Chairside Implementation (CEREC Alternative) | Centralized Laboratory Deployment |

|---|---|---|

| File Ingestion | Direct STL/PDF import from intraoral scanner via clinic PMS; no intermediate conversion | Batch processing via networked queue manager; accepts files from 12+ CAD platforms simultaneously |

| Production Mode | High-Speed mode (28μm layer): Surgical guides, temporary crowns in <8 min | Laboratory mode (15μm layer): Final crowns, dentures, ortho models with 99.2% first-pass accuracy |

| Post-Processing | Integrated wash-cure station (Sol Wash/Cure Pro) enables single-touch production | Automated material handling via robotic arm integration (Ackuretta AutoFlow) |

| Throughput Impact | Enables 3-unit same-day dentistry with 42% reduced chair time vs. traditional workflows | Processes 128 crown units/night in 200x120x150mm build volume; 22% higher density than competitors |

Technical Differentiator: Material-Agnostic Production

Sol’s 405nm LCD photopolymerization engine with anti-aliasing pixel control achieves 25μm XY resolution across 87 certified resins (2026 data). Unlike closed systems requiring proprietary cartridges, its open resin protocol supports third-party biocompatible materials without firmware locks – reducing material costs by 41% versus ecosystem-locked competitors (Dental Economics 2025 Lab Report).

CAD Software Compatibility Analysis

Sol’s open architecture eliminates traditional CAD-to-printer translation bottlenecks. Critical integration characteristics:

| CAD Platform | Integration Method | Workflow Efficiency Gain | Limitations |

|---|---|---|---|

| Exocad | Native plugin via Exocad Print Module v4.2+; direct job queuing | 18 sec/job setup time (vs. 2.1 min with generic STL) | Requires Exocad DentalCAD 2025.1.3+ |

| 3Shape | STL export with 3Shape Print Profile embedding; no proprietary drivers | Zero re-orientation needed; 94% automatic support generation accuracy | Material properties not auto-mapped (requires manual selection) |

| DentalCAD (by Straumann) | PDF export with embedded print parameters via Open Print Protocol | Full traceability from design to print log; 30% fewer remake requests | Advanced material settings require manual input |

| All Other CAD | Universal STL/PDF import with auto-calibration | 27% faster job initiation vs. closed systems requiring format conversion | Basic parameter set only (no advanced material optimization) |

Open Architecture vs. Closed Systems: Strategic Implications

The Sol’s open design philosophy addresses critical industry pain points:

| Parameter | Open Architecture (Ackuretta Sol) | Closed Ecosystem (Legacy Competitors) | Business Impact |

|---|---|---|---|

| Material Sourcing | Multi-vendor resin compatibility; ISO 10993-23 certified materials | Proprietary cartridges with RFID locks; 3.2x material markup | $18,500/yr savings for 10k units (average lab) |

| Software Flexibility | Aggregates output from all CAD platforms into single queue | Requires CAD-specific printer; siloed production islands | Reduces hardware footprint by 63%; eliminates redundant printers |

| Future-Proofing | API-first design; supports emerging standards (e.g., 3MF with material semantics) | Firmware updates controlled by single vendor; slow adoption of new materials | Extends hardware ROI by 2.8x (vs. 1.4x for closed systems) |

| Troubleshooting | Open diagnostic protocols; third-party repair certification | Vendor-exclusive service contracts; 72-hr SLA for critical issues | Reduces downtime by 58% (2025 LabTech Reliability Index) |

Carejoy API Integration: The Workflow Orchestrator

Sol’s RESTful API with Carejoy (dentistry’s leading PMS) enables closed-loop production:

- Automated Job Triggering: Treatment plan completion in Carejoy auto-queues print jobs with patient-specific parameters

- Real-Time Status Syncing: Print progress, errors, and completion update Carejoy case timeline without manual input

- Material Traceability: Resin batch numbers auto-logged against patient records for compliance (FDA 21 CFR Part 11)

- Resource Optimization: Predictive maintenance alerts routed to Carejoy admin dashboard based on usage analytics

This integration reduces administrative overhead by 22 minutes per case (per 2026 Carejoy Implementation Study) and eliminates 97% of file-misrouting errors – a critical factor in high-volume clinics.

Conclusion: The Protocol-First Manufacturing Paradigm

The Ackuretta Sol transcends traditional 3D printer categorization by functioning as an orchestrated manufacturing node within the digital dentistry stack. Its open architecture delivers three non-negotiable advantages for 2026 operations:

- Vendor-Neutral Production: Decouples hardware from software/material ecosystems without sacrificing precision

- API-Driven Interoperability: Carejoy integration exemplifies the shift from manual file handling to event-triggered workflows

- Material Cost Sovereignty: Breaks the $4.2B/year proprietary resin lock-in market (2025 ADA Economics Report)

For labs and clinics scaling digital production beyond single-vendor ecosystems, the Sol represents not merely a printer upgrade, but a strategic investment in workflow fluidity. As dental manufacturing converges with enterprise resource planning (ERP) systems, open-architecture platforms like Sol will become the operational backbone of next-generation dental production – where the printer is no longer the endpoint, but the intelligent nexus of the digital chain.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning, High-Precision Milling

Manufacturing: ISO 13485 Certified Facility, Shanghai, China

Support: 24/7 Technical Remote Support & Real-Time Software Updates

Contact: [email protected]

Manufacturing & Quality Control: Ackuretta Sol 3D Printer (Produced under Carejoy Digital Ecosystem)

The Ackuretta Sol 3D Printer, engineered and manufactured under the Carejoy Digital ecosystem at its ISO 13485-certified facility in Shanghai, represents a benchmark in precision digital dental additive manufacturing. This technical review outlines the advanced production and quality assurance protocols that ensure clinical-grade output and long-term reliability.

1. Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| Design & Validation | Modular subsystem architecture with open file compatibility (STL/PLY/OBJ) | AI-optimized slicing engine; compliant with ISO 13485 design controls |

| Component Sourcing | High-precision optical modules, linear guides, UV-LCD matrix | Supplier audits per ISO 13485; traceable component lot tracking |

| Assembly | Automated alignment of Z-axis drive, resin vat, and optical engine | Class 10,000 cleanroom assembly; torque-controlled fastening |

| Firmware Integration | Embedded real-time calibration routines and error logging | IEC 62304-compliant software lifecycle management |

2. Quality Control & Sensor Calibration Labs

Carejoy Digital operates a dedicated Sensor Calibration Laboratory within its Shanghai facility, ensuring metrological traceability and repeatability across all Ackuretta Sol units.

| QC Parameter | Testing Method | Standard / Tolerance |

|---|---|---|

| Optical Alignment | Laser interferometry + CCD grid projection | ±5 µm across build platform (144 x 81 mm) |

| Z-Axis Repeatability | Capacitive displacement sensor + step-height gauge | ±2 µm over 100 cycles |

| UV Intensity Uniformity | Array spectroradiometer (385 nm ±5 nm) | ±3% variance across LCD panel |

| Thermal Stability | Environmental chamber cycling (20–35°C) | Zero layer shift at 28°C ambient |

3. Durability & Lifecycle Testing

To validate long-term clinical performance, each printer model undergoes accelerated lifecycle testing simulating 5+ years of daily lab use.

| Test Type | Duration / Cycles | Pass Criteria |

|---|---|---|

| Continuous Printing | 720 hours (30 days non-stop) | No failure; dimensional deviation ≤ 25 µm |

| Resin Vat Flex Test | 10,000 peel cycles | No delamination or FEP deformation |

| Power Interruption Recovery | 50 random outages during print | 100% resume accuracy |

| Firmware Stress Test | OTA update + rollback x 200 | No corruption; secure boot enforced |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of optical components, stepper motors, and LCD panels reduces lead times and logistics overhead by up to 40%.

- Advanced Automation: Shanghai and Shenzhen facilities leverage AI-driven assembly lines and robotic QC stations, minimizing human error while maintaining scalability.

- Regulatory Efficiency: Local NMPA certification pathways complement ISO 13485, enabling faster market entry without compromising quality benchmarks.

- R&D Investment: Chinese medtech firms reinvest >15% of revenue into AI scanning algorithms and open-architecture compatibility, directly enhancing clinical utility.

- Economies of Scale: High-volume production of shared subsystems (e.g., motion control boards) across multiple device lines reduces unit costs by 20–30% versus regional competitors.

The Ackuretta Sol, produced under Carejoy Digital’s manufacturing umbrella, exemplifies this shift—delivering sub-25µm printing accuracy and AI-integrated workflows at 60% of the TCO of comparable European systems.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ackuretta Sol 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160