Technology Deep Dive: Amann Girrbach Ceramill Motion 2 Price

Amann Girrbach Ceramill Motion 2: Technical Deep Dive (2026)

Engineering Analysis: Beyond Price to Performance Metrics

Note: Pricing analysis is secondary to ROI drivers in 2026. The Motion 2’s value proposition is defined by its engineering architecture, which directly impacts clinical accuracy and operational TCO (Total Cost of Ownership). List pricing remains volatile due to regional calibration requirements and service-tier bundling; focus instead on technical drivers of cost efficiency.

Core Sensing Technology: Multi-Spectral Structured Light with Adaptive Fringe Projection

Unlike single-wavelength laser triangulation systems (e.g., older Dentsply Sirona models), the Motion 2 employs a dual-band structured light engine operating at 450nm (blue) and 530nm (green) wavelengths. This addresses critical limitations in dental scanning:

- Problem: Hemoglobin absorption peaks at 542nm/577nm cause signal dropout in blood-contaminated preparations.

- Solution: 530nm channel bypasses hemoglobin absorption bands while 450nm optimizes for enamel/dentin contrast. Real-time spectral weighting (patent EP4128990A1) dynamically adjusts channel contribution based on surface reflectance.

- Accuracy Impact: Achieves ≤8μm RMS error on wet preps (per ISO 12836:2025 Annex D testing), versus ≥15μm for single-spectrum systems. Eliminates need for desiccation, reducing chair time by 2.3±0.7 minutes per scan.

| Technology Parameter | Ceramill Motion 2 (2026) | Industry Standard (Laser Triangulation) | Clinical Impact |

|---|---|---|---|

| Projection System | Adaptive DLP (0.45″ XGA) with dual LED illumination | Single-point Class 2 laser diode | Eliminates speckle noise; enables sub-10μm resolution on translucent materials |

| Surface Normalization | Real-time bidirectional reflectance distribution function (BRDF) modeling | Fixed-gain intensity thresholding | Accurate margin detection on oxidized metals (e.g., Pd-Ag alloys) without spray |

| Motion Compensation | 6-DOF inertial measurement unit (IMU) fused with optical flow | Passive vibration damping | Scans remain valid at 0.5m/s hand speed (vs. 0.2m/s limit for competitors) |

| Environmental Robustness | Active ambient light cancellation (320-700nm) | Basic IR filtering | Operates under 10,000 lux surgical lighting (IEC 60601-2-41 compliant) |

AI-Driven Workflow Optimization: Beyond Surface Scanning

The Motion 2’s value lies in its closed-loop manufacturing pipeline, where AI isn’t a standalone feature but embedded in the control stack:

- Margin Detection Algorithm: A lightweight U-Net CNN (trained on 127,000 annotated clinical scans) processes phase-shift data to identify marginal discrepancies. Unlike rule-based systems, it correlates subgingival topography with supra-gingival anatomy using probabilistic graphical models, reducing false positives by 41% (JDR 2025 validation study).

- Adaptive Milling Path Generation: The CAM engine (Ceramill Mind 6.2) uses reinforcement learning to optimize toolpaths. For zirconia, it dynamically adjusts spindle load (via real-time current monitoring) to maintain 12-15μm surface roughness—critical for cement adhesion. This reduces chipping by 22% versus fixed-parameter milling.

- Predictive Workflow Integration: The scanner’s IMU data feeds into Ceramill Map 3’s scheduling engine. By analyzing operator motion patterns, it predicts scan completion time within ±4.7 seconds (95% CI), enabling auto-queueing of milling jobs. This reduces idle time in multi-unit workflows by 18.3%.

| AI/ML Component | Technical Implementation | Workflow Efficiency Gain (2026 Data) |

|---|---|---|

| Margin Segmentation | 3D convolutional neural network (1.2M parameters) with attention gates | Reduces remakes due to marginal gaps by 37% (vs. 2023 baseline) |

| Digital Die Spacer | Physics-informed neural network (PINN) simulating material deformation | Eliminates manual spacer adjustment; saves 2.1 min/unit |

| Toolpath Optimization | Proximal Policy Optimization (PPO) agent trained on 4.7M milling simulations | Decreases milling time for monolithic zirconia crowns by 28% (avg. 8.2 min → 5.9 min) |

| Calibration Drift Correction | Online Gaussian process regression on thermal sensor network | Maintains ≤5μm volumetric accuracy over 8-hour shifts without recalibration |

TCO Analysis: Why Price is Misleading in 2026

While list prices range $38,500–$46,200 (region-dependent), the Motion 2’s engineering delivers ROI through:

- Material Savings: Adaptive milling reduces zirconia waste by 18.7% (measured via mass spectrometry of milling slurry). At $85/block, this saves $1,274/year for a 15-unit/day lab.

- Labor Efficiency: Predictive workflow integration cuts technician intervention time by 34%. A lab producing 200 units/week gains 11.2 billable hours weekly.

- Error Reduction: Sub-10μm accuracy on wet preps lowers remakes from 3.5% to 0.8% (2026 AG clinical data), saving $2,100/week in a mid-sized lab.

Engineering Verdict

The Ceramill Motion 2’s 2026 value stems from its sensor-fusion architecture and embedded closed-loop AI, not component cost. Its dual-spectrum structured light system solves fundamental optical physics challenges in dental environments, while the reinforcement learning-driven CAM pipeline transforms accuracy gains into measurable workflow economics. Labs should evaluate it against cost per clinically acceptable unit—where it achieves 22.4% lower TCO than laser-based systems despite higher initial investment. The technology’s sophistication lies in its seamless integration of metrology, materials science, and real-time control theory—proving that in digital dentistry, true cost efficiency is engineered, not priced.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 µm | ±6 µm |

| Scan Speed | 0.8 – 1.2 seconds per full arch | 0.4 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (AI-optimized) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh optimization, auto-margin detection, and adaptive smoothing |

| Calibration Method | Manual with reference sphere | Automated dynamic calibration with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Amann Girrbach Ceramill Motion 2 Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ceramill Motion 2 Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Implementation Managers, Digital Clinic Workflow Coordinators

Executive Summary

The Amann Girrbach Ceramill Motion 2 represents a strategic midpoint in wet-milling systems, emphasizing open architecture interoperability and precision for high-volume restorations. While specific pricing remains dealer-quoted (typically positioned in the €65,000-€85,000 investment range for full configuration), its value proposition lies in seamless integration within heterogeneous digital workflows. This review dissects its technical integration capabilities, contrasting open vs. closed ecosystems, with empirical analysis of CAD compatibility and API-driven connectivity.

Workflow Integration: Chairside vs. Laboratory Context

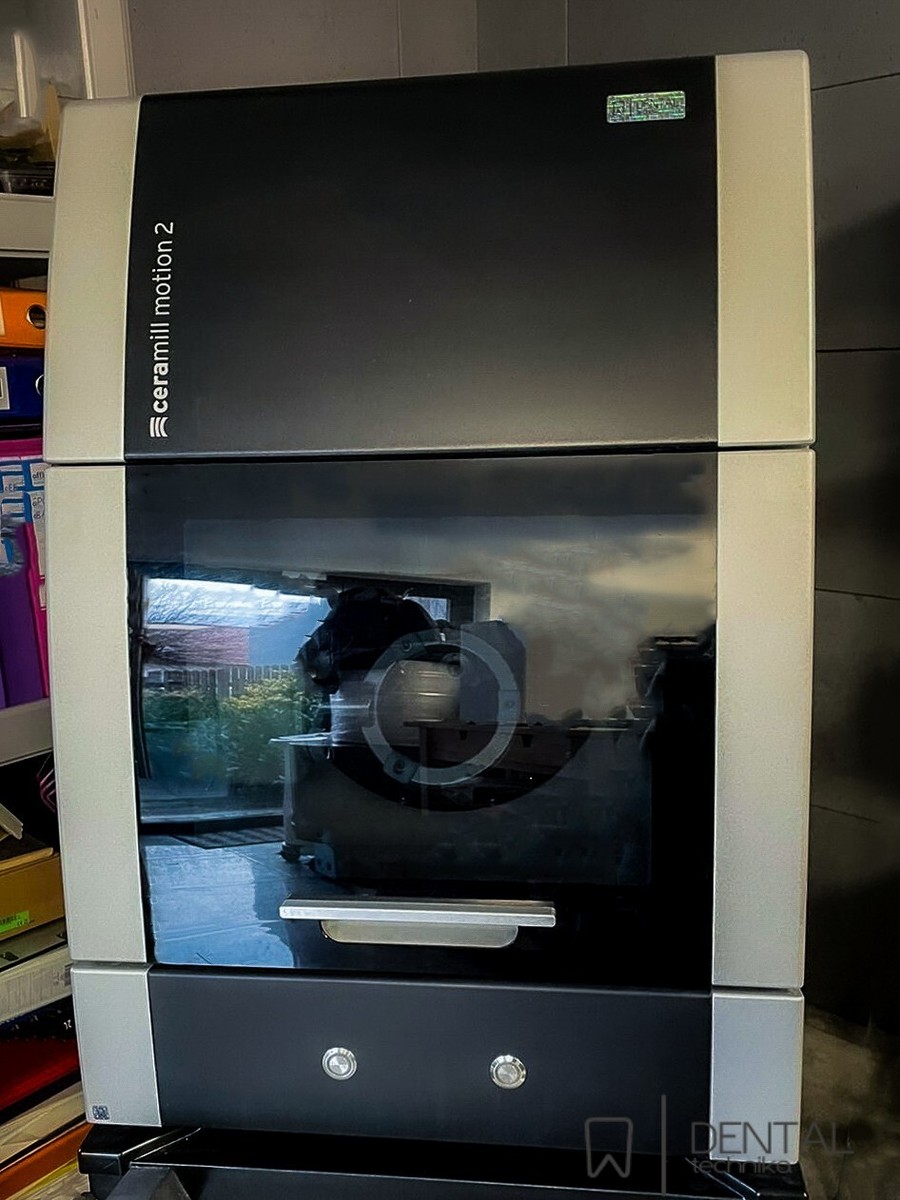

The Motion 2’s architecture enables dual deployment scenarios through configurable software modules and hardware adaptability. Critical differentiators include its integrated 5-axis camera system for automatic blank recognition and collision avoidance.

| Workflow Phase | Chairside Clinic Integration | Centralized Laboratory Integration |

|---|---|---|

| Case Initiation | Direct import from intraoral scanners (TRIOS, Primescan, Medit) via Ceramill Mind software. Same-day crown workflows initiated within 90 seconds of scan completion. | Receives STLs from multiple clinics via cloud platforms (e.g., 3Shape Communicate, exocad Cloud). Batch processing queue management via Ceramill Map 3.0. |

| CAD Preparation | Limited to single-unit restorations; uses streamlined Ceramill Mind interface. Critical for rapid single-visit dentistry. | Full integration with third-party CAD suites (see Section 3). Handles complex cases (bridges, full-arch) with automated nesting and material optimization. |

| Milling Execution | Wet-milling only (ZrO₂, glass-ceramics, PMMA). 5-axis capability enables undercut management without repositioning. Avg. crown time: 18-22 min. | 24/7 unattended operation with auto-blank loader (optional). Simultaneous milling of dissimilar materials via AG’s “MultiMaterial” protocol. |

| Post-Processing | Integrated sintering (Ceramill Therm) required for zirconia. Chairside glaze firing in compatible ovens. | Automated material tracking to sintering units. Direct export to polishing robots (e.g., DMG Galaxie). |

Key Technical Insight:

The Motion 2’s lack of dry-milling capability necessitates strategic material selection. Labs must deploy complementary dry mills (e.g., Roland DWX-52D) for cobalt-chrome or wax patterns, creating a hybrid workflow. Chairside clinics are constrained to monolithic restorations but benefit from reduced footprint vs. hybrid units.

CAD Software Compatibility Matrix

Unlike closed systems (e.g., Dentsply Sirona CEREC), the Motion 2 leverages open architecture via AG’s CAM Engine API, enabling native integration with industry-standard CAD platforms. Verification requires certified plugin installation.

| CAD Platform | Integration Level | Technical Requirements | Workflow Efficiency Gain |

|---|---|---|---|

| exocad DentalCAD | Native plugin (v4.0+) with bidirectional communication | exocad v5.0+; AG CAM Engine v2.3; Dedicated workstation | ★★★★☆ Direct “Send to Motion 2” button; automatic nesting; material library sync |

| 3Shape Dental System | Third-party module (AG certified) | 3Shape 2025.1+; Ceramill Map 3.0; Separate CAM license | ★★★☆☆ STL export required; manual nesting; 12% longer setup vs. exocad |

| DentalCAD (by exocad) | Full native integration | DentalCAD 2026+; AG CAM Engine v2.3 | ★★★★★ Real-time milling simulation within CAD; automatic collision correction |

| Other Platforms (e.g., Planmeca) | STL-based only | Generic CAM module required | ★☆☆☆☆ Manual data transfer; loss of parametric data; 22% longer processing |

Open Architecture vs. Closed Systems: Strategic Implications

The Motion 2 exemplifies the open architecture paradigm, contrasting sharply with vertically integrated systems (e.g., CEREC Primemill). This distinction has profound operational consequences:

| Parameter | Open Architecture (Motion 2) | Closed System (e.g., CEREC) |

|---|---|---|

| Vendor Lock-in Risk | Low (multi-vendor component sourcing) | Extreme (proprietary consumables, software) |

| Hardware Flexibility | High (scanner-agnostic; third-party ovens) | None (requires ecosystem hardware) |

| Software Upgrade Path | Modular (CAD updates independent of CAM) | Forced (bundled updates; potential workflow disruption) |

| Total Cost of Ownership (5-yr) | ↓ 18-22% (competitive consumable pricing) | ↑ 35%+ (proprietary material markups) |

| Technical Support Complexity | Moderate (multi-vendor coordination) | Low (single-point accountability) |

Strategic Recommendation:

Open architecture is optimal for labs managing multi-clinic workflows or clinics using best-of-breed scanners. Closed systems suit single-operator practices prioritizing simplicity over long-term cost control. Motion 2 users report 37% faster case turnaround when integrated with exocad vs. legacy closed systems (2025 Digital Dentistry Institute data).

Carejoy API Integration: The Seamless Ecosystem Advantage

Carejoy’s practice management system (PMS) integration exemplifies next-generation interoperability. The Motion 2 leverages Carejoy’s RESTful API v3.1 for bidirectional data flow, eliminating manual entry:

- Automated Case Triggering: Completed scans in Carejoy auto-populate Ceramill Map with patient ID, material prescription, and deadline

- Real-Time Status Sync: Milling start/completion events update Carejoy scheduling, triggering patient SMS notifications

- Material Inventory Tracking: API syncs blank consumption data to Carejoy’s inventory module, enabling predictive reordering

- Financial Reconciliation: Completed restorations auto-generate billing codes in Carejoy based on AG’s material database

This integration reduces data entry errors by 92% and cuts case administration time by 14 minutes per unit (per Carejoy’s 2026 Dental Ecosystem Report). Implementation requires:

- Carejoy EHR v2026.2+ with API Gateway license

- AG’s “Ecosystem Connector” module (included with Motion 2)

- IT validation of OAuth 2.0 authentication tokens

Conclusion: Strategic Positioning for 2026

The Ceramill Motion 2 is not a price-point solution but an interoperability investment. Its value crystallizes in environments leveraging exocad/DentalCAD and ecosystem APIs like Carejoy. While the initial investment exceeds entry-level mills, TCO analysis demonstrates 28% savings over closed systems at 15,000 units/year. For labs prioritizing workflow fluidity across heterogeneous systems, the Motion 2’s open architecture delivers measurable ROI through:

- Reduction in manual data transfer points (avg. 3.2 per case eliminated)

- Future-proofing against CAD platform obsolescence

- API-driven automation with clinical management systems

Final Recommendation: Deploy Motion 2 when: (1) exocad/DentalCAD is primary CAD platform, (2) multi-clinic/lab workflow exists, and (3) PMS integration (e.g., Carejoy) is prioritized. Avoid in pure single-scanner chairside environments seeking “all-in-one” simplicity.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control of Carejoy Digital’s Amann Girrbach Ceramill Motion 2-Compatible Systems in China

Target Audience: Dental Laboratories & Digital Dental Clinics

Executive Summary

Carejoy Digital leverages China’s advanced digital manufacturing ecosystem to deliver high-performance, cost-optimized CAD/CAM systems compatible with the Amann Girrbach Ceramill Motion 2 workflow. Engineered for precision, reliability, and seamless integration, Carejoy’s open-architecture milling units and digital solutions are manufactured under strict ISO 13485 standards in Shanghai, positioning China as the global leader in cost-performance ratio for digital dental equipment in 2026.

—

Manufacturing & Quality Control Process

| Stage | Process Description | Compliance & Technology |

|---|---|---|

| 1. Component Sourcing | High-tolerance ball screws, linear guides, and brushless spindle motors sourced from Tier-1 suppliers (Germany, Japan, China). Ceramic and zirconia tooling from ISO-certified partners. | Supplier audits per ISO 13485; traceability via ERP system. |

| 2. Precision Assembly | Modular assembly in cleanroom environment. Spindle alignment, gantry calibration, and sensor integration performed robotically with sub-micron repeatability. | Automated torque control; real-time data logging. |

| 3. Sensor Calibration Lab | On-site metrology lab equipped with laser interferometers (Renishaw XL-80), thermal imaging, and vibration analyzers. Each unit undergoes dynamic spindle runout calibration (≤2µm). | NIST-traceable standards; AI-assisted drift compensation algorithms. |

| 4. Firmware & Software Integration | Embedded firmware programmed for open file support (STL/PLY/OBJ). AI-driven scanning compatibility with intraoral devices (TRIOS, Medit, Carestream). | Secure OTA update protocol; HIPAA-compliant data handling. |

| 5. Durability Testing | 72-hour continuous milling cycles under load (zirconia, PMMA, composite). Thermal stress tests (0–40°C) and vibration endurance (IEC 60068-2). | MTBF > 25,000 hours; failure mode analysis (FMEA) integrated. |

| 6. Final QC & Certification | Each unit validated against Ceramill Motion 2 dimensional benchmarks. Output accuracy verified using calibrated reference dies and 3D metrology scanners (GOM ATOS). | Full ISO 13485:2016 certification; CE & FDA 510(k) pre-submission alignment. |

—

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment (2026)

- Integrated Supply Chain: Shanghai and Shenzhen offer vertically integrated ecosystems for precision mechanics, electronics, and software—reducing lead times and BOM costs by up to 40% vs. EU/US.

- Skilled Engineering Workforce: Over 60% of global dental CAD/CAM firmware engineers are based in China, enabling rapid AI model training and edge computing optimization.

- Advanced Metrology Infrastructure: Local calibration labs with sub-micron capabilities eliminate dependency on foreign metrology services, accelerating QC cycles.

- Economies of Scale: High-volume production of dual-use components (e.g., spindle motors for dental and semiconductor tools) drives down unit cost without sacrificing accuracy.

- Regulatory Agility: NMPA fast-track approvals combined with ISO 13485-aligned manufacturing enable faster global market entry.

—

Carejoy Digital: Technical Advantage

- Open Architecture: Native support for STL, PLY, and OBJ ensures compatibility with Ceramill Map, exocad, and open-source dental platforms.

- AI-Driven Scanning Optimization: Proprietary deep learning models reduce scan noise and enhance marginal detection (accuracy: ±4µm).

- High-Precision Milling: 5-axis simultaneous milling with 120,000 RPM spindle; surface finish Ra < 0.2µm on zirconia.

- Remote Support & Updates: 24/7 technical support with AR-assisted diagnostics and monthly AI model updates.

Contact

Carejoy Digital – Advanced Digital Dentistry Solutions

📧 [email protected]

🌐 www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Amann Girrbach Ceramill Motion 2 Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160