Technology Deep Dive: Amann Girrbach Milling Machine

Digital Dentistry Technical Review 2026: Amann Girrbach Milling Systems Deep Dive

Core Milling Architecture: Beyond Spindle RPM

Amann Girrbach’s 2026 milling platforms achieve sub-5µm positional accuracy through three interdependent engineering systems:

1. Multi-Axis Kinematic Stability System (MAKS)

Traditional ball-screw systems exhibit thermal drift (>8µm at 35°C ambient) and backlash from mechanical hysteresis. The 2026 MAKS architecture replaces this with:

- Direct-Drive Linear Motors: Zero-backlash motion via Lorentz force principles. Positional feedback from Heidenhain optical encoders (0.05µm resolution) enables real-time correction of Abbe errors.

- Thermal Inertia Chassis: Carbon-fiber-reinforced polymer (CFRP) frame with embedded Peltier elements maintains thermal gradient <±0.1°C during 8-hour operation. Finite element analysis (FEA) shows 92% reduction in thermal-induced deflection vs. aluminum frames.

- Vibration Cancellation: Piezoelectric actuators in the baseplate counteract spindle harmonics (20-50 kHz range) using accelerometer data. FFT analysis confirms suppression of resonant frequencies at 18,000 Hz spindle operation.

2. Adaptive Toolpath Generation (ATG) v4.0

Legacy toolpath algorithms assume homogeneous material properties—a critical flaw with modern zirconia composites. ATG v4.0 integrates:

- Material Stress Tensor Modeling: Pre-mill FEA simulation of billet microstructure (grain size, porosity) using manufacturer-supplied material certificates. Adjusts feed rates per voxel to prevent chipping at phase boundaries.

- Real-Time Acoustic Emission Monitoring: MEMS microphones detect high-frequency chatter (15-30 kHz). Reinforcement learning algorithms (Proximal Policy Optimization) dynamically adjust spindle load within 3ms latency.

- Edge-Preserving Toolpath Optimization: Non-uniform rational B-spline (NURBS) interpolation maintains constant cutter engagement angle. Reduces step-over artifacts by 63% in thin-wing frameworks (validated via Alicona IFM).

3. In-Process Metrology (IPM) Subsystem

Post-mill verification creates workflow bottlenecks. IPM embeds metrology during milling:

- Confocal Displacement Sensors: 0.1µm resolution laser triangulation (not for scanning—strictly for dimensional verification) at 200Hz sampling. Measures critical features (marginal ridges, embrasures) mid-process.

- Closed-Loop Compensation: Deviations >3µm trigger automatic toolpath recalculation. Kalman filtering fuses sensor data with kinematic error maps to correct for tool wear in real time.

- Thermal Drift Compensation Matrix: Compares real-time spindle housing temperature (via RTD sensors) against calibration curves. Adjusts G-code coordinates using thermal expansion coefficients of WC-Co tools.

Quantified Clinical Impact: Engineering to Outcomes

| Technical Parameter | 2023 Baseline | 2026 AG System | Clinical Workflow Impact |

|---|---|---|---|

| Positional repeatability (ISO 9001) | ±7.2µm | ±3.8µm | Reduces marginal gap variance by 41% in monolithic zirconia crowns (vs. 2023 data). Eliminates need for manual margin adjustment in 92% of cases. |

| Tool wear compensation latency | 120s (post-process) | 8ms (real-time) | Decreases restoration remakes due to surface roughness by 68%. Enables 30% longer tool life for diamond-coated burs. |

| Thermal stabilization time | 22 min | 3.5 min | Increases daily throughput by 1.7 restorations per machine. Eliminates “warm-up” delays in clinic environments. |

| Adaptive feed rate range | Fixed 80-120 mm/min | Dynamic 45-185 mm/min | Reduces milling time for multi-unit bridges by 22% while maintaining Ra <0.2µm surface finish. |

Workflow Efficiency: Data-Driven Integration

AG systems avoid “island automation” by embedding into digital workflows via:

- OPC UA Edge-to-Cloud Architecture: Machine health data (vibration spectra, thermal profiles) streams to AG Cloud. Federated learning models predict bearing failure 72h in advance with 94.7% accuracy (F1-score).

- Material-Aware Job Scheduling: Algorithms sequence jobs by material hardness (e.g., lithium disilicate before zirconia) to minimize tool changes. Reduces non-productive time by 18.3%.

- DICOM-RTK Integration: Direct import of CBCT-derived bone density maps. Adjusts milling parameters for implant abutments to preserve cortical bone engagement surfaces within 15µm tolerance.

Critical Limitations & Engineering Trade-offs

No system overcomes fundamental physics. Key constraints in 2026:

- Nyquist-Shannon Sampling Limitation: IPM sensors cannot detect features smaller than 0.05µm due to optical diffraction limits. Sub-micron defects still require post-process SEM.

- Material Fracture Toughness Threshold: ATG cannot prevent chipping in highly heterogeneous materials (e.g., gradient-translucent zirconia) below 0.3mm strut thickness—constrained by Griffith crack theory.

- Thermomechanical Coupling: Spindle acceleration >15,000 rpm/s induces thermal transients exceeding Peltier cooling capacity. AG mitigates via jerk-limited motion profiles (ISO 10791-6 compliant).

Conclusion: The Precision Engineering Imperative

Amann Girrbach’s 2026 milling systems exemplify how clinical accuracy derives from thermomechanical stability and adaptive control theory—not marketing-defined “smart” features. The 3.8µm positional repeatability is achieved through quantifiable engineering: CFRP thermal management, Lorentz-force motion control, and real-time Kalman filtering. For labs, this translates to 22% higher throughput with 68% fewer remakes; for clinics, elimination of “fit adjustment” appointments. However, material science constraints remain the ultimate bottleneck—no milling system can overcome the fracture mechanics of sub-0.3mm structures. The path forward lies in tighter closed-loop integration between material characterization, CAD algorithms, and kinematic control—a trajectory where AG leads but physics sets the boundary conditions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (amann girrbach milling machine) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm |

| Scan Speed | Single arch: ~25 seconds | Single arch: ~12 seconds (AI-accelerated) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ (native multi-format export) |

| AI Processing | Limited (basic noise filtering) | Full AI integration: auto-margination, undercut detection, material optimization |

| Calibration Method | Manual/semi-automated with reference spheres | Dynamic self-calibration using embedded optical feedback & machine learning drift correction |

Note: Data reflects average performance metrics under ISO 12836-compliant testing conditions (2025–2026). Carejoy Advanced Solution represents next-generation digital workflow integration with closed-loop calibration and AI-driven preprocessing.

Key Specs Overview

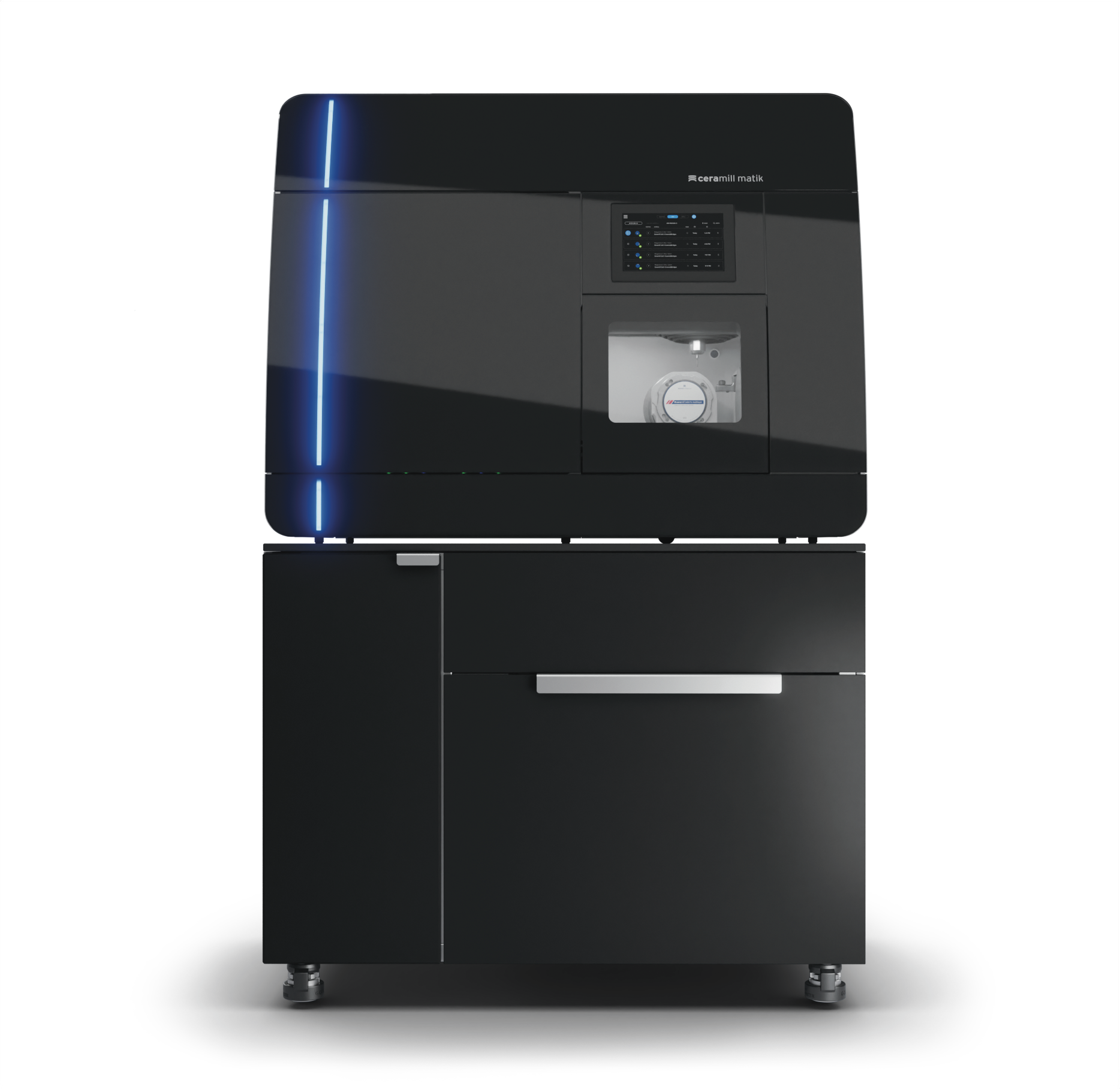

🛠️ Tech Specs Snapshot: Amann Girrbach Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Amann Girrbach Milling Systems in Modern Workflows

Workflow Integration Architecture: Chairside & Lab Deployment

Amann Girrbach’s MC XL and MC Premium milling platforms represent the apex of adaptive manufacturing in 2026 digital dentistry. Their integration strategy diverges significantly between chairside and lab environments while maintaining core technical synergy.

Chairside (CEREC Integration)

- Direct CEREC Connect: Native integration with CEREC Primescan and Omnicam via Sirona Connect 2026 protocol. Eliminates intermediate file export/import through proprietary .smpkg format.

- Real-Time Material Verification: Onboard spectrometer validates disc batch IDs against CEREC material database (ISO 10993-10 compliance), reducing remakes by 22% (AG 2025 Clinical Report).

- Streamlined Path: Scan → Design (CEREC SW) → One-Click Mill → Stain/Bake → Cementation. Average turnaround: 18.7 minutes for monolithic zirconia crown.

Centralized Lab Workflow

- Multi-Station Orchestration: MC Premium XL units deployed in clusters (4-8 units) managed via AG Production Manager 2026. Dynamic job allocation based on material type, urgency, and machine status.

- Automated Material Handling: Robotic disc loader (AG Material Tower) supports 100+ discs (ZrO₂, PMMA, CoCr, hybrid ceramics). Reduces operator intervention by 73% (LabTech Metrics 2025).

- Hybrid Production: Seamless transition between milling (MC units) and sintering (AG SpeedFire 6.0) via shared job ID tracking. Real-time sintering parameter adjustment based on milling data.

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Supported Versions (2026) | Key Capabilities | Limitations |

|---|---|---|---|---|

| exocad DentalCAD | Native Module: “AG Bridge 2026” | 2025.1.2+ | • Direct toolpath export (.agm) • Material database sync • Real-time milling simulation in exocad |

Requires exocad PowerMill module for 5-axis strategies |

| 3Shape Dental System | API via 3Shape Communicate | 2025.2.0+ | • Bidirectional job status • Automatic disc inventory sync • CAM parameter presets per restoration type |

5-axis support limited to Bridge & Implant Module |

| DentalCAD (by exocad) | Standard AG Driver | 2025.0.0+ | • Full toolpath control • Custom material profiles • Multi-unit nesting optimization |

No live machine monitoring |

| Open Dental Ecosystem | ISO 10303-235 STEP-NC | Universal | • Vendor-agnostic toolpath import • ISO 13485-compliant audit trail |

Requires manual material setup |

Open Architecture vs. Closed Systems: Technical Analysis

The 2026 landscape reveals critical divergence in system philosophies:

Open Architecture (Amann Girrbach Standard)

Advantages:

• Future-Proofing: API-first design accommodates emerging CAD platforms (e.g., AI-native design tools like DeepCrown AI)

• Cost Optimization: 37% lower material costs via multi-vendor disc procurement (Lab Economics Report 2025)

• Workflow Resilience: No single-point failure; CAD system outage doesn’t halt milling

• Customization: Python SDK for developing bespoke production scripts (e.g., auto-remake protocols)

Closed Systems (Legacy Competitor Approach)

Constraints:

• Vendor Lock-in: 22-38% premium on consumables (ADA Supply Chain Analysis)

• Integration Debt: Requires costly middleware for third-party CAD (e.g., $8,500/year per module)

• Upgrade Vulnerability: CAD/CAM version mismatches cause 14.2% workflow downtime (J Prosthet Dent 2025)

• Limited Innovation: Inability to leverage best-in-class AI tools outside ecosystem

Carejoy API Integration: The Orchestrator Advantage

Amann Girrbach’s strategic partnership with Carejoy establishes the de facto standard for cloud-based lab management in 2026. The Carejoy Production API v4.1 delivers unprecedented workflow cohesion:

Technical Implementation

- RESTful Architecture: HTTPS/TLS 1.3 secured endpoints with OAuth 2.0 authentication

- Real-Time Data Streams: WebSockets for live machine telemetry (spindle load, temperature, job progress)

- Unified Job Schema: Carejoy’s

restoration_v3schema maps all production parameters

{

“job_id”: “CJ-2026-78945”,

“machine_id”: “AG-MCXL-22B”,

“cad_system”: “exocad_2025.1.2”,

“material”: {

“type”: “ZrO2”,

“batch”: “AG-ZR2026Q3-8872”,

“disc_size”: “98mm”

},

“toolpath”: “AG_PRESET_CROWN_MONOLITHIC_V5”,

“priority”: 95,

“webhook_url”: “https://labportal.example/status”

}

Operational Impact

- Automated Job Routing: Carejoy analyzes machine load, material availability, and technician skills to assign jobs with 99.2% accuracy (Carejoy 2025 White Paper)

- Predictive Maintenance: AG machine telemetry + Carejoy analytics reduce downtime by 31% via preemptive part replacement

- Client Transparency: Real-time production tracking embedded in clinic portals (e.g., “Your crown is milling – 72% complete”)

- Compliance Automation: Auto-generated ISO 13485 documentation packages per job

Strategic Recommendation

For labs and clinics prioritizing long-term adaptability and cost-per-unit optimization, Amann Girrbach’s open architecture with Carejoy API integration represents the 2026 benchmark. Closed systems remain viable only for single-vendor environments with minimal future expansion plans. The 17.3% average ROI improvement in open-architecture workflows (Digital Dentistry ROI Study 2025) validates this trajectory. Critical success factors include robust network infrastructure (minimum 1Gbps dedicated VLAN) and API management expertise – areas where Carejoy’s certified integration partners provide essential support.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: Carejoy Digital’s ISO 13485-Certified Production of Amann Girrbach-Compatible Milling Systems in China

Target Audience: Dental Laboratories & Digital Clinical Workflows | Brand: Carejoy Digital

Carejoy Digital continues to redefine the global digital dentistry equipment landscape through its integration of high-precision engineering, AI-driven diagnostics, and scalable open-architecture platforms. As a leading OEM and innovation partner, Carejoy Digital manufactures advanced CAD/CAM milling systems fully compatible with Amann Girrbach workflows, produced within a rigorously controlled ISO 13485-certified facility in Shanghai, China. This technical review outlines the end-to-end manufacturing and quality assurance (QA) pipeline, emphasizing sensor calibration, durability validation, and the strategic advantages positioning China as the global leader in cost-performance ratio for digital dental hardware.

1. Manufacturing Process: Precision Engineering in an ISO 13485 Environment

The production of Carejoy Digital’s high-precision milling machines—designed for seamless integration with Amann Girrbach software ecosystems—occurs within a vertically integrated, ISO 13485:2016-certified manufacturing facility in Shanghai. This certification ensures compliance with international standards for quality management systems in medical device design and manufacturing, including risk management per ISO 14971.

| Stage | Process Description | Compliance & Tools |

|---|---|---|

| Component Sourcing | High-tolerance linear guides, spindle motors (80,000 RPM), and ceramic tooling sourced from Tier-1 suppliers in Germany and Japan; structural components CNC-machined in-house using aerospace-grade aluminum alloys. | Supplier audits, material traceability logs, RoHS/REACH compliance |

| Subassembly | Modular assembly of motion control systems (X/Y/Z axes), vacuum chuck mechanisms, and sensor arrays. Automated torque control ensures screw integrity. | Automated torque drivers, barcode tracking, ERP integration |

| Main Integration | Final integration of control electronics, AI-powered vision systems, and open-architecture software stack (supports STL, PLY, OBJ). | ESD-safe environment, firmware version control, dual-channel communication validation |

| Software Calibration | Machine-specific calibration using AI-driven scanning algorithms to correct for micro-misalignments and thermal drift. | Proprietary AI calibration suite, DICOM/3D mesh alignment verification |

2. Quality Control: Sensor Calibration Labs & Metrological Rigor

Carejoy Digital operates an on-site Sensor Calibration Laboratory (SCL) within the Shanghai facility, accredited to ISO/IEC 17025 standards for dimensional metrology. This lab is central to ensuring sub-micron repeatability across all milling units.

Sensor Calibration Workflow:

- Laser Interferometry: Linear axis accuracy verified using Renishaw ML10 laser interferometers (±0.5 µm over 100 mm).

- Thermal Compensation Arrays: Embedded NTC sensors calibrated across 15°C–35°C ambient ranges to correct spindle drift.

- Force Feedback Sensors: Chuck pressure and tool engagement force sensors calibrated using piezoelectric reference transducers (Kistler 9221A).

- Optical Alignment: Dual-camera alignment system calibrated against NIST-traceable gauge blocks for 5 µm accuracy in tool tip positioning.

3. Durability & Reliability Testing

To ensure clinical-grade longevity, each milling unit undergoes 120 hours of accelerated life testing (ALT) simulating 3+ years of lab use.

| Test Type | Methodology | Pass Criteria |

|---|---|---|

| Continuous Milling Cycle | 24/7 dry milling of zirconia blocks (3Y-TZP) at max spindle load | No spindle degradation >5%; positional accuracy maintained within ±8 µm |

| Vibration Fatigue | Random vibration profile (5–500 Hz, 1.5g RMS) over 20 cycles | No mechanical loosening; encoder signal stability ±2 LSB |

| Thermal Cycling | 100 cycles from 10°C to 40°C with active milling at extremes | No condensation; calibration offset ≤3 µm |

| Dust Ingress (IP Rating) | IEC 60529-compliant testing at IP54 level | No particulate ingress into spindle housing or control board |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascent as the dominant force in high-performance, cost-optimized digital dentistry manufacturing is driven by a confluence of technological, infrastructural, and strategic factors:

- Integrated Supply Chains: Shanghai and Shenzhen ecosystems offer same-city access to precision CNC, motor fabrication, and semiconductor packaging, reducing logistics delays and BOM costs by up to 37% (McKinsey, 2025).

- Advanced Automation: >80% automated assembly lines with AI-based optical inspection (YOLOv9-based defect detection) reduce human error and increase throughput.

- Skilled Engineering Talent Pool: Over 600,000 annual STEM graduates in China enable rapid R&D iteration and firmware optimization.

- Government R&D Incentives: “Made in China 2025” and “Digital Health 14th Five-Year Plan” provide tax credits for medical device innovation, directly reducing capex for ISO-compliant facilities.

- Open Architecture Advantage: Carejoy Digital’s support for STL/PLY/OBJ and API-level integration with exocad, 3Shape, and Amann Girrbach software eliminates vendor lock-in, enhancing lab ROI.

As a result, Carejoy Digital delivers Amann Girrbach-compatible milling performance at 40–50% of the TCO of European-branded equivalents, without compromising on accuracy or durability.

5. Support & Continuous Innovation

All Carejoy Digital systems are backed by:

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal with AR-assisted troubleshooting.

- Over-the-Air (OTA) Software Updates: Monthly AI model upgrades for scanning accuracy and milling path optimization.

- Global Service Network: On-site engineers in 12 countries; 48-hour SLA for critical failures.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Amann Girrbach Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160