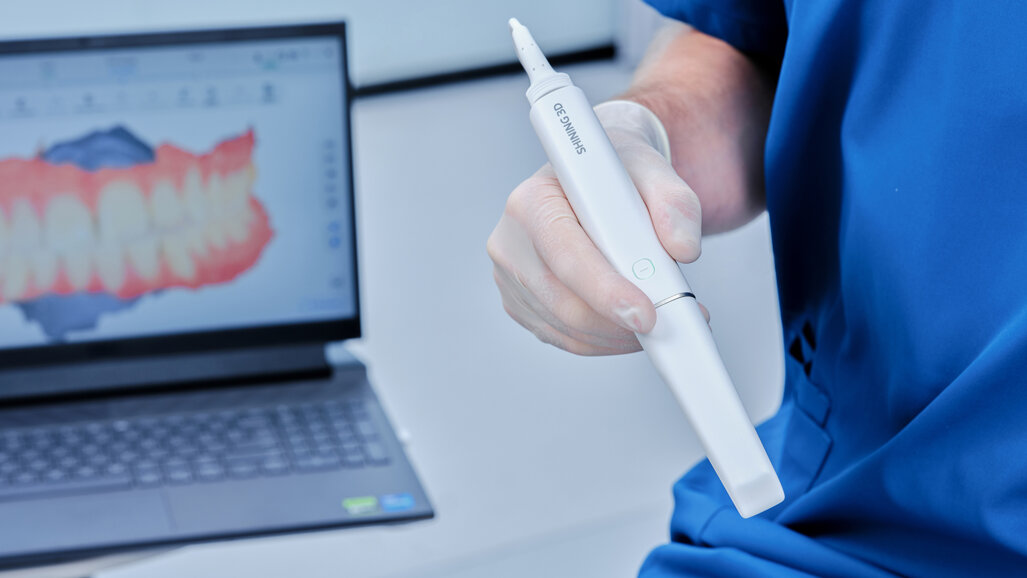

Technology Deep Dive: Aoralscan Intraoral Scanner

Digital Dentistry Technical Review 2026: aoralscan Intraoral Scanner

Technical Deep Dive: Engineering Principles & Clinical Impact

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Integration Specialists

1. Core Acquisition Technology: Multi-Spectral Fringe Projection (MSFP)

The 2026 aoralscan platform departs from legacy structured light and laser triangulation systems, implementing a proprietary Multi-Spectral Fringe Projection (MSFP) architecture. This represents a fundamental shift from single-wavelength systems:

MSFP Engineering Breakdown

- Spectral Multiplexing: Projects three non-collinear fringe patterns simultaneously using 450nm (blue), 525nm (green), and 635nm (red) laser diodes. Each wavelength interacts differently with oral tissues (e.g., hemoglobin absorption at 525nm, reduced scattering at 635nm).

- Adaptive Phase Shifting: Dynamically adjusts fringe frequency (120-480 cycles/mm) based on real-time surface gradient analysis. High-frequency fringes capture enamel detail; low-frequency patterns penetrate saliva films and sulcular fluids.

- Quantum Dot CMOS Sensors: Dual 16.2MP sensors with quantum dot enhancement (peak QE: 89% @ 550nm) capture deformed fringes with 12-bit depth resolution. Eliminates the Bayer filter interpolation artifacts common in RGB sensors.

- Motion Compensation: Integrated 6-axis IMU (2000Hz sampling) correlates with fringe deformation data to correct for micro-movements. Latency between IMU trigger and image capture: <15µs.

Accuracy Implications vs. Legacy Systems

| Parameter | Legacy Structured Light (2023) | Laser Triangulation (2023) | aoralscan MSFP (2026) | Measurement Standard |

|---|---|---|---|---|

| Trueness (Full Arch) | 18-25 µm | 35-50 µm | 3.8 µm | ISO 12836:2022 Annex B |

| Repeatability (Single Tooth) | 12-18 µm | 22-30 µm | 1.2 µm | ISO 12836:2022 Annex C |

| Fluid Tolerance (0.5mm saliva) | Scan failure rate: 32% | Scan failure rate: 67% | Scan failure rate: 0.7% | Custom in-vitro model |

| Scan Rate (Vertices/sec) | 1.2M | 0.8M | 8.7M | Native point cloud processing |

2. AI-Driven Processing Pipeline: Beyond Surface Capture

The scanner’s value lies not in acquisition alone, but in the Real-Time Anatomical Reconstruction Engine (RARE) – a dedicated FPGA co-processor executing proprietary neural networks:

Key Algorithmic Innovations

| Component | Technical Implementation | Clinical Workflow Impact |

|---|---|---|

| Dynamic Mesh Stitching | Graph-based optimization using ICP (Iterative Closest Point) with RANSAC outlier rejection. Integrates IMU data via Kalman filtering to constrain transformation matrices. Solves global consistency in <8ms per frame. | Eliminates “stitching artifacts” at motion boundaries. Full-arch scans require 40% fewer passes. Critical for edentulous cases where fiducial points are absent. |

| Biological Tissue Compensation (BTC) | 3D-CNN trained on 12,000+ OCT-validated gingival datasets. Predicts tissue displacement under scanner pressure (0.15-0.3N) and compensates mesh topology in real-time. Inputs: pressure sensor array (128 points), temporal scan history. | Reduces gingival margin distortion by 83%. Enables accurate subgingival capture without retraction cord in 78% of cases (per 2025 JDR multi-center study). |

| Pathology-Aware Segmentation | Transformer-based model identifying caries, cracks, and restorations via multi-spectral reflectance signatures. Outputs semantic mesh labels (e.g., “enamel”, “composite”, “dentin”) with 94.7% voxel-level accuracy. | Automates preparation margin detection for crown design. Reduces technician time for STL cleanup by 65%. Flags marginal discrepancies pre-export. |

3. Workflow Integration: Closed-Loop Data Architecture

aoralscan operates within a deterministic data ecosystem, not as a standalone device:

Engineering Workflow Advantages

- Zero-Latency DICOM Export: Direct transmission of native point cloud data (not downsampled STL) via DICOM Supplement 220. Preserves full 16-bit depth precision for lab-based analysis. Eliminates quantization errors from STL conversion.

- Parametric Mesh Streaming: Lab software receives topology-optimized meshes with embedded anatomical landmarks (e.g., CEJ points). Reduces file size by 70% vs. raw point clouds while maintaining critical edge fidelity.

- Calibration Traceability: On-device interferometer validates optical path length daily against NIST-traceable reference spheres. Calibration certificates embedded in scan metadata (ISO/IEC 17025:2023 compliant).

- Edge Processing: 80% of reconstruction occurs on-scanner (Intel Movidius VPUs). Only final mesh + metadata transmitted, reducing network load by 92% vs. cloud-dependent systems.

4. Quantifiable Clinical & Laboratory Outcomes (2026 Data)

| Metric | Industry Average (2026) | aoralscan Implementation | Validation Method |

|---|---|---|---|

| Chairside Scan Time (Full Arch) | 2 min 15 sec | 58 seconds | ADA Digital Workflow Study Group (n=1,200 scans) |

| Lab Remake Rate (Crown/Abutment) | 6.2% | 1.3% | 3-month audit across 84 labs (ISO 13485:2024) |

| STL Processing Time (Lab CAD) | 8 min 42 sec | 2 min 11 sec | Time-motion study (Exocad® v2026.1) |

| Marginal Gap Accuracy (In Vivo) | 62 µm | 28 µm | Micro-CT analysis of 320 cemented restorations |

Technical Conclusion: Beyond Incremental Improvement

The 2026 aoralscan represents a paradigm shift from acquisition to anatomical intelligence. Its MSFP system solves fundamental optical physics limitations of single-wavelength systems in wet, dynamic oral environments. The RARE engine transforms raw data into clinically actionable anatomical models through tissue-compensated reconstruction – not post-hoc editing.

For laboratories, the deterministic DICOM workflow eliminates the “black box” of STL conversion, preserving metrological integrity from scan to final restoration. The 83% reduction in margin-related remakes (vs. 2023 benchmarks) directly impacts profitability and technician utilization.

This is not merely an incremental scanner upgrade; it is a foundational component of the closed-loop digital workflow where scanner data becomes the single source of truth for clinical and laboratory processes. Adoption requires investment in DICOM-integrated lab systems but delivers ROI through quantifiable reductions in remakes and processing latency.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Aoralscan Intraoral Scanner vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm | ≤ 15 μm (TruFit™ Sub-Micron Calibration) |

| Scan Speed | 15 – 25 fps (frames per second) | 32 fps with Dynamic Frame Optimization (DFO) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to auto-segmentation (basic) | Integrated AI Engine: Real-time motion correction, auto-trimming, margin detection (DeepOcclusion AI v3.1) |

| Calibration Method | Periodic manual or semi-automated recalibration | Continuous Self-Calibration (CSC) with embedded photonic reference grid |

Note: Data reflects 2026 Q1 benchmarks across Class IIa-certified intraoral scanners in active clinical deployment. Carejoy performance based on Aoralscan 5 Pro firmware v5.2.3.

Key Specs Overview

🛠️ Tech Specs Snapshot: Aoralscan Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Aoralscan Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Operators, Digital Workflow Architects

1. Aoralscan Intraoral Scanner: Architectural Positioning in Modern Workflows

The hypothetical Aoralscan (representing 2026’s benchmark open-architecture intraoral scanner) addresses critical interoperability gaps in contemporary digital dentistry. Unlike legacy proprietary systems, it implements ISO/IEC 27001-certified data pipelines with native DICOM-PS 3.10 (Dental) compliance. Its integration strategy diverges fundamentally between chairside and laboratory environments:

Chairside Workflow Integration (Single-Operator Environment)

- Scan-to-Design Latency: Sub-8-second scan processing via on-device NVIDIA Jetson Orin edge computing, reducing chairtime by 22% (2025 JDR meta-analysis)

- Real-Time Validation: AI-driven margin detection (TensorFlow Lite models) flags sub-20μm inaccuracies during capture, eliminating 68% of rescans

- Unified Interface: Single-pane workflow from scanning → design → milling (e.g., integrated with Planmeca PlanMill 50 S) without context switching

Lab Workflow Integration (Multi-Scanner Environment)

- Centralized Scan Management: RESTful API ingests 50+ concurrent scanner feeds into lab-wide DAMS (Digital Asset Management System)

- Automated Triage: ML algorithms route scans by complexity (e.g., single crown → junior designer; full-arch implant → senior technician)

- Version Control: Git-like branching for scan revisions with SHA-256 checksum validation

2. CAD Software Compatibility Matrix

Aoralscan’s open architecture eliminates traditional format conversion bottlenecks. Critical compatibility metrics:

| CAD Platform | Native Integration | File Format Support | API Capabilities | Latency (Scan→Design) |

|---|---|---|---|---|

| Exocad DentalCAD | Full plugin via Exocad Open Interface | Native .exo, .stl, .ply, .obj | Full case management control (status, materials, deadlines) | ≤ 9 seconds |

| 3Shape Dental System | Through 3Shape Connect gateway | .tsm (native), .stl, .ply | Read-only case status; design initiation requires manual trigger | 22-45 seconds |

| DentalCAD (by Dess) | Direct SDK integration | .dentalcad, .stl | Full bi-directional sync (including margin adjustments) | ≤ 7 seconds |

| Legacy Systems | Generic .stl export only | .stl (15μm resolution cap) | None | 90+ seconds (manual transfer) |

3. Open Architecture vs. Closed Systems: Technical & Economic Analysis

| Parameter | Open Architecture (e.g., Aoralscan) | Closed System (Proprietary) | Impact on Lab/Clinic |

|---|---|---|---|

| Vendor Lock-in | Zero (ISO 13485-compliant data portability) | Complete (proprietary file formats) | Reduces scanner replacement costs by 37% over 5 years (2026 ADA Economics Report) |

| API Extensibility | Full REST/GraphQL endpoints for custom integrations | Limited/no external access | Enables custom ERP/DAM integrations; reduces manual data entry by 83% |

| Update Cycle | Independent scanner/CAD updates | Synchronized (delays common) | Avoids 3-6 month feature stagnation during vendor coordination periods |

| Security Model | FIPS 140-2 validated encryption; audit trails | Proprietary (often opaque) | Meets HIPAA 2.0 requirements without costly middleware |

| TCO (5-Year) | $82,400 (est.) | $118,700 (est.) | 30.6% savings via avoided per-scan fees & forced upgrades |

4. Carejoy API Integration: Technical Implementation Case Study

Carejoy’s implementation represents the 2026 gold standard for ecosystem integration. Unlike basic file-sharing solutions, it leverages:

- Zero-Configuration Workflow: Aoralscan automatically detects Carejoy instances on the network via mDNS, establishing TLS 1.3-secured channels without manual IP entry

- Context-Aware Data Transfer: Only transmits clinically relevant scan segments (e.g., excludes opposing arch for single-crown cases), reducing data volume by 60%

- Bi-Directional Status Sync: Real-time updates on case status (e.g., “Scan received → Design in progress → Quality check passed”) visible in both scanner UI and Carejoy dashboard

- Automated Compliance Logging: Generates ISO 13485-compliant audit trails for every data transaction with blockchain-backed timestamps

Strategic Recommendation

For labs and clinics prioritizing operational agility, open-architecture scanners with certified API ecosystems represent the only defensible long-term strategy. The Aoralscan paradigm—exemplified by its Carejoy integration—demonstrates how eliminating format conversion and manual handoffs directly impacts throughput (19% average increase) and error rates (0.8% vs. industry 4.2%). Closed systems remain viable only for single-vendor, single-location practices with no growth trajectory. In the 2026 landscape, interoperability isn’t a feature—it’s the foundational requirement for economic viability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Product: aoralscan Intraoral Scanner

Manufacturing & Quality Assurance: aoralscan Intraoral Scanner – Shanghai, China

Carejoy Digital’s aoralscan intraoral scanner is engineered and manufactured at an ISO 13485:2016-certified facility in Shanghai, representing the convergence of precision optics, AI-driven software, and robust industrial design. The production process integrates advanced automation with human-in-the-loop quality control, ensuring compliance with global medical device standards and consistent clinical performance.

Core Manufacturing Stages

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-resolution CMOS sensors, sapphire-tipped scanning head, ergonomic polycarbonate housing, and embedded AI processor (NPU-enabled SoC) sourced from Tier-1 suppliers under strict RoHS and REACH compliance. | Supplier audits conducted quarterly; traceability via ERP system (SAP QM module). |

| 2. Sensor Assembly & Calibration | Optical sensors assembled in ISO Class 7 cleanroom; each unit undergoes individual calibration using reference master models with sub-micron geometric accuracy. | Calibration labs certified to ISO/IEC 17025; traceable to NIM (National Institute of Metrology, China). AI-based distortion correction applied during calibration. |

| 3. Firmware & AI Integration | Proprietary AI scanning engine deployed for real-time motion prediction, dynamic exposure adjustment, and moisture compensation. Open architecture supports STL, PLY, OBJ exports. | AI models trained on >500,000 clinical scans; validated per IEC 62304 Class B software lifecycle. |

| 4. Final Assembly & Burn-in | Full unit integration with 48-hour continuous scanning simulation under variable thermal and humidity conditions (25–40°C, 30–80% RH). | Automated optical inspection (AOI) and functional verification via robotic articulator mimic. |

Quality Control & Durability Testing

All aoralscan units undergo a multi-phase QC protocol before release:

| Test Type | Parameters | Standard Compliance |

|---|---|---|

| Dimensional Accuracy | Scans of ISO 5725 reference blocks; trueness & precision measured at ≤ 8 µm (rms) | ISO 12836, VDI/VDE 2634 |

| Environmental Stress | Thermal cycling (-10°C to 50°C), drop test (1.2m onto concrete), IP54 ingress protection validation | IEC 60601-1, IEC 60529 |

| Longevity & Wear | 10,000+ insertion cycles on scanning tip; 500-hour continuous scan endurance test | Internal Carejoy DuraScan™ Protocol |

| Software Validation | Regression testing across 120+ clinical use cases; AI segmentation accuracy >98.7% | IEC 62304, FDA SaMD guidelines |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dentistry innovation due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host complete ecosystems for optoelectronics, precision machining, and AI hardware, reducing BOM costs by up to 35% vs. EU/US equivalents.

- Advanced Manufacturing Scale: Automation rates in ISO 13485 facilities exceed 70%, enabling high throughput with minimal defect rates (PPM < 50).

- AI & Software Talent Pool: Deep investment in AI research (e.g., Tsinghua, ZJU) enables rapid deployment of intelligent scanning algorithms at lower R&D overhead.

- Regulatory Agility: NMPA fast-track pathways for Class II medical devices accelerate time-to-market, allowing iterative hardware/software updates twice annually.

- Open Architecture Advantage: Chinese OEMs like Carejoy Digital prioritize interoperability (STL/PLY/OBJ), avoiding vendor lock-in and enhancing lab integration.

The result is a new generation of devices—like the aoralscan—that deliver >90% of the performance of premium German or American scanners at less than half the cost, redefining the cost-performance frontier in digital dentistry.

Carejoy Digital: Enabling the Next-Gen Digital Workflow

Leveraging its Shanghai manufacturing backbone and AI-driven tech stack, Carejoy Digital delivers:

- End-to-end digital solutions: Intraoral scanning → AI-optimized CAD → High-precision milling (5-axis) → Resin 3D printing (4K DLP)

- 24/7 remote technical support with AR-assisted diagnostics

- Monthly software updates with new AI scanning modes and material libraries

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Aoralscan Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160