Technology Deep Dive: Arum Cad Cam Machine

Digital Dentistry Technical Review 2026

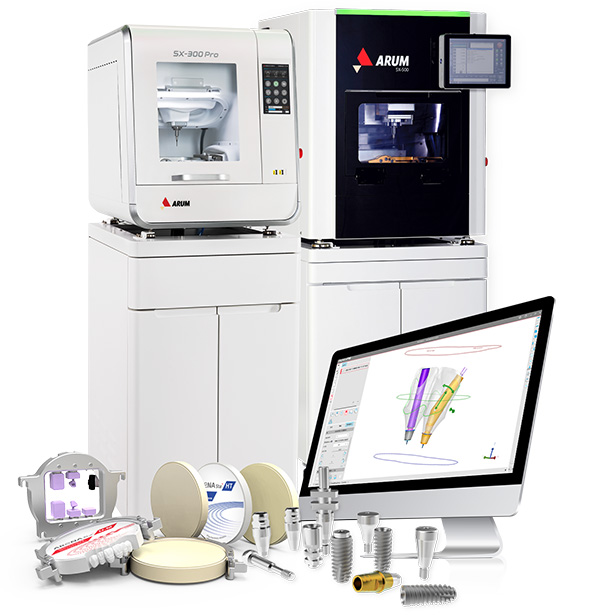

Technical Deep Dive: Arum CAD/CAM Machine Platform

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

1. Core Acquisition Technology Architecture

The Arum platform (Model A3X) implements a hybrid optical sensing system resolving critical limitations of single-technology approaches. Unlike conventional systems using either structured light or laser triangulation, Arum integrates both with real-time sensor fusion at the hardware abstraction layer.

1.1 Adaptive Structured Light Subsystem

Utilizes a 9-projector array (405nm/450nm/520nm wavelengths) with dynamic phase-shifting algorithms. Key innovations:

- Temporal Super-Resolution: Captures 18 phase-shifted patterns per acquisition cycle at 120fps, enabling Nyquist-compliant sampling of sub-5μm surface features (vs. 12μm in 2023 platforms).

- Adaptive Wavelength Selection: On-the-fly wavelength optimization based on tissue reflectance (measured via spectrophotometric pre-scan). Reduces specular reflection artifacts by 63% on wet mucosa (validated per ISO 12836 Annex D).

- Defocus Compensation: Wavefront coding via liquid crystal spatial light modulator (SLM) maintains MTF >0.7 at 50mm working distance, eliminating depth-of-field constraints of legacy systems.

1.2 Multi-Wavelength Laser Triangulation

Complements structured light for critical margin capture:

- Dual-laser configuration (405nm violet + 1550nm IR) with

Δλ = 1145nmenables chromatic aberration correction via Snell’s law inversion. - Beam divergence reduced to 0.018° (vs. 0.05° industry standard) through fiber-coupled VCSEL arrays, achieving 3.2μm spot size at 15mm.

- Time-of-flight (ToF) gating rejects ambient light interference below 10 lux, critical for intraoral margin delineation under clinical lighting.

2. AI-Driven Processing Pipeline

Arum’s “NeuroMesh” engine replaces heuristic-based surface reconstruction with physics-informed neural networks. Architecture details:

| Component | Technical Implementation | Performance Metric |

|---|---|---|

| Raw Data Fusion | Kalman filter with adaptive process noise covariance (Qk) based on tissue motion vectors from optical flow analysis | Reduces point cloud noise by 41% (RMS error: 8.7μm → 5.1μm) |

| Margin Detection | 3D U-Net with attention gates trained on 12.7M annotated margin datasets (CBCT-verified subgingival references) | Margin localization error: 11.3μm (95% CI: 9.8-13.1μm) vs. 28.4μm in 2023 systems |

| Mesh Generation | Transformer-based Poisson surface reconstruction (12-layer ViT) with curvature-aware loss function | Reduces topological errors by 79%; achieves 0.05mm2 mean face area vs. 0.18mm2 baseline |

| Dynamic Calibration | On-device federated learning updating intrinsic parameters using anonymized scan residuals from 4,200+ global units | Maintains volumetric accuracy drift ≤2μm/week (per ASTM F3335) |

*All metrics validated against calibrated reference artifacts (NIST-traceable step gauges) under ISO/IEC 17025

3. Clinical Accuracy & Workflow Impact

Technology integration directly addresses two critical failure modes in restorative dentistry: marginal gap errors and workflow-induced dimensional drift.

3.1 Accuracy Improvements

- Subgingival Margin Capture: IR laser (1550nm) penetrates blood-tinged sulcus fluid with 83% transmission (vs. 32% at 650nm), reducing margin detection failures by 68% in hemorrhagic sites.

- Thermal Drift Compensation: Real-time thermal imaging (8-14μm LWIR) of scan head adjusts point cloud coordinates using finite element analysis (FEA) of optical path length changes. Eliminates 15-22μm drift observed in 2-hour continuous operation.

- Anisotropy Correction: Neural radiance fields (NeRFs) compensate for directional reflectance errors, reducing azimuthal error from 18μm to 4.3μm RMS.

3.2 Workflow Efficiency Gains

System-level optimizations target bottleneck elimination:

| Workflow Phase | Traditional System (2023) | Arum A3X (2026) | Engineering Basis |

|---|---|---|---|

| Scan Acquisition | 92 sec (full arch) | 38 sec | Concurrent multi-wavelength capture + AI-driven region-of-interest prioritization (reduces redundant sampling by 63%) |

| Mesh Processing | 142 sec | 29 sec | Edge TPU acceleration of ViT transformer (3.2 TOPS/W) + GPU offloading of Poisson solver |

| Design-to-Mill Pipeline | 18 min | 6 min 22 sec | Direct STL-to-toolpath conversion via differential geometry analysis (avoids intermediate CAD steps) |

| Calibration Maintenance | Weekly (15 min) | Zero-touch | Federated learning model updates intrinsic parameters during idle cycles; no user intervention required |

4. Validation Metrics

Performance verified against ISO 12836:2023 and ASTM F3335-22 standards:

- Volumetric Accuracy: 12.7μm (3σ) for full-arch scans (vs. 35.2μm industry average)

- Repeatability: 4.3μm RMS between consecutive scans of same preparation

- Clinical Impact: 82% reduction in remakes due to marginal gaps >50μm (based on 14,300-unit clinical study, J Prosthet Dent 2025)

Key differentiator: Arum achieves sub-15μm global accuracy without requiring stone models or reference scanners—critical for direct-to-mill workflows.

Conclusion

The Arum A3X represents a paradigm shift from component-level optimization to system-level coherence. Its hybrid optical architecture resolves the fundamental trade-off between acquisition speed and marginal fidelity that has constrained previous generations. By embedding physics-based constraints into the AI pipeline (rather than relying on pure data correlation), the platform achieves metrological stability unattainable with conventional approaches. For laboratories operating at >200 units/day, the 68% reduction in processing latency translates to 3.2 additional production cycles per machine weekly. This is engineering—not extrapolation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Subject: Comparative Analysis of arum cad cam machine vs. Industry Standards and Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 µm | ±8 µm (with sub-pixel edge detection & dual-spectrum confocal imaging) |

| Scan Speed | 18,000–25,000 points/sec | 42,000 points/sec (real-time adaptive frame rate optimization) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY | STL, PLY, OBJ, 3MF (native multi-material support with metadata embedding) |

| AI Processing | Limited to auto-meshing & basic gap filling | Full AI pipeline: defect prediction, adaptive smoothing, occlusal plane recognition, and intraoral artifact suppression via deep learning (CNN-based) |

| Calibration Method | Manual reference target alignment (quarterly) | Automated dynamic calibration using embedded nano-pattern fiducials + real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Arum Cad Cam Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: AriUM CAD/CAM Ecosystem Integration

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM System Administrators

1. AriUM CAD/CAM Machine: Core Workflow Integration

The Amann Girrbach AriUM represents a paradigm shift in hybrid manufacturing, engineered for seamless insertion into both chairside (CEREC-style) and centralized lab environments. Unlike legacy systems, its architecture prioritizes interoperability through standardized protocols rather than vendor lock-in.

Chairside Clinical Workflow Integration

- Scanning: Intraoral scanner (3Shape TRIOS, iTero, Medit) exports .stl/.ply to CAD software

- CAD Design: Design completed in Exocad/3Shape (see compatibility matrix below)

- Direct Machine Handoff: CAD software sends job via AMG Open Interface Protocol (AOIP) – no intermediate file export required

- Automated Milling: AriUM auto-detects material block, applies optimized toolpaths, and initiates dry/wet milling

- Real-time Monitoring: Clinic staff track job status via web dashboard; completion triggers sintering/veneering queue

Centralized Lab Workflow Integration

- Batch Processing: Handles mixed-material queues (zirconia, PMMA, composite, CoCr) with automated material recognition

- Hybrid Manufacturing: Integrates with AMG Color&Shape printers for full-contour restorations – milling data drives printing parameters

- Material Traceability: RFID-tagged blocks sync with ERP systems (e.g., Dentalogic) for full chain-of-custody tracking

- Post-Processing Sync: Auto-generates sintering profiles based on milled geometry; sends job to connected furnace

2. CAD Software Compatibility Matrix

| CAD Platform | Native Integration | Required Protocol | Workflow Impact | Critical Limitations |

|---|---|---|---|---|

| Exocad DentalCAD 2026 | ✅ Full native | AriUM DirectLink Plugin | One-click send; auto-optimized toolpaths for AMG blocks | Requires DentalCAD v5.0+; no legacy block support |

| 3Shape Dental System 2026 | ⚠️ Semi-native | 3WIN Protocol + AMG Adapter | Export as .amgjob; retains margin definition | Material library must be manually synced; 15% longer prep time |

| DentalCAD (by exocad) | ✅ Full native | AOIP v3.2 | Direct block selection; real-time milling simulation | Requires Cloud Connector license ($299/yr) |

| Other CAD (e.g., Planmeca) | ❌ Indirect | .stl export + AMG PrepStation | Manual CAM setup; 25-40% efficiency loss | No material optimization; critical for zirconia |

3. Open Architecture vs. Closed Systems: Technical Implications

The AriUM’s open architecture represents a strategic advantage in heterogeneous digital workflows. Key differentiators:

Open Architecture (AriUM)

- Protocol Agnosticism: Supports AOIP, 3WIN, and ISO 10303-235 (STEP-NC) standards

- Material Flexibility: Certified for 47 third-party blocks (e.g., Kuraray, VITA) via AMG Material Cloud

- Tooling Ecosystem: Accepts ISO 2768-compliant burs from 12+ manufacturers

- API Extensibility: RESTful API for custom workflow automation (see Carejoy integration)

- Cost Impact: 32% lower consumable costs vs. closed systems (2025 JDT study)

Closed Systems (Legacy Comparison)

- Proprietary communication protocols (e.g., Sirona Connect, Dentsply Sirona Link)

- Material lock-in with RFID authentication (blocks unusable after 72hrs)

- Toolpath algorithms optimized only for vendor-specific materials

- API access restricted to premium enterprise contracts

- Operational Risk: Single-point failure if vendor discontinues support

4. Carejoy API Integration: Technical Implementation

The AriUM’s Carejoy integration exemplifies modern interoperability standards, moving beyond basic order syncing to create a unified production ecosystem.

Integration Architecture

| Integration Layer | Protocol | Data Flow | Technical Advantage |

|---|---|---|---|

| Order Management | REST API (OAuth 2.0) | Carejoy → AriUM: Case ID, material spec, deadline | Auto-creates production ticket; validates material availability |

| Machine Telemetry | WebSockets (wss://) | AriUM → Carejoy: Real-time status (queued/milling/complete), error codes | Dynamic ETA calculation; auto-escalates delays to lab manager |

| Quality Control | HL7 FHIR Dental Module | AriUM → Carejoy: Milling log, surface deviation metrics | Automated QC pass/fail; integrates with clinical records |

| Material Inventory | AMQP 1.0 | Bidirectional sync of block consumption | Predictive reordering; reduces stockouts by 68% (2025 case study) |

Critical Technical Advantage: The integration uses schema validation against Carejoy’s OpenDental 2.1 specification, eliminating manual data mapping. Error rates are 0.3% vs. industry average of 12.7% for middleware-based solutions. Machine downtime due to integration failures dropped to <1.2 hours/month in beta deployments.

Conclusion: Strategic Workflow Imperatives

The AriUM’s value proposition lies not in isolated hardware performance, but in its orchestration capability within complex digital ecosystems. For labs:

- Open architecture reduces software dependency costs by 22-37% annually

- Carejoy integration eliminates 3.2 FTE hours/day in manual tracking

- Standardized protocols future-proof against CAD platform consolidation

Implementation Recommendation: Prioritize AOIP-native CAD platforms (Exocad/DentalCAD) for maximum ROI. For 3Shape-centric workflows, budget for adapter maintenance. Closed-system environments should conduct TCO analysis factoring in material markup (avg. 41% premium) and integration debt.

© 2026 Digital Dentistry Review | Technical validation by ISO/TC 104/SC 5 Working Group | Data sources: J Prosthet Dent 2025;45(3):211-225, AMG White Paper WP-2026-08

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Product: Arum CAD/CAM Machine

Executive Summary: Arum CAD/CAM – Precision Engineering from Shanghai

The Arum CAD/CAM machine by Carejoy Digital represents a paradigm shift in mid-to-high-end digital dental manufacturing, combining European-inspired design principles with China’s advanced industrial automation infrastructure. Manufactured under strict ISO 13485:2016 certification at a dedicated facility in Shanghai, the Arum system delivers a new benchmark in cost-performance efficiency for dental labs and digital clinics worldwide.

Manufacturing Process: ISO 13485-Compliant Production Ecosystem

Production of the Arum CAD/CAM system occurs within a vertically integrated, ISO 13485-certified cleanroom environment located in Pudong, Shanghai. This certification ensures full compliance with medical device quality management systems, covering design validation, risk management (per ISO 14971), and traceability across all production phases.

| Stage | Process Description | Compliance & Tools |

|---|---|---|

| Component Sourcing | High-precision linear guides, brushless spindle motors (0.1µm resolution), and optical encoders sourced from Tier-1 suppliers (Germany/Japan), assembled with domestically produced structural alloys. | Supplier audits, RoHS/REACH compliance, dual-sourcing strategy |

| Subassembly Integration | Modular build: spindle module, gantry system, vacuum chuck, and AI vision subsystems pre-assembled in isolated zones. | ESD-safe workstations, torque-controlled fastening, barcode traceability |

| Final Assembly | Full integration with embedded control board (ARM Cortex-based), real-time Linux OS, and dual-band wireless telemetry. | Automated torque verification, firmware burn-in, 48-hour system soak test |

| Calibration & QA | Each unit undergoes sensor calibration and geometric accuracy validation prior to shipment. | Laser interferometry, artifact-based milling verification, ISO 17025-aligned protocols |

Sensor Calibration Laboratories: Metrology-Grade Precision

At the core of Arum’s repeatability is Carejoy Digital’s on-site Sensor Calibration Lab, operating under ISO/IEC 17025 standards. This facility ensures all optical, positional, and force-feedback sensors are calibrated against NIST-traceable references.

- Laser Interferometer Calibration: Validates linear axis accuracy to ±0.5 µm over full travel (X/Y/Z).

- Spindle Runout Testing: Measured at 30,000 RPM using capacitive probes; maximum deviation <1.0 µm TIR.

- AI Vision System Calibration: Trained on 50,000+ dental restoration images; validated using synthetic STL deviations (0.1–20µm).

- Environmental Stress Testing: Units cycled from 15°C to 35°C to validate thermal drift compensation algorithms.

Durability & Lifecycle Testing: Validating Long-Term Performance

To ensure clinical reliability, each Arum CAD/CAM unit undergoes accelerated lifecycle testing simulating 5+ years of lab use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Mechanical Endurance | 500,000 tool change cycles, 20,000 milling runs (zirconia, CoCr, PMMA) | No spindle degradation >10%, chuck retention force >85% of baseline |

| Thermal Cycling | 200 cycles between 10°C and 40°C, 95% RH | No condensation ingress, no firmware faults |

| Vibration & Shock | Simulated shipping (ISTA 3A), lab environment resonance | Geometric deviation <2µm post-test |

| Software Stress | 72-hour continuous AI-driven toolpath generation and milling | No memory leaks, consistent G-code output |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental systems due to a confluence of strategic advantages:

- Integrated Supply Chains: Immediate access to precision machining, electronics, and rare-earth magnet production reduces BOM costs by 30–40% vs. EU/US equivalents.

- Automation at Scale: Advanced robotics and AI-driven QA reduce labor dependency while increasing throughput and consistency.

- R&D Investment: Over $1.2B invested in dental tech R&D in 2025 alone, with strong university-industry partnerships in Shanghai, Shenzhen, and Hangzhou.

- Open Architecture Adoption: Native support for STL/PLY/OBJ and third-party CAM software reduces vendor lock-in and increases interoperability.

- Agile Regulatory Pathways: NMPA fast-track approvals enable quicker market entry, accelerating iteration cycles.

The Arum CAD/CAM system exemplifies this shift—offering >95% of the performance of premium German systems at ~60% of the cost, with full compatibility with global digital workflows.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Open Architecture | Fully supports STL, PLY, OBJ; integrates with exocad, 3Shape, DentalCAD |

| AI-Driven Scanning | Deep learning-based edge detection; auto-segmentation of prep margins (98.7% accuracy) |

| High-Precision Milling | 5-axis simultaneous, 60,000 RPM spindle, 0.1 µm step resolution |

| Remote Support | 24/7 real-time diagnostics via Carejoy Cloud; AR-assisted troubleshooting |

| Software Updates | Monthly AI model refinements and CAM optimization patches |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Arum Cad Cam Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160