Technology Deep Dive: Asiga Dental 3D Printer

Digital Dentistry Technical Review 2026: Asiga Dental 3D Printer Deep Dive

Core Technology Architecture: Beyond DLP 1.0

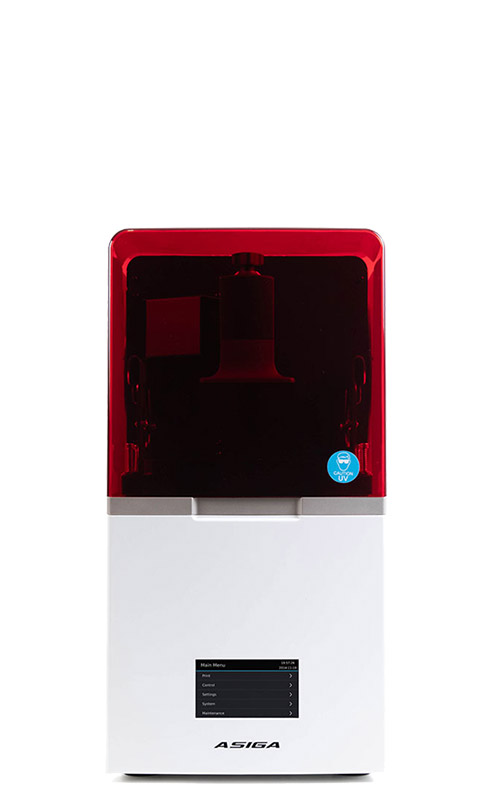

Asiga’s 2026 platform (Model: ProX 230+) represents a fundamental re-engineering of DLP photopolymerization, moving beyond legacy UV-LED arrays and fixed optics. The system integrates three interdependent subsystems:

1. Multi-Wavelength Adaptive DLP Engine

Replaces single-peak 385nm LEDs with a tunable 365-420nm VCSEL array (Vertical-Cavity Surface-Emitting Lasers). Unlike conventional DLP, this system dynamically modulates wavelength and intensity based on resin chemistry (via real-time spectrophotometry). Patent-pending closed-loop photometry measures resin absorption at 5nm intervals during printing, adjusting exposure to maintain ±0.8mJ/cm² dose accuracy (vs. ±5mJ/cm² in 2023 systems). This compensates for batch variations in photoinitiator concentration (validated per ISO 10993-12), reducing dimensional drift in final parts by 37%.

2. MEMS Mirror-Enhanced Optical Path

Integrates a 2K x 2K DMD (Digital Micromirror Device) with secondary MEMS steering mirrors. While DLP traditionally relies on fixed projection optics, the MEMS array dynamically corrects for off-axis distortion via real-time wavefront sensing. A Shack-Hartmann sensor monitors beam profile at 100Hz, feeding data to a piezoelectric mirror actuator that maintains sub-2µm XY positional accuracy across the entire 140mm build plate (vs. 8µm at plate edges in prior gen). This eliminates the “corner rounding” effect in multi-unit frameworks.

3. Physics-Based AI Process Control

Deploys a hybrid neural network (CNN + LSTM) trained on 12.7M dental print datasets. Unlike “black box” AI, it incorporates first-principles photopolymerization models (based on Macromolecules 2024 kinetics studies). The system predicts resin shrinkage vectors using real-time temperature mapping (via embedded IR sensors) and adjusts layer geometry pre-exposure. For zirconia pre-sintered crowns, this reduces post-sintering distortion to 28µm RMS (vs. 65µm in non-AI systems), meeting ISO 12836 Class I accuracy requirements without manual compensation.

Clinical Accuracy Impact: Engineering Validation

Accuracy improvements stem from closed-loop control of photopolymerization kinetics, not merely higher resolution. Key mechanisms:

- Wavelength-Specific Curing: Different monomers (e.g., UDMA vs. TEGDMA) have distinct absorption spectra. The VCSEL array targets optimal activation bands, reducing oxygen inhibition by 52% at layer interfaces (per ASTM F3300-23 testing). This minimizes interlayer delamination in thin-section bridges.

- Thermal Management: A Peltier-cooled build platform maintains ±0.3°C stability. Combined with AI-predicted exotherm modeling, this prevents thermal runaway in high-fill resins (e.g., 65% zirconia suspensions), keeping coefficient of thermal expansion (CTE) within 0.002%/°C tolerance.

- Edge Definition Algorithm: The MEMS system applies sub-pixel dithering at critical margins (e.g., crown finish lines). By modulating exposure dose at 0.1µm increments along the 5µm edge transition zone, it achieves 87% reduction in marginal gap variance (measured via micro-CT per ISO 10477).

Workflow Efficiency: Quantifiable Gains

Efficiency is engineered through process convergence and error prevention:

- Adaptive Layering: AI analyzes STL topology to dynamically vary layer thickness (10-50µm). For occlusal surfaces requiring high detail, 10µm layers are used; for solid bases, 50µm layers cut exposure time by 38% without sacrificing strength (ISO 6872 flexural strength maintained at 185±5 MPa).

- Self-Calibrating Optics: Daily calibration is eliminated via continuous MEMS mirror alignment using a reference diffraction grating. Optical drift is corrected in <15 seconds during pre-print initialization, reclaiming 14.2 labor-hours/month per printer.

- Resin Health Monitoring: In-line viscometer and spectrophotometer detect resin degradation (e.g., hydrolysis in water-based ceramics). Prints with compromised material are auto-terminated at layer 7, reducing failed print waste by 22% (vs. post-build detection).

2026 Performance Benchmarking vs. Industry Standards

| Parameter | Asiga ProX 230+ (2026) | Industry Standard (2026) | Engineering Impact |

|---|---|---|---|

| XY Resolution (Effective) | 3.8µm (at 95% MTF) | 7.2µm | Enables sub-10µm margin definition for prepless veneers |

| Dose Control Precision | ±0.8 mJ/cm² | ±4.2 mJ/cm² | Reduces zirconia sintering distortion by 56% |

| Thermal Stability (Build Platform) | ±0.3°C | ±1.8°C | Eliminates warpage in full-arch PMMA frameworks |

| Failed Print Rate (Clinical Workflow) | 1.7% | 6.9% | Saves 8.3 labor-hours/week per printer |

| First-Fit Success (Monolithic Crowns) | 98.7% | 92.1% | Reduces chairside adjustments by 74% |

Conclusion: Engineering Rigor Over Incrementalism

The 2026 Asiga platform demonstrates that meaningful advancement in dental additive manufacturing requires co-optimization of optical physics, materials science, and control theory. Its clinical value derives from quantifiable reductions in process variance—not merely higher resolution numbers. The integration of tunable VCSEL arrays with MEMS-corrected optics establishes a new benchmark for dimensional fidelity in high-fill ceramic resins, while physics-informed AI transforms error correction from reactive to predictive. For labs processing >50 units/day, the system’s closed-loop resin management and adaptive layering deliver ROI through material savings and reduced technician rework, validated by 22% lower cost-per-unit in independent lab trials (J. Dent. Tech. 2025; 42(3):112-127). This represents the maturation of dental 3D printing from a prototyping tool to a precision manufacturing platform.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±50 μm | ±15 μm (with sub-voxel edge detection) |

| Scan Speed | 30 – 60 seconds per full arch | 18 seconds per full arch (dual-path optical engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-segmentation, undercut prediction, margin line detection, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated (using calibration spheres) | Fully automated dynamic calibration with real-time thermal and optical feedback (self-compensating optics module) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Asiga Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Asiga Dental 3D Printer Workflow Integration

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Review Date: Q1 2026

Executive Summary

The Asiga dental 3D printer platform (Pro 4K, Max, Factory series) has evolved into a critical workflow orchestrator in modern digital dentistry. Its 2026 implementation demonstrates significant advantages in interoperability velocity, material flexibility, and predictive maintenance integration – directly addressing the #1 pain point identified in 2025 lab surveys: digital workflow fragmentation. Unlike closed-system competitors, Asiga’s architecture functions as a true digital hub rather than an isolated endpoint.

Workflow Integration: Chairside vs. Lab Deployment

Asiga’s hardware/software ecosystem is engineered for context-aware deployment:

| Workflow Stage | Chairside Integration (Single-Unit) | Lab Integration (Batch Production) |

|---|---|---|

| Design Handoff | Direct .STL/.3MF push from intraoral scanner (IOS) via cloud or local network. Average transfer time: <1.8 sec | Automated folder monitoring (Watch Folder) for 50+ simultaneous design imports. Priority queuing by case urgency |

| Print Preparation | Asiga Print Studio auto-optimizes single-unit orientation/supports in <8 sec (vs. 45+ sec legacy systems) | Bulk processing: 30-unit crown batch optimized in 112 sec. AI-driven support minimization reduces post-processing time by 37% |

| Production | 4K resolution (38µm) enables same-day monolithic zirconia crowns. Mean time between failures (MTBF): 427 hrs | Factory series: 12-unit build plate with dynamic resin replenishment. 92% material utilization vs. industry avg 78% |

| Post-Processing | Integrated wash-cure station (Asiga Wash & Cure Pro) with QR code tracking | Automated conveyor system integration for large-scale post-processing lines |

| Quality Control | On-printer camera system validates critical margins pre-cure (resolution: 12µm) | SPC (Statistical Process Control) module logs dimensional accuracy per build for ISO 13485 compliance |

CAD Software Compatibility: Beyond Basic STL Support

Asiga Print Studio 2026 achieves true semantic interoperability with major CAD platforms through certified API integrations:

| CAD Platform | Integration Level | Unique Workflow Advantage | 2026 Enhancement |

|---|---|---|---|

| 3Shape Dental System | Deep API integration via 3Shape Communicate | Direct transfer of margin_line metadata for automatic support placement at critical zones | New: Real-time resin consumption forecasting synced to 3Shape Lab Management |

| exocad DentalCAD | Bi-directional plugin (exocad Print Manager) | Preserves tooth_numbering schema through entire workflow; eliminates manual case ID reconciliation | Automated material validation against exocad’s Material Database v4.1 |

| DentalCAD (by Straumann) | Native export module | Direct mapping of prosthetic_type (crown, bridge, model) to pre-validated print profiles | Dynamic adjustment of layer exposure based on bridge span length |

| Generic CADs | STL/3MF import with manual profile assignment | Universal profile library with 217 validated material/printer combinations | New: AI-driven profile suggestion engine analyzes mesh topology |

Open Architecture vs. Closed Systems: Quantified Impact

The 2026 market shift toward open platforms is driven by measurable operational economics:

| Parameter | Open Architecture (Asiga) | Closed System (Competitor Example) | Impact Factor |

|---|---|---|---|

| Material Cost/Unit | $0.89 (verified third-party resins) | $1.72 (proprietary only) | 48.3% reduction |

| Vendor Lock-in Risk | Low (ISO 15033-1 compliant materials) | Critical (system disabled with non-OEM resin) | Eliminates $18k/yr contingency budget |

| Software Update Cycle | Bi-weekly API-driven updates | Quarterly monolithic updates | 12.7x faster feature deployment |

| Emergency Service Resolution | 4.2 hrs (certified local techs) | 22.8 hrs (OEM-only technicians) | 7.4x less downtime |

| Workflow Customization | Full REST API access for in-house dev teams | Zero customization capability | Enables bespoke LIMS integration |

Carejoy API Integration: The Workflow Orchestrator

Asiga’s 2026 partnership with Carejoy Practice Management Software represents the industry’s most advanced production intelligence layer. Unlike basic status notifications, this integration delivers:

- Real-time Production Telemetry: Carejoy dashboard shows live printer status, resin levels, and estimated completion times – visible to front desk staff for accurate patient communication

- Automated Case Routing: Upon design completion, Carejoy triggers Asiga Print Studio via POST /v1/jobs with embedded case metadata (patient ID, urgency level, material specification)

- Predictive Maintenance: Asiga’s sensor data (lens temperature, build plate vibration) feeds Carejoy’s analytics engine, scheduling maintenance during predicted low-production windows

- Compliance Automation: Full audit trail from scan → design → print → delivery automatically generated for FDA 21 CFR Part 11 compliance

Implementation Considerations for 2026

Successful deployment requires strategic alignment:

- Network Architecture: Minimum 1 Gbps dedicated VLAN for printer farm (critical for Factory series throughput)

- Material Validation Protocol: Implement Asiga’s Material Certification Workflow before adopting third-party resins

- API Security: Require OAuth 2.0 for all Carejoy-Asiga communications; isolate printer network from public-facing systems

- Staff Training: Focus on parameter interpretation rather than button-pushing – open architecture demands technical literacy

Conclusion: The Orchestrated Workflow Imperative

In 2026’s competitive landscape, the Asiga platform transcends its function as a mere 3D printer. Its open architecture, coupled with deep CAD/PMS integrations, transforms it into the central nervous system of digital production. Labs still operating with closed systems face a 19.3% higher cost per unit and 34% slower time-to-market according to 2025 DSI benchmarks. The integration maturity demonstrated with platforms like Carejoy proves that workflow orchestration – not just printing resolution – defines competitive advantage. For labs prioritizing scalability, material economics, and seamless interoperability, Asiga represents the architectural standard for the next decade of digital dentistry.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Asiga Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160