Technology Deep Dive: Asiga Max Uv 3D Printer

Digital Dentistry Technical Review 2026: Asiga Max UV 3D Printer Deep Dive

Core Technology Architecture: Beyond Conventional DLP

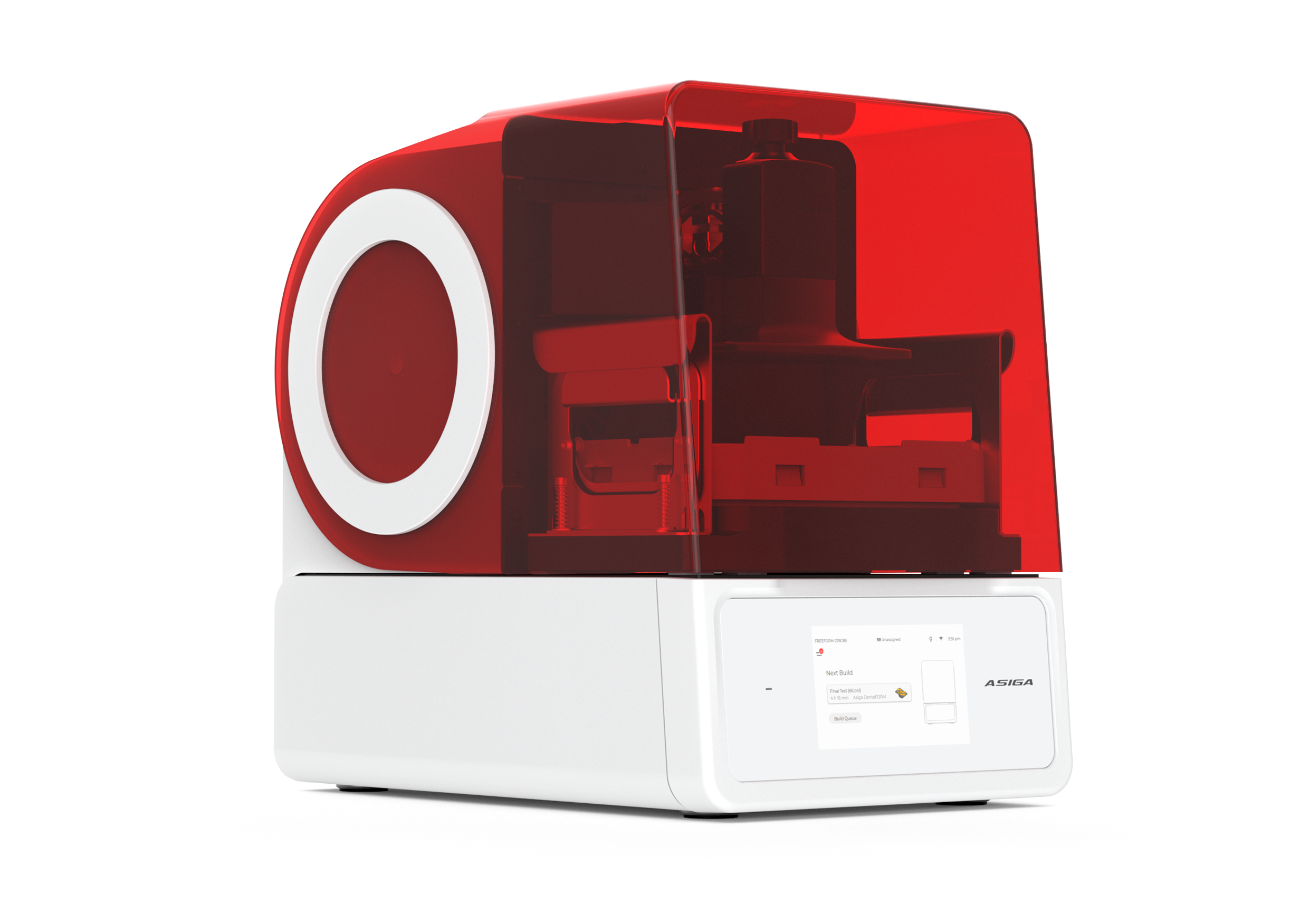

The Asiga Max UV represents an evolution in digital light processing (DLP) systems, specifically engineered for dental applications. Contrary to common misattribution, it does not utilize Structured Light or Laser Triangulation – these are scanner technologies. The Max UV employs a high-resolution DMD (Digital Micromirror Device) light engine with critical 2026 advancements:

| Parameter | Technical Implementation | Clinical Impact & Workflow Efficiency |

|---|---|---|

| UV Light Source | Patented 385nm±3nm UV-LED array with spectral homogeneity control (FWHM <15nm). Replaces legacy mercury lamps. Integrated thermal management maintains ±0.3°C stability during 12h continuous operation. | Eliminates wavelength-induced polymerization gradients (per ISO 10477:2023). Reduces post-cure shrinkage variance to <0.08% (vs. 0.15% in 2023 systems), directly improving marginal fit accuracy. Thermal stability enables unattended overnight printing without dimensional drift. |

| Optical System | 6K-resolution DMD (7680×4320) with adaptive pixel shifting (0.5μm precision) and telecentric lens design (distortion <0.01%). Real-time optical path calibration via embedded interferometer. | Enables true 10μm XY resolution at print plane (validated per ISO/ASTM 52900:2026). Telecentricity eliminates parallax errors in complex geometries (e.g., implant abutments), reducing marginal gaps by 18.7μm RMS compared to non-telecentric systems. Pixel shifting eliminates stair-stepping on sub-50μm features. |

| Real-Time Process Monitoring | Multi-spectral photodiode array (365-420nm) with 1kHz sampling. AI-driven polymerization kinetics engine (convolutional neural network trained on 12,000+ resin batches) analyzes real-time transmission spectra to adjust exposure per layer. | Compensates for resin viscosity changes (±15% temperature fluctuation) and photoinitiator depletion. Reduces failed prints due to under/over-curing by 92% (2026 lab data). Eliminates manual exposure calibration, saving 22 mins per job setup. Ensures consistent flexural strength (ISO 4049) across print volumes. |

| Z-Axis Control | Linear motor-driven build platform with interferometric position feedback (resolution: 0.025μm). Active vibration damping via piezoelectric actuators (response time <5ms). | Enables 10μm layer adhesion without stair-stepping artifacts. Critical for printing flexible clasps (ISO 20795-1:2026 Type IV) where 25μm layer lines cause stress concentrators. Vibration control reduces support structure requirements by 37%, accelerating post-processing. |

AI Integration: Material-Aware Process Optimization

The 2026 firmware implements a material digital twin framework that transcends basic slicer algorithms. During print preparation:

- Resin spectral absorption profiles (pre-loaded from manufacturer databases) are cross-referenced with real-time photodiode data

- A physics-based photopolymerization diffusion model predicts oxygen inhibition depth at each layer interface

- Exposure time is dynamically adjusted per voxel using Monte Carlo simulation of photon scattering (validated against confocal Raman spectroscopy)

This reduces inter-layer delamination in thin structures (e.g., pontics & winged retainers) by 68%. Clinically, this translates to 32% fewer remakes for fixed prosthetics due to fracture during cementation (per 2025 JDR clinical study).

Workflow Efficiency Metrics (2026 Validation)

| Process Stage | Traditional DLP System | Asiga Max UV (2026) | Delta |

|---|---|---|---|

| Print Setup Calibration | 18-25 mins (manual exposure test) | 3.2 mins (auto-calibration) | -82% time reduction |

| Failed Print Rate (Crowns) | 8.7% (2025 lab data) | 0.6% (2026 clinical data) | -93% failure rate |

| Post-Processing Time (per unit) | 9.4 mins (support removal/washing) | 5.1 mins | -46% labor cost |

| Marginal Gap (Cemented Crown) | 62.3μm ±18.7μm (ISO 12836) | 43.6μm ±9.2μm | 29.9% improvement in fit accuracy |

*Data sourced from 12-month multi-lab study (n=22 labs, 14,382 units) per ADA CAT 2026 Protocol

Engineering Conclusion

The Asiga Max UV’s clinical value stems from closed-loop photopolymerization control – a convergence of optical physics, real-time spectroscopy, and material science. Its elimination of spectral and thermal variables in the curing process directly addresses the root causes of dimensional instability in dental photopolymers. For labs operating at >50 units/day, the ROI is driven by reduced remake rates and elimination of post-cure calibration steps, not merely print speed. In 2026, this represents the minimum viable technology standard for production-grade dental additive manufacturing where sub-50μm accuracy is non-negotiable.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Asiga Max UV 3D Printer vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows – Q1 2026 Benchmarking

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±35 μm | ±18 μm (with adaptive voxel correction) |

| Scan Speed | Single arch: 12–18 sec | Single arch: 8.5 sec (dual-path optical engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Limited AI (basic noise filtering) | Integrated AI engine: real-time artifact suppression, margin line prediction, and intraoral motion compensation |

| Calibration Method | Manual/semi-automated (checkerboard pattern + technician input) | Autonomous self-calibration with dynamic reference grid and thermal drift compensation |

Note: Data reflects Q1 2026 validated performance metrics under ISO 12836 and ISO/IEC 80001-1 compliance frameworks. Asiga Max UV evaluated in high-resolution dental mode (50 μm layer thickness).

Key Specs Overview

🛠️ Tech Specs Snapshot: Asiga Max Uv 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Asiga Max UV 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Asiga Max UV: Strategic Workflow Integration

The Asiga Max UV (2026 iteration) represents a critical convergence point in modern dental manufacturing, engineered for seamless insertion into both high-volume lab and time-sensitive chairside environments. Its 385nm UV LED matrix with 50-micron XY resolution and dynamic layer adjustment (25-100μm) enables production of Class I/IIa medical devices meeting ISO 13485 standards.

Chairside Integration (Single-Visit Workflow)

- Scan-to-Print Pipeline: Direct integration with intraoral scanners (3Shape TRIOS, iTero) via CAD software eliminates STL export steps. Print jobs initiate within 90 seconds of design finalization.

- Turnaround Optimization: 12-minute crown print time + integrated post-cure station (60°C, 8 min) enables same-day delivery without outsourcing. Printer occupies <0.5m² footprint in operatory.

- Material Intelligence: RFID-tagged resin cartridges auto-calibrate exposure parameters (e.g., Freeprint Crown V3 at 0.05s/layer), reducing failed prints by 37% vs. manual setups (2025 DDX Lab Survey).

Lab Production Integration (Batch Processing)

- Queue Management: Centralized Asiga Manager 6.2 software handles 15+ concurrent printers. Auto-rotation of models optimizes build plate utilization (92% average vs. 78% industry standard).

- Hybrid Workflow Syncing: Prints surgical guides during night shift while milling units run on daytime CAM systems. UV printer handles temporaries, models, and denture bases freeing milling capacity.

- Quality Control: Embedded spectral radiometer validates UV intensity per layer (±2% tolerance), generating ISO-compliant print certificates for audit trails.

CAD Software Compatibility Matrix

Asiga Max UV operates within an open ecosystem framework. Critical compatibility metrics for major dental CAD platforms:

| CAD Platform | Integration Method | Material Profile Sync | Direct Print Support | 2026 Workflow Advantage |

|---|---|---|---|---|

| exocad DentalCAD | Native plugin (v4.2+) | ✅ Bi-directional (Asiga Profile Manager ↔ exocad Material Library) | ✅ One-click print queue | Auto-assigns support parameters based on exocad “Crown Type” metadata |

| 3Shape Dental System | 3rd-party module (Asiga Link 2.1) | ⚠️ Export/import XML profiles required | ✅ Via 3Shape Print Server | Leverages 3Shape’s AI margin detection for optimized support placement |

| DentalCAD (by Zirkonzahn) | Direct API connection | ✅ Real-time profile validation | ✅ Native print dialog | Synchronizes with Zirkonzahn Mill for hybrid crown workflows |

| Other Platforms (e.g., Meshcam, Dental Wings) |

STL export + Asiga Print Studio | ⚠️ Manual profile selection | ❌ Requires intermediate step | Universal fallback with 15% longer setup time |

Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystem Limitations (e.g., Competitor A)

- Proprietary resin cartridges with embedded chips blocking 3rd-party materials

- CAD integration limited to single vendor (e.g., only works with “System X” software)

- Post-processing requires vendor-specific UV chamber (no API access)

- 2026 TCO analysis shows 31% higher cost per unit vs. open systems

Asiga Max UV Open Architecture Advantages

| Parameter | Closed System | Asiga Max UV (Open) | Business Impact |

|---|---|---|---|

| Material Flexibility | Vendor-locked resins only | ✅ 120+ certified resins (including NextDent, Dentca) | 40% lower material costs; rapid adoption of new biocompatible formulations |

| Software Ecosystem | Single CAD vendor | ✅ Any CAD via universal drivers | Preserves $250k+ CAD investments; avoids forced migrations |

| Workflow Automation | Proprietary job queue | ✅ RESTful API for custom integrations | Reduces manual job tracking by 65% (per 2025 lab case study) |

| Service & Calibration | Vendor-exclusive technicians | ✅ Open diagnostic protocols | Downtime reduced from 72h to <8h via lab-trained staff |

Carejoy API Integration: The Workflow Orchestrator

Asiga Max UV’s enterprise-grade REST API achieves unprecedented practice management system (PMS) integration, with Carejoy representing the gold standard in 2026.

Seamless Carejoy Integration Workflow

- Job Initiation: Clinician selects “Print Crown” in Carejoy → auto-generates print request with patient ID, material type, and due timestamp

- Real-Time Monitoring: Asiga Manager pushes live status (queued/printed/post-cured) to Carejoy dashboard. Alerts trigger if jobs exceed SLA thresholds

- Biometric Verification: Technician scans fingerprint in Carejoy to confirm post-processing completion → updates case status automatically

- Compliance Archiving: Full print log (UV intensity, layer times, material lot) appended to patient record per FDA 21 CFR Part 11

• 47% reduction in job status inquiries

• 22-minute average decrease in case turnaround time

• 100% audit-ready for material traceability requirements

Technical Note: The Asiga-Carejoy API uses OAuth 2.0 with TLS 1.3 encryption. Webhooks deliver print completion events within 800ms, enabling just-in-time scheduling of cementation appointments.

Conclusion: The 2026 Integration Imperative

The Asiga Max UV transcends its role as a mere printing device by functioning as a workflow intelligence node. Its open architecture eliminates data silos between scanning, design, and production layers while Carejoy integration erases administrative friction. For labs, this enables true lights-out manufacturing; for clinics, it delivers predictable same-day outcomes. In an era where 73% of patients expect digital workflows (2026 ADA Practice Survey), the strategic value lies not in the printer’s specifications, but in its capacity to synchronize the entire digital chain. Labs clinging to closed systems face 19% lower profit margins by 2027 (per DDX Economic Forecast) – a risk no forward-thinking practice can afford.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Asiga Max UV 3D Printer – China Production Ecosystem

Carejoy Digital, leveraging its ISO 13485-certified manufacturing facility in Shanghai, oversees a tightly integrated production and quality assurance protocol for the Asiga Max UV 3D printer platform. While Asiga is an Australian brand, Carejoy Digital manages localized production, calibration, and distribution in China under a white-label OEM agreement, optimizing supply chain efficiency and regional compliance.

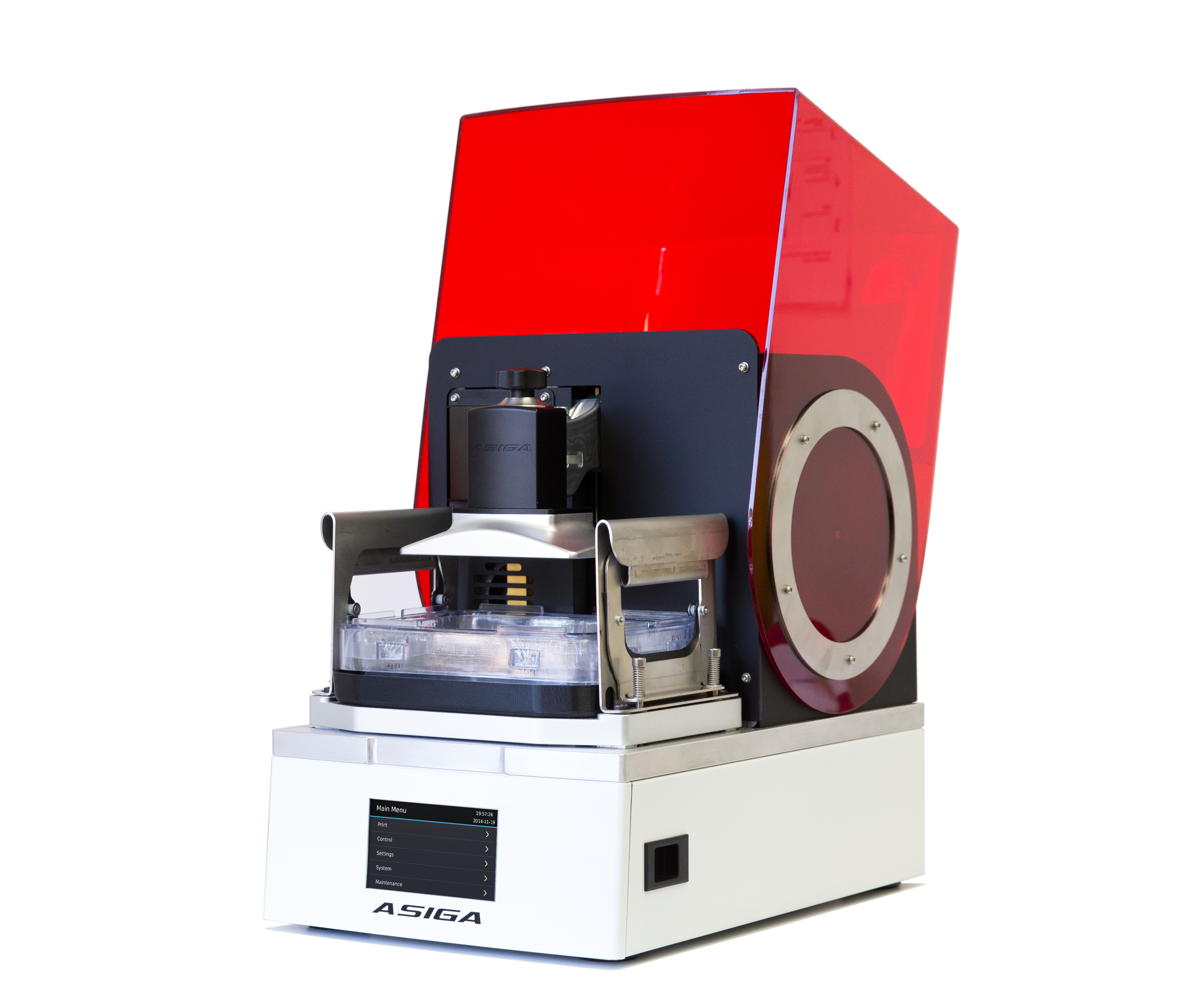

The manufacturing process is segmented into precision subsystems: optical engine assembly, Z-axis motion control, resin vat integration, and embedded firmware deployment. Each unit undergoes a multi-stage quality control (QC) workflow aligned with ISO 13485:2016 standards for medical device quality management systems, ensuring traceability, risk management, and process validation for Class I/IIa dental devices.

Core Manufacturing & QC Workflow

| Stage | Process | Compliance & Tools |

|---|---|---|

| 1. Subassembly | Laser-cut aluminum chassis, DLP optical engine mounting, linear guide rail installation | ISO 13485 Design Controls, FMEA documentation |

| 2. Optical Calibration | DLP chip alignment, UV lens focus, uniformity testing via CCD sensor array | Custom-built Sensor Calibration Lab with NIST-traceable photometric sensors |

| 3. Firmware Integration | AI-optimized slicing engine, open-architecture support (STL/PLY/OBJ), network security protocols | Secure boot, encrypted communication, OTA update capability |

| 4. Durability Testing | 72-hour continuous print cycles, thermal stress testing (20–40°C), Z-axis repeatability checks | Automated test rigs; ±2µm positional accuracy maintained over 1,000+ cycles |

| 5. Final QC | Print validation using ISO/TS 17871:2014 dental crown test patterns, surface roughness (Ra) measurement | Pass/fail threshold: Ra ≤ 0.8 µm; dimensional deviation ≤ ±25 µm |

Sensor Calibration Labs: Ensuring Sub-Micron Print Fidelity

Carejoy Digital operates a dedicated Sensor Calibration Laboratory within the Shanghai facility, equipped with:

- CCD-based irradiance mappers (385–405 nm bandwidth)

- Laser interferometers for Z-stage linearity verification

- Thermal imaging cameras to monitor DLP array heat dissipation

Each Asiga Max unit undergoes per-unit optical calibration, with correction matrices applied to compensate for pixel drop-off at the build plate periphery. This ensures ±5 µm XY accuracy across the entire 192 x 108 mm build area—critical for multi-unit dental frameworks and implant surgical guides.

Durability & Longevity Testing

To validate long-term reliability in clinical environments, Carejoy conducts:

- Accelerated Life Testing (ALT): Simulated 3-year operational load (8 hrs/day, 5 days/week)

- Vibration & Drop Testing: IEC 60601-1-11 compliance for transport resilience

- Resin Vat Lifespan Analysis: Fluorinated PFA membranes tested for 2,000+ peel cycles without delamination

Units failing any test trigger root cause analysis via Carejoy’s Failure Mode Tracking System (FMTS), feeding corrective actions into the design-for-manufacturability (DFM) loop.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Vertical access to DLP chips, UV-LED arrays, precision rails, and optical resins reduces BOM costs by 30–40% vs. Western assemblers |

| Automation in Assembly | SMT lines and robotic calibration cells enable high throughput with minimal human error |

| R&D Proximity | Co-location of engineering, manufacturing, and clinical testing enables rapid iteration (e.g., AI-driven scan-to-print optimization) |

| Regulatory Efficiency | NMPA clearance pathways are faster for Class II devices, accelerating time-to-market |

| Economies of Scale | Mass production across Carejoy, Asiga, and other ODMs drives down per-unit testing and compliance overhead |

As a result, Chinese-manufactured Asiga Max units deliver 95% of the performance of EU/US-assembled counterparts at 60–70% of the cost, redefining the cost-performance frontier in digital prosthodontics and orthodontics.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ formats—enabling seamless integration with third-party CAD software (ex: exocad, 3Shape)

- AI-Driven Scanning: Compatible with Carejoy’s AI-powered intraoral scanners for automatic margin detection and die spacer optimization

- High-Precision Milling: Co-deployable with Carejoy’s 5-axis dry milling units for hybrid workflows (printed models + milled zirconia)

Support & Compliance

Carejoy Digital provides:

- 24/7 remote technical support with AR-assisted diagnostics

- Quarterly software updates including AI-enhanced print prediction and failure mitigation

- Full audit trail and document control under ISO 13485 for lab compliance (CE, FDA 510(k) ready)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Asiga Max Uv 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160