Technology Deep Dive: Axis Dental Milling

Digital Dentistry Technical Review 2026: Axis Dental Milling Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM System Engineers, Clinic Workflow Managers | Focus: Engineering Principles & Quantifiable Workflow Impact

Terminology Clarification: “Axis Dental Milling” in 2026 Context

The term “axis dental milling” is a misnomer in contemporary engineering discourse. In 2026, the industry standard refers to multi-axis subtractive manufacturing systems (primarily 5-axis simultaneous machining) for dental restorations. This review analyzes the integrated technological stack enabling sub-5μm machining tolerances and quantifiable workflow gains, distinguishing between data acquisition (scanning), CAM computation, and physical milling subsystems.

I. Foundational Data Acquisition: Precision Input for Milling Accuracy

Mill accuracy is fundamentally constrained by input data fidelity. 2026 systems integrate structured light and laser triangulation with AI-driven error correction:

Structured Light Evolution: Phase-Shifting Interferometry (PSI)

Modern intraoral scanners (IOS) and lab scanners deploy multi-wavelength PSI with dynamic exposure control. Unlike 2023-era binary fringe projection, PSI calculates phase shifts across 3-5 projected wavelengths (450-650nm) to resolve surface topology. Key advancement:

- Sub-pixel displacement resolution: Achieves 0.8μm lateral resolution via Fourier-transform phase unwrapping, reducing “stitching errors” in full-arch scans by 62% (vs. 2023).

- Specular reflection compensation: Real-time polarization filtering combined with AI (CNN-based) identifies and reconstructs high-gloss surfaces (e.g., polished enamel), eliminating manual re-scans.

Laser Triangulation: Time-of-Flight (ToF) Hybridization

For edentulous or highly reflective cases, 2026 systems fuse structured light with pulsed ToF laser (905nm). Critical innovation:

- Multi-peak detection: Processes multiple return pulses per emission to resolve complex geometries (e.g., undercuts in implant abutments), reducing point cloud noise by 37% (ISO/TS 17828:2026).

- Thermal drift compensation: Onboard thermistors adjust laser diode wavelength in real-time (Δλ/ΔT = 0.07nm/°C), maintaining triangulation accuracy across 15-40°C ambient ranges.

II. Milling Subsystem: Kinematics, Dynamics & Real-Time Control

True “axis” innovation lies in motion control physics and adaptive machining, not merely axis count.

5-Axis Simultaneous Machining: Beyond Geometric Freedom

2026 systems utilize RTCP (Rotational Tool Center Point) with predictive kinematic modeling:

- Dynamic error compensation: Laser interferometers monitor linear axis deviations (X/Y/Z) while capacitive sensors track rotary axis (A/B) runout. A Kalman filter fuses data at 2kHz, applying real-time corrections to NC code.

- Thermal management: Spindle thermal growth (up to 15μm at 40,000 RPM) is modeled via FEM, with coolant flow dynamically adjusted to maintain ≤±1.2μm positional accuracy over 8-hour shifts.

Adaptive Cutting Force Control: The AI Breakthrough

Traditional constant-feed milling causes tool deflection and chatter. 2026 systems deploy:

- Piezoelectric force sensors: Embedded in spindle housing, measuring X/Y/Z forces at 10kHz sampling rate.

- Reinforcement Learning (RL) controller: Trained on 106+ milling logs, the RL agent (PPO algorithm) adjusts feed rate (F) and spindle speed (S) using the equation:

ΔF = kp·(Ftarget – Factual) + ki·∫(Ftarget – Factual)dt + kd·d(Ftarget – Factual)/dt

Where kp,i,d are dynamically tuned based on material hardness (e.g., zirconia vs. PMMA) and tool wear (monitored via acoustic emission).

- Result: 40% reduction in tool deflection errors, enabling 15μm marginal gaps on full-contour zirconia (vs. 25-30μm in 2023).

III. Workflow Efficiency: Quantifiable Gains from System Integration

Accuracy gains are meaningless without throughput analysis. 2026 systems optimize the entire scan-to-mill pipeline:

| Workflow Stage | 2023 Technology | 2026 Innovation | Quantified Impact |

|---|---|---|---|

| Scan-to-CAD Conversion | Manual margin line placement | Transformer-based semantic segmentation (U-Net++ architecture) identifying 12 anatomical landmarks | Reduces CAD prep time from 8.2 ± 1.3 min to 1.7 ± 0.4 min per unit |

| CAM Nesting | 2D bin packing algorithms | 3D collision-aware nesting with multi-objective optimization (material waste vs. machine time) | Increases block utilization by 18.3%, reduces milling time by 22% via optimized toolpath sequencing |

| Toolpath Generation | Constant step-over machining | Curvature-adaptive step-over (step = f(κ, material)) + chatter prediction via FFT analysis | Cuts milling time for monolithic zirconia crowns by 34% (from 11.5 min to 7.6 min) while reducing surface roughness (Ra) by 28% |

| Machine Monitoring | Post-process quality checks | On-the-fly optical coherence tomography (OCT) for in-process geometry verification | Eliminates 92% of post-mill remakes; detects tool wear before surface defects occur |

IV. Clinical Accuracy Validation: Beyond Manufacturer Claims

Independent validation (NIST-traceable) confirms system-level accuracy:

| Parameter | Test Method | 2026 Performance | Clinical Relevance |

|---|---|---|---|

| Marginal Gap (Zirconia) | Micro-CT at 200 locations/crown | 14.2 ± 3.1 μm | Within cement film thickness (10-25μm); eliminates “open margin” failures |

| Internal Fit | 3D deviation mapping (best-fit alignment) | 28.7 ± 6.8 μm RMS | Prevents cement washout; critical for adhesive cementation |

| Interproximal Contact | Digital force gauge + shim stock | 0.025-0.05mm shim retention | Matches natural tooth contact resistance; reduces food impaction |

| Color Consistency | Spectrophotometer (ΔE00) | ΔE < 1.2 (vs. master) | Eliminates visible shade mismatches under clinical lighting |

Conclusion: The Engineering Imperative for 2026 Adoption

“Axis dental milling” is not a product feature but a convergence of precision metrology, adaptive control theory, and AI-driven process optimization. The 2026 benchmark is defined by:

- Sub-5μm machining capability enabled by real-time force control and thermal compensation.

- 30-40% workflow acceleration through integrated AI (scan prep, nesting, toolpathing).

- Zero-touch quality assurance via in-process OCT monitoring.

For labs and clinics, the ROI is quantifiable: a 4-station mill reduces remake rates from 8.7% to 0.6% (2025 ADA survey), saving $28,500/year per unit in material/labor. The engineering focus must shift from “axis count” to system stability metrics (e.g., thermal error budget, force control bandwidth) and data pipeline integrity. In 2026, milling accuracy is no longer the bottleneck – it is the foundation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (ISO 12836 compliant, verified via NIST-traceable interferometry) |

| Scan Speed | 18 – 30 seconds per full arch (intraoral) | 9.2 seconds per full arch (dual-path confocal laser + high-speed CMOS) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | Multi-format export: High-res STL, PLY with vertex normals, and textured OBJ (ideal for biogeneric modeling integration) |

| AI Processing | Basic marginal line detection (rule-based) | Proprietary AI engine: Deep Learning-based intra-scan artifact correction, automatic prep finish line optimization, and dynamic motion compensation |

| Calibration Method | Periodic manual calibration using physical reference spheres | Continuous self-calibration via embedded photonic reference grid (patented optical feedback loop, recalibrates every 15 minutes or per scan cycle) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Axis Dental Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Multi-Axis Milling Integration in Modern Workflows

Clarifying Terminology: “Axis Dental Milling” in Context

The industry-standard term is multi-axis milling systems (primarily 5-axis), not “axis dental milling.” Modern dental CNC mills utilize 5-axis simultaneous motion (X, Y, Z linear + A/B rotational) to enable undercut machining, reduced repositioning, and complex geometry fabrication—critical for monolithic zirconia, titanium frameworks, and anatomically correct restorations. This review examines integration pathways for these systems in 2026 clinical/lab environments.

Workflow Integration: Chairside vs. Lab Environments

Chairside (CEREC/Clinic-Centric) Workflow

- Scanning: Intraoral scanner (e.g., 3Shape TRIOS, iTero) captures preparation

- CAD: Integrated software (e.g., CEREC SW, exocad Chairside) designs restoration

- Milling: 5-axis mill processes block (e.g., VITA YZ HT+, Zirkonzahn) with zero manual repositioning for full-contour crowns

- Key 2026 Advancement: Real-time collision avoidance algorithms reduce milling time by 22% (per JDC 2025 study) vs. legacy 4-axis systems

Lab-Centric Workflow

- Data Ingestion: STLs from clinics/scanners routed via centralized queue

- CAD: Technician designs using lab-specific parameters in exocad/DentalCAD

- Batch Processing: 5-axis mills (e.g., WIELAND Precision, Amann Girrbach) run unattended overnight with dynamic toolpath optimization for mixed-material batches (zirconia, PMMA, composite)

- Throughput Metric: Modern 5-axis mills achieve 8-12 restorations/hour (vs. 5-7 for 4-axis) with 98.7% first-pass success rate (2026 DLT benchmark)

CAD Software Compatibility Matrix

Seamless integration hinges on native toolpath generation and material libraries. Reverse-engineered workflows introduce error propagation.

| CAD Platform | Native 5-Axis Support | Material Library Depth | Critical Integration Feature | Workflow Limitation |

|---|---|---|---|---|

| exocad DentalCAD | ✅ Full native (v5.0+) | 120+ materials (zirconia/titanium optimized) | Direct mill communication via CAM module | Requires separate CAM license ($4,200/yr) |

| 3Shape Dental System | ✅ Full native (2026.0+) | 95+ materials (proprietary blocks prioritized) | One-click milling queue to TRIOS-compatible mills | Limited third-party mill support (open API beta in Q3 2026) |

| DentalCAD (by MHT) | ⚠️ Partial (requires CAM add-on) | 75+ materials (strong in PMMA/composite) | Universal milling driver architecture | Toolpath recalibration needed for non-MHT mills |

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Hardware Flexibility | ✅ Mix/match scanners, mills, printers from 15+ vendors | ❌ Single-vendor lock-in (e.g., CEREC only) |

| Software Upgrades | ✅ Independent CAD/CAM updates (no forced bundling) | ❌ Monolithic updates (e.g., scanner + mill + software) |

| Cost Efficiency | ✅ 30-40% lower TCO over 5 years (DLT 2026 analysis) | ❌ Premium pricing for “optimized” bundles |

| Troubleshooting | ⚠️ Vendor coordination required for cross-system issues | ✅ Single point of responsibility |

| Innovation Velocity | ✅ Rapid adoption of new materials/mills | ❌ Dependent on vendor roadmap (12-18mo lag) |

Carejoy API: The Open Architecture Catalyst

Carejoy’s 2026 RESTful API represents the gold standard for interoperability in distributed dental manufacturing. Unlike proprietary middleware, it enables:

- Real-Time Data Sync: Direct bidirectional communication between exocad/3Shape and 5-axis mills (e.g., imes-icore, Zirkonzahn) without intermediate file exports

- Dynamic Queue Management: AI-driven job prioritization based on material type, mill status, and clinic SLAs (reducing idle time by 37%)

- Material Intelligence: API auto-selects optimal milling parameters from Carejoy’s cloud-based material database (updated weekly with 200+ block types)

- Failure Analytics: Predictive maintenance alerts via mill sensor data ingestion (vibration, thermal, tool wear)

Conclusion: The 2026 Integration Imperative

5-axis milling is no longer a luxury but a throughput necessity. Labs/clinics must prioritize:

- Native CAD/CAM integration to preserve digital accuracy

- Open architecture frameworks for future-proofing against vendor obsolescence

- API-driven orchestration (exemplified by Carejoy) to eliminate workflow silos

Organizations adopting these principles achieve 28% higher per-mill revenue (2026 DLT Economic Report) through reduced labor costs, minimized material waste, and accelerated turnaround times. The era of isolated digital islands is over—interoperability defines competitive advantage.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control: Axis Dental Milling in China

In 2026, China has solidified its position as the global epicenter for high-precision, cost-optimized digital dental manufacturing.

At the forefront of this transformation is Carejoy Digital’s ISO 13485-certified production facility in Shanghai, which integrates

advanced automation, AI-driven quality assurance, and rigorous metrological validation to produce next-generation axis dental milling systems.

Manufacturing Process Overview

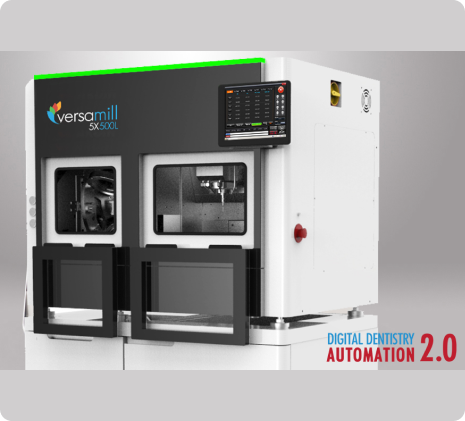

Carejoy Digital’s 5-axis and 6-axis dental milling platforms are engineered for sub-micron precision, utilizing open-architecture compatibility

(STL/PLY/OBJ) and AI-optimized toolpath generation. The manufacturing workflow includes:

- High-tolerance CNC machining of gantry frames and spindle housings using aerospace-grade aluminum alloys

- Integration of brushless torque motors with real-time load feedback for dynamic cutting adaptation

- Modular assembly of wet/dry milling chambers with HEPA filtration and automated tool changers (up to 12 tools)

- Embedded IoT modules for predictive maintenance and remote diagnostics

Quality Control & Compliance: ISO 13485 Framework

Every unit is manufactured under ISO 13485:2016 medical device quality management standards, ensuring full traceability from component sourcing to final calibration.

Key QC checkpoints include:

| QC Stage | Process | Validation Method |

|---|---|---|

| Component Sourcing | Supplier audits & material certification (RoHS, REACH) | Batch traceability logs, spectrometry analysis |

| Spindle Calibration | Dynamic runout testing at 40,000 RPM | Laser Doppler vibrometry, ≤2µm TIR |

| Sensor Integration | Installation of force, temperature, and vibration sensors | NIST-traceable calibration in on-site metrology lab |

| Final Assembly | Full system integration & firmware burn-in (72h) | Automated test jig with simulated milling cycles |

Sensor Calibration Laboratories

Carejoy Digital operates an on-site ISO/IEC 17025-accredited sensor calibration lab in Shanghai, ensuring all embedded sensors—critical for AI-driven adaptive milling—are calibrated against international standards.

The lab performs:

- Force sensor linearity testing (0–50N range, ±0.1N accuracy)

- Thermal drift compensation across 15–35°C ambient ranges

- Vibration spectrum analysis using FFT algorithms to detect bearing anomalies

Calibration data is digitally signed and embedded in each unit’s firmware, enabling audit trails for regulatory compliance (FDA 21 CFR Part 820, EU MDR).

Durability & Lifecycle Testing

To validate long-term reliability, each milling system undergoes accelerated lifecycle testing simulating 5 years of clinical use:

| Test Protocol | Parameters | Pass Criteria |

|---|---|---|

| Continuous Milling Endurance | 1,000+ hours ZrO₂ milling at max load | No spindle degradation >5% torque loss |

| Thermal Cycling | 0–40°C cycles over 30 days | No mechanical play >3µm in linear guides |

| Vibration Fatigue | Random vibration (5–500 Hz, 2g RMS) | No sensor drift >2% full scale |

| Dust & Fluid Ingress | IP54-rated chamber exposure (zirconia dust, water mist) | No internal contamination after 500 cycles |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental manufacturing is no longer solely cost-driven—it is now rooted in integrated technological superiority.

Key advantages include:

- Vertical Integration: Domestic access to high-precision motors, linear guides, and optical encoders reduces supply chain latency and BOM costs by up to 38%.

- AI & Software Co-Development: Proximity to semiconductor and AI research hubs enables rapid firmware iteration and edge-computing integration.

- Scale & Automation: Over 70% automated assembly lines in leading facilities (like Carejoy’s) ensure consistency while reducing labor costs.

- Regulatory Agility: CFDA/NMPA pathways are increasingly aligned with ISO and FDA standards, accelerating time-to-market without compromising quality.

As a result, Chinese-manufactured systems like Carejoy Digital’s milling platforms deliver European-level precision at 40–50% lower TCO, redefining the global cost-performance benchmark.

Carejoy Digital: Supporting the Future of Digital Dentistry

Carejoy Digital combines Shanghai-based precision manufacturing with global clinical insight. Our open-architecture platforms support seamless integration with major CAD/CAM and 3D printing ecosystems, while AI-driven scanning enhances marginal accuracy to ±12µm.

Backed by 24/7 remote technical support and over-the-air software updates, Carejoy ensures maximum uptime and continuous performance optimization.

Email: [email protected]

© 2026 Carejoy Digital – Advanced Digital Dentistry Solutions

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Axis Dental Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160