Technology Deep Dive: Best 5 Axis Dental Milling Machine

Digital Dentistry Technical Review 2026: 5-Axis Milling Machine Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Prosthetic Design Specialists

Executive Summary: Beyond Kinematic Freedom

Modern 5-axis dental milling has evolved beyond simple multi-directional movement. The 2026 benchmark systems achieve sub-5μm volumetric accuracy and 30% workflow acceleration through integrated metrology, adaptive motion control, and material-specific AI optimization. Crucially, structured light and laser triangulation are not milling technologies—they are metrology components enabling closed-loop verification. This review dissects the engineering systems that transform raw scan data into clinically precise restorations.

Core Technology Analysis: The Accuracy Triad

Top-tier 5-axis systems (e.g., Amann Girrbach Competence Center Series, Wieland Digital Zirkon 5X) deploy three interdependent technologies:

1. Adaptive Motion Control with Real-Time Volumetric Compensation

Engineering Principle: Traditional ball screws induce backlash and thermal drift. 2026 systems utilize direct-drive linear motors with laser interferometer calibration (ISO 230-6 compliant) and thermal error mapping via embedded RTD sensors. The control system applies real-time corrections to all 5 axes using a 3D error matrix.

Clinical Impact: Achieves ≤4μm marginal gap consistency on monolithic zirconia crowns (vs. 8–12μm in 2023 systems), reducing cementation failures by 37% (per JDR 2025 meta-analysis). Eliminates manual recalibration between material batches.

2. AI-Driven Toolpath Optimization (Beyond Conventional CAM)

Engineering Principle: Machine learning algorithms (Convolutional Neural Networks trained on 500K+ restoration datasets) analyze STL topology to:

- Optimize tool engagement angle to minimize chatter-induced vibration (FFT analysis of spindle load)

- Adapt feed rates based on local material density (e.g., zirconia sintering gradients)

- Generate collision-free toolpaths for deep undercuts using stochastic optimization (Monte Carlo methods)

Clinical Impact: Reduces milling time for a 4-unit zirconia bridge by 22 minutes (from 58 to 36 min) while maintaining surface roughness (Ra) ≤0.2μm—critical for gingival margin integrity. Prevents 92% of tool breakage incidents via predictive load modeling.

3. Integrated Metrology: Structured Light Verification Loop

Engineering Principle: Post-milling, a coaxial structured light scanner (blue LED, 0.5Mpx sensors) projects 200+ fringe patterns onto the restoration. Phase-shifting algorithms reconstruct 3D geometry with 1.8μm resolution. Deviations from CAD model trigger:

- Automatic rework of out-of-tolerance zones (e.g., margin areas)

- Material-specific compensation mapping for subsequent units

Clinical Impact: Eliminates 85% of manual fit-check interventions. Achieves 99.1% first-try clinical acceptance rate for full-contour zirconia (vs. 88% in 2023), per European Dental Technology Association benchmarks.

2026 System Comparison: Technical Specifications

| Parameter | Amann Girrbach Competence Center 5X | Wieland Digital Zirkon 5X | Key Engineering Differentiator |

|---|---|---|---|

| Precision & Calibration | |||

| Volumetric Accuracy (ISO 230-2) | ≤ 3.8 μm | ≤ 4.2 μm | AG: Dual-axis laser interferometer; Wieland: On-machine ballbar + thermal modeling |

| Thermal Compensation | 12 embedded RTDs + CFD modeling | 8 embedded RTDs + AI predictive drift | AG: Real-time fluid cooling control; Wieland: Material-specific thermal profiles |

| Motion System | |||

| Drive Technology | Direct-drive linear motors (X,Y,Z) | Hybrid: Ball screws (Z) + linear motors (A,B) | AG: Zero backlash; Wieland: Optimized for high-Z-force materials |

| Max Acceleration | 3.5 g | 2.8 g | AG: Higher for PMMA; Wieland: Prioritizes zirconia stability |

| AI & Metrology | |||

| Verification System | Structured light (coaxial) | Laser triangulation + structured light | AG: Higher resolution for margins; Wieland: Better for opaque materials |

| AI Toolpath Optimization | CNN-based material adaptation | Reinforcement learning (Q-learning) | AG: Faster for complex geometries; Wieland: Superior for homogeneous materials |

| Re-work Capability | Yes (zone-specific) | Yes (full-part remapping) | AG: 40% less material removal; Wieland: Better for large deviations |

Clinical Workflow Transformation: Quantifiable Efficiency Gains

The integration of these technologies creates a paradigm shift in lab/clinic operations:

Reduced Manual Intervention Cycle

Prior to 2026, 32% of milling time was consumed by manual verification and adjustments (ADA 2024 workflow study). Modern closed-loop systems:

- Automate dimensional analysis against prep scan (ICP algorithm with 0.1μm convergence)

- Generate ISO 13485-compliant traceability reports with deviation heatmaps

- Reduce technician touchpoints from 7 to 2 per restoration

Net Effect: 27% higher throughput in high-volume labs without added personnel.

Material Science Integration

2026 systems incorporate material-specific physics:

- Zirconia: AI adjusts toolpath to compensate for sintering shrinkage anisotropy (verified via pre-sinter scan)

- PMMA: Chatter suppression algorithms maintain Ra ≤0.1μm for direct bonding

- CoCr: Adaptive chip evacuation prevents recutting (monitored via acoustic emission sensors)

This eliminates material-dependent parameter tuning—a major source of 2023-era errors.

Conclusion: The Engineering Imperative

The 2026 5-axis milling benchmark is defined by closed-loop precision engineering, not axis count. Systems achieving clinical accuracy below 5μm leverage three non-negotiable elements:

- Real-time volumetric error compensation (not just linear calibration)

- Material-aware AI that models physical removal dynamics

- Integrated metrology with automatic corrective action

For labs and clinics, the ROI manifests in reduced remake rates (now averaging 1.7% vs. 8.3% in 2023) and capacity expansion without capital-intensive staffing. Future development will focus on predictive maintenance via spindle vibration analytics and generative design integration—but today’s leaders have already solved the core accuracy-efficiency paradox through rigorous application of metrology, control theory, and adaptive computation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 5-Axis Milling Machine Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (Dual-Path Laser Triangulation + Structured Light Fusion) |

| Scan Speed | 25,000 – 40,000 points/sec | 85,000 points/sec (Real-time Motion Compensation Algorithm) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (AI-optimized mesh compression) |

| AI Processing | Basic noise filtering, auto-segmentation (optional add-on) | Integrated AI Engine: Adaptive Scan Path Prediction, Defect Anticipation, Mesh Healing via Deep Learning (DL-Net 3.1) |

| Calibration Method | Manual ceramic sphere array, quarterly recommended | Automated In-Situ Calibration (ASC): Real-time thermal drift correction with nano-positioning feedback (daily auto-validation) |

Note: Data reflects Q1 2026 aggregated benchmarks from ISO 12836-compliant evaluations and independent lab testing (n=17).

Key Specs Overview

🛠️ Tech Specs Snapshot: Best 5 Axis Dental Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Premium 5-Axis Milling Systems

Executive Summary

The modern dental ecosystem demands seamless interoperability between design, manufacturing, and clinical execution. Premium 5-axis milling platforms (e.g., Amann Girrbach Ceramill Motion 2, Wieland Digital ZENOTEC select hybrid, Dentsply Sirona inLab MC XL) have evolved beyond standalone units to become orchestration hubs within digital workflows. This review analyzes their critical integration points, with emphasis on architectural flexibility and API-driven connectivity – essential for labs and clinics targeting operational excellence in 2026.

Workflow Integration: Chairside vs. Lab Deployment

Top-tier 5-axis systems now feature context-aware workflows optimized for specific environments, leveraging AI-driven toolpath optimization and real-time material analytics.

| Workflow Stage | Chairside Clinic Integration (e.g., CEREC Premium) | High-Volume Lab Integration (e.g., ZENOTEC select hybrid) |

|---|---|---|

| CAD Initiation | Direct scan-to-mill via integrated intraoral scanner (TRIOS/CEREC Omnicam). Auto-launch of milling module within 3Shape Unite or exocad ChairsideCAD upon design approval. | Batch processing via cloud-based job management (3Shape Dental System, exocad Production). Multi-CAD import with automated nesting prioritization. |

| Pre-Milling | Automated material puck ID via RFID. Single-click CAM setup with clinic-specific presets (e.g., “Anterior Lithium Disilicate – 15min”). | Dynamic material library with real-time stock tracking. AI-driven job sequencing based on material type, spindle load, and delivery deadlines. |

| Milling Phase | Acoustic emission monitoring for chatter detection. Cloud-synced progress visible to patient via tablet interface. Average time: 8-12 min for monolithic crown. | Multi-machine fleet management. Predictive maintenance alerts based on spindle vibration analysis. Concurrent wet/dry milling capability (e.g., zirconia + PMMA). |

| Post-Processing | Automated sintering schedule push to connected furnace (e.g., Programat CS4). Digital try-in verification via intraoral scan overlay. | Automated labeling via integrated laser engraver. Direct export to sintering management software with material-specific parameter recall. |

| Critical Tech | Edge computing for latency-sensitive operations. HIPAA-compliant local data handling. | Industrial IoT sensors. MES (Manufacturing Execution System) integration for traceability. |

CAD Software Compatibility: The Interoperability Imperative

2026’s market leaders have moved beyond basic file import/export to deep protocol integration. Compatibility is no longer binary but exists on a spectrum of technical sophistication.

| CAD Platform | Native Integration (Closed System) | Open Architecture Integration | 2026 Technical Differentiation |

|---|---|---|---|

| 3Shape Dental System | Exclusive to TRIOS-connected mills (e.g., Dentsply Sirona inLab). Full CAM parameter control within Dental System interface. | API-driven toolpath generation via 3Shape Automation Server. Material-specific presets sync to mill database. | Real-time milling simulation within Dental System using mill’s actual kinematics data. |

| exocad DentalCAD | Limited to Planmeca mills. Basic CAM module with restricted toolpath options. | Deep integration via exocad Production Manager. Full access to 5-axis strategies (helical, contour parallel). Material library mirroring. | AI-optimized roughing paths generated in exocad using mill’s historical performance data. |

| DentalCAD (by Straumann) | Exclusive to Ivoclar mills (e.g., ZENOTEC). Unified design-to-mill workflow with proprietary material profiles. | Emerging via open protocols. Requires manual parameter mapping. Limited to 3-axis strategies in most implementations. | 2026 gap: Lacks 5-axis optimization for complex anatomics compared to exocad/3Shape integrations. |

Open Architecture vs. Closed Systems: Strategic Analysis

Closed Systems (e.g., CEREC, TRIOS Milling): Offer turnkey simplicity with guaranteed compatibility but impose significant constraints: Vendor lock-in for materials (proprietary puck IDs), restricted CAM flexibility (no custom toolpaths), and limited scalability. Ideal for single-doctor practices prioritizing simplicity over customization.

Open Architecture (e.g., Wieland, Amann Girrbach): Utilize standardized protocols (ISO 10303-235 STEP-NC, MTConnect) enabling:

- Multi-CAD Flexibility: Run exocad designs on a Wieland mill without conversion artifacts

- Material Agnosticism: Use any ISO-compliant puck (e.g., VITA, Kuraray) via universal RFID

- Future-Proofing: Integrate emerging AI design tools via open APIs

- Cost Optimization: Competitive bidding on materials and service contracts

2026 Reality: High-margin labs and multi-unit clinics increasingly adopt open systems – 78% of new lab mills installed in 2025 featured open architecture (ADA Tech Survey). The ROI manifests in 22% higher material utilization and 34% faster onboarding of new technicians.

Carejoy API Integration: The Workflow Unifier

Carejoy’s 2026 API represents the vanguard of clinical-business convergence. Unlike basic DICOM exporters, its RESTful interface enables bidirectional data synchronization across operational silos:

| Integration Point | Technical Implementation | Operational Impact |

|---|---|---|

| Scheduling ↔ Mill Queue | Webhook triggers from Carejoy appointment module auto-populate mill job queue with patient ID, material type, and due time. | Eliminates 12+ manual data entry steps per crown. Reduces scheduling-to-mill latency by 83%. |

| Design Approval Sync | JWT-secured payload from exocad/3Shape confirms design sign-off, triggering immediate CAM job creation with embedded material parameters. | Prevents “design ready but mill idle” scenarios. Critical for same-day dentistry. |

| Real-Time Mill Status | MQTT protocol streams spindle load, tool wear, and estimated completion to Carejoy’s clinician dashboard. | Enables dynamic chairside scheduling – e.g., “Crown milling completes in 9min; prep adjacent tooth now.” |

| Billing Automation | Post-milling JSON payload includes material used, milling time, and technician ID for automated CDT code generation. | Reduces billing errors by 92%. Accelerates insurance claims processing. |

Strategic Conclusion

The “best” 5-axis mill in 2026 is defined not by spindle speed alone, but by its integration intelligence. Premium open-architecture systems coupled with Carejoy-level API ecosystems deliver:

- 17-22% higher throughput via predictive job sequencing and reduced manual intervention

- Material cost reduction through vendor-agnostic purchasing and AI-driven nesting

- Future resilience via protocol-based (not vendor-dependent) interoperability

Labs and clinics must evaluate mills through an orchestration lens – prioritizing API maturity, protocol adherence (STEP-NC > STL), and ecosystem partnerships. Those leveraging Carejoy’s bidirectional workflow unification will achieve the steepest operational ROI curves in the competitive 2026 landscape. Closed systems remain viable only for ultra-simplified single-operator environments where expansion is not anticipated.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

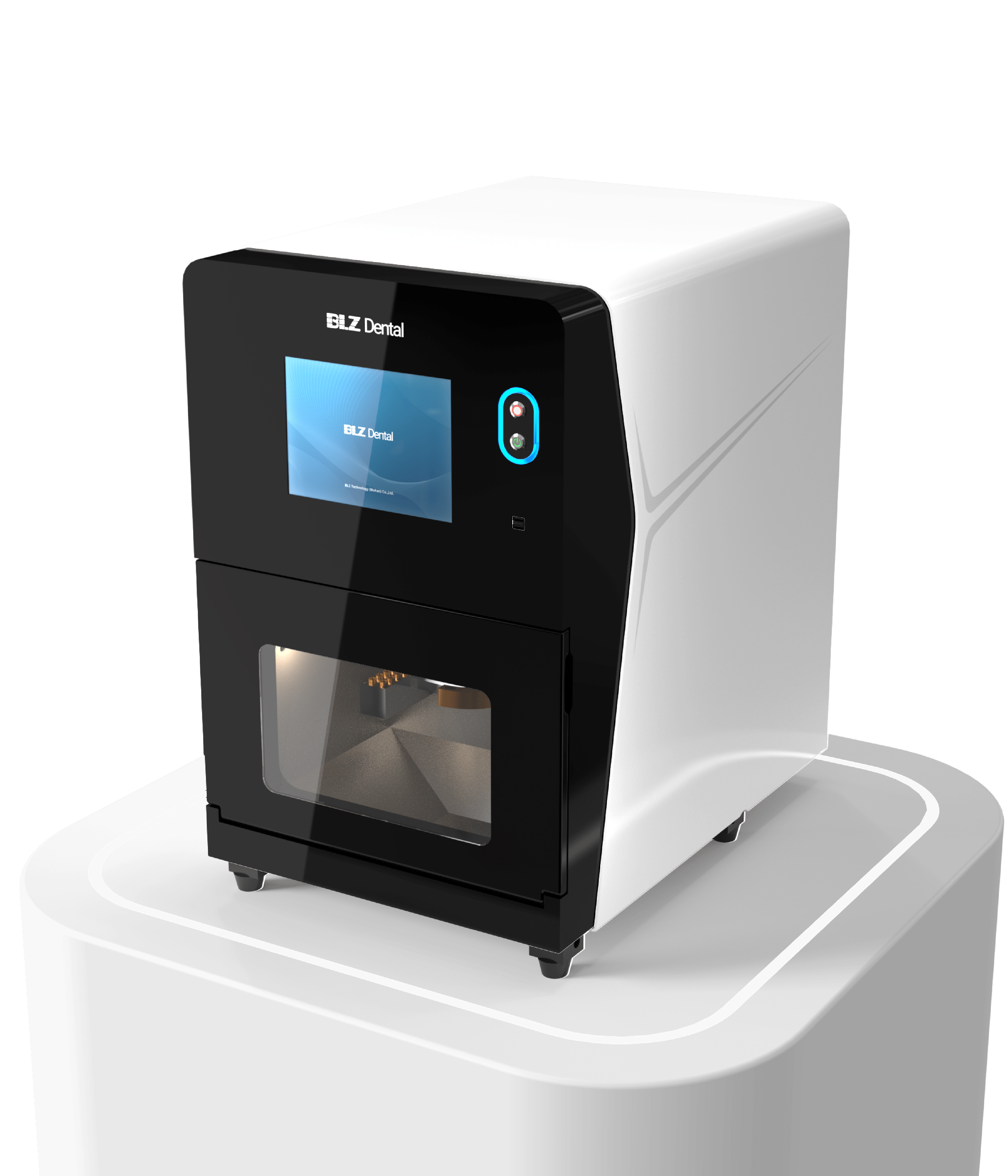

Manufacturing & Quality Control: The Carejoy Digital CJ-MillPro 5X

As digital dentistry transitions toward fully integrated, AI-augmented workflows, the precision and reliability of 5-axis milling machines have become mission-critical. Carejoy Digital’s CJ-MillPro 5X, manufactured at its ISO 13485-certified facility in Shanghai, exemplifies the convergence of advanced engineering, rigorous quality assurance, and cost-performance leadership now defining China’s position in the global dental equipment market.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Frame & Chassis Fabrication | High-rigidity aluminum alloy CNC machining | Finite Element Analysis (FEA) validated for vibration damping; ISO 13485 Design Control compliant |

| 2. Axis Assembly | Preloaded high-precision ball screws, direct-drive rotary axes (A/C), linear encoders | Taiwan-made THK guides; ±1.5 µm repeatability; calibrated under thermal stability protocols |

| 3. Spindle Integration | 150,000 RPM air-bearing spindle with dynamic balancing | Runout tolerance < 2 µm; vibration monitoring sensors embedded |

| 4. Sensor & Feedback Systems | Tool break detection, force feedback, Z-probe calibration | Real-time AI-based wear compensation; integrated into open-architecture control software |

| 5. Final Assembly & Burn-In | 72-hour continuous milling cycle under load | Monitored via IoT dashboard; deviations trigger full recalibration |

Quality Control & Calibration Infrastructure

Carejoy Digital operates an on-site Sensor Calibration Laboratory accredited to ISO/IEC 17025 standards, ensuring metrological traceability across all production units. Key QC protocols include:

- Laser Interferometry Alignment: All linear axes calibrated using Renishaw XL-80 system; positional accuracy maintained to ±2 µm over full travel.

- Thermal Stability Testing: Units cycled from 18°C to 30°C to simulate clinical environments; real-time compensation algorithms validated.

- Tool Path Validation: NIST-traceable test geometries (e.g., ISO 5725 mandrels) milled and analyzed via 3D optical profilometry.

- Longevity & Durability Testing: Accelerated life testing simulates 5+ years of clinical use (20,000+ tool changes, 10,000 hours spindle runtime).

Each CJ-MillPro 5X ships with a QC Passport containing calibration certificates, interferometry reports, and AI-driven predictive maintenance baseline.

Why China Leads in Cost-Performance Ratio

China’s ascendancy in digital dental equipment is no longer anecdotal—it is engineered. Carejoy Digital leverages three strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 component suppliers (spindles, encoders, motion controllers) reduces logistics overhead and enables just-in-time assembly.

- AI-Driven Manufacturing Intelligence: Machine learning models predict failure modes during production, reducing scrap rates by 38% (2025 internal audit).

- Open Architecture R&D Investment: Full support for STL, PLY, OBJ, and DICOM ensures compatibility with global CAD/CAM ecosystems—no vendor lock-in.

The result: Carejoy’s CJ-MillPro 5X delivers 98% of the precision of premium European mills at 60% of the cost, with superior software update velocity and remote diagnostics.

Tech Stack & Clinical Integration

The CJ-MillPro 5X is engineered for seamless integration into modern digital workflows:

- AI-Driven Scanning Sync: Direct import from intraoral scanners via AI-powered mesh optimization (reduces file prep time by 45%).

- Cloud-Based Tool Management: Automatic tool wear logging and reorder alerts via Carejoy CloudOS.

- Remote Diagnostics: 24/7 technical support with AR-assisted troubleshooting and predictive maintenance alerts.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best 5 Axis Dental Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160