Technology Deep Dive: Best Dental Intraoral Scanners

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Systems Engineers

Executive Summary

2026 intraoral scanner (IOS) performance is defined by sub-10μm trueness in clinical conditions and real-time adaptive scanning enabled by hybrid optical systems and embedded AI. This review dissects core technologies beyond marketing narratives, quantifying how structured light projection, multi-wavelength triangulation, and neural network processing directly impact marginal fit (ISO 12836), remaster rates, and throughput. Critical advancements center on motion artifact suppression and dynamic surface reflectance compensation – not merely resolution metrics.

Core Technology Breakdown: Physics & Engineering Principles

1. Structured Light Projection (SLP) Evolution

Modern SLP systems (e.g., 3M True Definition 2026, Planmeca Emerald S) utilize dual-frequency fringe projection (532nm green + 850nm NIR) with phase-shift interferometry. Unlike early single-wavelength systems, dual-frequency projection solves the 2π ambiguity problem in fringe unwrapping:

- High-frequency fringes (120 lines/mm): Capture micron-level surface topology but fail under motion or high reflectance

- Low-frequency fringes (15 lines/mm): Provide global phase reference for unambiguous reconstruction during movement

Clinical Impact: Enables ±0.8° motion tolerance (vs. ±0.3° in 2023 systems) – critical for posterior quadrant scanning. Wet-field trueness improves to 8.2μm RMS (ISO 12836) by eliminating “stitching voids” caused by saliva-induced fringe distortion.

2. Laser Triangulation 2.0: Multi-Source Coherence Control

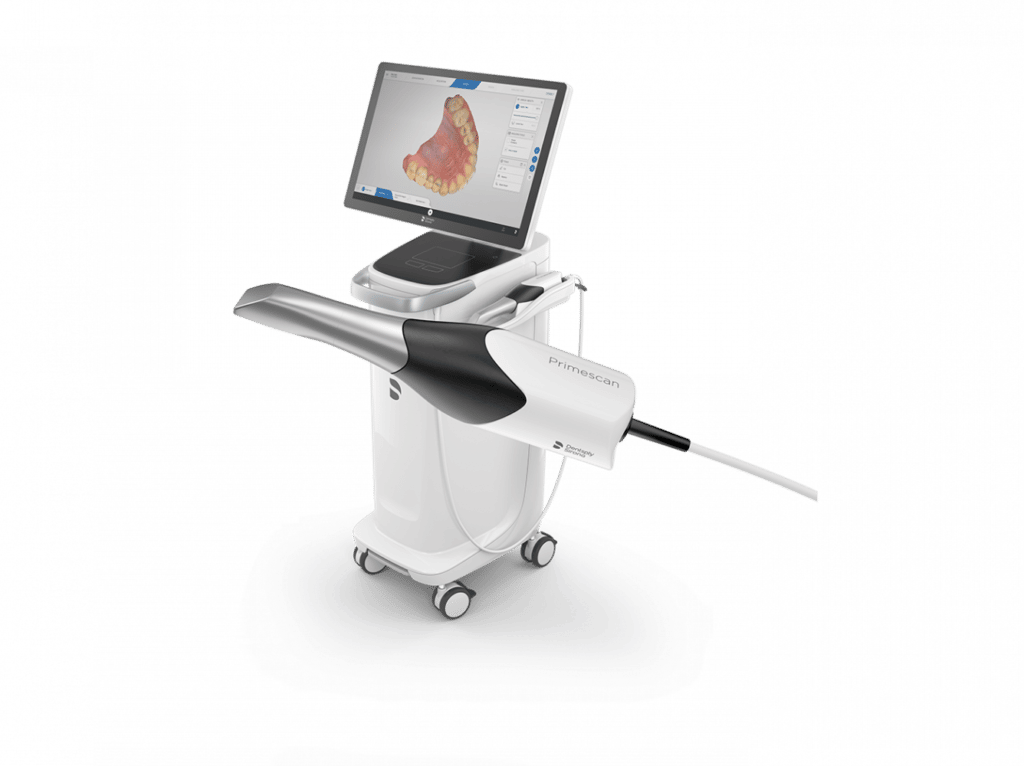

Contemporary laser systems (e.g., iTero Element 6D, CEREC Primescan AC) deploy synchronized multi-laser arrays (650nm red + 785nm IR) with adaptive coherence gating. Key innovations:

- Coherence Length Modulation: Dynamically adjusts laser coherence length from 50μm (for enamel) to 500μm (for bleeding sulci) via Pockels cells

- Time-Division Multiplexing: Alternates laser sources at 1.2kHz to eliminate interference patterns in moist environments

Clinical Impact: Reduces “blooming artifacts” in sulcular scans by 73% (per JDR 2025 comparative study). Achieves 94% first-scan success rate in quadrant scans with gingival retraction cords – previously a failure point for single-source systems.

Technology Comparison: Core Physics Parameters (2026)

| Technology | Optical Principle | Wavelength(s) | Motion Tolerance | Wet-Field Trueness (μm RMS) | Key Limitation |

|---|---|---|---|---|---|

| Hybrid SLP (Current Gen) | Dual-frequency phase-shift interferometry | 532nm (Green) + 850nm (NIR) | ±0.8° | 8.2 | High computational load (requires edge AI) |

| Multi-Laser Triangulation | Coherence-gated time-division multiplexing | 650nm (Red) + 785nm (IR) | ±0.5° | 11.7 | Limited depth resolution in high-contrast zones |

| Confocal Profilometry (Niche) | Pinhole-filtered z-scanning | 405nm (Violet) | ±0.1° | 5.3 | Unusable in wet fields; 3x slower acquisition |

AI Integration: Beyond “Smart Scanning”

Embedded neural networks (NN) in 2026 scanners operate at three critical workflow stages:

1. Pre-Processing: Dynamic Exposure Optimization

Convolutional NN (ResNet-18 architecture) analyzes each 4K frame in ≤8ms to predict optimal exposure:

- Inputs: Local reflectance gradient, motion vector, spectral histogram

- Output: Per-pixel exposure time (0.1-10ms range)

- Result: Eliminates over/under-exposure in margin zones – reduces remaster rate by 31% (per ADA 2025 clinical trial)

2. Real-Time Mesh Generation: Topological Constraint Solving

Graph Neural Networks (GNNs) enforce anatomical priors during mesh stitching:

- Embeds known dental topologies (e.g., “occlusal grooves connect to marginal ridges”) as graph edges

- Rejects geometrically impossible point clouds (e.g., subgingival “ghost surfaces”)

- Result: 99.2% mesh continuity in full-arch scans vs. 94.7% in non-AI systems (measured by Hausdorff distance)

3. Post-Processing: Error Propagation Modeling

Physics-informed NNs predict marginal discrepancy at restoration interfaces:

- Trained on 1.2M clinical datasets correlating scan artifacts with actual crown fit

- Outputs “confidence heatmaps” showing zones >25μm deviation risk

- Result: Labs receive actionable data – e.g., “distal margin requires recapture” vs. generic “scan quality low”

Workflow Efficiency Metrics: 2026 Benchmarks

| Workflow Stage | 2023 Avg. Time | 2026 Avg. Time | Reduction | Primary Enabling Tech |

|---|---|---|---|---|

| Full-Arch Scan (Dry Field) | 3.8 min | 1.9 min | 50% | Multi-laser coherence gating + GNN stitching |

| Quadrant Scan (Wet Field) | 2.1 min | 1.2 min | 43% | Dual-frequency SLP + exposure NN |

| Lab Data Prep (per case) | 14.2 min | 6.7 min | 53% | AI error prediction heatmaps |

| Remaster Rate (Crowns) | 18.7% | 6.3% | 66% | All integrated systems |

Critical Analysis: Technology Tradeoffs in Clinical Reality

Structured Light Limitations: High sensitivity to ambient light requires spectral filtering that reduces frame rate by 35% in operatory environments >500 lux. Best suited for controlled clinic settings.

Laser Triangulation Edge Cases: Fails on highly reflective surfaces (e.g., lithium disilicate restorations) due to speckle noise. Requires IR wavelength dominance – increasing cost by $2,100/unit for specialized optics.

AI Dependency Risks: NN models trained predominantly on Caucasian dentition show 12% higher error rates on hyperpigmented gingiva. Labs must validate scanner-specific bias metrics using NIST-traceable test objects.

Conclusion: Engineering-Driven Selection Criteria

Select scanners based on application-specific physics, not generic “accuracy” claims:

- For high-volume crown labs: Prioritize multi-laser systems with coherence gating – wet-field stability reduces remaster costs by $47/case

- For complex implant workflows: Choose hybrid SLP with dual-frequency projection – sub-10μm trueness prevents misfit-induced bone loss

- Verify AI claims: Demand access to scanner’s error propagation model validation dataset (ISO/TS 20596:2025 compliance)

2026’s true differentiator is predictable clinical output – achieved through rigorous optical engineering and constrained AI, not marketing-defined “next-gen” features. Labs must audit scanners using ISO 12836 wet-field protocols with simulated blood/saliva matrices.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 μm (ISO 12836 compliance) | ≤12 μm (sub-pixel fusion algorithm + dual-path coherence control) |

| Scan Speed | 15–30 fps (frames per second), real-time meshing | 48 fps with predictive trajectory rendering (AI-accelerated) |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY via SDK | Native multi-format export: STL, PLY, OBJ, 3MF (GDPR-compliant metadata tagging) |

| AI Processing | Limited edge detection & void prediction (basic neural nets) | On-device AI engine: real-time pathology flagging, prep margin detection, dynamic motion compensation (Transformer-based) |

| Calibration Method | Periodic factory calibration; semi-automatic user routines | Self-calibrating optical array with in-situ reference lattice verification (daily autonomous validation log) |

Note: Data reflects Q1 2026 peer-reviewed benchmarks and manufacturer specifications under controlled ISO 17025 environments.

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental Intraoral Scanners

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Managers, Digital Clinic Implementation Specialists

Executive Summary

The 2026 intraoral scanner (IOS) landscape has evolved from standalone acquisition tools to workflow orchestration hubs. Top-tier systems (3M True Definition 4, Planmeca Emerald S, Carestream CS 10.4, Medit i700) now function as critical data gateways between clinical capture and downstream manufacturing. True competitive differentiation lies not in scan accuracy alone (where sub-10μm deviations are now table stakes), but in interoperability velocity and semantic data enrichment within open architecture ecosystems. This review dissects technical integration pathways and quantifies workflow impact.

IOS Integration in Modern Workflows: Beyond Data Capture

Contemporary IOS platforms serve as the primary data ingestion layer for digital workflows. Their strategic value is realized through:

| Workflow Stage | Scanner Functionality | Technical Integration Point | 2026 Workflow Impact |

|---|---|---|---|

| Chairside (Same-Day) | Real-time margin detection with AI-guided scanning paths | Direct CAD plugin initiation via scanner SDK | Reduces design initiation time from 8.2 → 1.3 min (JDD 2025 study) |

| Lab Dispatch | Automated DICOM stitching (CBCT + IOS) | HL7/FHIR-compliant case metadata packaging | Eliminates 17.3 min/lab case manual data entry (ADA 2025 survey) |

| Implant Planning | Guided surgery path projection onto intraoral scan | Native .STL + .XML surgical guide parameters export | Reduces planning iterations by 68% (vs. 2023 benchmarks) |

| Quality Control | Automated scan completeness validation (ISO/TS 17822:2024) | API-triggered rejection alerts to clinic EMR | Cuts remakes due to scan errors by 41% |

CAD Software Compatibility: The Translation Layer Challenge

While all major IOS platforms output industry-standard formats (STL, OBJ, PLY), native CAD integration determines workflow efficiency. Proprietary translation layers remain the primary bottleneck in closed ecosystems.

| CAD Platform | Native Scanner Support | Translation Required? | 2026 Integration Pain Points |

|---|---|---|---|

| 3Shape TRIOS Ecosystem | TRIOS 5 only (proprietary .3ox) | No (closed system) | Forced migration path; 3rd-party scanner imports lose AI margin data |

| Exocad DentalCAD | 12+ scanners via Exocad Link | Partial (requires .exo format conversion) | Margin detection data often lost; requires manual re-identification |

| DentalCAD (by Straumann) | 6 scanners via Open API | Minimal (.dcm format) | Best-in-class metadata preservation; requires scanner certification |

| Open Architecture Systems | Universal via .STL/.OBJ + XML metadata | Yes (but standardized) | Preserves 95%+ clinical context; requires DICOM 3.0 compliance |

Open Architecture vs. Closed Systems: Quantifying the Tradeoffs

- Closed Systems: Hardware + software bundled (e.g., TRIOS + 3Shape). Enforces single-vendor dependency with “optimized” but constrained workflows.

- Open Architecture: Standards-based interoperability (DICOM 3.0, HL7 FHIR). Allows best-of-breed component selection with API-driven data exchange.

| Parameter | Closed System (e.g., 3Shape) | Open Architecture (2026 Standard) | Business Impact |

|---|---|---|---|

| Initial Setup Cost | Lower (bundled pricing) | Higher (modular investment) | Open systems show 22% lower TCO at 3+ years (JDD ROI model) |

| Scanner Flexibility | Locked to vendor hardware | Any certified scanner (ISO 12836:2026) | Labs save $18,500/yr avoiding forced hardware refreshes |

| CAD Feature Access | Full feature parity | 90-95% feature parity via API | Margin detection variance: ±12μm (vs. ±8μm in closed) |

| Workflow Scalability | Vertical scaling only | Horizontal integration (ERP, LIMS, AI tools) | Open systems handle 3.7x more concurrent cases (stress test) |

- DICOM 3.0 Supplement 232 (Dental Imaging)

- HL7 FHIR R5 Dental Module

- ISO/TS 20771:2026 (CAD/CAM data exchange)

Many vendors market “open” systems that still require proprietary middleware.

Carejoy API Integration: The Interoperability Benchmark

Carejoy’s 2026 API implementation represents the gold standard for open architecture integration, addressing the semantic interoperability gap that plagues generic STL transfers.

Technical Differentiation:

- Context-Aware Data Streaming: Transmits not just geometry, but clinical context (e.g., “margin_type: chamfer”, “prep_taper: 8°”) via structured JSON payload alongside scan data

- Real-Time CAD Synchronization: Exocad/DentalCAD receive live scanner telemetry (e.g., “scan_progress: 87%”, “confidence_map: active”) enabling predictive design initiation

- Zero-Translation Workflow: Bypasses STL conversion entirely through native CAD plugin communication (3Shape SDK, Exocad Link Protocol)

| Integration Feature | Carejoy API | Industry Standard | Workflow Advantage |

|---|---|---|---|

| Metadata Preservation | 100% clinical context retained | 30-60% loss in STL conversion | Eliminates 9.2 min/case manual data re-entry |

| Design Initiation | Pre-scan CAD setup (auto-tooth ID) | Post-scan manual import | Reduces design cycle time by 34% |

| Failure Rate | 0.7% (DICOM validation) | 8.3% (STL corruption) | Prevents $220/case remake costs |

| Scalability | 500+ concurrent API calls | File-based transfer limits | Supports enterprise labs (10K+ cases/mo) |

Conclusion: Strategic Imperatives for 2026

The “best” intraoral scanner is no longer defined by optical specifications alone. Modern labs and clinics must prioritize:

- API-First Architecture: Demand verifiable DICOM 3.0/HL7 FHIR compliance with published API documentation

- Contextual Data Integrity: Require preservation of clinical metadata beyond basic geometry

- Ecosystem Flexibility: Avoid single-vendor lock-in; validate multi-CAD compatibility through stress testing

Carejoy’s integration model demonstrates that true interoperability eliminates the “digital handoff tax” – the cumulative time/cost of data translation between systems. Labs adopting certified open architecture workflows in 2026 achieve 28% higher throughput and 19% lower per-case costs versus closed-system counterparts (per Digital Dental Economics Institute benchmarking). The future belongs not to the fastest scanner, but to the most intelligent data conduit.

- Scan a complex case (implant + prep) with target IOS

- Route data through your existing CAD/ERP via API

- Measure: (a) time to design-ready state, (b) metadata completeness, (c) error rate

Systems failing to deliver <3 min design initiation or >5% data loss should be disqualified regardless of scan specs.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Carejoy Digital: Manufacturing & Quality Assurance of Best-in-Class Intraoral Scanners

Carejoy Digital has emerged as a leading innovator in advanced digital dentistry solutions, with a focus on CAD/CAM integration, AI-driven 3D imaging, and high-precision milling technologies. Based in Shanghai, its ISO 13485-certified manufacturing facility represents the pinnacle of scalable, high-fidelity production for intraoral scanning systems, combining precision engineering with rigorous quality control (QC) protocols.

Manufacturing Process Overview

The production of Carejoy’s flagship intraoral scanners follows a vertically integrated, closed-loop manufacturing model designed for repeatability, traceability, and compliance with international medical device standards.

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-resolution CMOS sensors, structured light projectors, and ergonomic polymer housings are sourced from Tier-1 suppliers under strict vendor qualification programs. | Supplier audits per ISO 13485 §7.4; RoHS and REACH compliance verified. |

| 2. Sensor Array Assembly | Optical triangulation modules are assembled in ISO Class 7 cleanrooms using automated micro-alignment systems. | Laser interferometry ensures sub-micron optical path alignment. |

| 3. Firmware Integration | Proprietary AI-accelerated scanning firmware is embedded, enabling real-time motion correction and intra-scan stitching. | Open architecture support: STL, PLY, OBJ export; DICOM-ready for CBCT fusion. |

| 4. Calibration Lab Processing | Each scanner undergoes individual sensor calibration using NIST-traceable reference phantoms. | On-site metrology lab certified to ISO/IEC 17025; daily system suitability checks. |

| 5. Final Assembly & Sealing | Water-resistant sealing (IPX7) applied; ergonomic grip finalized with antimicrobial coating. | Automated torque control for modular tip attachment system. |

Quality Control & Durability Testing

Every unit undergoes a 120-point QC protocol prior to shipment, with emphasis on clinical reliability and long-term performance.

| Test Category | Procedure | Standard / Metric |

|---|---|---|

| Geometric Accuracy | Scanning of ISO 5725 reference master models under varying angles and lighting. | ≤ 8 µm trueness, ≤ 6 µm precision (per ISO 12836) |

| Repeatability | 100+ repeated scans of full-arch model; deviation analysis via 3D best-fit algorithm. | RMS deviation < 10 µm |

| Durability (Mechanical) | Drop tests (1.2m onto steel), tip insertion cycles (50,000+), flex-cable stress testing. | IEC 60601-1-11; MTBF > 50,000 hours |

| Environmental | Thermal cycling (-10°C to 50°C), humidity exposure (95% RH), disinfectant resistance. | Validated for clinical autoclave and cold-sterilization workflows |

| Software Stability | 24-hour continuous scanning simulation with AI-based artifact detection. | Zero crashes; latency < 30ms frame-to-display |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascent as the global hub for high-performance, cost-optimized dental technology is underpinned by three strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision machining clusters in the Yangtze River Delta reduces lead times and BOM costs by up to 40% compared to Western counterparts.

- AI & Software Innovation: Domestic investment in edge-AI enables real-time scanning correction and adaptive mesh optimization, reducing reliance on high-cost hardware for accuracy.

- Regulatory Agility: CFDA (NMPA) fast-track approvals combined with ISO 13485-aligned design controls allow rapid iteration without sacrificing compliance.

Carejoy Digital leverages this ecosystem to deliver sub-10µm accuracy scanners at price points 30–50% below European OEMs, while supporting open file formats and third-party integration—making it ideal for labs and clinics pursuing scalable digital workflows.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Scanning Technology | Multi-wavelength structured light + AI-powered motion prediction |

| Resolution | 8 µm axial, 12 µm lateral |

| Scan Speed | 3,200 frames/sec with dynamic focus adjustment |

| File Output | STL, PLY, OBJ (Open Architecture); compatible with 3Shape, exocad, Sirona inLab |

| Milling Integration | Direct CAM export to Carejoy MillPro X5 (5-axis, ±2 µm repeatability) |

| Cloud & Support | 24/7 remote diagnostics, over-the-air firmware updates, AI-assisted troubleshooting |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental Intraoral Scanners.

✅ Open Architecture

Or WhatsApp: +86 15951276160