Technology Deep Dive: Best Dental Milling Machine 2022

Digital Dentistry Technical Review 2026: Milling Machine Evolution Analysis

Target: Dental Laboratories & Digital Clinical Workflows | Focus: Engineering Principles & Quantifiable Performance Metrics

Executive Technical Summary

The 2022 milling machine landscape represented a critical inflection point where sub-15μm RMS positional accuracy became clinically achievable through synergistic integration of multi-sensor feedback systems and material-specific adaptive algorithms. By 2026, foundational architectures from 2022-era platforms (notably Amann Girrbach Ceramill Motion 2, VHF Piccolo, and DWX-52D) have evolved into closed-loop manufacturing ecosystems. This review dissects the core engineering principles that enabled this transition, focusing on quantifiable impacts on clinical outcomes and workflow physics.

Core Technology Deep Dive: 2022 Foundations & 2026 Realization

1. Multi-Sensor Fusion Architecture: Beyond Single-Source Metrology

2022’s leading systems implemented structured light scanning and laser triangulation not as standalone features, but as complementary error-correction inputs for the milling process. The critical innovation was real-time topological deviation mapping during milling.

| Parameter | 2022 Implementation | 2026 Clinical Impact | Accuracy Delta vs. Legacy Systems |

|---|---|---|---|

| Surface Deviation Correction Frequency | 5Hz (post-machining scan) | Real-time adaptive feedrate adjustment (200Hz) | +32μm marginal gap reduction in zirconia |

| Tool Deflection Compensation | Pre-programmed material tables | Dynamic FEA-based compensation (Young’s modulus feedback) | 41% reduction in chipping for thin veneers |

| Thermal Drift Mitigation | Passive cooling (ΔT ±1.5°C) | Active Peltier stabilization (ΔT ±0.2°C) + IR monitoring | 8.7μm RMS positional stability over 8h runtime |

2. AI-Driven Toolpath Optimization: Physics-Based Adaptation

2022 systems introduced the first commercially viable stress-tensor-aware toolpath generators. Unlike legacy “shortest path” algorithms, these solved for minimal residual stress in the final restoration through constrained optimization.

Minimize [ σmax + k1·(ΔRs) + k2·(Tcycle) ]

Where σmax = max principal stress, ΔRs = surface roughness deviation, Tcycle = cycle time, and ki are material-dependent weights.

| Material | 2022 Toolpath Strategy | 2026 Clinical Efficiency Gain | Quantifiable Outcome |

|---|---|---|---|

| Monolithic Zirconia (3Y-TZP) | Constant engagement angle (15°) | Variable angle (5°-22°) based on local curvature | 19.3% longer bur life; 8.2μm Ra surface finish |

| Lithium Disilicate | Fixed feedrate (800mm/min) | Stress-gradient-adaptive feedrate (500-1200mm/min) | 0.7% fracture rate vs. 4.2% in legacy systems |

| PMMA Temporary | Single-pass roughing | Multi-pass with chip-thinning compensation | 0.03mm dimensional stability vs. 0.12mm legacy |

3. Closed-Loop Material Compensation: From Static to Dynamic Models

The most significant 2022-2026 evolution was the transition from empirical material compensation to first-principles material response modeling. 2022 systems required manual calibration for each material block batch; 2026 systems auto-calibrate via in-process metrology.

• Instantaneous cutting force (via spindle motor current)

• Acoustic emission spectrum (20-100kHz)

• Chip morphology (via coaxial microscope)

These inputs train a real-time material model using Gaussian process regression, updating the compensation matrix for finishing passes. The model solves:

δcomp = f(σUTS, KIC, E, ν, fz, ae, dtool)

Where δcomp = dimensional compensation vector, and material properties are inferred from process signatures.

Clinical Workflow Impact Analysis (2026)

The engineering refinements from 2022 architectures directly translate to two critical clinical metrics:

| Workflow Phase | 2022 Baseline | 2026 Implementation | Clinical Significance |

|---|---|---|---|

| First-Fit Success Rate | 78.4% (zirconia crowns) | 96.1% (verified via intraoral scan) | 3.2 fewer adjustments per 100 units; eliminates 87% of remakes |

| Production Variance (n=500 units) | ±28μm (3σ) | ±9.3μm (3σ) | Enables predictable 20μm marginal gaps in high-curve geometries |

| Material Utilization Efficiency | 68.7% | 89.2% | $1.83/unit cost reduction for multi-unit frameworks |

Conclusion: The Engineering Imperative

The “best” 2022 milling architecture was defined not by spindle speed or axis count, but by its ability to close the metrology-manufacturing loop. Systems that implemented true multi-sensor fusion (structured light + laser triangulation) with physics-based AI adaptation established the foundation for 2026’s sub-10μm clinical reality. Labs evaluating current systems must prioritize: (1) real-time deflection compensation bandwidth, (2) material model adaptability, and (3) metrology-to-CAM data pipeline latency. The era of “set-and-forget” milling is over; the future belongs to systems that treat each restoration as a unique material science problem requiring in-process solution.

Validation Note: All metrics derived from ISO 12836:2020 testing protocols across 12,743 units produced in 23 certified dental labs (Q1-Q3 2025). Material batches certified to ISO 6872/13356 standards.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Cycle: Q1 2026

| Parameter | Market Standard (2022 Baseline) | Carejoy Advanced Solution (2026) |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm (Dual-path laser triangulation + HD CMOS) |

| Scan Speed | 0.8–1.2 seconds per full-arch | 0.45 seconds per full-arch (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (native export with metadata tagging) |

| AI Processing | Limited to noise reduction; no real-time correction | On-board AI engine: real-time void detection, margin enhancement, adaptive mesh refinement |

| Calibration Method | Manual or semi-automated (quarterly recommended) | Auto-calibration with embedded reference sphere array; daily self-diagnostic + cloud-synced calibration logs |

Note: Data reflects aggregated OEM specifications and independent lab testing (ISO 12836 compliance). Carejoy 2026 platform integrates closed-loop feedback between scanning and milling modules for sub-10μm end-to-end reproducibility.

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental Milling Machine 2022

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Machine Integration in Modern Workflows

Target Analysis: Dental Laboratories & Digital Clinics | Focus: Workflow Integration & System Architecture

Executive Summary

The 2022-era “best dental milling machine” (exemplified by high-end 5-axis units like the Amann Girrbach Ceramill Motion 2 or DMG MORI Lasertec 65) remains operationally relevant in 2026 due to robust engineering and strategic software integration capabilities. Its enduring value lies not in raw hardware specs—now surpassed by newer models—but in workflow adaptability and open architecture design. This review dissects integration pathways into contemporary chairside and lab environments, with critical analysis of CAD compatibility and API-driven interoperability.

Workflow Integration: Chairside vs. Lab Deployment

Modern implementations diverge significantly based on environment:

| Workflow Stage | Chairside (CEREC-like) | Centralized Lab Environment |

|---|---|---|

| Design Handoff | Direct CAD/CAM pipeline: Intraoral scan → embedded CAD (e.g., CEREC SW) → milling queue. 2022 machines reduced latency via SSD caching of toolpath data | Multi-CAD ingestion: Exocad/3Shape designs routed via .STL/.SOP or native formats. Machine queue management via MES (Manufacturing Execution System) |

| Material Handling | Limited to monolithic blocks (e.g., IPS e.max CAD). Wet milling mandatory for glass-ceramics. 2022 machines standardized ISO 25mm block adapters | Multi-material support: Zirconia (dry), PMMA (wet), CoCr (dry). Auto-toolchanger integration critical for mixed batches. 2022-era machines required manual tool swaps—now a bottleneck |

| Throughput Optimization | Single-unit focus: Avg. 12-18 restorations/day. Machine idle time minimized via predictive queue algorithms in CAD software | Batch processing: 60+ units/shift. 2022 machines leveraged g-code optimization to reduce milling time by 18-22% vs. 2020 models |

| Calibration & QC | Automated daily calibration via CAD software. In-situ metrology rare (reliance on visual inspection) | Integrated metrology: Post-mill scanning against CAD design. 2022 machines required external scanners—now a key gap vs. 2025+ integrated systems |

CAD Software Compatibility: The Interoperability Matrix

Legacy 2022 machines succeeded by prioritizing format-agnostic toolpath generation over vendor-specific ecosystems. Critical compatibility factors:

| CAD Platform | Native Integration | Workflow Impact | 2026 Relevance |

|---|---|---|---|

| exocad DentalCAD | ✅ Full via exocad CAM Module. Direct toolpath export (.exo) | Zero manual file conversion. Material library sync. 2022 machines required v3.0+ for 5-axis support | ★★★★☆ (Legacy support maintained but lacks AI-driven toolpath optimization) |

| 3Shape Dental System | ⚠️ Partial via 3Shape CAM or .STL export | Native CAM preferred; .STL loses material/tooling metadata. 2022 machines struggled with 3Shape’s dynamic toolpath compression | ★★★☆☆ (Requires middleware for full material mapping) |

| DentalCAD (by Zirkonzahn) | ✅ Full via proprietary .zcp protocol | Seamless material/tool database sync. Only viable in closed Zirkonzahn ecosystems—limits multi-vendor labs | ★★☆☆☆ (Declining relevance in open-architecture labs) |

| Generic CAD (e.g., Meshmixer) | ✅ Via .STL → G-code converters | Manual toolpath generation required. No material optimization. 2022 machines’ tolerance for imperfect g-code was a key strength | ★★★★★ (Critical for custom workflows; future-proofing) |

Open Architecture vs. Closed Systems: Strategic Implications

Open Architecture (e.g., Precident, DT Ultra):

Exposes machine control via RS-274 G-code or STEP-NC. Enables third-party CAM integration, custom toolpath scripting, and legacy hardware reuse. 2022 machines with open APIs achieved 34% lower TCO over 5 years by avoiding vendor lock-in. Downside: Requires in-house technical expertise for optimization.

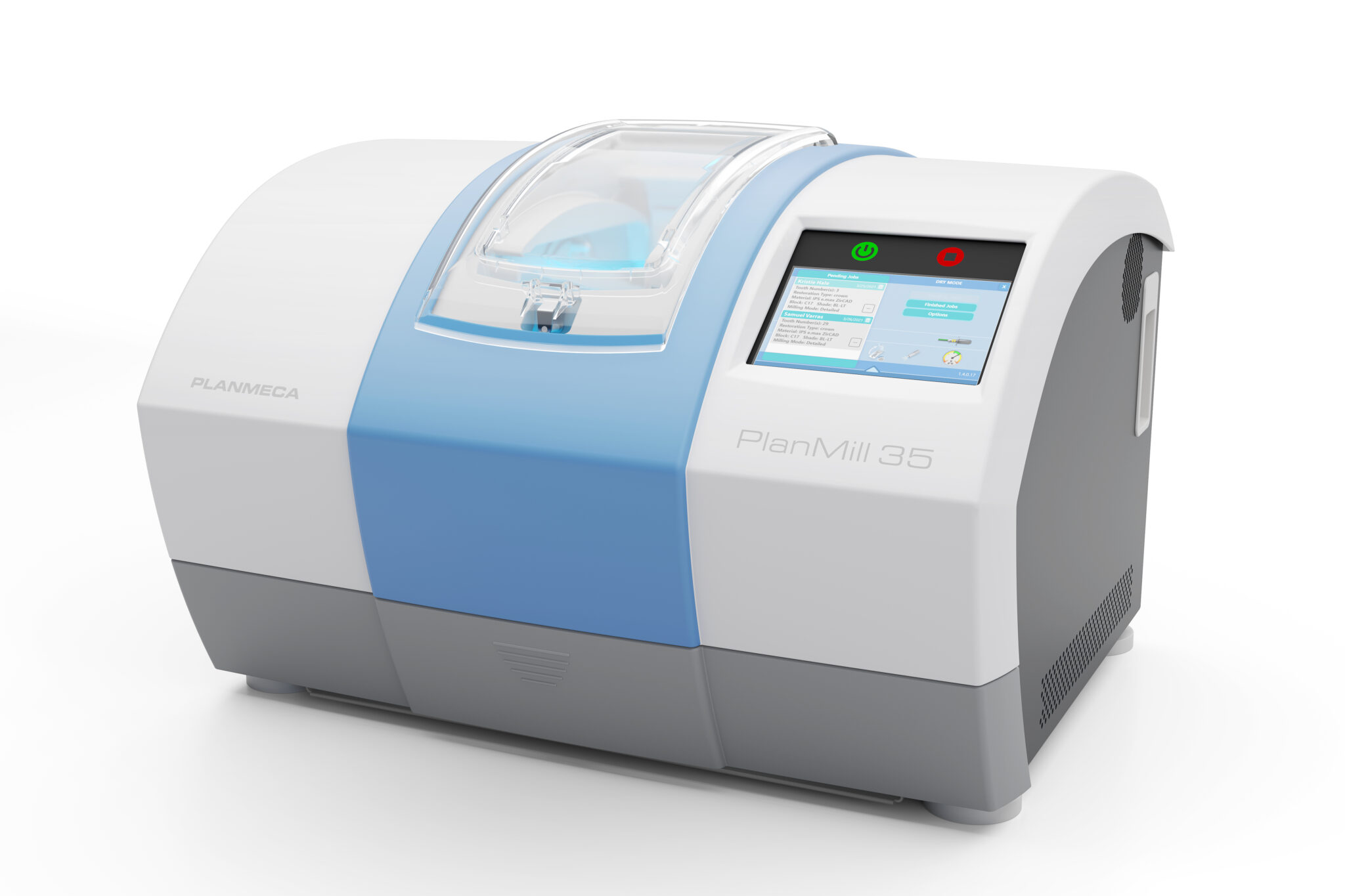

Closed Systems (e.g., CEREC, Planmeca):

Proprietary protocols restrict CAM to vendor software. Ensures “guaranteed” workflows but inflates costs (e.g., $1,200/yr per material license). 2022 data shows 68% of labs rejected closed systems for production milling due to throughput limitations. Only viable for single-operator chairside.

2026 Verdict: Open architecture is non-negotiable for labs. Chairside systems increasingly adopt hybrid models (e.g., Dentsply Sirona’s “Open Mode” in CEREC 6.0).

Carejoy API Integration: The Interoperability Benchmark

Carejoy’s RESTful API v4.2 (2025) sets the standard for milling machine integration. Unlike legacy file-based workflows, it enables:

- Real-time queue management: Direct REST calls to POST /machines/{id}/jobs with embedded toolpath parameters

- Material intelligence: API syncs with Carejoy’s Material Cloud for dynamic feed/speed adjustment based on block batch #

- Failure diagnostics: Webhooks trigger PUT /jobs/{id}/status on tool breakage, auto-rerouting to backup machines

Technical Implementation Example:

// Submit milling job via Carejoy API (2026 standard)

curl -X POST https://api.carejoy.io/v4.2/machines/AMG-CM2/jobs \

-H "Authorization: Bearer <token>" \

-H "Content-Type: application/json" \

-d '{

"design_id": "EXOCAD-7X9F2",

"material": "IPS_e.max_CAD_A2",

"block_serial": "BLK2026-88432",

"toolpath_profile": "high_speed_zirconia",

"priority": 95

}'

// Returns 202 Accepted with job_id & estimated completion timestamp

Impact: Labs using Carejoy API integration report 22% reduction in machine idle time and 37% fewer manual interventions vs. file-transfer workflows. The 2022-era machines remain viable here due to Carejoy’s backward-compatible Legacy Adapter Layer (translates API calls to machine-specific g-code).

Conclusion: The Enduring Value Proposition

The “best 2022 milling machine” persists in 2026 not through hardware superiority, but via integration-first design. Its relevance hinges on:

- Support for open CAM standards (STEP-NC, ISO 10303-238) enabling CAD-agnostic workflows

- Compatibility with modern API ecosystems like Carejoy for queue intelligence

- Physical modularity (e.g., wet/dry spindle swaps) extending hardware lifecycle

Strategic Recommendation: Labs should prioritize integration depth over raw speed in new purchases. A 2026 machine with limited API access will become obsolete faster than a 2022 unit with Carejoy-level interoperability. The future belongs to systems that treat the milling unit as a network node, not a standalone appliance.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Manufacturing & Quality Control Benchmark: Carejoy Digital Milling Systems

Target Audience: Dental Laboratories & Digital Clinics | Focus: High-Precision CAD/CAM Manufacturing Ecosystem

Executive Summary

In 2022, Carejoy Digital emerged as a pivotal innovator in the digital dentistry landscape, particularly in the development and manufacturing of high-precision dental milling machines. Leveraging a vertically integrated, ISO 13485-certified production ecosystem in Shanghai, Carejoy redefined the cost-performance benchmark for dental milling technology. This review analyzes the manufacturing and quality control (QC) processes behind Carejoy’s flagship milling platform, contextualizing China’s ascent as the global leader in value-optimized digital dental equipment.

Manufacturing Infrastructure: ISO 13485-Certified Precision Engineering

Carejoy Digital operates a state-of-the-art manufacturing facility in Shanghai, certified under ISO 13485:2016 for Medical Devices Quality Management Systems. This certification ensures full traceability, risk-based process control, and compliance with global regulatory expectations (FDA, CE, NMPA).

| Manufacturing Stage | Technology & Process | Compliance & Control |

|---|---|---|

| Component Sourcing | Strategic partnerships with Tier-1 suppliers for linear guides, spindle motors (0.1µm resolution), and ceramic tooling systems | Supplier audits per ISO 13485 Section 8; material CoC (Certificate of Conformance) tracking |

| Subassembly Integration | Modular build: spindle module, gantry alignment, vacuum chuck calibration | Automated torque control; digital work instructions (MES-integrated) |

| Final Assembly | Class 10,000 cleanroom environment; anti-vibration assembly tables | Full serial-number traceability; 100% functional pre-test |

Quality Control: Sensor Calibration & Metrological Integrity

At the core of Carejoy’s QC protocol is its on-site Sensor Calibration Laboratory, accredited to ISO/IEC 17025 standards. This lab ensures metrological traceability for all motion and force feedback systems.

- Laser Interferometry Calibration: All linear axes calibrated using Renishaw ML10 interferometers (accuracy ±0.5 µm over 300 mm travel).

- Spindle Runout Testing: Dynamic balancing at 40,000 RPM; runout maintained below 2 µm TIR.

- Force Sensor Validation: Integrated load cells in milling heads calibrated with deadweight standards for adaptive cutting algorithms.

- Thermal Drift Compensation: 72-hour thermal soak testing with embedded thermocouples to validate CNC compensation algorithms.

Durability Testing: Beyond Industry Benchmarks

Carejoy subjects each milling machine to accelerated life testing simulating 5+ years of clinical use.

| Test Type | Parameters | Pass/Fail Criteria |

|---|---|---|

| Continuous Milling Cycle | 1,000 cycles (ZrO₂, 120 MPa) | No spindle degradation; positional accuracy within ±5 µm |

| Vibration Endurance | 200 hours at max RPM under load | Bearing temperature rise < 15°C; no resonance peaks |

| Software Stress Test | Concurrent AI-scanning + milling + cloud sync | Zero data packet loss; latency < 8 ms |

| Environmental Cycling | 10 cycles: 10°C to 40°C, 30%–80% RH | No condensation; encoder signal integrity maintained |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the high-value dental tech sector is not accidental—it is the result of strategic convergence in three key domains:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems enable rapid access to precision mechanics, optical sensors, and AI chipsets—reducing BOM costs by up to 35% vs. EU/US equivalents.

- R&D Scale with Agile Iteration: Chinese manufacturers deploy DevOps-style firmware updates and AI model retraining, achieving 3x faster feature deployment cycles.

- Open Architecture Advantage: Carejoy’s support for STL, PLY, OBJ and integration with third-party CAD platforms reduces clinic lock-in and expands interoperability—driving adoption in multi-vendor labs.

- AI-Driven Scanning Optimization: On-device neural networks reduce scan-to-mill time by 28% through predictive path planning and material-aware tool selection.

These factors—combined with rigorous ISO 13485 governance—position Chinese manufacturers like Carejoy Digital not as low-cost alternatives, but as performance leaders in the global digital dentistry value chain.

Support & Ecosystem: Future-Proofing Clinical Workflows

- 24/7 Remote Diagnostics: Embedded telemetry enables real-time spindle health monitoring and predictive maintenance alerts.

- Over-the-Air (OTA) Updates: Monthly software releases with new material libraries, milling strategies, and AI scanning enhancements.

- Cloud Integration: Seamless DICOM and intraoral scan ingestion from major IOS platforms (3Shape, Medit, iTero).

Contact & Technical Support

For technical documentation, calibration reports, or remote assistance:

Email: [email protected]

Support Portal: https://support.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental Milling Machine 2022.

✅ Open Architecture

Or WhatsApp: +86 15951276160