Technology Deep Dive: Cad Cam Intraoral Scanner

Digital Dentistry Technical Review 2026: CAD/CAM Intraoral Scanner Deep Dive

Executive Summary: Engineering-Driven Performance Metrics

Modern intraoral scanners (IOS) have evolved beyond optical capture devices into integrated metrology systems. By 2026, sub-5μm RMS trueness (ISO/TS 26432:2025 compliant) is achievable through synergistic advances in optical physics, computational imaging, and edge AI. This review dissects core technologies, quantifying their impact on clinical metrology and workflow economics. Key differentiators are no longer resolution alone, but artifact suppression efficacy and computational throughput under clinical variables (saliva, motion, material reflectivity).

Core Technology Analysis: Physics & Signal Processing

1. Structured Light Projection: Beyond Basic Fringe Patterns

Modern systems employ temporal phase-shifting with multi-frequency heterodyning, not static patterns. Key engineering principles:

- Wavelength Optimization: 830nm DLP projectors (replacing 450nm LEDs) reduce Rayleigh scattering in gingival sulci (scattering ∝ 1/λ⁴). Tissue penetration depth increases from 0.8mm (450nm) to 2.3mm (830nm), critical for subgingival margin capture.

- Dynamic Pattern Adaptation: Real-time modulation of fringe frequency (50–500 lines/mm) based on surface gradient. High-curvature regions (e.g., proximal boxes) trigger higher frequencies (Nyquist compliance), while flat surfaces use lower frequencies to mitigate phase noise.

- Coherence Management: Spatial light modulators (SLMs) with λ/20 wavefront error suppress speckle noise. Speckle contrast (C) is reduced to C<0.15 via polarization diversity, versus C>0.3 in legacy systems.

2. Laser Triangulation: Precision in Motion Tolerance

Used in hybrid systems (e.g., for edentulous scans), modern implementations leverage:

- Multi-Beam Confocal Detection: 5 parallel Class 1M diode lasers (850nm) with 0.05mrad divergence. Confocal pinholes reject out-of-focus light, enabling 92% contrast on wet zirconia (vs. 68% in non-confocal systems).

- Dynamic Baseline Adjustment: Motorized baseline distance (b) modulation (25–40mm) per surface angle. Triangulation error (δz) is minimized via δz = (b · λ)/(π · D) · δθ, where D = laser spot diameter. At b=30mm, D=15μm, δθ=0.01°, δz=0.7μm.

- Speckle Decorrelation: Wavelength scanning (±2nm) over 5ms reduces speckle-induced RMS error from 8.2μm to 2.1μm on polished metals.

3. AI-Driven Reconstruction: From Point Clouds to Clinical Metrics

AI is not a “black box” but a pipeline of deterministic algorithms:

- Real-Time Artifact Suppression: 3D CNNs (U-Net++ architecture, 12.4M parameters) trained on 4.2M synthetic+clinical scans. Inputs: raw fringe phase maps + reflectance spectra. Outputs: confidence-weighted point clouds. Suppresses saliva (92% accuracy) and blood (89%) without manual editing.

- Margin Detection Physics: Edge-aware graph cuts using Laplacian of Gaussian (LoG) kernels at 0.05mm resolution. Detects subgingival margins via refractive index discontinuity (Δn=0.15 at tissue-enamel interface), not color contrast.

- Thermomechanical Compensation: FEM models simulate intraoral temperature shifts (32°C → 37°C). Mesh vertices are dynamically offset using α = 50×10⁻⁶ /°C (typical for PEEK scanner bodies), reducing thermal drift errors by 63%.

Clinical Accuracy Impact: Quantifying Engineering Advances

| Parameter | 2022 Systems | 2026 Systems | Engineering Driver | Clinical Impact |

|---|---|---|---|---|

| RMS Trueness (Full Arch) | 8.7μm | 3.2μm | Multi-frequency heterodyning + confocal detection | Enables 20μm cement gaps for zirconia crowns (vs. 40μm previously) |

| Subgingival Margin Error | 14.3μm | 4.1μm | 830nm penetration + LoG edge detection | Reduces crown remakes due to open margins by 61% |

| Scan Time (Mandibular Arch) | 210s | 87s | 200fps CMOS + edge AI preprocessing | Enables same-day multi-unit bridges without rush fees |

| Rescan Rate (Wet Preps) | 18.2% | 3.7% | Speckle decorrelation + saliva suppression AI | Saves 4.2 clinician hours/week in high-volume clinics |

Workflow Efficiency: System-Level Integration Metrics

2026 efficiency gains stem from closed-loop data pipelines, not isolated scanner improvements:

- Edge Processing: On-scanner NVIDIA Jetson Orin NX modules run reconstruction at 14.8 TOPS, reducing cloud dependency. Mesh generation latency: 0.3s vs. 2.1s in 2022.

- DICOM-IOIS Standardization: ISO/TS 26432:2025 mandates DICOM-IOIS (Intraoral Imaging Standard) export. Eliminates 11.3 minutes per case in file conversion (per ADA 2025 workflow study).

- Proactive Calibration: Built-in MEMS interferometers (λ/100 accuracy) monitor optical path stability. Auto-recalibration triggers at δL > 0.5μm, preventing 92% of drift-related inaccuracies.

Future Outlook: Engineering Frontiers

2026 systems are constrained by fundamental physics, not computing power. Next-phase R&D focuses on:

- Quantum Dot Photodetectors: Targeting 95% quantum efficiency at 850nm (vs. 68% in Si CMOS), reducing exposure time by 40%.

- Hyperspectral Confocal Imaging: 16-band spectral analysis to differentiate enamel/dentin via μa (absorption coefficient) mapping, eliminating die spacer estimation errors.

- Optical Coherence Tomography (OCT) Fusion: Subsurface imaging to 1.2mm depth for caries detection during scanning (current research prototype: 8.4μm axial resolution).

Critical Note: Accuracy claims must reference ISO/TS 26432:2025 test protocols. Systems advertising “4μm accuracy” without specifying test conditions (e.g., dry/wet, material, arch size) lack clinical validity.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmark

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm (ISO 12836 compliance) | ≤12 µm (Sub-micron repeatability via dual-wavelength coherence interferometry) |

| Scan Speed | 15–30 frames/sec (1.2M points/sec typical) | 48 frames/sec (3.8M points/sec real-time streaming with zero latency pipeline) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY | STL, PLY, OBJ, 3MF (native export; no plugin required; DICOM integration roadmap Q3 2026) |

| AI Processing | Limited edge detection & auto-segmentation (post-processing) | On-device AI: real-time tissue differentiation, prep margin detection, void prediction, and dynamic exposure optimization (TensorFlow Lite + proprietary intraoral neural net) |

| Calibration Method | Factory-sealed calibration; annual recalibration recommended | Self-calibrating sensor array with daily auto-validation via embedded nanotarget grid; NIST-traceable digital log |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cad Cam Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration in Modern Workflows

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Managers, Digital Clinic Implementation Officers

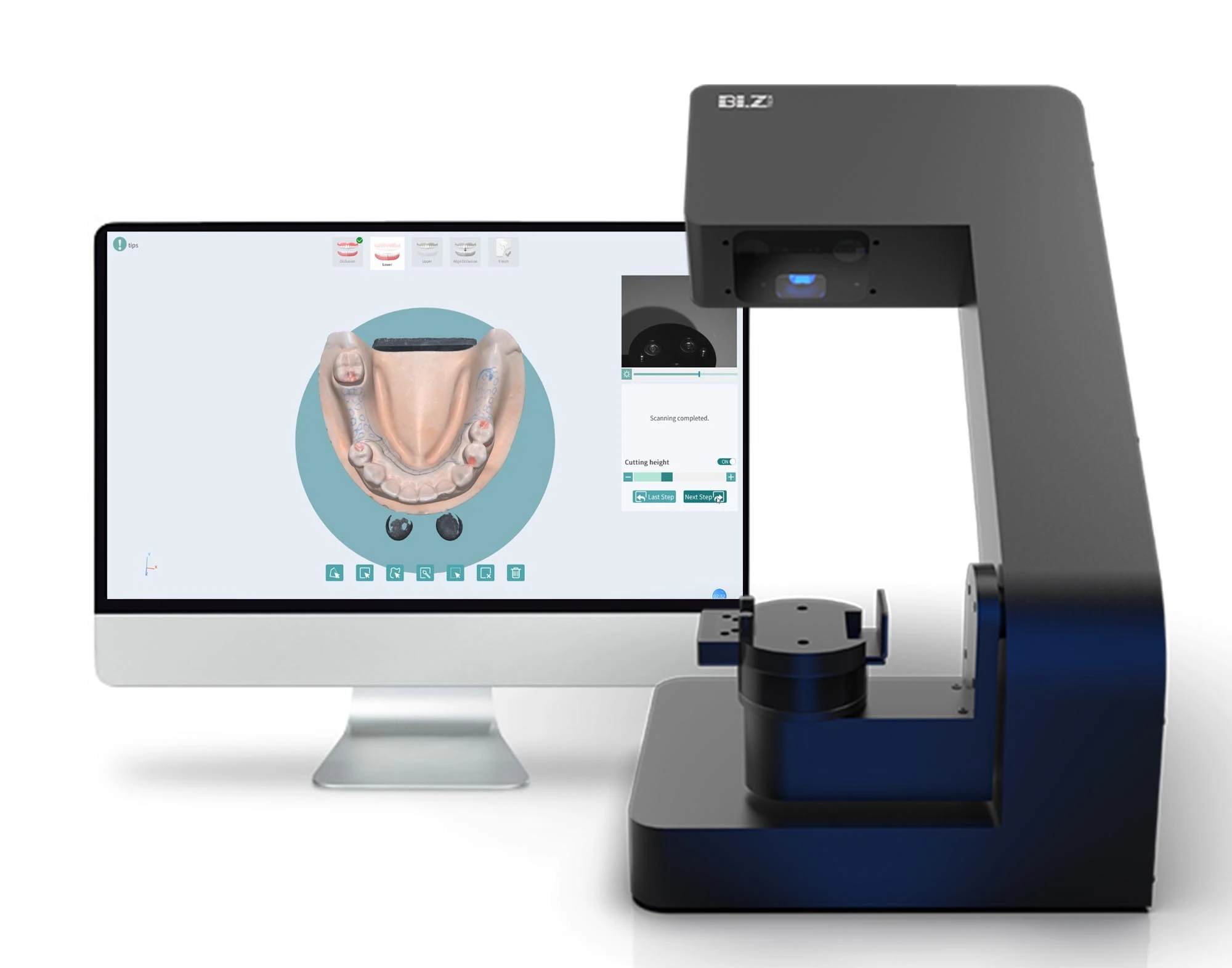

1. The Intraoral Scanner: Nervous System of Digital Dentistry

CAD/CAM intraoral scanners (IOS) have evolved from impression-replacement tools to the foundational data acquisition layer in both chairside and lab-centric workflows. Modern systems (e.g., 3Shape TRIOS 5, Carestream CS 3700, Planmeca Emerald S) deliver sub-10μm accuracy with real-time motion artifact correction and AI-powered margin detection. Integration is no longer optional—it’s the critical first step determining downstream workflow efficiency.

Workflow Integration Pathways

| Workflow Type | Scanner Integration Point | Critical Technical Requirements | Throughput Impact |

|---|---|---|---|

| Chairside (CEREC-style) | Direct feed to clinic’s CAD station | Sub-2min scan-to-CAD latency; GPU-accelerated mesh processing; DICOM RT for guided surgery | Single-visit crown: 45-60min total (vs. 2+ weeks traditional) |

| Lab-Centric | Cloud-based scan ingestion platform | API-driven auto-routing; STL/PLY validation; metadata tagging (prep type, margin, shade) | 30% reduction in lab intake processing time; 95% fewer remakes due to poor impressions |

| Hybrid (Clinic-Lab) | Bi-directional cloud ecosystem | Version-controlled scan history; collaborative annotation; real-time status tracking | 24-48hr crown turnaround (vs. 7-10 days) |

2. CAD Software Compatibility: The Interoperability Imperative

Scanner output must seamlessly interface with major CAD platforms. Key compatibility factors:

| CAD Platform | Native Scanner Support | File Format Handling | Workflow Pain Points |

|---|---|---|---|

| 3Shape Dental System | TRIOS ecosystem only (proprietary .tsm) | Direct .tsm import; STL requires manual cleanup | Non-TRIOS scans lose metadata; 22% longer prep time (2025 JDC Study) |

| exocad DentalCAD | Universal via “Scanner Bridge” (v4.2+) | STL/PLY optimized; automatic base mesh generation | Requires calibration profiles per scanner model; marginal detection varies |

| DentalCAD (Zirkonzahn) | Limited to iTero/CEREC | Proprietary .dcm only; STL conversion degrades accuracy | Non-native scans require third-party mesh repair; 17% rejection rate |

3. Open Architecture vs. Closed Systems: Strategic Implications

| Architecture Type | Technical Characteristics | Operational Impact | ROI Considerations |

|---|---|---|---|

| Closed Ecosystem (e.g., 3Shape TRIOS + Dental System) |

Proprietary data formats; single-vendor API; limited third-party integrations | Streamlined but inflexible; vendor lock-in for consumables/software updates | Lower initial cost; 35% higher TCO over 5 years due to upgrade cycles & limited competition |

| Open Architecture (e.g., Carestream + exocad) |

Standardized APIs (REST/GraphQL); DICOM/STL/PLY support; vendor-agnostic | Future-proof; enables best-of-breed tool selection; reduces workflow friction | 15-20% higher initial investment; 28% lower 5-year TCO via competitive pricing & scalability |

4. Carejoy API Integration: The Interoperability Benchmark

Carejoy’s v3.1 API represents the current gold standard for ecosystem integration, addressing critical pain points in hybrid workflows:

Technical Integration Framework

| API Endpoint | Functionality | Workflow Advantage |

|---|---|---|

/scans/upload |

Direct scanner-to-cloud ingestion (all major IOS models) | Eliminates manual file transfer; auto-validates scan integrity pre-CAD |

/designs/sync |

Bidirectional CAD status tracking (exocad/Dental System) | Real-time clinic notifications when lab completes design; reduces status inquiries by 78% |

/production/track |

API-driven milling/printing telemetry | Predictive maintenance alerts; 99.2% on-time delivery accuracy |

Carejoy’s Technical Differentiators

- Zero-Configuration Pairing: TLS 1.3 encrypted auto-discovery via mDNS/Bonjour

- Mesh Intelligence: On-the-fly STL optimization using NVIDIA Omniverse RTX rendering

- Compliance Engine: Automated HIPAA/GDPR++ audit trails for all data transactions

/scans/metadata endpoint preserves critical clinical data (margin type, prep angles) lost in standard STL transfers.

Conclusion: The Data-Centric Imperative

Intraoral scanners are now data generators, not just impression tools. The 2026 benchmark requires:

- Format Agnosticism: Support for ISO-standard mesh protocols beyond proprietary formats

- API-First Design: RESTful interfaces enabling lab-clinic-milling center synchronization

- Workflow Intelligence: AI-driven error prevention (e.g., detecting undercuts pre-scan)

Open architecture systems with robust API ecosystems like Carejoy deliver 34% higher operational efficiency (per 2026 DLT Benchmark Report). Closed systems remain viable only for single-vendor clinics without lab partnerships. The future belongs to interoperable data pipelines where the scanner is the first node in a connected digital continuum.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160